Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Ewa Skrzetuska | -- | 1125 | 2023-09-14 10:59:49 | | | |

| 2 | Sirius Huang | + 3 word(s) | 1128 | 2023-09-15 04:04:54 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Skrzetuska, E.; Szablewska, P. Textile Chemical Sensors. Encyclopedia. Available online: https://encyclopedia.pub/entry/49160 (accessed on 07 February 2026).

Skrzetuska E, Szablewska P. Textile Chemical Sensors. Encyclopedia. Available at: https://encyclopedia.pub/entry/49160. Accessed February 07, 2026.

Skrzetuska, Ewa, Paulina Szablewska. "Textile Chemical Sensors" Encyclopedia, https://encyclopedia.pub/entry/49160 (accessed February 07, 2026).

Skrzetuska, E., & Szablewska, P. (2023, September 14). Textile Chemical Sensors. In Encyclopedia. https://encyclopedia.pub/entry/49160

Skrzetuska, Ewa and Paulina Szablewska. "Textile Chemical Sensors." Encyclopedia. Web. 14 September, 2023.

Copy Citation

Textronic applications are already visible in many areas of everyday life. Many researchers around the world have focused on the invention of textronic systems to increase security, create technological innovations and make everyday life easier and more interesting.

chemical sensor

gas sensor

textronics

1. Introduction

Times of dynamic technological development have resulted in research work on minimizing electronic systems. As early as the 20th century, the term and idea of textronics were introduced to connect electronic circuits with textiles, as in 1980, Steve Mann was integrating many textronic components into clothing. Thus, scientists around the world began to focus on the development of this field [1]. Many types of textronic sensors have been invented, responding to stimuli of various sources ranging from physical, biological and chemical ones. Their response can be programmed and built in many ways, including changes in resistance, impedance and color change. Textronics are present in many fields of life. There are applications in medicine, sport, health and safety, motorization, military, entertainment, heating materials, communication and fashion. They provide a lot of valuable information about one’s state of health, target parameters or delight with their design. The topic of connecting electronic systems and textiles is new, and many innovative solutions and applications are to be discovered. The field is rapidly developing due to the high demand for smart clothing in all areas of everyday existence. There are already projects that try to combine several areas of life into one solution. A group of researchers led by E. Saoutieff developed a product in the form of a sensor platform. The product is characterized by low power consumption, a wireless design and energy efficiency and has a multifunctional wearable system. The project offers one the ability to monitor their lifestyle, obtain real-time healthcare and collect medical data. The system is compatible with several types of sensors. The goal was to combine the platform with other products that can monitor not only a person’s health indicators but also the external environment. The analysis will involve the chemical molecules NOx, COx and NHx to monitor health exposure on an ongoing basis [2].

2. Textile Chemical Sensors

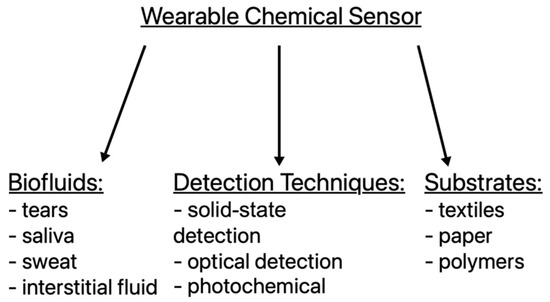

Wearable chemical sensors are divided into two subgroups according to their detection technique—electrochemical and optical. They can have different bases like textiles, polymer hydrogels or paper and detect an entire range of chemically active analytes [3]. The development of wearable chemical sensors has been gaining momentum for years due to their many applications. Solutions can be implemented in areas such as medicine, safety, health and sports [4]. Sensors in this group are based on changes in conductometry. Results can be monitored in real time by changes in electrical conductivity [5], resistivity or color [6]. There are many types of textile chemical sensors, such as humidity, sweat, pH, gas or biomolecule sensors [1]. They use a wide range of materials and active substances. The division is shown in Figure 1. The choice of these two components is an important aspect in creating wearable electronics. Together, they must meet the requirements of electrical performance, mechanical strength, flexibility, durability, and lightness, and in addition, their production is cheap. It is also impossible to consider the functional properties that are supposed to ensure comfort of use, i.e., air permeability, moisture and aesthetic values [7]. There are several groups of active substances: conductive polymers [8], carbon-based materials on the micro- and nanoscale [9] and conductive metallic structures on the nanoscale [10].

Figure 1. Division of wearable textile chemical sensors.

Minimalism in textronics is one of the main goals of textronic development. The aim is to achieve solutions in which all electronic functions could be implemented in the fiber itself. Such fibers would allow textronics to be integrated with the textiles already in place during the weaving process. Currently, for technological reasons, the production of such a product is very difficult. Polymers are the materials of the future, especially organic polymers, and they are low-molecular-weight compounds. They are characterized by flexibility and integrate into fiber-producing composite materials. As they are made of basic building blocks, it is possible to adjust their chemical, physical and electronic properties to meet the required needs [11]. Organic polymers exhibit electrical properties like those of metals. Examples of conductive polymers are polypyrrole, polyaniline and polythiophene. Organic polymers are the most promising materials [12]. There are 0-, 1- and 2-dimensional carbon-based micro/nanomaterials used in textronics—graphene, in the form of nanosheets, and carbon nanotubes and nanoparticles. They are flexible and suitable for use in textronic systems. They are characterized by high conductivity, impeccable mechanical properties, a huge surface area, high stability and low production costs. The most-used nanomaterials in research are carbon nanotubes and graphene. Metal nanostructures are great for making flexible and wearable fiber-based electronics because they boast remarkably high conductivity. They have small dimensions; examples are nanowires, nanorods and nanoparticles. The known metals used are silver, zinc oxide, gold and platinum. They are also available in such forms as pastes, whereby they obtain excellent conductive properties. The downside of this form is the demanding stability. Another form is thread. Metal threads can be a component factor of the material and can be a part of it or be embroidered in the form of embroidery already at the weaving level. They have conductive properties and are resistant to sweat and washing. Metal nanostructures can also be applied to textiles in the form of a thin film [1][4]. Metal oxides, carbon nanotubes, conductive polymers and 2D materials are classified as semiconductors; hence, the detection solutions made of them are called semiconductor gas sensors. The principle of operation of these sensors is the direct reaction of gas molecules with the sensing material, changing its parameters such as its conductivity, permittivity and work function. Then, the transducer present in the system converts the received information in the form of physical parameters into electrical parameters, such as resistance, capacitance and inductance. It successively produces a voltage or current signal characterized by measurable magnitudes such as frequency and phases. Semiconductor gas sensors, where there is a direct interaction between the gas molecules and the treatment material, allow for the definition of characteristic values such as the sensitivity, stability and biocompatibility [13]. Currently used on a large scale, three subgroups of semiconductor gas sensors can be distinguished: electrochemical sensors, which are based on electrolytes; pellistors based on catalytic combustion; and conductometric/chemoresistance-based gas sensors, which are based on the resistance modulation of semiconducting oxides [14].

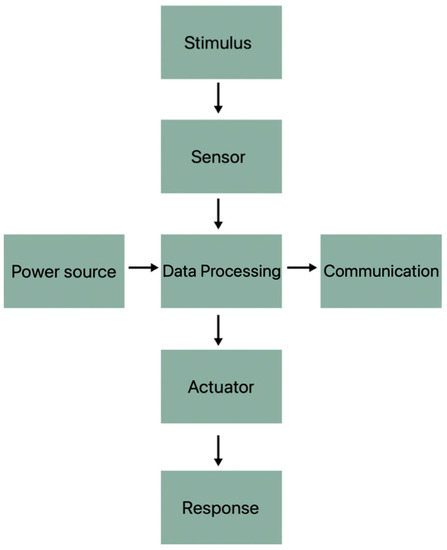

Figure 2 shows the mandatory components of the textronic system and the order in which they must be placed next to each other. The sensor whose task is to detect the intended stimulus needs, depending on the operating technique, a power source, an element that converts the stimulus into a signal, an analyzing cell and a response element.

Figure 2. Block diagram of the cells needed for the proper operation of textile sensors.

References

- Hatamie, A.; Angizi, S.; Kumar, S.; Pandey, C.M.; Simchi, A.; Willander, M.; Malhotra, B.D. Review—Textile Based Chemical and Physical Sensors for Healthcare Monitoring. J. Electrochem. Soc. 2020, 167, 037546.

- Saoutieff, E.; Polichetti, T.; Jouanet, L.; Faucon, A.; Vidal, A.; Pereira, A.; Boisseau, S.; Ernst, T.; Miglietta, M.L.; Alfano, B.; et al. A Wearable Low-Power Sensing Platform for Environmental and Health Monitoring: The Convergence Project. Sensors 2021, 21, 1802.

- Promphet, N.; Ummartyotin, S.; Ngeontae, W.; Puthongkham, P.; Rodthongkum, N. Non-invasive wearable chemical sensors in real-life applications. Anal. Chim. Acta 2021, 1179, 338643.

- Gualandi, I.; Tessarolo, M.; Mariani, F.; Possanzini, L.; Scavetta, E.; Fraboni, B. Textile Chemical Sensors Based on Conductive Polymers for the Analysis of Sweat. Polymers 2021, 13, 894.

- Zeng, W.; Shu, L.; Li, Q.; Chen, S.; Wang, F.; Tao, X.M. Fiber-based wearable electronics: A review of materials, fabrication, devices, and applications. Adv. Mater. 2014, 26, 5310–5336.

- Wu, R.; Selvaganapathy, P.R. Porous biocompatible colorimetric nanofiber-based sensor for selective ammonia detection on personal wearable protective equipment. Sens. Actuators B Chem. 2023, 393, 134270.

- Podsiadły, B.; Walter, P.; Kamiński, M.; Skalski, A.; Słoma, M. Electrically Conductive Nanocomposite Fibers for Flexible and Structural Electronics. Appl. Sci. 2022, 12, 941.

- Veeramuthu, L.; Venkatesan, M.; Benas, J.-S.; Cho, C.-J.; Lee, C.-C.; Lieu, F.-K.; Lin, J.-H.; Lee, R.-H.; Kuo, C.-C. Recent Progress in Conducting Polymer Composite/Nanofiber-Based Strain and Pressure Sensors. Polymers 2021, 13, 4281.

- Shao, W.; Cui, T.; Li, D.; Jian, J.; Li, Z.; Ji, S.; Cheng, A.; Li, X.; Liu, K.; Liu, H.; et al. Carbon-Based Textile Sensors for Physiological-Signal Monitoring. Materials 2023, 16, 3932.

- Liman, M.L.R.; Islam, M.T.; Hossain, M.M. Mapping the Progress in Flexible Electrodes for Wearable Electronic Textiles: Materials, Durability, and Applications. Adv. Elect. Mater. 2022, 8, 2100578.

- Sibinski, M.; Jakubowska, M.; Sloma, M. Flexible Temperature Sensors on Fibers. Sensors 2010, 10, 7934–7946.

- Peng, S.; Wang, D.; Lu, J.; He, M.; Xu, C.; Li, Y.; Zhu, S. A Review on Organic Polymer-Based Thermoelectric Materials. J. Polym. Environ. 2017, 25, 1208–1218.

- Nikolic, M.V.; Milovanovic, V.; Vasiljevic, Z.Z.; Stamenkovic, Z. Semiconductor Gas Sensors: Materials, Technology, Design, and Application. Sensors 2020, 20, 6694.

- Korotcenkov, G. Metal oxides for solid-state gas sensors: What determines our choice? Mater. Sci. Eng. B 2007, 139, 1–23.

More

Information

Subjects:

Engineering, Industrial

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

503

Revisions:

2 times

(View History)

Update Date:

15 Sep 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No