| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Changhee Lee | + 3393 word(s) | 3393 | 2021-05-21 12:00:37 | | | |

| 2 | Conner Chen | Meta information modification | 3393 | 2021-05-25 09:58:00 | | |

Video Upload Options

The interest in natural gas engines as an alternative to diesel engines has intensified as crude oil prices have risen and global environmental regulations have become more stringent. Natural gas engines can improve thermal efficiency through lean combustion, owing to combustion of a wide range of fuels; meanwhile, the low carbon content of the fuel reduces CO2 emissions, which is crucial in reducing greenhouse gas emissions. Natural gas engines also exhibit excellent fuel economy and low fuel costs. Unlike crude oil, natural gas is widely distributed worldwide and offers an advantage in terms of supply and demand. As a result, the demand for gas engines is increasing rapidly. Therefore, many marine engine manufacturers have developed micropilot-type gas engines that inject diesel fuel only for ignition.

1. Background

Concerns regarding fossil fuel stockpiling and strict legislation against contaminated emissions from internal combustion engines have forced engine designers and manufacturers to continuously pursue improved engine performance and emission characteristics. Extensive research has been conducted to simultaneously improve engine efficiency and reduce emission levels through the application of new technologies, such as engine reduction, new combustion concepts, alternative and/or renewable energy sources, turbocharging, and improved fuel-air mixing. To meet the above-mentioned demands, natural gas has been adopted as an alternative fuel because it is suitable for use in internal combustion engines and has widespread global reserves and acceptable emission behavior. Gas engines are becoming increasingly attractive in applications such as industrial prime mounds, transportation, and stationary power. Further research is also being conducted to improve gas engine performance and emission characteristics and overcome deficiencies in various load plans to become feasible alternatives for various applications. Kalam et al. [1] have previously compared natural gas and gasoline performance in engines. To evaluate the output and emission levels, a bifuel spark ignition (SI) multicylinder engine operated under several partial and full-load test conditions was investigated for either gasoline or natural gas. Results show that while natural gas produced 15–20% less power than gasoline, the brake-specific fuel consumption (BSFC) was lower by 18%. At the same output power, natural gas produced fewer emissions, except for NOx. Klimkiewicz and Teodorczyk [2] investigated direct injection SI engines to improve gas engine performance. A series of frame sealer photographs related to injection and combustion processes was obtained along with the in-cylinder pressure profile. The effect of the spark plug location on gas engine performance was shown to be lower than that of conventional engines. The dual gas injection fuel delivery system also improved engine performance by providing a more stable gas–air mixing ignition function in the combustion chamber. Evans et al. [3] made another comparison of gasoline and natural gas combustion for single-cylinder engines. The authors showed that while much lower emissions could be achieved by natural gas, the brake average effective pressure (BMEP) of natural gas fuel engines was ~12% lower at any ignition timing. As a result, at full load, the gas engine produced ~50% less total hydrocarbons (THCs) and carbon monoxide (CO) than the gasoline engine. When an engine is designed as a dedicated natural gas engine, some parts and systems must be redesigned to provide optimal performance compared to conventional engines. This includes modifications of compression ratios, spark plugs, cooling and lubrication systems, charging entertainment, and gas exchange processes to meet the thermal fluid design criteria. One of the most important considerations for an internal combustion engine is the design of an appropriate camshaft profile. Proper valve timing is required, as the combustion chamber must have the appropriate trapped air:fuel ratio, while the optimum pumping loss and overlapping pumping loss must be achieved simultaneously.

The Miller cycle [4] was initially proposed to improve engine efficiency. This cycle is an over-expanded cycle, i.e., one with a higher expansion ratio than compression ratio. It has recently been proposed as a means of reducing hazardous emissions while maintaining engine efficiency by lowering the engine compression rates and maximizing the gas temperature and pressure in cylinders.

Many reports have described the concept of the Miller cycle engine and investigated various aspects of the Miller cycle engine design and operation. Alsargh et al. [5] and Zhao and Chen [6] conducted theoretical investigations on Miller cycle engine performance and studied the effects of key engine design variables and system inversibility. Endo et al. [7] have described the design of a large commercial (280–1100 kW) gas engine using the Miller cycle principle, claiming a fuel economy advantage of >5% over existing technologies of its class. Gheorghiu and Uberschör [8] studied overextended engines for use in hybrid vehicles and investigated the causes of efficiency loss in common implementations of these cycles. Wang and Lucston [9] and Wang et al. [10] investigated the application of the Miller cycle concept to reduce engine emissions and found that a significant reduction in engine fuel consumption was possible, despite its penalties.

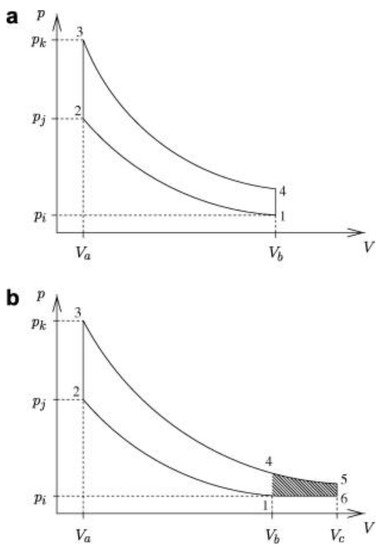

Figure 1 shows the air-standard auto and Miller cycles and the additional work that can be extracted from the Miller cycle (shaded). Heywood [11] showed that it is possible to achieve significant increases in engine efficiency in excessively extended cycles, especially at low compression rates.

Figure 1. Comparison of Otto and Miller air-standard cycles. (a) Air-standard Otto cycle; (b) Air-standard Miller cycle.

The Miller cycle is a modification of the overinflation cycle, which provides a higher expansion ratio than the compression ratio with improved thermal efficiency compared to the conventional internal combustion engine operating conditions [12]. In practice, this difference in expansion ratio can be achieved through a compression stroke that includes a late or early closing of the intake valve. This effectively reduces the compression stroke, but maintains the combustion and expansion processes as normal to extract additional energy before the exhaust process while reducing the brake average effective pressure (BMEP) to improve thermal efficiency [12][13]. The brake mean effective pressure metric is used to define the operation of the actual engine output defined in the brake output. To avoid a short compression stroke, turbochargers or superchargers have been used to maintain a stable BMEP level and thus ensure continued benefits of this cycle [12]. Therefore, the Miller cycle uses boosting to recover the lost charge caused by a smaller displacement during compression. This cycle also provides cooling to the precombustion fuel–air mixture according to the inlet valve closing timing to help minimize the combustion knock problems with SI engine operation prior to ignition [13].

Miller [14] also demonstrated that controlling the paging of the intake valve closure (IVC) and exhaust valve opening (EVO) has a significant impact on engine performance. Similar to the Atkinson cycle [15], the expansion ratio in the Miller cycle exceeds the compression ratio (Figure 1). This can be achieved by either late-intake valve closure (LIVC) or early intake valve closure (EIVC), depending on the engine boost pressure and engine speed [15][16][17][18]. Unlike the Atkinson cycle, however, the Miller cycle can improve engine efficiency without reducing power because of supercharged and turbocharged utilization. In recent years, numerous studies have been conducted to improve engine performance using Miller cycles. Anderson et al. [19] examined the naturally aspirated Miller cycle SI engine using LIVC based on primary and secondary law analysis. The authors found that the LIVC required less fuel to produce the same output compared to the base engine and showed 6.3% higher thermal efficiency at partial loads. In addition, LIVC had better thermal-mechanical criteria owing to the high inlet manifold pressure. We et al. [20] simulated Miller cycles to compare them with standard auto cycles based on thermodynamic models. For Miller cycle applications, superchargers have been recommended because the trapped mass is too low without supercharging, even lower than the default Otto cycle. However, no such loss has been shown in other studies of optimal power density properties for the Atkinson, Miller, and dual cycles [21][22][23].

To overcome the disadvantages of exhaust gas recirculation (EGR), Benazes et al. [24] investigated whether the Atkinson cycle was suitable for lowering the filling temperature in cylinders. This was achieved by advancing the IVC on a medium diesel engine equipped with a fully variable valve drive (VVA) system, maintaining constant inlet and exhaust pressure. The results confirmed that the Atkinson cycles could reduce gas temperature in cylinders along with gas pressure and density during the compression stroke.

Al-Sarki et al. [16] investigated the relationship between thermal efficiency, compression ratio, and expansion ratio for ideal naturally aspirated (air-standard) Miller cycles using finite-time thermodynamics. This model provides instructions for predicting the performance of the Miller cycle engine when the correct model parameters are used. Martins and Lanzanova [25] presented a detailed 1D simulation analysis of the Miller cycle SI engine at full load when driving ethanol hydroxide with different supercharges and valve train configurations. In the study, the effects of IVC timing and camshaft profiles, charge dilution through EGR or excessive air on combustion periods, and temperature in the cylinders were investigated. Detailed evaluations of major losses have also been conducted, and several possible arrangements have been studied. When applying the Miller cycle concept, a diesel engine brake efficiency of >40% has been achieved. They [25] showed that the highest efficiency values were achieved with solenoid-operated valves and initial IVCs. The pumping loss associated with LIVC reduces the appeal of this option. However, the high intake pressure required for very high EIVC cases (>5 bar) makes this option very difficult for current engines. Operation is expected to be practically unachievable at EIVC prior to 460 crank angle (CAD) after ignition TDC.

Gas engine emissions include THCs, CO, CO2, and NOx, among which NOx are the most harmful to the environment. The Miller cycle engine is one of the most promising ways to reduce these emissions as it has a much lower combustion temperature that reduces NOx formation. An experimental study by Wang et al. [26] showed that the application of Miller cycles in standard auto-cycles results in a NOx reduction rate of ~8% and a loss of engine power at full load of only 1%. Similar studies on the Miller cycle concept of Wang and Ruxton [27] showed a significant reduction in NOx.

Konka et al. [28] conducted performance analysis for output and thermal efficiency. The maximum output and thermal efficiency criteria were investigated for air-standard non-reversible double Miller cycles using LIVC. In this study, optimal engine operation and design parameters were achieved through thermodynamic optimization to maximize the output and thermal efficiency. Furthermore, the application of this method to a single-cylinder, direct injection diesel engine was studied experimentally and theoretically. Two Miller cycle approaches, which provided 5 and 10 CAD-delayed IVCs compared to standard conditions, were applied in conjunction with two different camshafts. The results showed that NO and CO2 emissions had decreased by 48% and 2.2%, while HC(hydro-carbon) and CO emissions were increased by 46% and 34%, respectively. Further, effective power and efficiency were decreased by 6.4%, and 9.2% respectively. The optimal condition was defined as 10 CAD delay because of maximum NO reduction [29].

Linaldini et al. [30] investigated the possibility of reducing soot formation at NOx and partial loads and the limitations thereof by applying a Miller cycle on conventional high-speed diesel engines. Analysis was performed using GT power and Kiva-3V simulation tools for engine analysis and in-cylinder analysis, respectively, showing that combustion was essentially cleaner with a 10% and 50% reduction in NOx and soot formation, respectively. However, these authors focused on the dedicated (pure) gas engine to simplify the fuel supply system and engine operating mode, and to improve the characteristics of emission.

2. Gas Engine Development

2.1. Concept of the Target Gas Engine

This study is intended to be the first step toward entering the gas engine market. Therefore, we aimed at developing a spark-ignited-type gas engine in an easy and inexpensive manner. The target output of the engine was 1.6 MW (200 kW per cylinder); aiming for the best performance among engines of the same class, the target engine efficiency was 45% [31]. Further, considering land power generation as a future market, the standard NOx emissions were limited to 50 ppm at 15% O2 composition, conforming to the regulations for Korean land power engines. In addition, the target brake mean effective pressure at an engine speed of 1000 rpm was 2.1 MPa, which is significantly higher than that of a typical gas engine. The development goals and operating conditions of the gas engine are summarized in Table 1.

Table 1. Development targets and operating conditions of the gas engine.

| Phase | Target |

|---|---|

| Power | 1.6 MW |

| Brake mean effective pressure | 2.1 MPa |

| Thermal efficiency | 45% (acc. to ISO 3046-1) |

| NOx | ≤50 ppm at 15% O2 |

| Ambient temperature | 25 °C |

| Ambient pressure | 0.1 MPa |

| Intake depression | 5.0 kPa |

| Charged air temperature | 40 °C |

| Exhaust back pressure | 4.0 kPa |

The above-mentioned development objectives—gas engines with a significant level of output performance—are considerably difficult to achieve because of abnormal combustion conditions such as knocking and misfiring [32]. To overcome these challenges, several development technologies were applied.

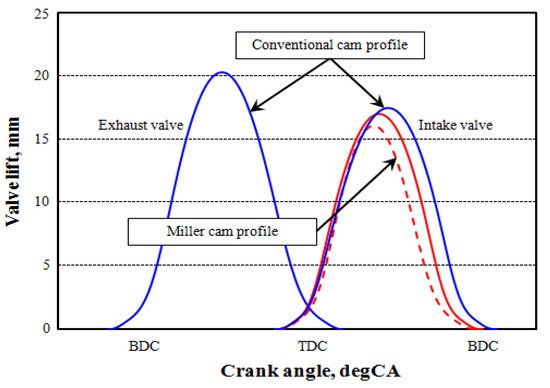

High-efficiency and high-output gas engines encounter several problems such as knocking and increased NOx emissions owing to high heat loads. We applied the Miller cycle and lean combustion techniques to solve these problems [33][34]. The Miller cycle improves thermal efficiency by reducing the compression work, and this is achieved by closing the intake valve early, as depicted in Figure 2 which of intake cam profile is composed of conventional com profile(blue line) and miller cam profile between red line and red dot line. Further, the Miller cycle reduces knocking and NOx emissions simultaneously by lowering the combustion chamber temperature. These Miller cycles were realized through design calibration of the cam shape and using a high-performance turbocharger to compensate for the reduction in the amount of the intake mixture [35].

Figure 2. Miller cam profile.

Lean combustion enables complete combustion, which can be expected to improve thermal efficiency. However, if the lean level is expanded, it may cause combustion instability. Therefore, an appropriate lean limit must be derived [35]. In this study, NOx reduction was realized as lean combustion [36][37]. Although lean combustion can reduce the temperature of the combustion gases and NOx emissions, it causes several problems such as combustion instability, incomplete combustion, and misfiring. To solve these problems, a precombustion chamber method was applied, and the piston shape and turbulence flow were optimized. A little richer fuel mixture was supplied and ignited by a spark plug in the precombustion chamber, and the leaner mixture in the main chamber was combusted by the flame ejected from the precombustion chamber. The optimization of piston shapes also facilitated lean combustion by activating turbulence and flame propagation.

2.2. Components of the Main Gas Engine

A photograph and key specifications of the 1.6 MW gas engine developed in this study are presented in Figure 3 and Table 2, respectively.

Figure 3. Photograph of the gas engine developed in this study.

Table 2. Specifications of the gas engine developed in this study.

| Phase | Specification |

|---|---|

| Bore/stroke | 200/300 |

| Arrangement of cylinder | 8 in-line |

| Engine speed | 1000 rpm |

| Compression ratio | 12.0 |

| Fuel | Natural gas |

| Fuel admission | Central gas mixer |

| Engine speed control | Throttle valve |

| Ignition | Spark plug with PC |

2.2.1. Cylinder Heads and Precombustion Chamber

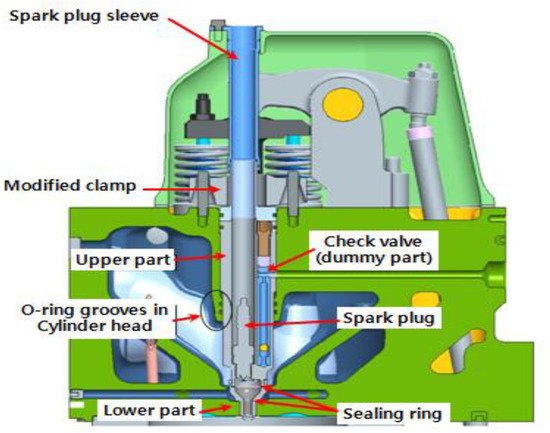

Figure 4 provides an overview of the cylinder head and combustion chamber of the developed gas engine. The cylinder head removed as much unnecessary space as possible (starting air hole, induction hole, injector cooling hole, etc.) to improve the responsiveness in the transition operation area and reduce compression losses. In addition, the cooling system was enhanced to alleviate thermal stress, considering the increased thermal load. The side of the cylinder head was equipped with a knock detection sensor to detect and suppress knock generation; this sensor was connected to the engine control system. The precombustion chamber was installed at the injector position of an existing diesel engine. In the dedicated gas engine, the precombustion chamber should be generally applied to prevent knock generation in the case of approximately over 170 mm bore. Inside the precombustion chamber, a check valve for supplying the gas fuel and a spark plug for ignition of the mixture was installed. The O-ring prevented the leakage of the coolant from the precombustion chamber, and the cylinder head was improved to facilitate the maintenance and repair of the spark plug.

Figure 4. Cylinder head and precombustion chamber.

2.2.2. Fuel Supply

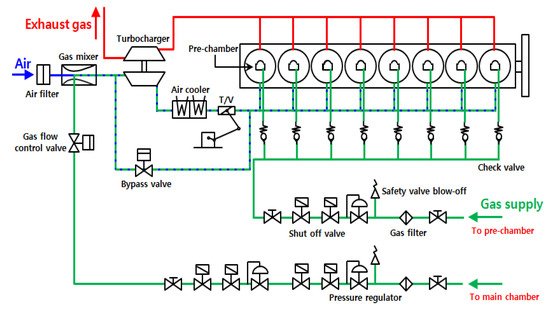

As depicted in Figure 5, the gas fuel supply was divided into a low-pressure gas supply system, which primarily supplied the gas fuel to the main combustion chamber, and a high-pressure gas supply system.

Figure 5. Schematic of the gas supply system.

The low-pressure gas fuel was supplied to the intake system through two levels of pressure control, wherein the gas fuel was decompressed and mixed with air through a gas mixer. The gas mixer was installed at the front of the turbocharger to form a relatively homogeneous mixture.

The high-pressure gas fuel was supplied to the precombustion chamber through a pressure regulator and a check valve for each cylinder. The gas fuel was only supplied to the precombustion chamber, resulting in a relatively rich mixture. The check valve operated through the difference between the pressure in the combustion chamber and the gas fuel pressure.

The gas fuel pressure was automatically adjusted by the engine control system according to the engine load.

2.2.3. Ignition System

The gas engine used an SI method, with ignition coils and a spark plug installed on each cylinder. The ignition timing was controlled by the engine control and could be adjusted from 20° CA BTDC up to 10° CA ATDC using the crankshaft and camshaft pick-up signals. The engine operation considered the same ignition timing to improve the throttle valve behavior and load fluctuations in the engine. Meanwhile, the ignition timing was independently controlled for each cylinder for stable combustion and minimization of pressure fluctuations between cylinders.

2.2.4. Engine Control System

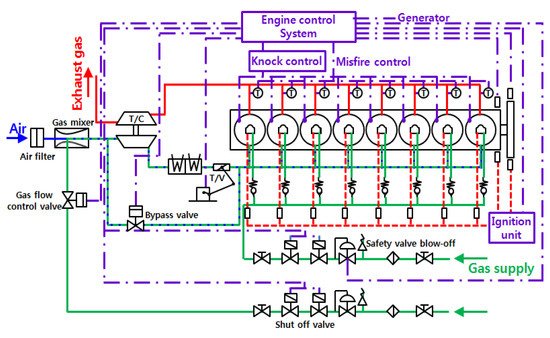

In dedicated gas engines, engine control systems are paramount for stable operation and prevention of abnormal combustion conditions, such as knocking and misfires. Thus, as the initial stage of gas engine development, the engine control and monitoring functions of the control system were reinforced, as shown in Figure 6.

Figure 6. Engine control system.

The engine control system prevented knocking by retarding the ignition timing by 0.4° CA when knocking occurred and repeated this delay up to a maximum of 8.0° CA. If knocking was successfully avoided by delaying the ignition timing, the ignition timing returned to its original value, and if knocking continued despite delayed ignition up to 8.0° CA, the load was reduced. The likelihood of misfiring in the combustion chamber was determined by the temperature change in exhaust gas; when the engine misfired, the air:fuel ratio of the mixture was adjusted. The engine control system was built to enable real-time monitoring of all these situations.

As diesel engines and gas engines have fundamentally different combustion mechanisms, customization of certain engine parts is necessary. In the developed gas engine, a mixture was provided for the combustion chamber such that the overlap period was reduced. This reduced the flow of the mixture toward the exhaust valve during the valve overlap period, and the camshaft was redesigned according to the application of the Miller cycle. For the application of Miller cycles, high-performance turbochargers were used, and a two-stage air cooler was employed to enhance the cooling effect of the compression mixtures. In addition, aluminum pistons were applied to avoid knocking caused by the hot spots on the top of the piston, and simultaneously, the piston inertial force was reduced. As a high compression ratio in conventional diesel engines leads to knocking, we reduced the compression ratio in the gas engine. However, because this reduced the thermal efficiency, an appropriate compression ratio was selected in consideration of the maximum pressure in the combustion chamber.

Meanwhile, owing to changes in gas fuel, all diesel fuel supply systems were removed. The air motor method operated by compressed air was adopted as the engine starting system because the mixture was supplied to the combustion chamber. In addition, a safety device was added to the crankcase to prevent explosion by unburned gas.

2.3. Gas Fuel Characteristics

The fuel gas used for performance evaluation of the gas engine was natural gas with a CH4 content of more than 90% and a lower heating value of ~39.33 MJ/Nm3. The fuel characteristics are listed in Table 3.

Table 3. Gas characteristics for the engine performance test.

| Phase | Unit | Quality |

|---|---|---|

| CH4 composition | % | >90 |

| Lower heating value | MJ/Nm3 | 39.33 |

| Density | kg/m3 | 0.7976 |

| Stoichiometric ratio | - | 16.87 |

| Molecular weight | kg/kmol | 17.77 |

| Methane number | - | 73 |

| Gas supply pressure, (g) | MPa | >0.55 |

The methane number of the supplied natural gas (73) was lower than 80, which is the value that is generally considered in performance evaluation. Methane number is a value representing the anti-knock property of the gas fuel and affects the thermal efficiency and output performance of the engine. The gas fuel supply pressure should be maintained at a minimum of 0.55 MPa in consideration of the fuel pressure supplied to the precombustion chamber.

References

- Kalam, M.A.; Masjuki, H.H.; Maleque, M.A.; Amalina, M.A.; Abdesselam, H.; Mahlia, T.M.I.; Aslam, M.U.; Varman, M. Power improvement of a modified natural gas engine. In Proceedings of the 1st Conference & Exhibition on Natural Gas for Vehicles (ANGVA 2005), Kuala Lumpur, Malaysia, 26–28 July 2005.

- Klimkiewicz, D.; Teodorczyk, A. An experimental study of SI engine combustion system with direct methane injection. In Proceedings of the Third European combustion meeting ECM, Crete, Greece, 11–13 April 2007.

- Evans, R.L.; Blaszczyk, J. A compartive study of the performance and exhaust emissions of a spark ignition engine fuelled by natural gas and gasoline. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 1996, 211, 39–47.

- Miller, R.H. Supercharging and internal cooling cycle for high output. Trans. ASME 1947, 69, 453–457.

- Al-Sarkhi, A.; Jaber, J.; Probert, S. Efficiency of a Miller engine. Appl. Energy 2006, 83, 343–351.

- Zhao, Y.; Chen, J. Performance analysis of an irreversible Miller heat engine and its optimum criteria. Appl. Therm. Eng. 2007, 27, 2051–2058.

- Endo, H.; Tanaka, K.; Kakuhama, Y.; Goda, Y.; Fujiwaka, T.; Nishigaki, M. Development of the lean burn Miller cycle gas engine. In Proceedings of the 5th International Symposium on Diagnostics and Modeling of Combustion in Internal Combustion Engines (COMODIA 2001), Nagoya, Janpan, 1–4 July 2001.

- Gheorghiu, V.; Ueberschar, D. Enhancement potential of the thermal conversion efficiency of ICE cycles especially for use in hybrid vehicles. In Proceedings of the 5th International Conference on Heat Transfer, Fluid Mechanics and Thermodynamics (HEFEAT2007), Sun City, South Africa, 1–4 July 2007.

- Wang, Y.; Ruxton, T. An experimental investigation of NOx emission reduction from automotive engine using the Miller cycle. In Proceedings of the ASME 2004 Fall Technical Conference, Long Beach, CA, USA, 24–27 October 2004.

- Wang, Y.; Lin, L.; Roskilly, A.P.; Zeng, S.; Huang, J.; He, Y.; Huang, X.; Huang, H.; Wei, H.; Li, S.; et al. An analytic study of applying Miller cycle to reduce NOx emission from petrol engine. Appl. Therm. Eng. 2007, 27, 1779–1789.

- Heywood, J.B. Internal Combustion Engine Fundamentals; McGraw-Hill Inc.: New York, NY, USA, 1988.

- Branyon, D.; Simpson, D. Miller Cycle Application to the Scuderi Split Cycle Engine (by Downsizing the Compressor Cylinder); SAE Technical Paper 2012-01-0419; SAE International: Warrendale, PA, USA, 2012.

- Wu, C.; Puzinauskas, P.V.; Tsai, J.S. Performance analysis and optimization of a supercharged Miller cycle Otto engine. Appl. Therm. Eng. 2003, 23, 511–521.

- Hatamura, K.; Hayakawa, M.; Goto, T.; Hitomi, M. A study of the improvement effect of Miller-cycle on mean effective pressure limit for high-pressure supercharged gasoline engines. JSAE Rev. 1997, 18, 101–106.

- Martins, J.J.G.; Uzuneanu, K.; Ribeiro, B.S.; Jasasky, O. Thermodynamic Analysis of an Over-Expanded Engine. SAE Trans. 2004, 113, 476–490.

- Al-Sarkhi, A.; Akash, B.A.; Jaber, J.O.; Mohsen, M.S.; Abu-Nada, E. Efficiency of Miller engine at maximum power density. Int. Commun. Heat Mass Transf. 2002, 29, 1159–1167.

- Ebrahimi, R. Thermodynamic modeling of performance of a Miller cycle with engine speed and variable specific heat ratio of working fluid. Comput. Math. Appl. 2011, 62, 2169–2176.

- Mikalsen, R.; Wang, Y.; Roskilly, A. A comparison of Miller and Otto cycle natural gas engines for small scale CHP applications. Appl. Energy 2009, 86, 922–927.

- Anderson, M.K.; Assanis, D.N.; Filipi, Z.S. First and second law analyses of a naturalaspirated, Miller cycle, SI engine with late intake valve closure. SAE Trans. 1998, 107, 1355–1370.

- Kesgin, U. Efficiency improvement and NOx emission reduction potentials of two-stage turbocharged Miller cycle for stationary natural gas engines. Int. J.Energy Res. 2005, 29, 189–216.

- Chen, L.; Lin, J.; Sun, F.; Wu, C. Efficiency of an Atkinson engine at maximum power density. Energy Convers. Manag. 1998, 39, 337–341.

- Gonca, G.; Hocaoglu, M.F. Performance Analysis and Simulation of a Diesel-Miller Cycle (DiMC) Engine. Arab J Sci Eng 2019, 44, 5811–5824.

- Sahin, B.; Kesgin, U.; Kodal, A.; Vardar, N. Performance optimization of a new combined power cycle based on power density analysis of the dual cycle. Energy Convers. Manag. 2002, 43, 2019–2031.

- Benajes, J.; Molina, S.; Martín, J.; Novella, R. Effect of advancing the closing angle of the intake valves on diffusion-controlled combustion in a HD diesel engine. Appl. Therm. Eng. 2009, 29, 1947–1954.

- Martins, M.E.S.; Lanzanova, T.D. Full-load Miller cycle with ethanol and EGR: Potential benefits and challenges. Appl. Therm. Eng. 2015, 90, 274–285.

- Lin, J.C.; Hou, S.S. Performance analysis of an air-standard Miller cycle with considerations of heat loss as a percentage of fuel’s energy, friction and variable specific heats of working fluid. Int. J.Therm. Sci. 2008, 47, 182–191.

- Ge, Y.; Chen, L.; Sun, F.; Wu, C. Effects of heat transfer and variable specific heats of working fluid on performance of a Miller cycle. Int. J. Ambient. Energy 2005, 26, 203–214.

- Gonca, G.; Sahin, B.; Ust, Y. Performance maps for an air-standard irreversible DualeMiller cycle (DMC) with late inlet valve closing (LIVC) version. Energy 2013, 54, 285–290.

- Gonca, G.; Sahin, B.; Parlak, A.; Ust, Y.; Ayhan, V.; Cesur, I.; Boru, B. The effects of steam injection on the performance and emission parameters of a Miller cycle diesel engine. Energy 2014, 78, 266–275.

- Rinaldini, C.A.; Mattarelli, E.; Golovitchev, V.I. Potential of the Miller cycle on a HSDI diesel automotive engine. Appl. Energy 2013, 112, 102–119.

- Dexter, S.G.; Ennemoser, C. Fire Not Misfire in Pre-Chamber Gas Engines. In Proceedings of the 21st CIMAC Congress, Interlaken, Switzerland, 15–18 May 1995.

- Herdin, G.R.; Gruber, F.; Henkel, W.; Fahringer, A. The New High Efficiency 1.5 MW Engine of Jenbacher AG, High Efficiency Concept–HEC. In Proceedings of the 23rd CIMAC Congress, Hamburg, Germany, 7–10 May 2001; pp. 966–975.

- Takemoto, T. Development of High Efficiency Gas Engine Improvement of Knocking Limit by Optimized Engine System. In Proceedings of the 24th CIMAC Congress, Kyoto, Japan, 7–11 June 2004.

- Herdin, G.R.; Gruber, F. Miller Cycle-Efficiency Potentials for Gas Engines. In Proceedings of the 24th CIMAC congress, Kyoto, Japan, 7–11 June 2004.

- Kondo, M. Development of the 1000 kW-Class Gas Engine (MD20G). In Proceedings of the 25th CIMAC Congress, Vienna, Austria, 21–24 May 2007.

- Edwards, K.D.; Wagner, R.M.; Daw, C.S. Adaptive Control for Extending the Effective Lean Limit in a Spark-Ignition Engine Model. In Proceedings of the 24th CIMAC Congress, Kyoto, Japan, 7–11 June 2004.

- Murakami, S.; Baufeld, T. Current Status and Future Strategies of Gas Engine Development. In Proceedings of the CIMAC 2013, Shanghai, China, 13–17 May 2013.