Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Md Shahinoor Islam | -- | 1339 | 2023-02-22 13:10:15 | | | |

| 2 | Sirius Huang | Meta information modification | 1339 | 2023-02-23 05:24:07 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Rahman, T.U.; Roy, H.; Islam, M.R.; Tahmid, M.; Fariha, A.; Mazumder, A.; Tasnim, N.; Pervez, M.N.; Cai, Y.; Naddeo, V.; et al. Membrane Bioreactor Technology for Sustainable Water Treatment. Encyclopedia. Available online: https://encyclopedia.pub/entry/41540 (accessed on 07 February 2026).

Rahman TU, Roy H, Islam MR, Tahmid M, Fariha A, Mazumder A, et al. Membrane Bioreactor Technology for Sustainable Water Treatment. Encyclopedia. Available at: https://encyclopedia.pub/entry/41540. Accessed February 07, 2026.

Rahman, Tanzim Ur, Hridoy Roy, Md. Reazul Islam, Mohammed Tahmid, Athkia Fariha, Antara Mazumder, Nishat Tasnim, Md. Nahid Pervez, Yingjie Cai, Vincenzo Naddeo, et al. "Membrane Bioreactor Technology for Sustainable Water Treatment" Encyclopedia, https://encyclopedia.pub/entry/41540 (accessed February 07, 2026).

Rahman, T.U., Roy, H., Islam, M.R., Tahmid, M., Fariha, A., Mazumder, A., Tasnim, N., Pervez, M.N., Cai, Y., Naddeo, V., & Islam, M.S. (2023, February 22). Membrane Bioreactor Technology for Sustainable Water Treatment. In Encyclopedia. https://encyclopedia.pub/entry/41540

Rahman, Tanzim Ur, et al. "Membrane Bioreactor Technology for Sustainable Water Treatment." Encyclopedia. Web. 22 February, 2023.

Copy Citation

The advancement in water treatment technology has revolutionized the progress of membrane bioreactor (MBR) technology in the modern era. The large space requirement, low efficiency, and high cost of the traditional activated sludge process have given the necessary space for the MBR system to come into action.

membrane bioreactor (MBR)

structural features

sustainable water treatment

1. Introduction

In recent times, rapid industrial growth that is due to an ever-increasing population has caused an increase in demand for water [1][2][3]. The increase in the use of fresh water and discharging without adequate treatment poses a significant challenge to the world [4][5]. At present, there are two billion people who live in countries with water scarcity, and it is estimated that 25% of the children will be living in places with severe water scarcity by 2040, according to the United Nations Children’s Fund (UNICEF) [6]. Other than water scarcity, water pollution due to the discharge of industrial effluents has a significant impact on the environment [7][8]. As a result, there is a necessity of developing sustainable and efficient wastewater treatment technologies for better water cycle management and reuse [4]. The membrane bioreactor (MBR) has received attention in the past few decades as one of the promising technologies for wastewater treatment and reuse [9][10][11].

MBR is the process that combines biological treatment (aerobic, anaerobic) with membrane technology for the treatment of wastewater [12]. This process uses microfiltration or ultrafiltration for the separation of sludge produced by biological treatments instead of using a clarifier for gravity settling as in conventional biological treatments. In comparison to the conventional activated sludge (CAS) process, MBR offers several benefits. The solid retention time (SRT) in MBR is higher compared with CAS, whereas the hydraulic retention time (HRT) is lower in MBR than in the CAS process. Moreover, the separation of sludge is more efficient in the case of MBR. The effluent quality of MBR is much better in terms of biochemical oxygen demand (BOD), suspended solids, and turbidity, making it suitable for water reclamation and requiring less space [3][12]. Other than CAS, MBR can also be used in anaerobic treatments by replacing conventional anaerobic digestion by using an up-flow anaerobic sludge blanket (UASB), expanded granular sludge bed (EGSB), or anaerobic baffled tank reactor [13]. The anaerobic membrane bioreactor (AnMBR) can produce high-quality effluent with lower chemical oxygen demand (COD) compared with the conventional process by controlling the biomass concentration [13][14].

The MBR process was first introduced in 1969 by Dorr-Oliver Inc. However, the initial developments could not be translated to widespread industrial applications, owing to the large expenses associated with membrane material and energy [3][15]. Since then, further improvements in membrane materials, configurations, and process parameters have been made for its utilization in commercial applications. The development of MBR on a commercial scale has gained momentum since its application started in the treatment of industrial and municipal wastewater [16].

2. Water Treatment Stages in the Modern Age

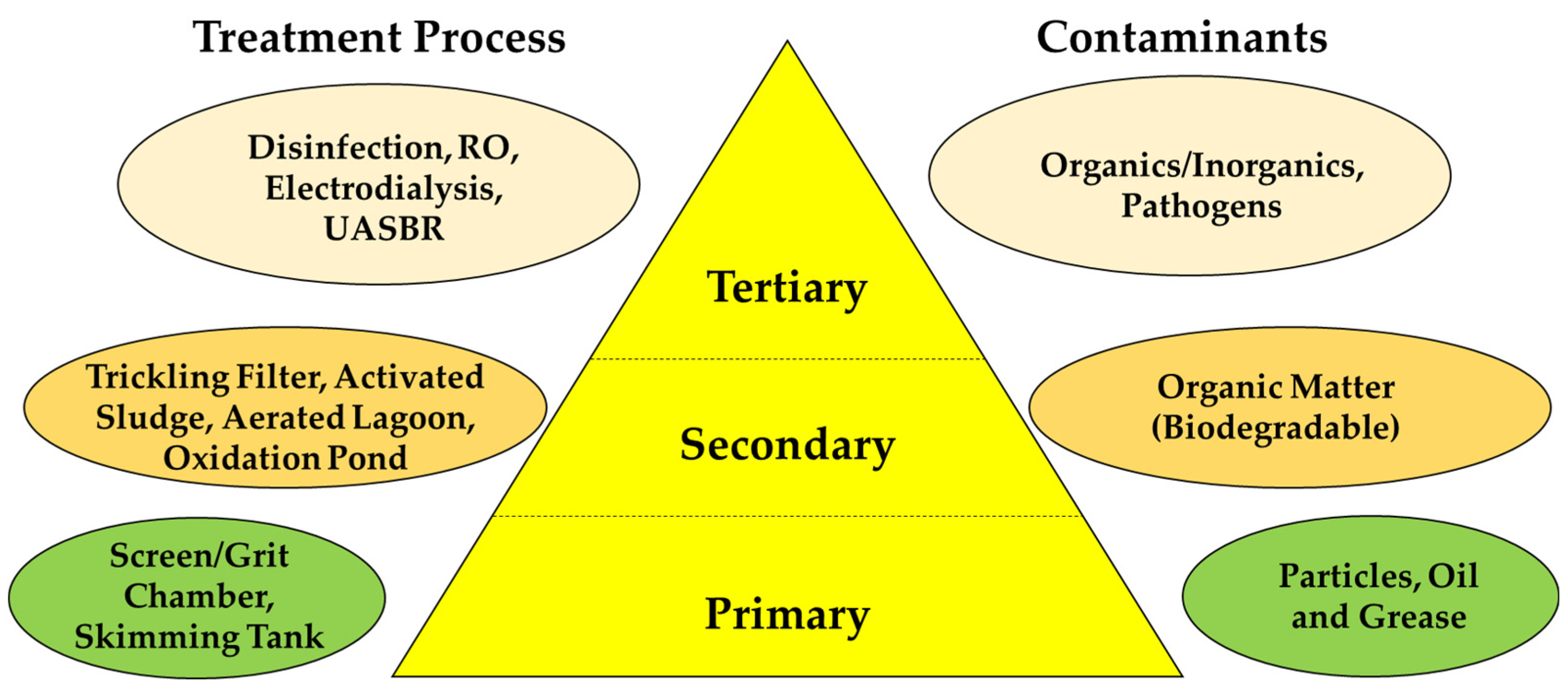

At present, conventional wastewater treatment consists of three stages: primary, secondary, and tertiary (Figure 1).

Figure 1. Different levels of wastewater treatment.

Primary treatment has two steps: preliminary treatment and the sedimentation tank. Preliminary treatment consists of screening to remove large particles, oil, fat, rock, and debris, and with small screens, it screens out even algae. The sedimentation tank is chemical precipitation (coagulation, flocculation) in a primary settling tank to remove organic matter and colloidal suspended particles. Secondary treatment is the degradation of biodegradable and soluble organics by microorganisms through aeration and an activated sludge process. Tertiary treatment, also known as advanced treatment, is responsible for the removal of nutrients (nitrogen, phosphorus), suspended solids, pathogenic bacteria, viruses, and heavy metals. Membrane filtration, electrodialysis, photocatalysis, and water oxidation are some of the advanced treatment methods [17].

Currently, MBR is one of the promising methods for municipal and industrial wastewater treatment. It is a combination of the microfiltration or ultrafiltration of the advanced treatment stage with a biological treatment process of the secondary stage [18]. Membrane bioreactors are compact and can remove suspended and soluble compounds, viruses, and bacteria from wastewater and produce excellent-quality effluent. It eliminates the use of secondary clarifiers and the time associated with them [19].

3. MBR Technology for Sustainable Water Treatment

3.1. Configuration of MBR

Conventional aerobic treatment has been used for over a century to treat industrial wastewater and effluent. However, the high energy requirement for the aeration process, the bulk amount of sludge generation, the greenhouse gases such as nitrous oxide (N2O) emissions, the huge environmental imprint, and the high maintenance costs of the conventional aerobic process demand a more efficient method of wastewater treatment. In anaerobic treatments, the production of methane-rich biogas from the breakdown of organic matter lowers the energy needed for wastewater treatment [3]. Typically, aerobic processes are used to treat effluents with biodegradable COD contents less than 1000 mg/L, while the anaerobic technique is widely employed to treat strong and highly polluting processes (e.g., biodegradable COD contents >4000 mg/L) [20]. The advantages of high effluent quality, low environmental impact, and other factors have accelerated MBR technology’s development to treat wastewater [21].

The MBR process, which combines membrane filtration with biological treatment using a reactor, is similar to CAS; however, it operates without secondary clarification and tertiary processes, e.g., a sand filter, an activated carbon filter, etc. [22][23]. Out of the two configurations of MBRs, the side-stream membrane module system is compact. However, to limit the fouling rate, it employs a high suspension regeneration flow rate throughout the membrane module, which increases its power requirement. The submerged membrane module operates at low transmembrane pressure (TMP) and uses air fluid to create turbulence [24][25].

Depending on the membrane shear velocity, an external or side-stream MBR arrangement can be advanced in two ways. The first one is BioFlow mode, which treats wastewater with greater fouling potential e.g., greasy sewage of 75–150 L/m2 h permeate flux at 3.5–4.5 m/s velocity (inside membrane). The second uses BioPulse mode to treat wastewater with a moderate fouling potential, such as municipal or industrial effluent of 40–70 Lm−2h−1 and 1–2 m/s velocity (inside membrane). In this mode, water pulses back from the permeate side to the mixed liquor side at irregular intervals [26].

In recent years, the advanced airlift side-stream MBR (ArMBR) systems have received a lot of attention. The idea incorporates the benefits of the low-energy submerged systems and, at the same time, applies the side-stream airlift principle employing a stable and dependable side-stream arrangement [22]. However, the ArMBR systems are still in the development phase. In 2018, Shin and Bae reported that a lab-sized (maximum capacity of 135 kWhm3) ArMBR system requires lower energy for a pilot study, compared with a typical external submerged AnMBR configuration [25].

3.2. Impact of MBR in Sustainable Wastewater Treatment

Wastewater treatment has become a necessity to resolve the water scarcity issues and reclamation of water as an essential resource. Membrane bioreactor technology is an advanced and unique option for this purpose. Since the 2000s, the MBR technology has undergone considerable development [3]. What with energy limitations, climatic changes, and resource depletion, conventional wastewater treatment systems face significant obstacles [27]. When compared with CAS, MBR has several significant advantages, e.g., better permeate quality, simpler operational management, and a reduced footprint [28]. Banti et al., (2020) conducted a life-cycle analysis (LCA) study to compare the CAS plant with an MBR plant in northern Greece to assess their respective environmental impacts. The life-cycle impact assessment (LCIA) showed lower values for impact factors such as global warming potential (GWP), ozone depletion potential, etc. for the MBR plant. The results proved that the MBR plant process was more environmentally sustainable [29]. Recent research has indicated that using an ammonia-N-based aeration management technique reduced aeration and energy consumption rates in full-scale MBRs by 20% and 4%, respectively [30]. The reduction in the air flow rate decreases energy consumption and GHG emissions thanks to the incomplete nitrification in MBR [31]. The study suggests that closed-loop aeration with consistent dissolved oxygen (DO) levels inside the aerobic reactor rather than open-loop aeration will successfully bring down the operating cost of MBRs plants by 13–17% [32]. Moreover, MBR can achieve the goal of zero discharge. MBRs and their variants would dominate this sector for future sustainable water treatment technologies.

References

- He, C.; Liu, Z.; Wu, J.; Pan, X.; Fang, Z.; Li, J.; Bryan, B.A. Future Global Urban Water Scarcity and Potential Solutions. Nat. Commun. 2021, 12, 4667.

- Jahan, N.; Tahmid, M.; Shoronika, A.Z.; Fariha, A.; Roy, H.; Pervez, M.N.; Cai, Y.; Naddeo, V.; Islam, M.S. A Comprehensive Review on the Sustainable Treatment of Textile Wastewater: Zero Liquid Discharge and Resource Recovery Perspectives. Sustainability 2022, 14, 15398.

- Al-Asheh, S.; Bagheri, M.; Aidan, A. Membrane Bioreactor for Wastewater Treatment: A Review. Case Stud. Chem. Environ. Eng. 2021, 4, 100109.

- Jhansi, S.C.; Mishra, S.K. Wastewater Treatment and Reuse: Sustainability Options. Consilience 2013, 10, 1–15.

- Akter, S.; Suhan, M.B.K.; Islam, M.S. Recent Advances and Perspective of Electrocoagulation in the Treatment of Wastewater: A Review. Environ. Nanotechnol. Monit. Manag. 2022, 17, 100643.

- UNICEF. Water Scarcity|UNICEF. Available online: https://www.unicef.org/wash/water-scarcity (accessed on 22 December 2022).

- Kader, S.; Al-Mamun, M.R.; Suhan, M.B.K.; Shuchi, S.B.; Islam, M.S. Enhanced Photodegradation of Methyl Orange Dye under UV Irradiation Using MoO3 and Ag Doped TiO2 Photocatalysts. Environ. Technol. Innov. 2022, 27, 102476.

- Roy, H.; Islam, M.S.; Arifin, M.T.; Firoz, S.H. Chitosan-ZnO Decorated Moringa Oleifera Seed Biochar for Sequestration of Methylene Blue: Isotherms, Kinetics, and Response Surface Analysis. Environ. Nanotechnol. Monit. Manag. 2022, 18, 100752.

- Pervez, M.N.; Mahboubi, A.; Uwineza, C.; Zarra, T.; Belgiorno, V.; Naddeo, V.; Taherzadeh, M.J. Factors Influencing Pressure-Driven Membrane-Assisted Volatile Fatty Acids Recovery and Purification—A Review. Sci. Total Environ. 2022, 817, 152993.

- Pervez, M.N.; Bilgiç, B.; Mahboubi, A.; Uwineza, C.; Zarra, T.; Belgiorno, V.; Naddeo, V.; Taherzadeh, M.J. Double-Stage Membrane-Assisted Anaerobic Digestion Process Intensification for Production and Recovery of Volatile Fatty Acids from Food Waste. Sci. Total Environ. 2022, 825, 154084.

- Pervez, M.N.; Balakrishnan, M.; Hasan, S.W.; Choo, K.H.; Zhao, Y.; Cai, Y.; Zarra, T.; Belgiorno, V.; Naddeo, V. A Critical Review on Nanomaterials Membrane Bioreactor (NMs-MBR) for Wastewater Treatment. npj Clean Water 2020, 3, 43.

- Eddy, M.; Abu-Orf, M.; Bowden, G.; Burton, F.L.; Pfrang, W.; Stensel, H.D.; Tchobanoglous, G.; Tsuchihashi, R.; Firm, A. Wastewater Engineering: Treatment and Resource Recovery; McGraw Hill Education: New York, NY, USA, 2014; ISBN 1259010791.

- Hu, Y.; Cheng, H.; Ji, J.; Li, Y.Y. A Review of Anaerobic Membrane Bioreactors for Municipal Wastewater Treatment with a Focus on Multicomponent Biogas and Membrane Fouling Control. Environ. Sci. Water Res. Technol. 2020, 6, 2641–2663.

- Vinardell, S.; Astals, S.; Peces, M.; Cardete, M.A.; Fernández, I.; Mata-Alvarez, J.; Dosta, J. Advances in Anaerobic Membrane Bioreactor Technology for Municipal Wastewater Treatment: A 2020 Updated Review. Renew. Sustain. Energy Rev. 2020, 130, 109936.

- Ladewig, B.; Al-Shaeli, M.N.Z. Fundamentals of Membrane Bioreactors; Springer Nature Singapore Pte Ltd.: Singapore, 2017; ISBN 978-981-10-2013-1.

- Iorhemen, O.T.; Hamza, R.A.; Tay, J.H. Membrane Bioreactor (Mbr) Technology for Wastewater Treatment and Reclamation: Membrane Fouling. Membranes 2016, 6, 33.

- Gedda, G. Introduction to Conventional Wastewater Treatment Technologies: Limitations and Recent Advances. Mater. Res. Found. 2021, 91, 1–36.

- Hoinkis, J.; Deowan, S.A.; Panten, V.; Figoli, A.; Huang, R.R.; Drioli, E. Membrane Bioreactor (MBR) Technology—A Promising Approach for Industrial Water Reuse. Procedia Eng. 2012, 33, 234–241.

- Brown, J.A. The Early History of Wastewater Treatment and Disinfection. In Impacts of Global Climate Change, Proceedings of the World Water and Environmental Resources Congress, Anchorage, AK, USA, 15–19 May 2005; American Society of Civil Engineers: Reston, VA, USA, 2005; pp. 1–7.

- Jain, M.; Kumar, S.S.; Goswami, L. Aerobic and Anaerobic Bioreactor Systems for Wastewater Treatment. In Techno-Economics and Life Cycle Assessment of Bioreactors. Post-COVID-19 Waste Management Approach; Elsevier: Amsterdam, The Netherlands, 2022; pp. 13–22.

- Fazal, S.; Zhang, B.; Zhong, Z.; Gao, L.; Lu, X.; Fazal, S.; Zhang, B.; Zhong, Z.; Gao, L.; Lu, X. Membrane Separation Technology on Pharmaceutical Wastewater by Using MBR (Membrane Bioreactor). J. Environ. Prot. 2015, 6, 299–307.

- Lin, H.; Gao, W.; Meng, F.; Liao, B.Q.; Leung, K.T.; Zhao, L.; Chen, J.; Hong, H. Membrane Bioreactors for Industrial Wastewater Treatment: A Critical Review. Crit. Rev. Environ. Sci. Technol. 2012, 42, 677–740.

- Bertanza, G.; Canato, M.; Laera, G.; Vaccari, M.; Svanström, M.; Heimersson, S. A Comparison between Two Full-Scale MBR and CAS Municipal Wastewater Treatment Plants: Techno-Economic-Environmental Assessment. Environ. Sci. Pollut. Res. Int. 2017, 24, 17383–17393.

- Lee, T.H.; Young, S. Effects of Membrane Orientation on Permeate Flux Performance in a Submerged Membrane Bioreactor. Membr. Water Treat. 2012, 3, 141–149.

- Shin, C.; Bae, J. Current Status of the Pilot-Scale Anaerobic Membrane Bioreactor Treatments of Domestic Wastewaters: A Critical Review. Bioresour. Technol. 2018, 247, 1038–1046.

- Dixon, M.A.; Abbas, T.R.; Al-Furaiji, M.H.; Abed-Ali, R.H. Membrane Bioreactor with External Side-Stream Membranes and High Cross Flow Velocity to Treat Municipal Wastewater. Eng. Technol. J. 2020, 38, 1–8.

- Lei, Z.; Yang, S.; Li, Y.Y.; Wen, W.; Wang, X.C.; Chen, R. Application of Anaerobic Membrane Bioreactors to Municipal Wastewater Treatment at Ambient Temperature: A Review of Achievements, Challenges, and Perspectives. Bioresour. Technol. 2018, 267, 756–768.

- Judd, S.J. The Status of Industrial and Municipal Effluent Treatment with Membrane Bioreactor Technology. Chem. Eng. J. 2016, 305, 37–45.

- Banti, D.C.; Tsangas, M.; Samaras, P.; Zorpas, A. LCA of a Membrane Bioreactor Compared to Activated Sludge System for Municipal Wastewater Treatment. Membranes 2020, 10, 421.

- Sun, J.; Liang, P.; Yan, X.; Zuo, K.; Xiao, K.; Xia, J.; Qiu, Y.; Wu, Q.; Wu, S.; Huang, X.; et al. Reducing Aeration Energy Consumption in a Large-Scale Membrane Bioreactor: Process Simulation and Engineering Application. Water Res. 2016, 93, 205–213.

- Aslam, A.; Khan, S.J.; Shahzad, H.M.A. Anaerobic Membrane Bioreactors (AnMBRs) for Municipal Wastewater Treatment- Potential Benefits, Constraints, and Future Perspectives: An Updated Review. Sci. Total Environ. 2022, 802, 149612.

- Maere, T.; Verrecht, B.; Moerenhout, S.; Judd, S.; Nopens, I. BSM-MBR: A Benchmark Simulation Model to Compare Control and Operational Strategies for Membrane Bioreactors. Water Res. 2011, 45, 2181–2190.

More

Information

Subjects:

Environmental Sciences

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

2.0K

Entry Collection:

Wastewater Treatment

Revisions:

2 times

(View History)

Update Date:

23 Feb 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No