Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Nannan Wang | -- | 1997 | 2023-11-17 01:38:21 | | | |

| 2 | Sirius Huang | Meta information modification | 1997 | 2023-11-17 09:26:14 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Wang, N.; Li, L.; Wang, K.; Huang, X.; Han, Y.; Ma, X.; Wang, M.; Lv, X.; Bai, X. Ultrasound-Enhanced Organic Wastewater Treatment Equipments. Encyclopedia. Available online: https://encyclopedia.pub/entry/51718 (accessed on 28 February 2026).

Wang N, Li L, Wang K, Huang X, Han Y, Ma X, et al. Ultrasound-Enhanced Organic Wastewater Treatment Equipments. Encyclopedia. Available at: https://encyclopedia.pub/entry/51718. Accessed February 28, 2026.

Wang, Nannan, Liangwei Li, Kai Wang, Xitong Huang, Yanhe Han, Xuejiao Ma, Menghan Wang, Xiao Lv, Xinming Bai. "Ultrasound-Enhanced Organic Wastewater Treatment Equipments" Encyclopedia, https://encyclopedia.pub/entry/51718 (accessed February 28, 2026).

Wang, N., Li, L., Wang, K., Huang, X., Han, Y., Ma, X., Wang, M., Lv, X., & Bai, X. (2023, November 17). Ultrasound-Enhanced Organic Wastewater Treatment Equipments. In Encyclopedia. https://encyclopedia.pub/entry/51718

Wang, Nannan, et al. "Ultrasound-Enhanced Organic Wastewater Treatment Equipments." Encyclopedia. Web. 17 November, 2023.

Copy Citation

Ultrasound waves have been widely used in the field of organic wastewater treatment due to their mechanical, thermal, and chemical effects derived from their cavitation effect. Many researchers have combined ultrasound waves with other organic wastewater treatment methods because they have the potential to offset the disadvantages of other method.

cavitation mechanism

ultrasound operation mode

ultrasound reactor

organic wastewater treatment

physical fields

1. Introduction

Environmental pollution has become a concern worldwide, because it seriously hinders the sustainable development of our world [1]. Organic wastewater is one of the main pollution sources because of toxic refractory organic pollutants in wastewater, which can be enriched in the human body and animals through the food chain; this seriously endangers human health and natural ecology [2]. The main types of organic wastewater include dye wastewater, pharmaceutical wastewater, coking wastewater, atrazine wastewater, high saline petrochemical wastewater, dairy wastewater, etc. [3][4][5][6][7][8][9][10][11][12]. In order to effectively eliminate organic pollutants in wastewater, many methods have been explored, and they can be divided into a chemical oxidation degradation process [13], biochemical degradation process [14], and physicochemical degradation process. However, every method has shortcomings [15]. Against this backdrop, some physical fields such as an ultrasound field, MW field, and UV/visible light field were introduced to compensate for these shortcomings, thus enhancing the treatment efficiency of wastewater.

In these physical fields, the ultrasound field is different from other physical fields because it belongs to a mechanical field, while other physical fields belong to the electromagnetic field; ultrasound works by relying on high-frequency vibrations and a subsequent cavitation effect [16]. According to the definition from the American National Standards Institute, ultrasound is a type of dense longitudinal wave with a frequency of >20 kHz; it can be generated by a piezoelectric effect (generated by the interaction of mechanical pressure and electricity) or magnetostriction (generated in electromagnetic fields) [17]. Ultrasound can transmit strong energy and produce a considerable impact between interfaces when it is propagated in a gas, liquid, or solid, accompanied with the consumption of energy and the corrosion of equipment and materials [18][19]. As the application of ultrasound in the treatment of organic wastewater does not involve the addition of chemicals and does not cause secondary pollution [20], ultrasound is welcomed by many researchers, and it has been applied in combination with other treatment methods such as electrochemistry oxidation, photocatalytic oxidation, FE oxidation, membrane filtration, and PS oxidation [21]; its excellent enhancement capacity to various treatment methods of organic wastewater has been confirmed by many reports [22][23][24].

2. Typical Ultrasound-Enhanced Organic Wastewater Treatment Equipment

2.1. Classification by Reactor Type

2.1.1. Ultrasound Cleaning Tank-Type Reactor

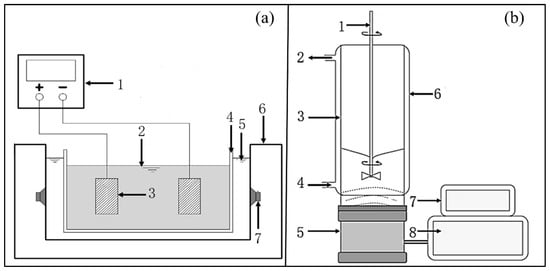

Ultrasound cleaning tank-type reactors are usually equipped with transducers on both sides (No. 7 in Figure 1a) or at the bottom of the reactor (No. 4 in Figure 1b). The advantage of the installation position of the transducer is that the transducer can be controlled easily to adjust the output power, and corrosion of the transducer can be avoided [25].

Figure 1. Device diagram of (a) ultrasound cleaning tank reactor and (b) ultrasound amplifier coupled transducer [4][26]. ((a) 1. Power supply, 2. wastewater, 3. electrode, 4. Perspex vessel, 5. water (20 °C), 6. ultrasound generation, 7. ultrasound transducer. (b) 1. Stirrer, 2. cooling water outlet, 3. cylindrical glass reactor, 4. cooling water inlet, 5. ultrasound transducer, 6. cooling jacket, 7. ultrasound amplifier and frequency controller, 8. ultrasound power supply).

As shown in Figure 1a, the temperature of the cooling water (No. 5) in the cleaning tank can be adjusted to control the temperature of the wastewater in Perspex vessel (No. 4) to achieve the optimal treatment temperature. In addition, researchers can achieve the optimal frequency and power of ultrasound by adjusting the transducer. Yang et al. removed more than 94.0% of COD from cephalosporin pharmaceutical wastewater by using this experimental device [4].

As shown in Figure 1b, ultrasound with a frequency of 3.82–140 kHz can be generated by a disk transducer (No. 5) at the bottom of the glass reactor (No. 3) [27]. The reactor is surrounded by a cooling jacket (No. 6) to achieve the required treatment temperature. This kind of device can easily output high-frequency ultrasound to effectively realize cavitation conditions. Bremner et al. [26] obtained a 29.0% removal rate of TOC in the aqueous phenol solutions by using the device in Figure 1b.

2.1.2. Ultrasound Probe Reactor

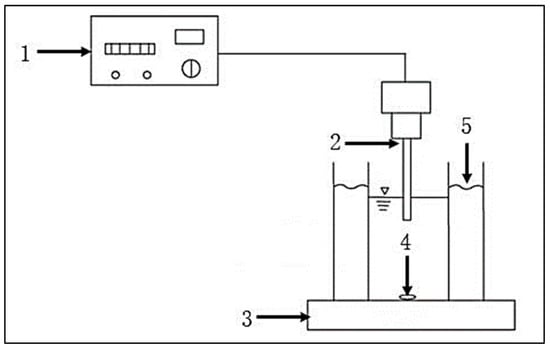

As shown in Figure 2, the probe transducer (No. 2) is the most important part of the reactor. The maximum transmission coefficient of ultrasound takes place along the axial direction of the probe and drops sharply in the radial direction of the probe. In addition, the emission power of the probe is adjustable. As the small diameter of the probe limits its effective working range, the use of this kind of reactor has been limited to the laboratory stage until now [28].

Figure 2. The device diagram of ultrasound probe reactor [28]. (1. Ultrasound generator reactor, 2. probe transducer, 3. magnetic stirrer, 4. magnetic bar, 5. constant temperature water bath).

It is noteworthy that this kind of reactor is convenient to use, but the probe immersed in the solution can be eroded easily using the mechanical effect of ultrasound, and the vibration from the probe will raise the temperature of the solution and affect its service life. Thus, low-temperature liquid should be circulated in the jacket when necessary [25].

The treatment efficiency of organic wastewater in such a kind of reactor cannot satisfy people’s requirements. However, ultrasound can play an excellent auxiliary role and promote the efficiency of organic degradation when combined with other methods. Peng et al. [29] reported that only 4.0% of polycyclic aromatic hydrocarbons were degraded by ultrasound alone in 120 min, while the degradation rate reached 84.8% in the ultrasound-PS process. In addition, in the treatment of carbofuran [30], the removal efficiency of carbofuran (99.0%) in the ultrasound–FE process was much higher than that (60.0%) in the ultrasound alone system.

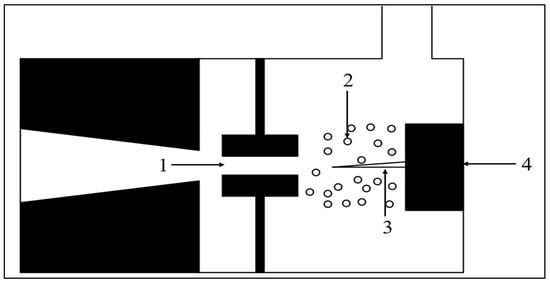

The above two types of reactors are the mainstream reactors at present, whereas the liquid whistle reactor is not common now. Unlike transducers, ultrasound in the liquid whistle reactor is generated by the jet impinging on the metal blade (No. 3, Figure 3). The sound intensity in the reactor can be adjusted by changing the shape of the jet. In addition, ultrasound frequency can be adjusted by the flow rate. This kind of reactor is always used in the emulsification and homogenization of oily wastewater [31].

Figure 3. Device diagram of the liquid whistle-type ultrasound reactor [31]. (1. Adjustable channel for liquid flow, 2. cavitation zone, 3. metal blade, 4. stainless steel block).

2.1.3. Comparison of Ultrasound Reactors with Different Types

Table 1 compares the advantages and disadvantages of three types of ultrasound reactors. Firstly, the cleaning tank reactor has a wide range of uses and can be used to clean experimental equipment. It is relatively common to simply place the reaction tank in the cleaning tank during the reaction, and the external water bath can also control the temperature, but this also limits the size of the reaction tank. Subsequently, the ultrasound probe-type reactor only needs to insert the probe into the reaction solution during reaction, which is easy to operate. However, the ultrasound distribution is uneven, and the probe is prone to corrosion after long-term use. Finally, liquid whistle-type reactors are uncommon now, which are used for the averaging and emulsification of oily wastewater.

Table 1. Comparison of different types of reactors.

| Reactors | Advantages | Disadvantages |

| Ultrasound cleaning tank-type reactor | Ultrasound wave is evenly distributed; Can easily control temperature. |

Limiting the reactor size. |

| Ultrasound probe reactor | Uneven distribution of ultrasound wave; The probe is prone to corrosion. |

Easy operation. |

| Liquid whistle reactor | Application in homogenization of oily wastewater. | Ancient, with certain limitations. |

2.2. Classified According to Liquid Flow Mode

2.2.1. Fully Mixed Reactor

The ultrasound cleaning tank-type reactor and ultrasound probe reactor can both work in fully mixed mode. The fully mixed reactor can be used in various ultrasound processes, including ultrasound alone, the ultrasound–PS process, the ultrasound–FE process, the ultrasound–electrochemistry process, the ultrasound–photocatalytic oxidation process, etc.

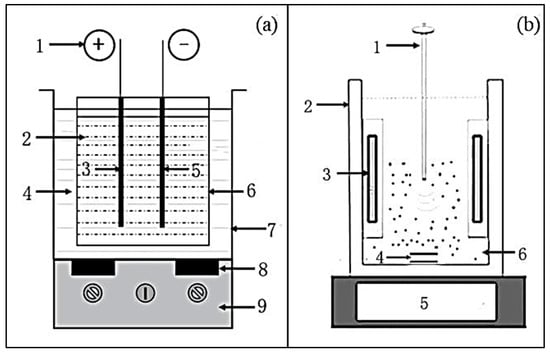

When ultrasound works alone or works with PS or a Fenton-like process, the reaction can be easily started by adding PS or Fe2+/H2O2 to the system. However, in the ultrasound–electrochemistry process (Figure 4a) the addition of an anode and cathode at both sides of the reactor (No. 3 and 5) is necessary. In addition, particle electrode may be needed as well if the fully mixed reactor can play the role of a three-dimensional electrode system. When the fully mixed reactor works with the photocatalytic oxidation process, UV lamp (No. 3, Figure 4b) or other light sources and a photocatalyst are needed.

The fully mixed reactor is generally equipped with a mechanical stirrer to evenly mix the wastewater and chemical reagents [32]. If the temperature and pH need to be controlled, a temperature controller and pH sensor will be set, respectively. The wastewater in the fully mixed reactor can be easily mixed uniformly. However, the capacity of the fully mixed reactor is limited, and it cannot work in a continuous mode. The treatment efficiency of organic wastewater in such a kind of reactor is very high, for example, the decolorization rate of reactive black 5 dye treated by the reactor, outlined in Figure 4a, reached 89.0% [33], while 99.9% rhodamine 6G and 88.7% phenol were removed by the reactor, as outlined in Figure 4b [34].

Figure 4. Experimental device of (a) ultrasound−EC process, and (b) continuous stirred tank of ultrasound−UV process [33][34]. ((a) 1. DC power supply, 2. dye solution, 3. anode, 4. distilled water, 5. cathode, 6. glass reactor, 7. ultrasound bath, 8. transducer, 9. ultrasound control unit. (b) 1. Ultrasound probe, 2. cooling water jacket, 3. UV lamp, 4. magnetic bar, 5. magnetic stirrer, 6. dye solution).

2.2.2. Continuous Reactor

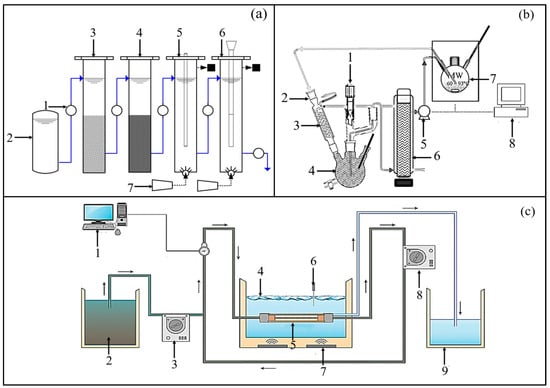

In the continuous reactor, the ultrasound unit always works with other organic wastewater treatment units, and common treatment processes include, but are not limited to, the ultrasound–O3 process (Figure 5a), the ultrasound–MW process (Figure 5b), the ultrasound–membrane process (Figure 5c), etc.

Figure 5. Experimental device diagram of (a) push flow reactor of ultrasound–UV–O3 process, (b) ultrasound–MW process, (c) ultrasound-membrane process [35][36][37]. ((a) 1. Pump, 2. storage tank, 3. coarse sand, 4. fine sand, 5. UV unit, 6. ultrasound unit, 7. O3 generators. (b) 1. Inlet, 2. cooling water outlet, 3. intensive condenser, 4. outlet and sampler, 5. pump, 6. ultrasound generator, 7. MW generator, 8. control center. (c) 1. Pressure meter and transducer, 2. feed tank, 3. peristaltic pump, 4. ice, 5. membrane module, 6. ultrasound bath, 7. temperature probe, 8. peristaltic pump, 9. permeate tank).

As for the ultrasound–O3 process, the organic wastewater is first filtered by coarse sand (No. 3) and fine sand (No. 4) and then sequentially entered into the UV unit (No. 5) and the ultrasound unit (No. 6). After the treatment, the treated organic wastewater can be discharged. Both of the bottoms of the UV unit and ultrasound unit are equipped with O3 generators (No. 7). They can determine the optimal scheme to adjust the experimental scheme. Using this device, 97.7% of atrazine was degraded in the study of Jing et al. [35].

As for the ultrasound–MW process, the function of MW is to control temperature. After the ultrasound treatment (No. 6), organic wastewater enters the circulation system for cooling. A control center is usually set (No. 8) to control the flow, temperature, and MW power. Using this device, up to 76.0% of phenol was degraded in the study of Wu et al. [36], which is equivalent to the sum of the degradation achieved by the separate treatment of ultrasound and MW.

As for the ultrasound–membrane process, the membrane module (No. 5) is usually immersed in the ultrasound bath (No. 6), and then the wastewater is pumped into the ultrasound bath and flows out after the ultrasound treatment and membrane filtration. The continuous reactor is suitable for the tandem treatment of wastewater by sequentially passing the treatment units. The disadvantage is that the reactor design is complex, and the operation cost is high.

2.2.3. Comparison of Ultrasound Reactors with Different Flow Modes

Table 2 is a comparative table of advantages and disadvantages classified by flow mode. For a fully mixed flow reactor, the reaction solution can be completely mixed and fully reacted, and the operation is simple, but it can only be reacted in batches. For continuous flow reactors, the solution can be continuously treated, but different types of treatment methods require redesigning the reactor, which is costly.

Table 2. Comparison of reactors with different flow modes.

| Types | Advantages | Disadvantages |

|---|---|---|

| Fully mixed reactor | Mix the solution evenly. Convenient combination with other processing methods. | Unable to process continuously. |

| Continuous reactor | Continuous processing. | Complex design and high cost. |

References

- Babu, S.G.; Ashokkumar, M.; Neppolian, B. The Role of Ultrasound on Advanced Oxidation Processes. Top Curr. Chem. 2016, 374, 75.

- Zhang, Q.-Q.; Jin, R.-C. The Application of Low-Intensity Ultrasound Irradiation in Biological Wastewater Treatment: A Review. Crit. Rev. Environ. Sci. Technol. 2015, 45, 2728–2761.

- Li, H.; Lei, H.; Yu, Q.; Li, Z.; Feng, X.; Yang, B. Effect of low frequency ultrasonic irradiation on the sonoelectro-Fenton degradation of cationic red X-GRL. Chem. Eng. J. 2010, 160, 417–422.

- Yang, B.; Zuo, J.; Li, P.; Wang, K.; Yu, X.; Zhang, M. Effective ultrasound electrochemical degradation of biological toxicity and refractory cephalosporin pharmaceutical wastewater. Chem. Eng. J. 2016, 287, 30–37.

- Rasheed, Q.J.; Pandian, K.; Muthukumar, K. Treatment of petroleum refinery wastewater by ultrasound-dispersed nanoscale zero-valent iron particles. Ultrason. Sonochem. 2011, 18, 1138–1142.

- Abdelhay, A.; Othman, A.A.; Albsoul, A. Treatment of slaughterhouse wastewater using high-frequency ultrasound: Optimization of operating conditions by RSM. Environ. Technol. 2021, 42, 4170–4178.

- Liu, W.; Huang, F.; Liao, Y.; Zhang, J.; Ren, G.; Zhuang, Z.; Zhen, J.; Lin, Z.; Wang, C. Treatment of CrVI-Containing Mg(OH)2 Nanowaste. Angew. Chem. 2008, 120, 5701–5704.

- Dong, Y.; Yuan, H.; Ge, D.; Zhu, N. A novel conditioning approach for amelioration of sludge dewaterability using activated carbon strengthening electrochemical oxidation and realized mechanism. Water Res. 2022, 220, 118704.

- Chang, T.; Wang, Y.; Wang, Y.Q.; Zhao, Z.; Shen, Z.; Huang, Y.; Veerapandian, S.K.P.; De Geyter, N.; Wang, C.; Chen, Q.; et al. A critical review on plasma-catalytic removal of VOCs: Catalyst development, process parameters and synergetic reaction mechanism. Sci. Total Environ. 2022, 828, 154290.

- Feng, X.; Wang, B.; Gao, G.; Gao, S.; Xie, C.; Shi, J.-W. MnyCo3−yOx bimetallic oxide prepared by ultrasonic technology for significantly improved catalytic performance in the reduction of NOx with NH3. Fuel 2023, 352, 129159.

- Chen, D.; Wang, Q.; Li, Y.; Li, Y.; Zhou, H.; Fan, Y. A general linear free energy relationship for predicting partition coefficients of neutral organic compounds. Chemosphere 2020, 247, 125869.

- Suna, S.; Liu, H.; Zhang, J.; Wang, W.; Xu, P.; Zhu, X.; Wang, Y.; Wan, S. Application of a novel coagulant in reservoir water treatment in Qingdao. Desalin. Water Treat. 2023, 284, 49–60.

- Yaqub, A.; Ajab, H. Applications of sonoelectrochemistry in wastewater treatment system. Rev. Chem. Eng. 2013, 29, 123–130.

- Scannapieco, D.; Naddeo, V.; Belgiorno, V. Control of fouling in MBRs through nanospheres addition. Desalin. Water Treat. 2014, 55, 702–711.

- Qin, W.; Ma, Y.; He, T.; Hu, J.; Gao, P.; Yang, S. Enhanced Heterogeneous Fenton-like Process for Sulfamethazine Removal via Dual-Reaction-Center Fe-Mo/rGO Catalyst. Nanomaterials 2022, 12, 4138.

- Zhu, G.F.; Xiong, S.H.; Shi, C.; Jin, Y.; Ge, M.Q. Ceria-promoted heterogeneous Fenton-like oxidation of polyvinyl alcohol, Rhodamine-B, and Reactive Red X-3B over Fe/Cu@gamma-Al2O3 microspheres under neutral conditions. J. Alloys Compd. 2022, 924, 15.

- Musielak, G.; Mierzwa, D.; Kroehnke, J. Food drying enhancement by ultrasound—A review. Trends Food Sci. Technol. 2016, 56, 126–141.

- Yu, Q.; Fan, L.; Li, J. A novel process for asparagus polyphenols utilization by ultrasound assisted adsorption and desorption using resins. Ultrason. Sonochem. 2020, 63, 104920.

- Liao, T.; Xi, Y.; Zhang, L.; Li, J.; Cui, K. Removal of toxic arsenic (As()) from industrial wastewater by ultrasonic enhanced zero-valent lead combined with CuSO4. J. Hazard. Mater. 2021, 408, 124464.

- Cardenas Sierra, R.S.; Zuniga-Benitez, H.; Penuela, G.A. Elimination of cephalexin and doxycycline under low frequency ultrasound. Ultrason. Sonochem. 2021, 79, 105777.

- Pirsaheb, M.; Moradi, N. A systematic review of the sonophotocatalytic process for the decolorization of dyes in aqueous solution: Synergistic mechanisms, degradation pathways, and process optimization. J. Water Process Eng. 2021, 44, 102314.

- Ritesh, P.; Srivastava, V.C. Understanding of ultrasound enhanced electrochemical oxidation of persistent organic pollutants. J. Water Proc. Eng. 2020, 37, 101378.

- Zhu, Y.; Fan, W.; Feng, W.; Wang, Y.; Liu, S.; Dong, Z.; Li, X. A critical review on metal complexes removal from water using methods based on Fenton-like reactions: Analysis and comparison of methods and mechanisms. J. Hazard. Mater. 2021, 414, 125517.

- Yang, L.; Xue, J.; He, L.; Wu, L.; Ma, Y.; Chen, H.; Li, H.; Peng, P.; Zhang, Z. Review on ultrasound assisted persulfate degradation of organic contaminants in wastewater: Influences, mechanisms and prospective. Chem. Eng. J. 2019, 378, 122146.

- Meroni, D.; Djellabi, R.; Ashokkumar, M.; Bianchi, C.L.; Boffito, D.C. Sonoprocessing: From Concepts to Large-Scale Reactors. Chem. Rev. 2022, 122, 3219–3258.

- Bremner, D.H.; Molina, R.; Martínez, F.; Melero, J.A.; Segura, Y. Degradation of phenolic aqueous solutions by high frequency sono-Fenton systems (US–Fe2O3/SBA-15–H2O2). Appl. Catal. B 2009, 90, 380–388.

- Prakash, L.V.; Gopinath, A.; Gandhimathi, R.; Velmathi, S.; Ramesh, S.T.; Nidheesh, P.V. Ultrasound aided heterogeneous Fenton degradation of Acid Blue 15 over green synthesized magnetite nanoparticles. Sep. Purif. Technol. 2021, 266, 118230.

- Zhang, H.; Fu, H.; Zhang, D. Degradation of C.I. Acid Orange 7 by ultrasound enhanced heterogeneous Fenton-like process. J. Hazard. Mater. 2009, 172, 654–660.

- Peng, L.; Wang, L.; Hu, X.; Wu, P.; Wang, X.; Huang, C.; Wang, X.; Deng, D. Ultrasound assisted, thermally activated persulfate oxidation of coal tar DNAPLs. J. Hazard. Mater. 2016, 318, 497–506.

- Ma, Y.S.; Sung, C.F.; Lin, J.G. Degradation of carbofuran in aqueous solution by ultrasound and Fenton processes: Effect of system parameters and kinetic study. J. Hazard. Mater. 2010, 178, 320–325.

- Mason, T.J.; Paniwnyk, L.; Lorimer, J.P. The uses of ultrasound in food technology. Ultrason. Sonochem. 1996, 3, S253–S260.

- Ghanbari, F.; Zirrahi, F.; Lin, K.-Y.A.; Kakavandi, B.; Hassani, A. Enhanced electro-peroxone using ultrasound irradiation for the degradation of organic compounds: A comparative study. J. Environ. Chem. Eng. 2020, 8, 104167.

- Johin, J.; Nidheesh, P.V.; Sivasankar, T. Sono-electro-chemical Treatment of Reactive Black 5 Dye and Real Textile Effluent Using MnSO4/Na2S2O8 Electrolytes. Arabian J. Sci. Eng. 2019, 44, 9987–9996.

- Demir, N.; Gunduz, G.; Dukkanci, M. Degradation of a textile dye, Rhodamine 6G (Rh6G), by heterogeneous sonophotoFenton process in the presence of Fe-containing TiO2 catalysts. Environ. Sci. Pollut. Res. Int. 2015, 22, 3193–3201.

- Jing, L.; Chen, B.; Wen, D.; Zheng, J.; Zhang, B. Pilot-scale treatment of atrazine production wastewater by UV/O3/ultrasound: Factor effects and system optimization. J. Environ. Manag. 2017, 203, 182–190.

- Wu, Z.L.; Ondruschka, B.; Cravotto, G. Degradation of Phenol under Combined Irradiation of Microwaves and Ultrasound. Environ. Sci. Technol. 2008, 42, 8083–8087.

- Secondes, M.F.; Naddeo, V.; Belgiorno, V.; Ballesteros, F., Jr. Removal of emerging contaminants by simultaneous application of membrane ultrafiltration, activated carbon adsorption, and ultrasound irradiation. J. Hazard. Mater. 2014, 264, 342–349.

More

Information

Subjects:

Environmental Sciences

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.2K

Entry Collection:

Wastewater Treatment

Revisions:

2 times

(View History)

Update Date:

17 Nov 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No