Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Mohit SHARMA | + 1979 word(s) | 1979 | 2021-09-15 10:48:30 | | | |

| 2 | Conner Chen | Meta information modification | 1979 | 2021-09-24 10:12:00 | | | | |

| 3 | Conner Chen | Meta information modification | 1979 | 2021-09-24 10:12:28 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Sharma, M. Global Plastic Waste is Increasing. Encyclopedia. Available online: https://encyclopedia.pub/entry/14239 (accessed on 07 February 2026).

Sharma M. Global Plastic Waste is Increasing. Encyclopedia. Available at: https://encyclopedia.pub/entry/14239. Accessed February 07, 2026.

Sharma, Mohit. "Global Plastic Waste is Increasing" Encyclopedia, https://encyclopedia.pub/entry/14239 (accessed February 07, 2026).

Sharma, M. (2021, September 16). Global Plastic Waste is Increasing. In Encyclopedia. https://encyclopedia.pub/entry/14239

Sharma, Mohit. "Global Plastic Waste is Increasing." Encyclopedia. Web. 16 September, 2021.

Copy Citation

Global plastic waste is increasing rapidly. In general, densely populated regions generate tons of plastic waste daily, which is sometimes disposed of on land or diverged to sea. Most of the plastics created in the form of waste have complex degradation behavior and are non-biodegradable by nature. These remain intact in the environment for a long time span and potentially originate complications within terrestrial and marine life ecosystems. The strategic management of plastic waste and recycling can preserve environmental species and associated costs.

blockchain

circular economy

digital badge

supply chain

sustainable plastic technologies

Composites recycling

1. Classification of Plastics and Recycling Process

Plastics are typically labeled through the chemical shape of the polymer’s spine and aspect chains; a few classifications are acrylics, polyesters, silicones, polyurethanes, and halogenated plastics. Plastics can also be functionalized through the chemical technique during synthesis, together with condensation, polyaddition, and cross-linking. The most prevalent type of marine debris found in our oceans and the Great Lakes is plastic [1]. Plastic waste can come in all shapes and sizes, but “microplastics” are those that are less than five millimeters in length (or about the size of a sesame seed). Microplastics come from several sources, including larger debris of plastic that degrades into smaller and smaller parts. In addition, very tiny pieces of processed polyethylene plastic are known as microbeads, a form of microplastic, applied to health and beauty products. According to industry estimates, an Indian consumes 11 kg of plastic every year. Though it is much less compared with other countries, it is still a problem for society [2]. There are different types of plastics present in the environment such as amorphous plastics and crystalline plastics, conductive polymers, biodegradable plastics, and bioplastics. The semicrystalline plastics consist of polyethylene, polypropylene, polyvinyl chloride, polyamides (nylons), polyesters, and a few polyurethanes. These are usually used in food jars, cosmetics boxes, and soft drink bottles. It is worth noting that natural polymers such as collagen, chitosan, fibroin, and hydrogel are conductive polymers mainly used for electronic devices, solar energy conversion, energy storage devices, tissue engineering, regenerative medicine, and biosensors [3]. Biodegradable plastics are plastics that degrade or smash down upon exposure to daylight or ultraviolet radiation, water or dampness, microorganisms, enzymes, or wind abrasion. These are usually used in shopping bags, compostable waste collection bags, trays, and punnets for fruit, meat, and vegetables. While maximum plastics are made of petrochemicals, bioplastics are made drastically produced from renewable plant substances such as cellulose and starch [4]. Bioplastics are used in medical applications that include implants such as screws, pins, or plates, as well as material for pills and capsules. It is worth noting that production, consumption, and plastic pollution have been increasing rapidly [5] and therefore, it is important to recycle plastics to maintain the sustainability of society.

Figure 1 shows a schematic diagram of the typical plastic recycling process. In plastic industries, it has been observed that most plastic product manufacturers preferred raw plastic materials instead of recycled ones because of the lack of information available regarding the quality, suitability, and complex process as shown in Figure 1. Most of the segregators are just segregating the plastics without knowing the impact of this on society. Thus, it is much sought-after to reduce plastic pollution.

Figure 1. The typical stages involved in plastic recycling.

2. Blockchain-Based Technology for Plastic Recycling and Circular Economy

Efficient recycling technology is essential to reduce plastic pollution. Many technologies have been employed to enhance plastic recycling. Among them, blockchain is promising for plastic recycling and circular economy (CE). Blockchain, a distributed ledger, consists of some ordered blocks which are unchangeable. This can be considered an exemplary way to push the transactions of their customers under the same blockchain technology. Because of the decentralized system and minimum transaction costs, most companies prefer blockchain technology [6]. The advantages of blockchain technology are decentralization, transparency, openness, and temper-proof constructions. Therefore, most industries or companies rely on this technology [7].

In this regard, Chidepatil and co-workers have developed a blockchain smart contract technique enabled with various sensors and AI-based algorithms. This technique helped them to identify good-quality recycled plastics [8]. Another most important concept was also recognized, known as the CE. The CE helps to understand our economy by introducing the rethink and redesign concepts. CE works on multiple levels such as micro to macro levels and provides economic opportunities as well as social and environmental benefits. Blockchain technology makes the CE stronger by introducing various information support systems [9].

Blockchain technology and the CE are the two emerging concepts that will revolutionize lives in the upcoming decades. The introduction of Industry 4.0 also changes the various organizational activities by providing different technological transformations. The inclusion of blockchain technology with the CE is one of the examples of this technological innovation. Furthermore, CE objectives are much supported by blockchain technology, as it provides transparent information and reliability [10]. The 3Cs which are of utmost importance in blockchain technology are (i) cooperation, (ii) coordination, and (iii) collaboration, which makes the decision-making process much easier and transforms the working culture of various sectors like agriculture, banking, supply chain, healthcare, etc., by providing high-level security and transparency [11].

Recently, an “IBM-Plastic Bank Activity Kit” was launched by IBM for solving plastic waste issues. The motive of this kit is to provide “grab and go resources” which encourage students or volunteers to come forward and talk about potential issues which are of primary concern to our society and environment. This activity kit also assists in teaching people about their plastic footprints and motivates them to reduce plastic waste globally and from their local premises/areas [12]. We all know that plastic recycling is a most critical and severe issue, but the introduction of blockchain technology attempts to minimize all the issues related to waste management and recycling. Blockchain brings greater transparency in the recycling sector that will help the decision-making process accurately [13]. The CE can be pushed forward through the utilization of digitalization. Concerning this, blockchain along with Artificial Intelligence (AI) and the Internet of Things (IoT) helps in developing and improving transparency and traceability [14].

Blockchain technology enhances the capital flow by minimizing the transaction costs, and reducing investment risk (inclusive liquidity risk), resulted in reduced capital cost and improved chances of investments with the running financial infrastructure [15]. In addition, Forrest and coworkers have reported that industrial contribution in fossil fuel-based plastic production may provide an economical and technical solution to restrict the plastic flow movement by incentivizing and converting it into a useful commodity and promoting polymer technology industries [16]. In this paper, we have discussed plastic production using machine learning and an Auto-Regressive Integrated Moving Average (ARIMA). In addition, we have discussed blockchain technology to boost plastic recycling and CE.

3. Statistics and Forecasting of the Plastic Waste Production Globally

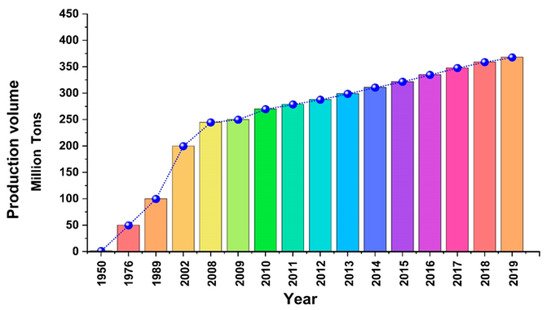

We used machine learning techniques to predict plastic generation globally. For the prediction of plastic generation, we collected plastic generation data from previous years [17]. The statistics were generated using Python language, importing suitable packages. The Pandas library was used for the data structures and operations for analyzing numerical tables and time series. Matplotlib.pyplot is the collection of functions that make matplotlib work like MATLAB. The data was collected from the year 1950, and the production volume is in million metric tons as shown in Figure 2. It totaled as 368 million metric tons by 2019. The data concluded that plastic waste never decreased and grew progressively. As we are dealing with progressing data over time, ARIMA—an Auto-Regressive Integrated Moving Average is used to capture standard temporal structures in time series data, especially over trends of seasonality and noise. ARIMA has three components, i.e., AR-autoregressive term, I-differencing term, and MA-moving average term. AR refers to past values that are used for forecasting the next value. It is defined by parameter ‘p’. The value of ‘p’ is determined by PACF (Partial Auto Correlation Function). MA refers to the number of past forecast errors that is used to predict the future values. It is represented by ‘q’, which is calculated using ACF plot (Auto Correlation Function). This pre-processing of data might consume lot of time. Auto ARIMA in this way is powerful because it automates this process and makes these calculations simple. Auto ARIMA considers the AIC (Akaike Information Criterion) and BIC (Bayesian Information Criterion) values generated to determine the best combination of parameters. AIC and BIC values are estimators to compare models. The lower these values, the better the model is.

Figure 2. Plastic waste generation from 1950 to 2019.

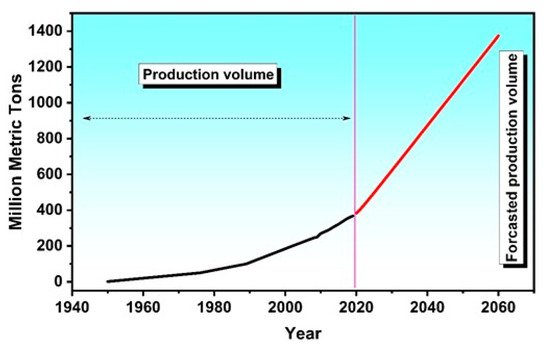

The auto ARIMA from the pmdarima package is used to evaluate the effect of different kinds of orders. The objective here is to allocate a score (such as Akaike Information Criteria, AIC) for every order, and the goal is to minimize the AIC. Auto Arima gives out the best order by comparing AIC values, and with the best order that has minimum AIC, we train the model. In this case, the AIC value is 139.358 and BIC value is 141.482. The values of p (number of autoregressive terms), d (number of nonseasonal differences needed for stationarity), and q (number of lagged forecast errors in the prediction equation) are 1, 1, and 0, respectively. The result is depicted in Figure 3. The forecasted values of the waste that is going to be produced in the next 40 years range from 368 Mt to 1392 Mt. This shows that there is a ~62% increase in the plastic waste produced worldwide. In Figure 3, the portion of the graph plotted with red color shows the forecasted values generated by the ARIMA model.

Figure 3. Forecasting of production volume with black being recorded data and red being forecasted data.

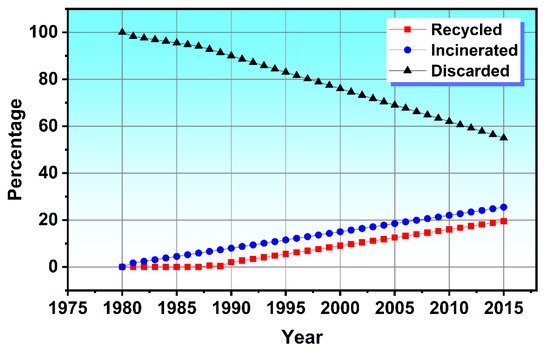

There are three types of plastic waste disposals, namely recycling, incineration, and disposal. Recycling processes were negligible on a global scale until late 1987. Incineration and disposal were the only ways observed. Notable percentages of the recycling process were observed only after 1987, and humans achieved recycling 19.7% of the whole plastic waste in the year 2015. Disposal readings of the waste produced globally can be seen in Figure 4.

Figure 4. Global waste disposal readings.

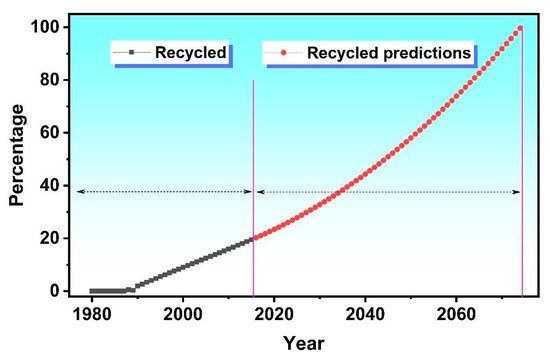

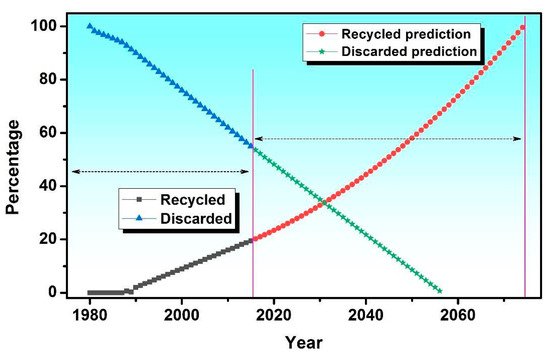

The disposal percentages were decreased and replaced with recycling and incineration. Forecasting these percentages over a time series gives us an in-depth look into the chain of the plastic economy. Figure 5 shows forecasting of rates of recycling. In an ideal scenario where the disposals and incineration process are stopped and the ideal recycling process is achieved, with the current trend, it would take 60 years from now to achieve the ideal state. Since reducing incineration and disposal percentages to 0 and recycling to 100 is entirely ideal, we tend to achieve more regulated processes. According to the forecast, there exists an equilibrium point where all the three percentages tend to be similar. This point occurs around 2030–2034, as shown in Figure 6.

Figure 5. Forecasting of percentages of recycling rate.

Figure 6. Forecasted data explaining the transition state and equilibrium point around 2030–2034.

As of the year 2034, statistically, there might be growth in the recycling process, but the incineration percentages tend to have the same growth. The reason disposal percentage decreases over the time period is due to the increase in recycling process efficiency, increase in land occupancy, and awareness over the plastic decomposition period and incinerating approaches. A transition can be observed where demand for recycled plastics increases in the journey of technological advances. The efficiency of plastic recycling increases due to an increase in the awareness of recycled plastic quality in manufacturers. Secondly, when the raw material feedstock prices increase to a point where the production of virgin plastic feedstock is not economically profitable, manufacturers tend to work with recycled plastics. This change in feedstock prices takes more time, and hence we boil it down to the point where we say, “prevention is better than cure”. In this process, poorer nations tend to incinerate the stock rather than recycling, leading to totally different environmental pollution scenarios. According to the statistics, this change might occur after the 2050s where the disposal rate is very low, but the incineration percentage might play a major role on par with recycling.

References

- Cheang, C.C.; Ma, Y.; Fok, L. Occurrence and Composition of Microplastics in the Seabed Sediments of the Coral Communities in Proximity of a Metropolitan Area. Int. J. Environ. Res. Public Health 2018, 15, 2270.

- Chen, Y.; Awasthi, A.K.; Wei, F.; Tan, Q.; Li, J. Single-use plastics: Production, usage, disposal, and adverse impacts. Sci. Total. Environ. 2020, 752, 141772.

- Nezakati, T.; Seifalian, A.; Tan, A.; Seifalian, A. Conductive Polymers: Opportunities and Challenges in Biomedical Applications. Chem. Rev. 2018, 118, 6766–6843.

- Xia, Q.; Chen, C.; Yao, Y.; Li, J.; He, S.; Zhou, Y.; Li, T.; Pan, X.; Yao, Y.; Hu, L. A strong, biodegradable and recyclable lignocellulosic bioplastic. Nat. Sustain. 2021, 4, 627–635.

- Wang, C.; Liu, Y.; Chen, W.; Zhu, B.; Qu, S.; Xu, M. Critical review of global plastics stock and flow data. J. Ind. Ecol. 2021.

- Wong, S.; Yeung, J.-K.-W.; Lau, Y.-Y.; So, J. Technical Sustainability of Cloud-Based Blockchain Integrated with Machine Learning for Supply Chain Management. Sustainability 2021, 13, 8270.

- Xu, M.; Chen, X.; Kou, G. A systematic review of blockchain. Financ. Innov. 2019, 5, 27.

- Chidepatil, A.; Bindra, P.; Kulkarni, D.; Qazi, M.; Kshirsagar, M.; Sankaran, K. From Trash to Cash: How Blockchain and Multi-Sensor-Driven Artificial Intelligence Can Transform Circular Economy of Plastic Waste? Adm. Sci. 2020, 10, 23.

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain technology and its relationships to sustainable supply chain man-agement. Int. J. Prod. Res. 2019, 57, 2117–2135.

- Kouhizadeh, M.; Zhu, Q.; Sarkis, J. Blockchain and the circular economy: Potential tensions and critical reflections from practice. Prod. Plan. Control. 2019, 31, 950–966.

- Komalavalli, C.; Saxena, D.; Laroiya, C. Overview of Blockchain Technology Concepts. In Handbook of Research on Blockchain Technology; Academic Press: Cambridge, MA, USA, 2020; pp. 349–371.

- Katz, D. Plastic Bank: Recycling Ecosystems. Good Tech IBM, 1–5. 2021. Available online: https://www.ibm.com/blogs/corporate-social-responsibility/2020/04/plastic-bank-recycling-ecosystems/ (accessed on 12 February 2021).

- Park, A.; Li, H. The Effect of Blockchain Technology on Supply Chain Sustainability Performances. Sustainability 2021, 13, 1726.

- Ghoreishi, M.; Happonen, A. New promises AI brings into circular economy accelerated product design: A review on supporting literature. E3S Web Conf. 2020, 158, 06002.

- David, U.; Guerdat, P. Impact Tokens: A Blockchain-Based Solution for Impact Investing; IISDA: Winnipeg, MB, Canada, 2019; Available online: https://www.cabdirect.org/cabdirect/abstract/20208400105 (accessed on 13 February 2021).

- Forrest, A.; Giacovazzi, L.; Dunlop, S.; Reisser, J.; Tickler, D.; Jamieson, A.; Meeuwig, J.J. Eliminating Plastic Pollution: How a Voluntary Contribution From Industry Will Drive the Circular Plastics Economy. Front. Mar. Sci. 2019, 6, 627.

- Source for Data Analysis. Available online: https://ourworldindata.org/faq-on-plastics#how-much-plastic-and-waste-do-we-produce (accessed on 13 February 2021).

More

Information

Subjects:

Green & Sustainable Science & Technology; Materials Science, Composites; Engineering, Mechanical

Contributor

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.8K

Revisions:

3 times

(View History)

Update Date:

24 Sep 2021

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No