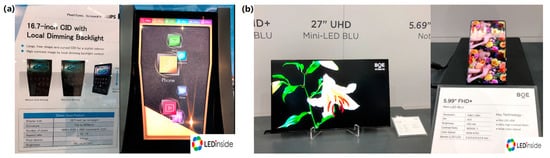

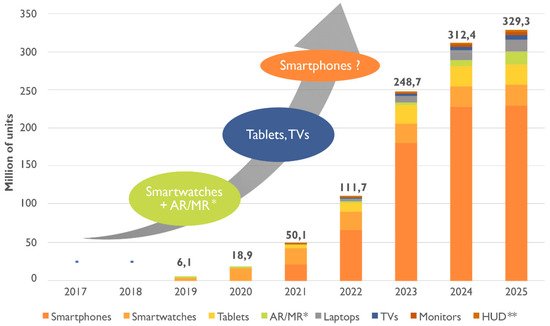

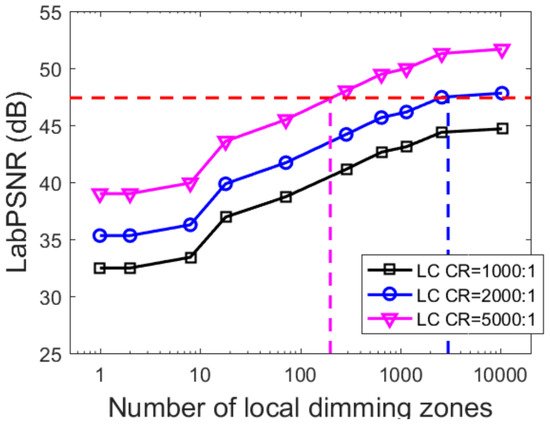

The mini-LEDs with chip sizes ranging from 100 to 200 μm have already been commercialized for backlight sources in consumer electronics applications. The realized local diming can greatly improve the contrast ratio at relatively low energy consumptions. The micro-LEDs with chip size less than 100 μm, still remain in the laboratory.

- mini-LED

- micro-LED

- full-color display

- quantum dot

1. Introduction

Mini-LED | Micro-LED |

|---|

3. Micro-LED

Application | Auto Display | TV | Digital Display | ||||||||

| | | |||||||||

Panel Size (inch) | 6~12 | 32~100 | 150~220 | ||||||||

PPI | 150~250 | 40~80 | 20~30 | ||||||||

Chip volume (M) | 4.1 | 24.9 | 24.9 | ||||||||

Chip Size (μm) | 50~100 | 50~80 | 80~100 | ||||||||

Application | AR | Watch | Mobile | ||||||||

| |||||||||||

Size (μm) | 100~200 | <100 | |||||||||

Purpose | Backlight for LCD | Self-emitting display | |||||||||

Features | High dynamic range, power saving, thin | High contrast, high efficiency, high resolution, high response time | |||||||||

Yield | >80% | Hard to estimate | |||||||||

Application | LCD backlight—From small to large LCD panel | Micro-projection display, display from small to large size |

2. Mini-LED

| |||||||||||

| |||||||||||

|

| ||||||||||

Panel Size (inch) | 0.5~1 | 1~1.5 | 4~6 | ||||||||

PPI | 450~2000 | 200~300 | 300~800 | ||||||||

Chip volume (M) | 49.8 | 0.4 | 6.2 | ||||||||

Chip Size (μm) | 1~5 |

Company | Principle | Description | |||||||

|---|---|---|---|---|---|---|---|---|---|

10~30 | |||||||||

30~50 | |||||||||

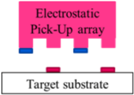

Electrostatic array | LuxVue | | The transfer heads are divided by the dielectric layer to form a pair of silicon electrodes, which are positively and negatively charged, respectively, before picking up the target LED. | ||||||||

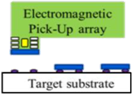

Magnetic array | ITRI | | Micro-LEDs are adsorbed and placed by the electromagnetic force generated by the coil. | ||||||||

Elastomer stamp | X-Celeprint | | The pick-up and transfer processes are aided by the Van der Waals forces between the viscoelastic elastomer stamp and the solid micro-LEDs. | ||||||||

Roll to plate | KIMM | | A roll-based transfer technology for transferring nanoscale objects from a donor substrate to a target substrate with high yields and productivity. |