| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Pin Han Chen | -- | 2240 | 2023-12-27 05:25:04 | | | |

| 2 | Catherine Yang | Meta information modification | 2240 | 2023-12-27 06:27:23 | | |

Video Upload Options

The global surge in solar energy adoption is a response to the imperatives of sustainability and the urgent need to combat climate change. Solar photovoltaic (PV) energy, harnessing solar radiation to produce electricity, has become a prevalent method for terrestrial power generation. At the forefront of this shift are crystalline silicon photovoltaics modules (PVMs), the primary tools in PV systems for solar energy capture. This growth is evidenced by a significant increase in installations, with an over 90% surge in the past decade, from 104 to 1053 gigawatts (GWs). These PVMs, predominantly silicon-based and representing 95% of global PV production in 2020, have a lifespan of 20–30 years. Projections indicate that by 2030, worldwide solar capacity might approach 2840 GW, and by 2050, it could climb to 8500 GW.

1. Current State in PV Recycling

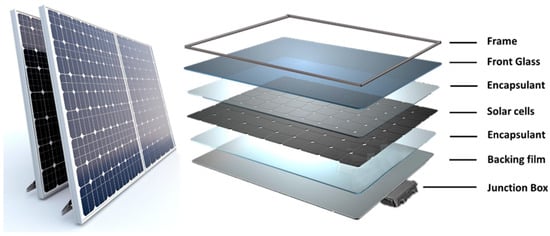

2. Crystalline Silicon Solar Panel Composition

2.1. Front Glass (or Cover)

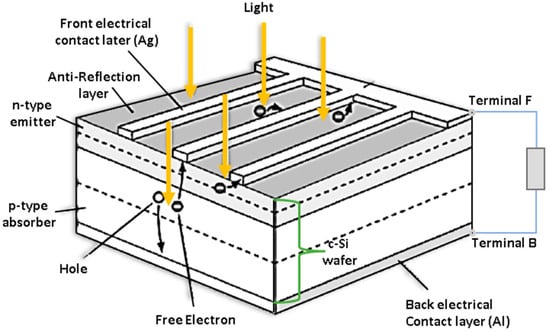

2.2. Silicon Solar Cells

2.3. Anti-Reflective Coating

2.4. Backing Film

| Characteristic | Double Fluoropolymer | Single Fluoropolymer | Non-Fluoropolymer |

|---|---|---|---|

| Composition | A Polyethylene Terephthalate (PET) core layer is encased by two external layers of fluoropolymer material, potentially Tedlar (Polyvinyl Fluoride, PVF) or Kynar (Polyvinylidene Fluoride, PVDF) | Tedlar or Kynar on the outer side; PET and primer or EVA layers on the inner side | Two PET layers and one primer or EVA layer |

| Protection Level | Superior | Satisfactory | Basic, but improving with advancements |

| Price | Most expensive | Moderate | Cheapest |

| UV Durability | High | Satisfactory | High (with recent advancements) |

| Historical Context | Preferred for high protection | Developed to balance cost and performance | Initially avoided due to degradation risks |

| Advancements | N/A | N/A | Significant, leading to highly UV-durable films |

2.5. Junction Box and Electrical Connections

2.6. Frame

2.7. Encapsulants

2.8. Composition and Recyclability

| Unit | Main Component |

[23] | [29] | [30] | [9] |

|---|---|---|---|---|---|

| Front Glass | Glass | 70% | 70% | 63% | 54.721% |

| Silicon solar cells | Silicon | 3.56% | 3.65% | 4% | 3.101% |

| Silver | 0.05% | 0.05% | <0.01% | 0.03% | |

| Copper | 1.14% | 0.11% | Not Available | 0.451% | |

| Tin | 0.053% | 0.05% | <0.1% | Not Available | |

| Lead | <0.1% | ||||

| Aluminum | 0.53% | 0.53% | 19% | ||

| Frame | Aluminum | 18% | 18% | 12% | |

| Junction Box and Electrical Connections |

Box body (including copper or plastic terminal), lid, diode, cables, connectors | 1% | Copper: 0.33% Plastic: 0.67% |

Copper: 0.6% Others: Not available |

Not Available |

| Encapsulants | EVA | 5.1% | 5.1% | Organic:11% | 10% |

| Backing film | PVF, PVDF, PET, etc. | 1.5% | 1.5% | 17.091% |

3. Current Challenges in Solar Panel Recycling

3.1. Volume Concern

3.2. Material Recovery

3.3. Environmental Impact

3.4. Economic Viability

References

- Franco, M.A.; Groesser, S.N. A Systematic Literature Review of the Solar Photovoltaic Value Chain for a Circular Economy. Sustainability 2021, 13, 9615.

- Sica, D.; Malandrino, O.; Supino, S.; Testa, M.; Lucchetti, M.C. Management of end-of-life photovoltaic panels as a step towards a circular economy. Renew. Sustain. Energy Rev. 2018, 82, 2934–2945.

- Luo, W.; Khoo, Y.S.; Kumar, A.; Low, J.S.C.; Li, Y.; Tan, Y.S.; Wang, Y.; Aberle, A.G.; Ramakrishna, S. A comparative life-cycle assessment of photovoltaic electricity generation in Singapore by multicrystalline silicon technologies. Sol. Energy Mater. Sol. Cells 2018, 174, 157–162.

- Kim, S.; Jeong, B. Closed-loop supply chain planning model for a photovoltaic system manufacturer with internal and external recycling. Sustainability 2016, 8, 596.

- Farrell, C.; Osman, A.I.; Harrison, J.; Vennard, A.; Murphy, A.; Doherty, R.; Russell, M.; Kumaravel, V.; Al-Muhtaseb, A.a.H.; Zhang, X.; et al. Pyrolysis Kinetic Modeling of a Poly(ethylene-co-vinyl acetate) Encapsulant Found in Waste Photovoltaic Modules. Ind. Eng. Chem. Res. 2021, 60, 13492–13504.

- Chowdhury, M.S.; Rahman, K.S.; Chowdhury, T.; Nuthammachot, N.; Techato, K.; Akhtaruzzaman, M.; Tiong, S.K.; Sopian, K.; Amin, N. An overview of solar photovoltaic panels’ end-of-life material recycling. Energy Strategy Rev. 2020, 27, 100431.

- Jamali, M.Y.; Aslani, A.; Moghadam, B.F.; Naaranoja, M.; Madvar, M.D. Analysis of photovoltaic technology development based on technology life cycle approach. J. Renew. Sustain. Energy 2016, 8, 035905.

- Peeters, J.R.; Altamirano, D.; Dewulf, W.; Duflou, J.R. Forecasting the composition of emerging waste streams with sensitivity analysis: A case study for photovoltaic (PV) panels in Flanders. Resour. Conserv. Recycl. 2017, 120, 14–26.

- Xu, Y.; Li, J.; Tan, Q.; Peters, A.L.; Yang, C. Global status of recycling waste solar panels: A review. Waste Manag. 2018, 75, 450–458.

- Tao, M.; Fthenakis, V.; Ebin, B.; Steenari, B.M.; Butler, E.; Sinha, P.; Corkish, R.; Wambach, K.; Simon, E.S. Major challenges and opportunities in silicon solar module recycling. Prog. Photovolt. Res. Appl. 2020, 28, 1077–1088.

- Komoto, K.; Lee, J.-S.; Zhang, J.; Ravikumar, D.; Sinha, P.; Wade, A.; Heath, G.A. End-of-Life Management of Photovoltaic Panels: Trends in PV Module Recycling Technologies; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2018.

- Klugmann-Radziemska, E.; Ostrowski, P. Chemical treatment of crystalline silicon solar cells as a method of recovering pure silicon from photovoltaic modules. Renew. Energy 2010, 35, 1751–1759.

- Klugmann-Radziemska, E.; Ostrowski, P.; Cenian, A.; Sawczak, M. Chemical, thermal and laser processes in recycling of photovoltaic silicon solar cells and modules. Ecol. Chem. Eng. S 2010, 17, 384–391.

- Latunussa, C.E.L.; Ardente, F.; Blengini, G.A.; Mancini, L. Life Cycle Assessment of an innovative recycling process for crystalline silicon photovoltaic panels. Sol. Energy Mater. Sol. Cells 2016, 156, 101–111.

- Jung, B.; Park, J.; Seo, D.; Park, N. Sustainable system for raw-metal recovery from crystalline silicon solar panels: From noble-metal extraction to lead removal. ACS Sustain. Chem. Eng. 2016, 4, 4079–4083.

- Ilias, A.V.; Meletios, R.G.; Yiannis, K.A.; Nikolaos, B. Integration & assessment of recycling into c-Si photovoltaic module’s life cycle. Int. J. Sustain. Eng. 2018, 11, 186–195.

- Mohammed Niyaz, H.; Meena, R.; Gupta, R. Impact of cracks on crystalline silicon photovoltaic modules temperature distribution. Sol. Energy 2021, 225, 148–161.

- Tune, D.D.; Flavel, B.S. Advances in carbon nanotube–silicon heterojunction solar cells. Adv. Energy Mater. 2018, 8, 1703241.

- Yu, H.F.; Hasanuzzaman, M.; Rahim, N.A.; Amin, N.; Nor Adzman, N. Global Challenges and Prospects of Photovoltaic Materials Disposal and Recycling: A Comprehensive Review. Sustainability 2022, 14, 8567.

- Shahsavari, A.; Yazdi, F.; Yazdi, H. Potential of solar energy in Iran for carbon dioxide mitigation. Int. J. Environ. Sci. Technol. 2019, 16, 507–524.

- Tawalbeh, M.; Al-Othman, A.; Kafiah, F.; Abdelsalam, E.; Almomani, F.; Alkasrawi, M. Environmental impacts of solar photovoltaic systems: A critical review of recent progress and future outlook. Sci. Total Environ. 2021, 759, 143528.

- Walker, G.R.; Sernia, P.C. Cascaded DC-DC converter connection of photovoltaic modules. IEEE Trans. Power Electron. 2004, 19, 1130–1139.

- Tan, J.; Jia, S.; Ramakrishna, S. End-of-Life Photovoltaic Modules. Energies 2022, 15, 5113.

- Muteri, V.; Cellura, M.; Curto, D.; Franzitta, V.; Longo, S.; Mistretta, M.; Parisi, M.L. Review on Life Cycle Assessment of Solar Photovoltaic Panels. Energies 2020, 13, 252.

- De Oliveira, M.C.C.; Cardoso, A.S.A.D.; Viana, M.M.; Lins, V.d.F.C. The causes and effects of degradation of encapsulant ethylene vinyl acetate copolymer (EVA) in crystalline silicon photovoltaic modules: A review. Renew. Sustain. Energy Rev. 2018, 81, 2299–2317.

- Kahoul, N.; Chenni, R.; Cheghib, H.; Mekhilef, S. Evaluating the reliability of crystalline silicon photovoltaic modules in harsh environment. Renew. Energy 2017, 109, 66–72.

- Han, H.; Dong, X.; Li, B.; Yan, H.; Verlinden, P.J.; Liu, J.; Huang, J.; Liang, Z.; Shen, H. Degradation analysis of crystalline silicon photovoltaic modules exposed over 30 years in hot-humid climate in China. Sol. Energy 2018, 170, 510–519.

- Corcelli, F.; Ripa, M.; Leccisi, E.; Cigolotti, V.; Fiandra, V.; Graditi, G.; Sannino, L.; Tammaro, M.; Ulgiati, S. Sustainable urban electricity supply chain—Indicators of material recovery and energy savings from crystalline silicon photovoltaic panels end-of-life. Ecol. Indic. 2018, 94, 37–51.

- Herceg, S.; Pinto Bautista, S.; Weiß, K.-A. Influence of Waste Management on the Environmental Footprint of Electricity Produced by Photovoltaic Systems. Energies 2020, 13, 2146.

- Sander, K.; SchillingJan, S.; Reinschmidt; Wambach, K.; Schlenker, S. Study on the Development of a Takeback and Recovery System for Photovoltaic Modules; Ökopol: Hamburg, Germany, 2007.

- Majewski, P.; Al-Shammari, W.; Dudley, M.; Jit, J.; Lee, S.-H.; Myoung-Kug, K.; Sung-Jim, K. Recycling of solar PV panels—product stewardship and regulatory approaches. Energy Policy 2021, 149, 112062.

- Pagnanelli, F.; Moscardini, E.; Granata, G.; Atia, T.A.; Altimari, P.; Havlik, T.; Toro, L. Physical and chemical treatment of end of life panels: An integrated automatic approach viable for different photovoltaic technologies. Waste Manag. 2017, 59, 422–431.

- Padoan, F.C.S.M.; Altimari, P.; Pagnanelli, F. Recycling of end of life photovoltaic panels: A chemical prospective on process development. Sol. Energy 2019, 177, 746–761.

- Nain, P.; Kumar, A. Ecological and human health risk assessment of metals leached from end-of-life solar photovoltaics. Environ. Pollut. 2020, 267, 115393.

- Savvilotidou, V.; Antoniou, A.; Gidarakos, E. Toxicity assessment and feasible recycling process for amorphous silicon and CIS waste photovoltaic panels. Waste Manag. 2017, 59, 394–402.

- Lee, J.-K.; Lee, J.-S.; Ahn, Y.-S.; Kang, G.-H.; Song, H.-E.; Lee, J.-I.; Kang, M.-G.; Cho, C.-H. Photovoltaic performance of c-Si wafer reclaimed from end-of-life solar cell using various mixing ratios of HF and HNO3. Sol. Energy Mater. Sol. Cells 2017, 160, 301–306.

- Verma, S.; Lee, T.; Sahle-Demessie, E.; Ateia, M.; Nadagouda, M.N. Recent advances on PFAS degradation via thermal and nonthermal methods. Chem. Eng. J. Adv. 2022, 100421.

- Salama, A.; Richard, G.; Medles, K.; Zeghloul, T.; Dascalescu, L. Distinct recovery of copper and aluminum from waste electric wires using a roll-type electrostatic separator. Waste Manag. 2018, 76, 207–216.

- Zachmann, N. Separation of Organic Components from Crystalline Silicon Solar Cells by Supercritical Fluid Technology. Master’s Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2020.

- D’Adamo, I.; Miliacca, M.; Rosa, P. Economic feasibility for recycling of waste crystalline silicon photovoltaic modules. Int. J. Photoenergy 2017, 2017, 4184676.

- Granata, G.; Altimari, P.; Pagnanelli, F.; De Greef, J. Recycling of solar photovoltaic panels: Techno-economic assessment in waste management perspective. J. Clean. Prod. 2022, 363.

- Zeng, X.; Mathews, J.A.; Li, J. Urban Mining of E-Waste is Becoming More Cost-Effective Than Virgin Mining. Env. Sci Technol 2018, 52, 4835–4841.

- Li, J.; Shao, J.; Yao, X.; Li, J. Life cycle analysis of the economic costs and environmental benefits of photovoltaic module waste recycling in China. Resour. Conserv. Recycl. 2023, 196, 10727.

- Dias, P.R.; Schmidt, L.; Chang, N.L.; Lunardi, M.M.; Deng, R.; Trigger, B.; Gomes, L.B.; Egan, R.; Veit, H. High yield, low cost, environmentally friendly process to recycle silicon solar panels: Technical, economic and environmental feasibility assessment. Renew. Sustain. Energy Rev. 2022, 169, 112900.