| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Sushobhan Pradhan | -- | 784 | 2025-01-06 03:37:26 | | | |

| 2 | Sirius Huang | Meta information modification | 784 | 2025-01-06 03:45:49 | | |

Video Upload Options

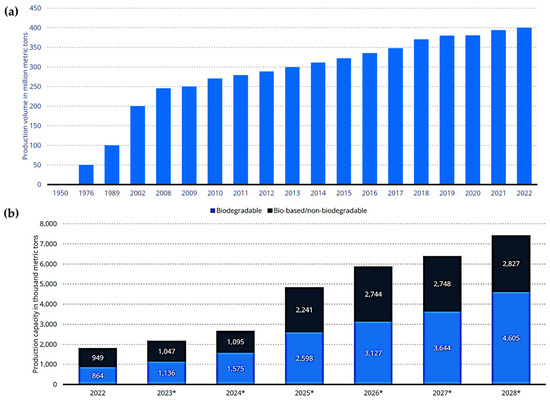

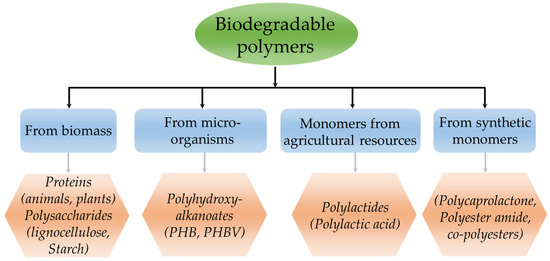

A polymer is a long-chain molecule formed by linking numerous simpler repeating chemical units, known as monomers, with identical structures. Over the past two centuries, there has been a significant increase in the global production and use of petrochemical-based plastics. This surge has led to widespread ecological imbalances, affecting air quality, terrestrial and marine ecosystems, food chains, and plant life. Consequently, the excessive use of such polymers has created challenges in solid waste management, with methods like bio- or photo-degradation, incineration, landfilling, and recycling proving to be time-consuming and laborious. Therefore, there is a growing urgency for biodegradable polymers due to increasing demand. Biodegradable polymers consist of interconnected monomers with unstable links in the backbone, facilitated by various functional groups. Throughout the degradation process of these polymers, numerous biologically acceptable molecules are produced. This study examines the significance of biopolymers over petroleum-based counterparts, offering a detailed analysis. It is noteworthy that within the spectrum of biodegradable polymers, polyhydroxyalkanoates (PHAs) emerge as exceptionally promising candidates for substituting petroleum-derived polymers, owing to their remarkable physical attributes. Therefore, this study provides a systematic overview of PHAs, including their classification, historical background, methods of production, potential challenges to commercialization, and diverse applications.

1.1. Overview to Petroleum-Derived Polymers

1.2. Overview to Bio-Based Polymers

References

- Fried, J.R. Polymer Science and Technology; Pearson Education: London, UK, 2014.

- Gowariker, V.R.; Viswanathan, N.; Sreedhar, J. Polymer Science; New Age International: Delhi, India, 1986.

- de Paula, F.C.; de Paula, C.B.; Contiero, J. Prospective biodegradable plastics from biomass conversion processes. In Biofuels: State of Development; IntechOpen: London, UK, 2018; pp. 245–271.

- Ritchie, H.; Samborska, V.; Roser, M.; Plastic Pollution. Our World in Data. 2023. Available online: https://ourworldindata.org/grapher/global-plastics-production (accessed on 16 October 2024).

- Pradhan, S.; Dikshit, P.K.; Moholkar, V.S. Production, Characterization, and Applications of Biodegradable Polymer: Polyhydroxyalkanoates. In Advances in Sustainable Polymers; Springer: Singapore, 2020; pp. 51–94.

- Khanna, S.; Srivastava, A.K. Recent advances in microbial polyhydroxyalkanoates. Process Biochem. 2005, 40, 607–619.

- Bioplastics Market Development Update 2023; European Bioplastics e.V.: Berlin, Germany, 2023.

- Bioplastic Industry Worldwide; Statistics Report on the Global Bioplastic Industry; Statista: Hamburg, Germany, 2024.

- ASTM D5488-94de1; Standard Terminology of Environmental Labeling of Packaging Materials and Packages. ASTM International: West Conshohocken, PA, USA, 1994.

- Averous, L. Biodegradable multiphase systems based on plasticized starch: A review. J. Macromol. Sci. Part C Polym. Rev. 2004, 44, 231–274.

- Anne, B. Environmental-friendly biodegradable polymers and composites. In Integrated Waste Management; InTechOpen: London, UK, 2011; Volume I.

- Avérous, L.; Pollet, E. Biodegradable polymers. In Environmental Silicate Nano-Biocomposites; Springer: Berlin/Heidelberg, Germany, 2012; pp. 13–39.