| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Tingzhu Wu | + 1987 word(s) | 1987 | 2021-06-17 07:43:20 | | | |

| 2 | Peter Tang | Meta information modification | 1987 | 2021-06-24 05:44:17 | | |

Video Upload Options

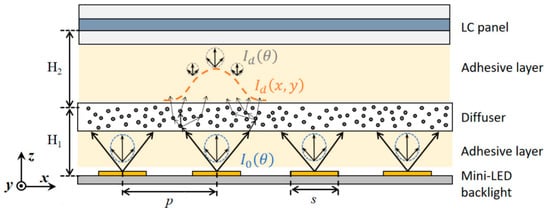

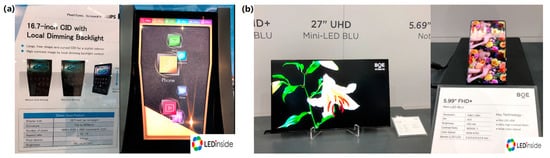

The mini-LEDs with chip sizes ranging from 100 to 200 μm have already been commercialized for backlight sources in consumer electronics applications. The realized local diming can greatly improve the contrast ratio at relatively low energy consumptions. The micro-LEDs with chip size less than 100 μm, still remain in the laboratory.

1. Introduction

|

Mini-LED |

Micro-LED |

|

|---|---|---|

|

Size (μm) |

100~200 |

<100 |

|

Purpose |

Backlight for LCD |

Self-emitting display |

|

Features |

High dynamic range, power saving, thin |

High contrast, high efficiency, high resolution, high response time |

|

Yield |

>80% |

Hard to estimate |

|

Application |

LCD backlight—From small to large LCD panel |

Micro-projection display, display from small to large size |

2. Mini-LED

3. Micro-LED

|

Application |

Auto Display |

TV |

Digital Display |

|

|

|

|

|

|

Panel Size (inch) |

6~12 |

32~100 |

150~220 |

|

PPI |

150~250 |

40~80 |

20~30 |

|

Chip volume (M) |

4.1 |

24.9 |

24.9 |

|

Chip Size (μm) |

50~100 |

50~80 |

80~100 |

|

Application |

AR |

Watch |

Mobile |

|

|

|

|

|

|

Panel Size (inch) |

0.5~1 |

1~1.5 |

4~6 |

|

PPI |

450~2000 |

200~300 |

300~800 |

|

Chip volume (M) |

49.8 |

0.4 |

6.2 |

|

Chip Size (μm) |

1~5 |

10~30 |

30~50 |

|

Company |

Principle |

Description |

|

|---|---|---|---|

|

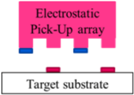

Electrostatic array |

LuxVue |

|

The transfer heads are divided by the dielectric layer to form a pair of silicon electrodes, which are positively and negatively charged, respectively, before picking up the target LED. |

|

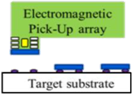

Magnetic array |

ITRI |

|

Micro-LEDs are adsorbed and placed by the electromagnetic force generated by the coil. |

|

Elastomer stamp |

X-Celeprint |

|

The pick-up and transfer processes are aided by the Van der Waals forces between the viscoelastic elastomer stamp and the solid micro-LEDs. |

|

Roll to plate |

KIMM |

|

A roll-based transfer technology for transferring nanoscale objects from a donor substrate to a target substrate with high yields and productivity. |

References

- Robert, L.; Barbin, A.S.P. Cathode-ray tube displays. In Wiley Encyclopedia of Electrical and Electronics Engineering; Wiley Online Library: Hoboken, NJ, USA, 1999.

- Weber, L.F. History of the plasma display panel. IEEE Trans. Plasma Sci. 2006, 34, 268–278.

- Chang, N.; Choi, I.; Shim, H. DLS: Dynamic backlight luminance scaling of liquid crystal display. IEEE Trans. Very Large Scale Integr. (VLSI) Syst. 2004, 12, 837–846.

- Boeuf, J.P. Plasma display panels: Physics, recent developments and key issues. J. Phys. D Appl. Phys. 2003, 36, R53–R79.

- Schadt, M. Milestone in the History of Field-Effect Liquid Crystal Displays and Materials. Jpn. J. Appl. Phys. 2009, 48.

- Peng, F.L.; Chen, H.W.; Gou, F.W.; Lee, Y.H.; Wand, M.; Li, M.C.; Lee, S.L.; Wu, S.T. Analytical equation for the motion picture response time of display devices. J. Appl. Phys. 2017, 121.

- Li, C.-H.; Lu, S.-H.; Lin, S.-Y.; Hsieh, T.-Y.; Wang, K.-S.; Kuo, W.-H. Ultra-fast moving-picture response-time LCD for virtual reality application. In SID Symposium Digest of Technical Papers; Wiley Online Library: Hoboken, NJ, USA, 2018; Volume 49, pp. 678–680.

- Tang, C.W.; Vanslyke, S.A. Organic electroluminescent diodes. Appl. Phys. Lett. 1987, 51, 913–915.

- Geffroy, B.; Le Roy, P.; Prat, C. Organic light-emitting diode (OLED) technology: Materials, devices and display technologies. Polym. Int. 2006, 55, 572–582.

- Chen, H.W.; Tan, G.J.; Wu, S.T. Ambient contrast ratio of LCDs and OLED displays. Opt. Express 2017, 25, 33643–33656.

- Chen, H.-W.; Lee, J.-H.; Lin, B.-Y.; Chen, S.; Wu, S.-T. Liquid crystal display and organic light-emitting diode display: Present status and future perspectives. Light Sci. Appl. 2018, 7, 17168.

- Lv, X.; Loo, K.H.; Lai, Y.M.; Tse, C.K. Energy-saving driver design for full-color large-area LED display panel systems. IEEE Trans. Ind. Electron. 2014, 61, 4665–4673.

- Templier, F. GaN-based emissive microdisplays: A very promising technology for compact, ultra-high brightness display systems. J. Soc. Inf. Display 2016, 24, 669–675.

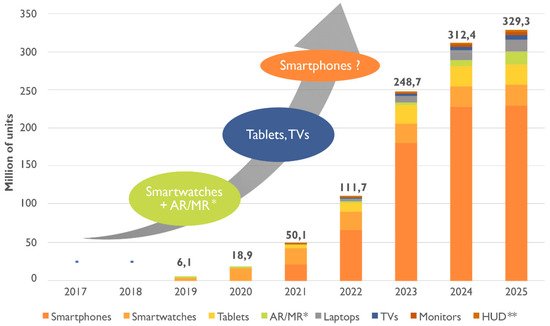

- Micro-LED Market by Application, Display Panel Size, Vertical, and Geography-Global Forecast to 2025. Available online: (accessed on 30 July 2018).

- MicroLED Displays Could Disrupt LCD and OLED. Available online: (accessed on 30 July 2018).

- Seetzen, H.; Heidrich, W.; Stuerzlinger, W.; Ward, G.; Whitehead, L.; Trentacoste, M.; Ghosh, A.; Vorozcovs, A. High dynamic range display systems. In ACM Transactions on Graphics (TOG); ACM: New York, NY, USA, 2004; Volume 23, pp. 760–768.

- Daly, S.; Kunkel, T.; Sun, X.; Farrell, S.; Crum, P. Viewer preferences for shadow, diffuse, specular, and emissive luminance limits of high dynamic range displays. In SID Symposium Digest of Technical Papers; Wiley Online Library: Hoboken, NJ, USA, 2013; Volume 44, pp. 563–566.

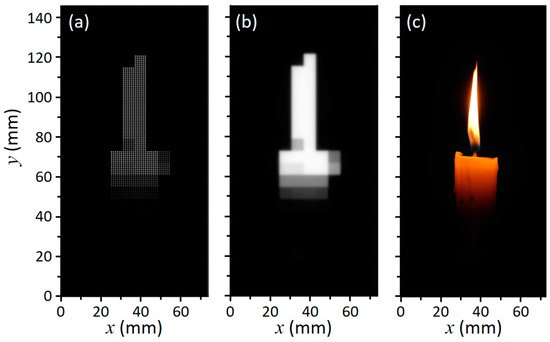

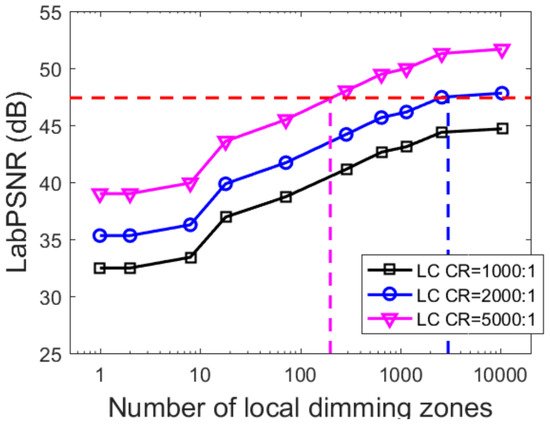

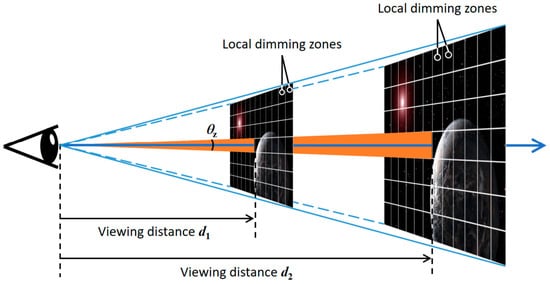

- Tan, G.J.; Huang, Y.G.; Li, M.C.; Lee, S.L.; Wu, S.T. High dynamic range liquid crystal displays with a mini-LED backlight. Opt. Express 2018, 26, 16572–16584.

- Deng, Z.; Zheng, B.; Zheng, J.; Wu, L.; Yang, W.; Lin, Z.; Shen, P.; Li, J. High dynamic range incell LCD with excellent performance. In SID Symposium Digest of Technical Papers; Wiley Online Library: Hoboken, NJ, USA, 2018; Volume 49, pp. 996–998.

- AUO’s Full Series of Mini LED Backlit LCDs Make Stunning Appearance to Establish Foothold in High-End Application Market. Available online: (accessed on 30 July 2018).

- [Display Week 2018 Show Report]-Mini LED Backlight Business Opportunities Boost. Available online: (accessed on 30 July 2018).

- Jin, S.X.; Li, J.; Li, J.Z.; Lin, J.Y.; Jiang, H.X. GaN microdisk light emitting diodes. Appl. Phys. Lett. 2000, 76, 631–633.

- Jin, S.X.; Li, J.; Lin, J.Y.; Jiang, H.X. InGaN/GaN quantum well interconnected microdisk light emitting diodes. Appl. Phys. Lett. 2000, 77, 3236–3238.

- Jiang, H.X.; Jin, S.X.; Li, J.; Shakya, J.; Lin, J.Y. III-nitride blue microdisplays. Appl. Phys. Lett. 2001, 78, 1303–1305.

- Wu, T.; Lin, Y.; Zhu, H.; Guo, Z.; Zheng, L.; Lu, Y.; Shih, T.; Chen, Z. Multi-function indoor light sources based on light-emitting diodes-a solution for healthy lighting. Opt. Express 2016, 24, 24401–24412.

- Wu, T.; Lu, Y.; Guo, Z.; Zheng, L.; Zhu, H.; Xiao, Y.; Shih, T.; Lin, Y.; Chen, Z. Improvements of mesopic luminance for light-emitting-diode-based outdoor light sources via tuning scotopic/photopic ratios. Opt. Express 2017, 25, 4887–4897.

- Wu, T.; Lin, Y.; Zheng, L.; Guo, Z.; Xu, J.; Liang, S.; Liu, Z.; Lu, Y.; Shih, T.; Chen, Z. Analyses of multi-color plant-growth light sources in achieving maximum photosynthesis efficiencies with enhanced color qualities. Opt. Express 2018, 26, 4135–4147.

- Wang, L.; Wang, X.; Kohsei, T.; Yoshimura, K.-I.; Izumi, M.; Hirosaki, N.; Xie, R.-J. Highly efficient narrow-band green and red phosphors enabling wider color-gamut LED backlight for more brilliant displays. Opt. Express 2015, 23, 28707–28717.

- Jiang, H.X.; Lin, J.Y. Nitride micro-LEDs and beyond—A decade progress review. Opt. Express 2013, 21, A475–A484.

- Tian, P.; McKendry, J.J.D.; Gu, E.; Chen, Z.; Sun, Y.; Zhang, G.; Dawson, M.D.; Liu, R. Fabrication, characterization and applications of flexible vertical InGaN micro-light emitting diode arrays. Opt. Express 2016, 24, 699–707.

- Zhang, K.; Peng, D.; Lau, K.M.; Liu, Z. Fully-integrated active matrix programmable UV and blue micro-LED display system-on-panel (SoP). J. Soc. Inf. Display 2017, 25, 240–248.

- Zhang, L.; Ou, F.; Chong, W.C.; Chen, Y.J.; Li, Q.M. Wafer-scale monolithic hybrid integration of Si-based IC and III-V epi-layersA mass manufacturable approach for active matrix micro-LED micro-displays. J. Soc. Inf. Display 2018, 26, 137–145.

- Cok, R.S.; Meitl, M.; Rotzoll, R.; Melnik, G.; Fecioru, A.; Trindade, A.J.; Raymond, B.; Bonafede, S.; Gomez, D.; Moore, T.; et al. Inorganic light-emitting diode displays using micro-transfer printing. J. Soc. Inf. Display 2017, 25, 589–609.

- Corbett, B.; Loi, R.; Zhou, W.D.; Liu, D.; Ma, Z.Q. Transfer print techniques for heterogeneous integration of photonic components. Prog. Quantum Electron. 2017, 52, 1–17.

- Chanyawadee, S.; Lagoudakis, P.G.; Harley, R.T.; Charlton, M.D.B.; Talapin, D.V.; Huang, H.W.; Lin, C.H. Increased color-conversion efficiency in hybrid light-emitting diodes utilizing non-radiative energy transfer. Adv. Mater. 2010, 22, 602–606.

- Zhuang, Z.; Guo, X.; Liu, B.; Hu, F.; Li, Y.; Tao, T.; Dai, J.; Zhi, T.; Xie, Z.; Chen, P.; et al. High color rendering index hybrid III-nitride/nanocrystals white light-emitting diodes. Adv. Funct. Mater. 2016, 26, 36–43.

- Kang, C.-M.; Lee, J.-Y.; Park, M.-D.; Mun, S.-H.; Choi, S.-Y.; Kim, K.; Kim, S.; Shim, J.-P.; Lee, D.-S. Hybrid integration of RGB inorganic LEDs using adhesive bonding and selective area growth. In SID Symposium Digest of Technical Papers; Wiley Online Library: Hoboken, NJ, USA, 2018; Volume 49, pp. 604–606.