The incorporation of graphene into cellulose matrices has emerged as a promising strategy for enhancing the structural and functional properties of composite materials. This comprehensive review provides a critical analysis of recent advances in optimizing graphene content in cellulose matrices and its impact on composite performance. Various optimization techniques, including response surface methodology, particle swarm optimization, and artificial neural networks, have been employed to identify optimal graphene concentrations and processing conditions. Quantitative analyses demonstrate significant improvements in mechanical properties, with notable increases in tensile strength and Young’s modulus reported for graphene/microfibrillated cellulose composites. Substantial enhancements in thermal stability have been observed in lysozyme-modified graphene nanoplatelet–cellulose composites. Electrical conductivity has been achieved at low graphene loading levels. Additionally, barrier properties, biocompatibility, and functionality for applications such as energy storage and environmental remediation have been substantially improved. This review explores case studies encompassing the optimization of thermal conductivity, viscosity, durability behaviors, pollutant removal, and various other properties. Despite promising results, challenges remain, including uniform dispersion, scalability, cost-effectiveness, and long-term stability. Strategies such as surface functionalization, solvent selection, and protective coatings are discussed. Future research directions, including novel processing techniques like 3D printing and electrospinning, as well as the incorporation of additional functional materials, are outlined. This review synthesizes current knowledge, identifies emerging trends, and provides a roadmap for future research in the rapidly evolving field of graphene–cellulose composites.

The integration of graphene oxide (GO) into cellulose matrices has emerged as a promising frontier in materials science, offering unprecedented opportunities to enhance the structural and functional properties of composite materials. This synergistic combination leverages the unique characteristics of GO—a two-dimensional carbon-based material with abundant oxygen-containing functional groups, high specific surface area, and excellent dispersibility in aqueous solutions—with the abundant, renewable, and biodegradable nature of cellulose

[1][2]. Unlike pristine graphene, GO’s oxygen-rich surface chemistry facilitates stronger interactions with cellulose, making it particularly suitable for composite applications. A study by Luo et al. (2018) reported the fabrication of bacterial cellulose–graphene oxide hydrogels using layer-by-layer assembly, resulting in extremely enhanced mechanical properties

[3]. Another study by Song et al. (2017) demonstrated the creation of nanofibrillated cellulose (NFC)–reduced graphene oxide (RGO) hybrid films using layer-by-layer assembly, achieving a high tensile strength of 107 MPa along with outstanding flexibility

[4]. Another study explored the synergistic effects of GO and CNC on the properties of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) nanocomposites. The researchers prepared ternary nanocomposites consisting of PHBV and CNC-GO nanohybrids using a simple solution casting method. The study found that the ternary nanocomposites displayed significantly improved properties compared to neat PHBV and binary nanocomposites. Specifically, the ternary nanocomposites with 1 wt% covalent bonded CNC-GO exhibited excellent barrier properties, along with enhanced thermal stability, mechanical properties, and antibacterial activity

[5]. These studies underscore the versatility of GO–cellulose composites in addressing challenges in materials engineering and environmental sustainability.

The optimization of GO content within cellulose matrices remains a critical challenge that significantly influences the final properties and performance of these composites. Factors such as the degree of oxidation of GO, the method of incorporation, and the processing conditions all play crucial roles in determining the overall efficacy of the composite. To address this challenge, researchers have employed various sophisticated optimization techniques. For instance, Basha et al. (2022) utilized response surface methodology (RSM) to optimize the adsorption of methylene blue dye using sulfonated graphene oxide impregnated cellulose acetate floated beads, demonstrating the effectiveness of statistical approaches in tailoring composite properties

[6]. Building on this work, Khiam et al. (2022) applied particle swarm optimization (PSO) in conjunction with artificial neural networks (ANN) to optimize GO content in graphene oxide–chitosan composites for methylene blue adsorption, highlighting the potential of machine learning techniques in materials design

[7]. Furthermore, Balasubramani et al. (2020) employed a similar ANN-PSO approach to model and optimize the removal of an antidepressant using graphene oxide–cellulose nanogel composites, further emphasizing the growing importance of these techniques in environmental applications

[8].

Advancements in understanding the fundamental mechanisms underlying the enhanced properties of GO–cellulose composites have also been made. Recent advancements in understanding the fundamental mechanisms underlying the enhanced properties of graphene oxide (GO)–cellulose composites have provided significant insights into their remarkable performance and potential applications. These composites have garnered considerable attention due to their synergistic combination of the exceptional properties of GO and the abundant, renewable nature of cellulose. The enhanced properties of GO–cellulose composites can be largely attributed to the strong interfacial interactions between the two components. Recent studies have elucidated the nature of these interactions, revealing a complex interplay of hydrogen bonding, electrostatic interactions, and mechanical interlocking

[9]. The presence of oxygen-containing functional groups on both GO and cellulose surfaces facilitates the formation of an extensive hydrogen bonding network, which significantly contributes to the improved mechanical properties of the composites

[9][10]. Furthermore, molecular dynamics simulations have provided valuable insights into the nanoscale mechanisms of reinforcement. These simulations have demonstrated that the incorporation of GO into cellulose-based matrices can enhance the Young’s modulus and tensile strength by up to 32.1% and 23.8%, respectively. This remarkable improvement is attributed to the formation of hydrogen bonds and the presence of Ca

2+ ions near the interface, which play a crucial role in improving interfacial adhesion and facilitating load transfer between GO and the cellulose matrix

[10].

Recent research has also highlighted the multifunctional nature of GO–cellulose composites, particularly in environmental remediation applications. These composites have shown exceptional performance in the removal of heavy metals, organic compounds, dyes, and microbial contaminants from wastewater

[11]. The high surface area, superior mechanical strength, and notable biodegradability of nanocellulose composites, when combined with GO, create a powerful platform for addressing complex environmental challenges

[10].

In the context of water treatment, GO–cellulose composites have demonstrated remarkable adsorption capacities for various pollutants. The integration of GO with cellulose-based materials has been shown to enhance the stability and processability of the composites, making them more suitable for large-scale industrial applications

[12]. Moreover, these composites exhibit excellent regeneration potential, further enhancing their economic viability and sustainability in wastewater treatment processes

[13].

D’Amora et al. (2023) conducted an extensive molecular dynamics study to elucidate the complex interfacial interactions between graphene oxide (GO) and cellulose nanofibrils

[14]. Their research employed advanced simulation techniques to model the behavior of GO sheets and cellulose nanofibrils at the molecular level. The study revealed that hydrogen bonding plays a crucial role in the mechanical reinforcement of GO–cellulose composites. Specifically, they observed that the oxygen-containing functional groups on GO surfaces formed strong hydrogen bonds with the hydroxyl groups of cellulose chains. This interaction significantly enhanced the interfacial adhesion between GO and cellulose, leading to improved mechanical properties of the composite. Furthermore, the simulations demonstrated that the density and distribution of oxygen-containing groups on GO surfaces directly influenced the strength of these interfacial interactions. This finding provides valuable insights for optimizing GO functionalization to maximize its reinforcing effect in cellulose matrices.

Many studies explored on developed an innovative 3D printing methods for fabricating GO–cellulose aerogels with hierarchical porous structures

[15][16][17][18]. Their approach utilized a custom-designed extrusion-based 3D printer capable of precisely depositing a GO–cellulose nanofiber (CNF) ink. The ink formulation was carefully optimized to achieve the right viscosity and shear-thinning behavior necessary for successful printing. The researchers employed a freeze-drying process post-printing to create the aerogel structure. The resulting 3D-printed GO–cellulose aerogels exhibited remarkable mechanical strength, with compressive moduli up to 150% higher than conventionally prepared composites. Additionally, the hierarchical porous structure, consisting of macropores from the printed architecture and mesopores within the GO-CNF network, led to enhanced electrical conductivity. The authors demonstrated the potential of these 3D-printed aerogels in various applications, including as high-performance supercapacitor electrodes and efficient oil absorption materials for environmental remediation.

Biswas et al. (2023) conducted a comprehensive study on the use of GO–cellulose nanocrystal (CNC) composites as efficient drug carriers for controlled release applications

[19]. The researchers developed a novel synthesis method that involved the in situ reduction of GO in the presence of CNCs, resulting in a uniform dispersion of reduced GO (rGO) within the CNC matrix. They investigated the drug loading and release characteristics of these composites using doxorubicin, a common anticancer drug, as a model compound. The study revealed that the GO-CNC composites exhibited a remarkably high drug loading capacity of up to 85%, significantly higher than pure CNCs or GO alone. The researchers attributed this enhanced loading to the synergistic effects of π-π stacking interactions between the drug and rGO sheets, as well as hydrogen bonding with the CNC surface. Furthermore, the drug release profiles showed a sustained release behavior over 72 h, with the ability to modulate the release rate by adjusting the GO content in the composite. In vitro cytotoxicity studies demonstrated that the drug-loaded GO-CNC composites effectively inhibited the growth of cancer cells while showing minimal toxicity to healthy cells. The authors also conducted in vivo studies using a mouse tumor model, which showed improved tumor reduction compared to free doxorubicin administration. This comprehensive study highlights the potential of GO–cellulose nanocomposites in developing advanced drug delivery systems for cancer therapy.

Another study made significant strides in developing GO–cellulose nanofiber composite electrodes for high-performance supercapacitors

[20]. The research focused on optimizing the GO content and the nanostructure of the composite to maximize energy storage capacity and cycling stability. The team employed a layer-by-layer assembly technique to create highly ordered GO-CNF nanostructures with precisely controlled thickness and composition. They investigated the effect of GO content (ranging from 5 to 30 wt%) on the electrochemical performance of the composites. The study revealed that a GO content of 20 wt% resulted in the optimal balance between electrical conductivity and ion accessibility. These optimized GO-CNF electrodes exhibited an exceptionally high specific capacitance of 412 F/g at a current density of 1 A/g, which is among the highest reported for cellulose-based supercapacitors. Moreover, the electrodes demonstrated remarkable cycling stability, retaining 95% of their initial capacitance after 10,000 charge–discharge cycles. The researchers attributed this outstanding performance to the synergistic effects of GO’s high electrical conductivity and the CNF’s porous structure, which facilitated rapid ion transport and provided a large surface area for charge storage.

To further demonstrate the practical applicability of their GO-CNF supercapacitors, Kasprzak et al. fabricated a flexible, all-solid-state device using a gel electrolyte

[21]. This device maintained excellent capacitive behavior under various bending conditions, showcasing its potential for use in wearable electronics and flexible energy storage systems.

These case studies illustrate the diverse and promising applications of GO–cellulose composites, highlighting the importance of continued research in this field to unlock their full potential in various technological domains.

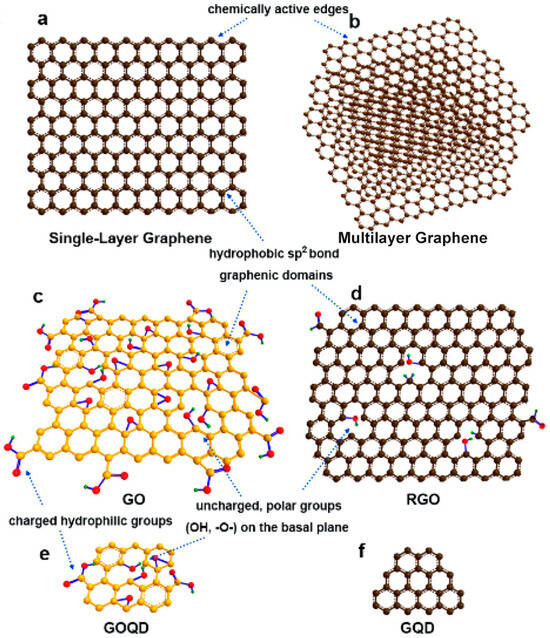

From a chemical and physical perspective, graphene can be categorized into two primary classes: CVD-prepared graphene and oxidized graphene. CVD-prepared single- or multilayer graphene exhibits well-defined aromatic structures with minimal defects, as illustrated in

Figure 1a,b. While these graphene sheets possess highly reactive surfaces suitable for bioelectrode applications, their poor solubility limits their use in nanomedicine or as nanocarriers. In contrast, graphene oxide (GO), depicted in

Figure 1c, is a highly oxidized form of graphene that combines hydrophobic sp2- and sp3-bonded carbon with numerous hydrophilic functional groups, resulting in an amphiphilic colloid with enhanced dispersibility in aqueous and polar solvents. GO’s unique structure enables π-π interactions, weak hydrogen bonding, and strong electrostatic interactions, making it suitable for various chemical modifications and interactions with biological systems. Reduced graphene oxide (RGO), shown in

Figure 1d, offers a balance between the properties of graphene and GO, while graphene quantum dots (GQDs) and graphene oxide quantum dots (GOQDs), illustrated in

Figure 1e,f, are nanometer-sized fragments with unique optical properties, opening up new possibilities for biological applications such as cell imaging and bioelectrodes

[22].

Figure 1. The forms of graphene and its derivatives that have been used for the construction of bioactive architectures: (

a) single-layer graphene, (

b) multilayer graphene, (

c) GO, (

d) RGO, (

e) GOQD, (

f) GQD. Adapted with permission from ref.

[22]. Copyright 2017 ACS Publications.