Video Upload Options

With the global energy shortages, sustainable energy scavenging from the natural environment is desperately needed. Unlike solar cell or wind power, which depends heavily on weather conditions, triboelectric nanogenerator (TENG) has received extensive attention as an efficient all–weather energy–harvesting technology. Based on the coupling principle of contact electrification (CE) and electrostatic induction, conventional TENGs convert mechanical energy into an alternating current (AC) output. However, the typically distributed sensor systems in the ubiquitous Internet of Things (IoTs) request a direct current (DC) input. Direct current triboelectric nanogenerators (DC-TENGs) with the constant output characteristic are critical to satisfy the above requirements.

1. Introduction

2. DC-TENGs Based on Different Types of Materials

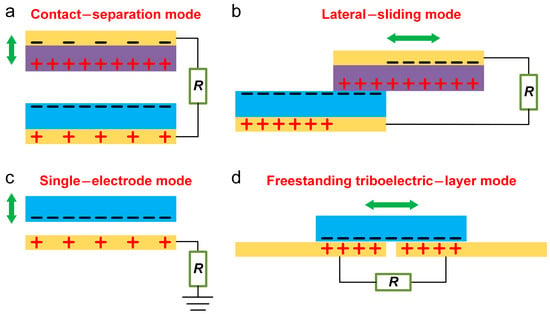

2.1. Operating Mechanism of TENG

2.2. DC-TENGs Based on Dielectric Materials

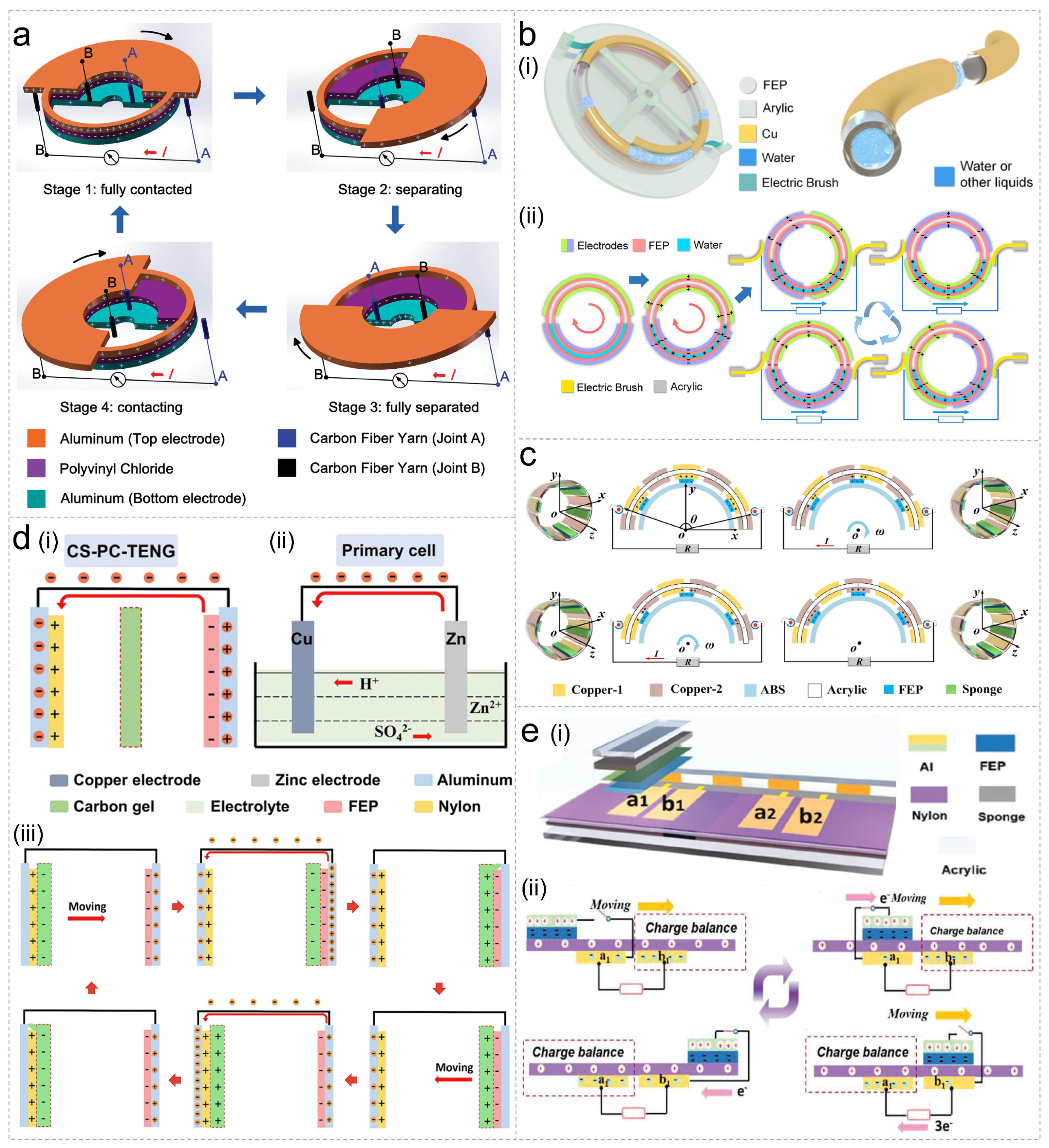

2.2.1. Mechanical Rectification

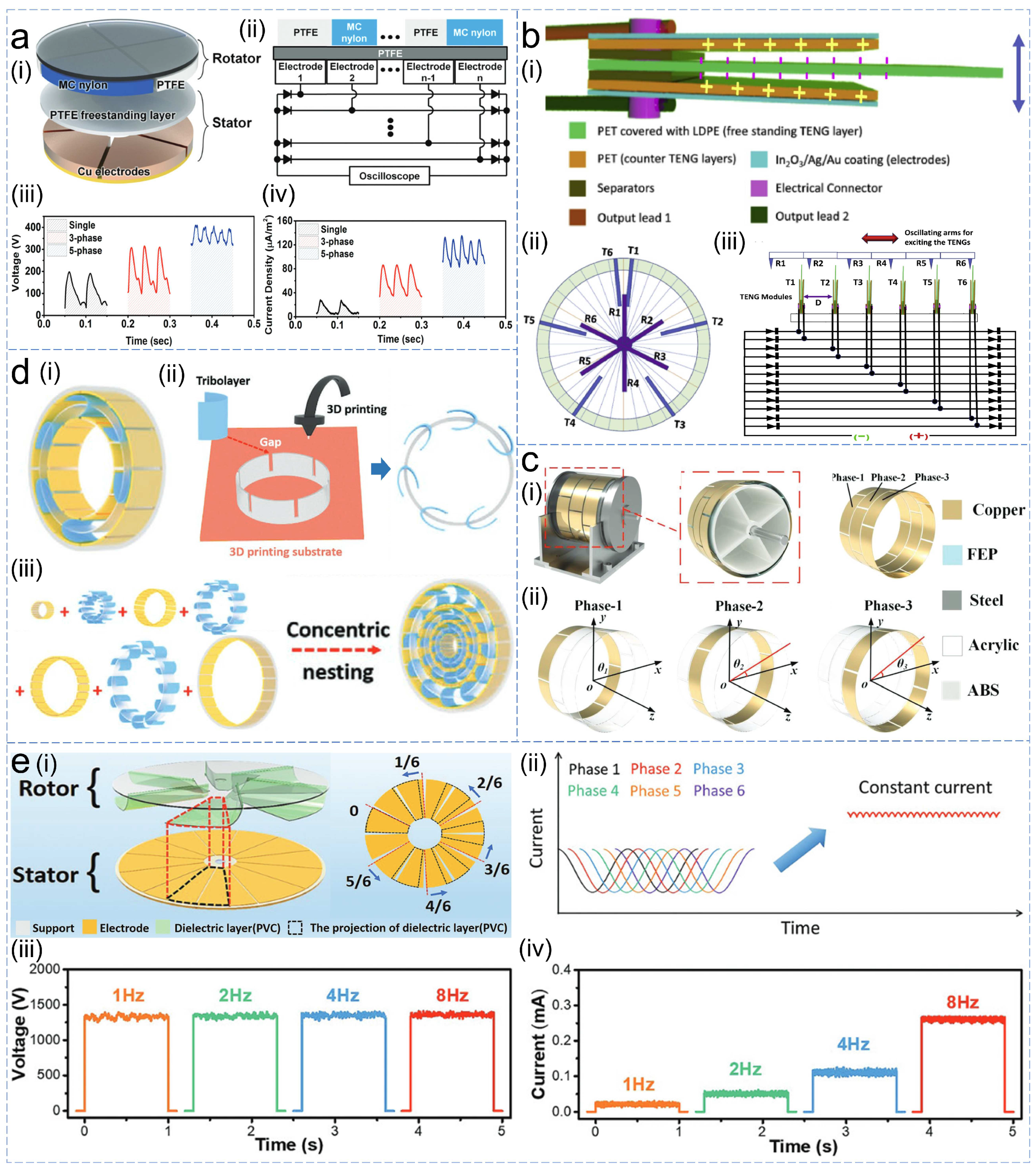

2.2.2. Phase Coupling

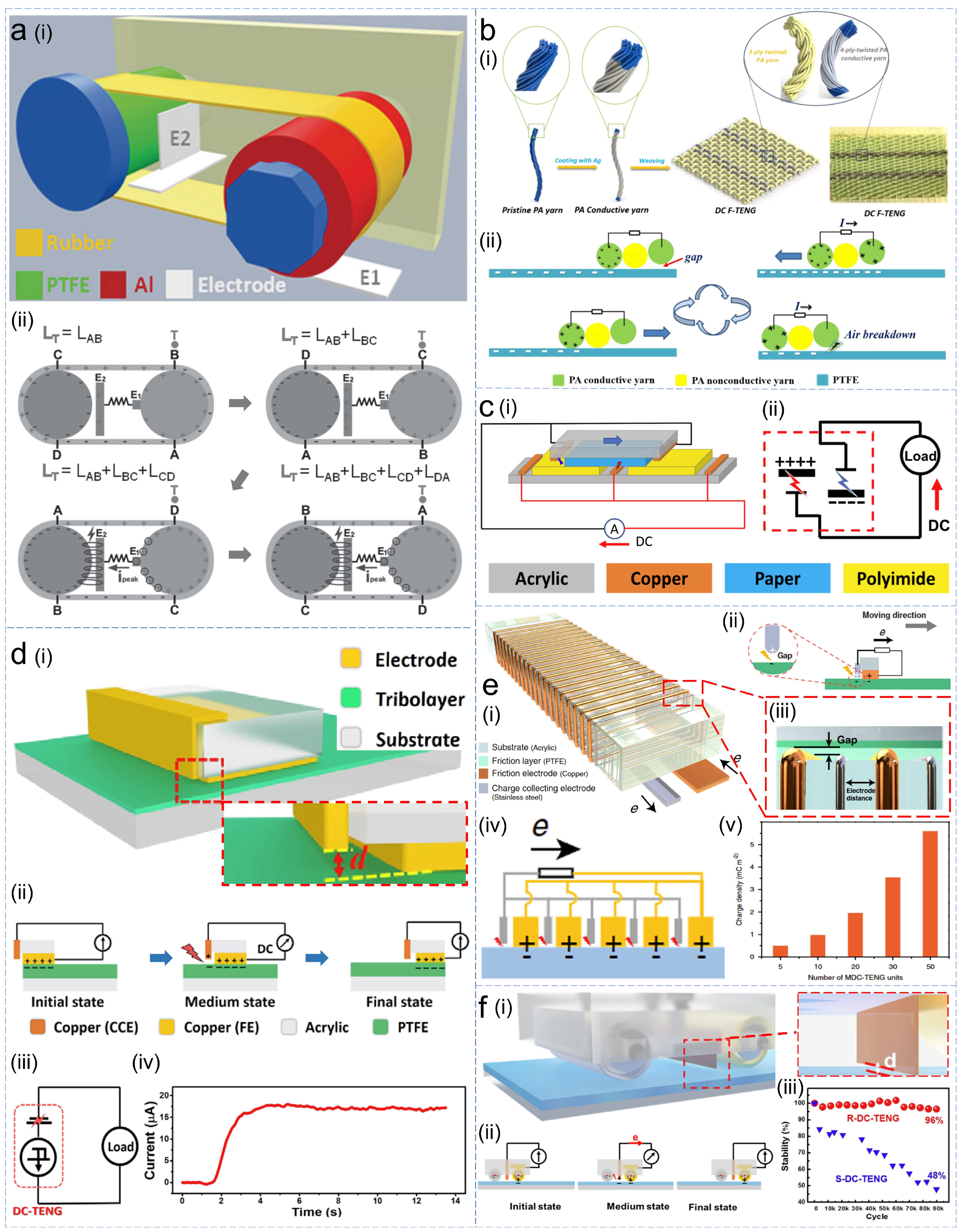

2.2.3. Dielectric Breakdown

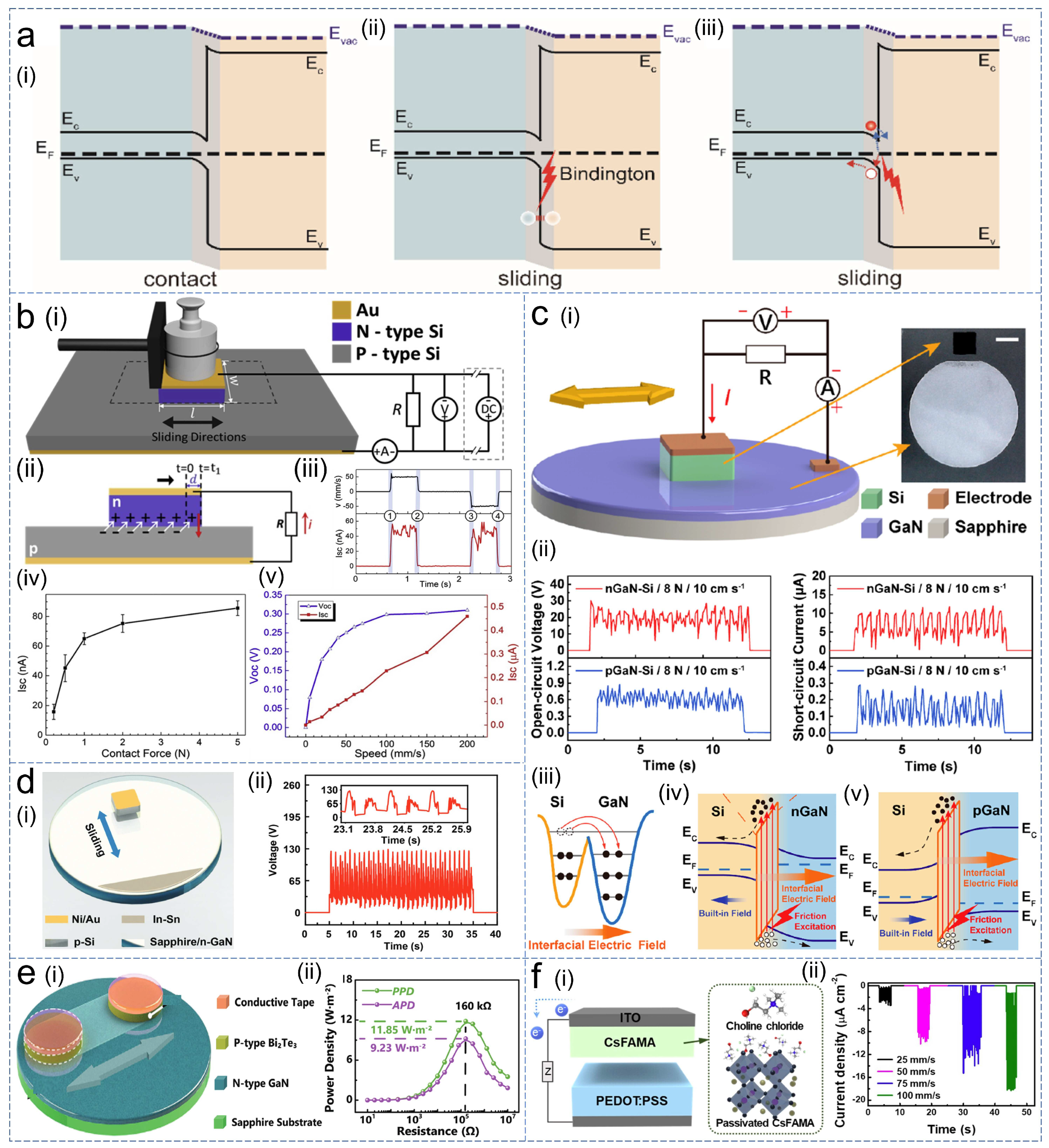

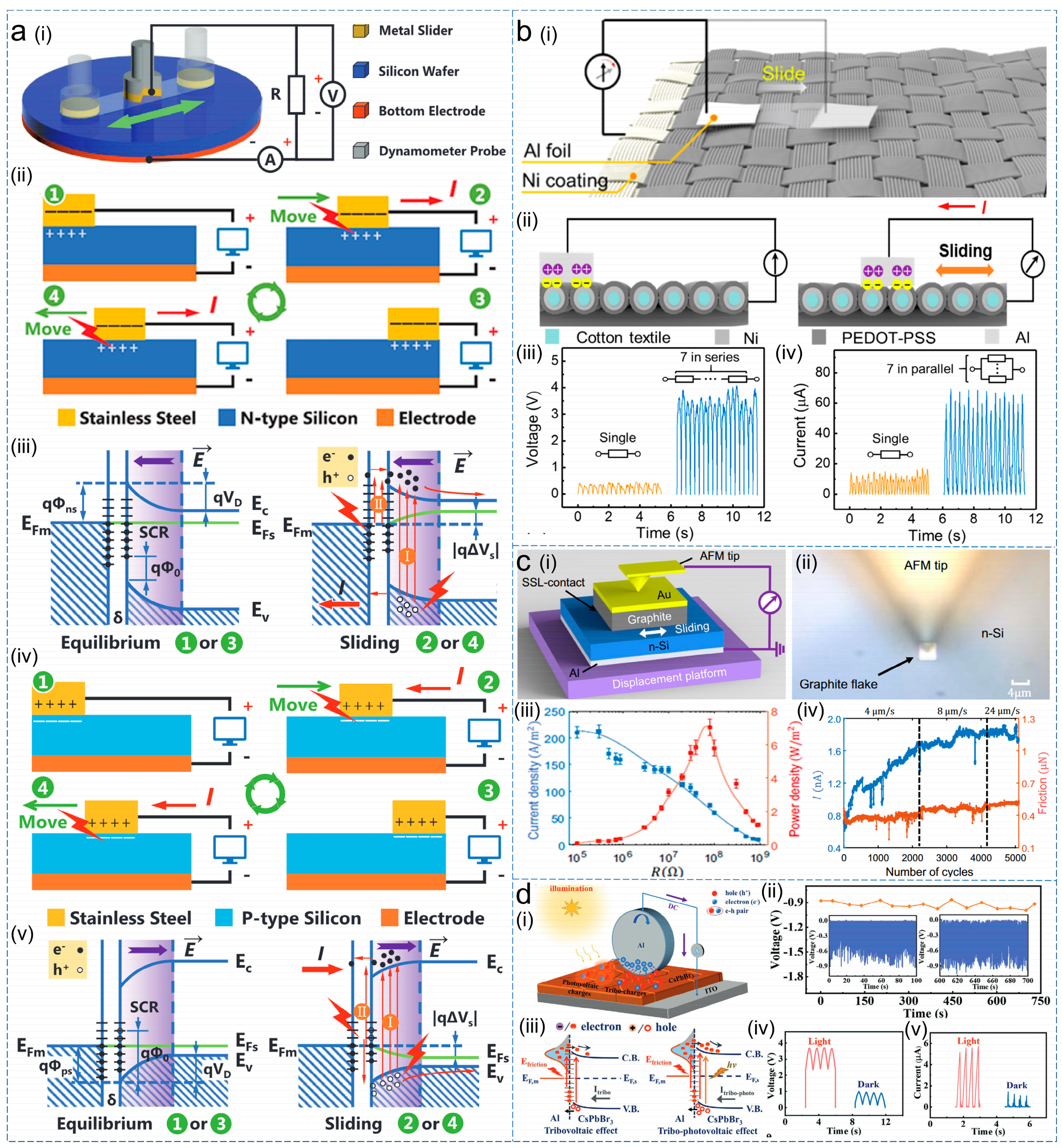

2.3. DC-TENGs Based on Semiconductor Materials

2.3.1. Semiconductor–Semiconductor Contact

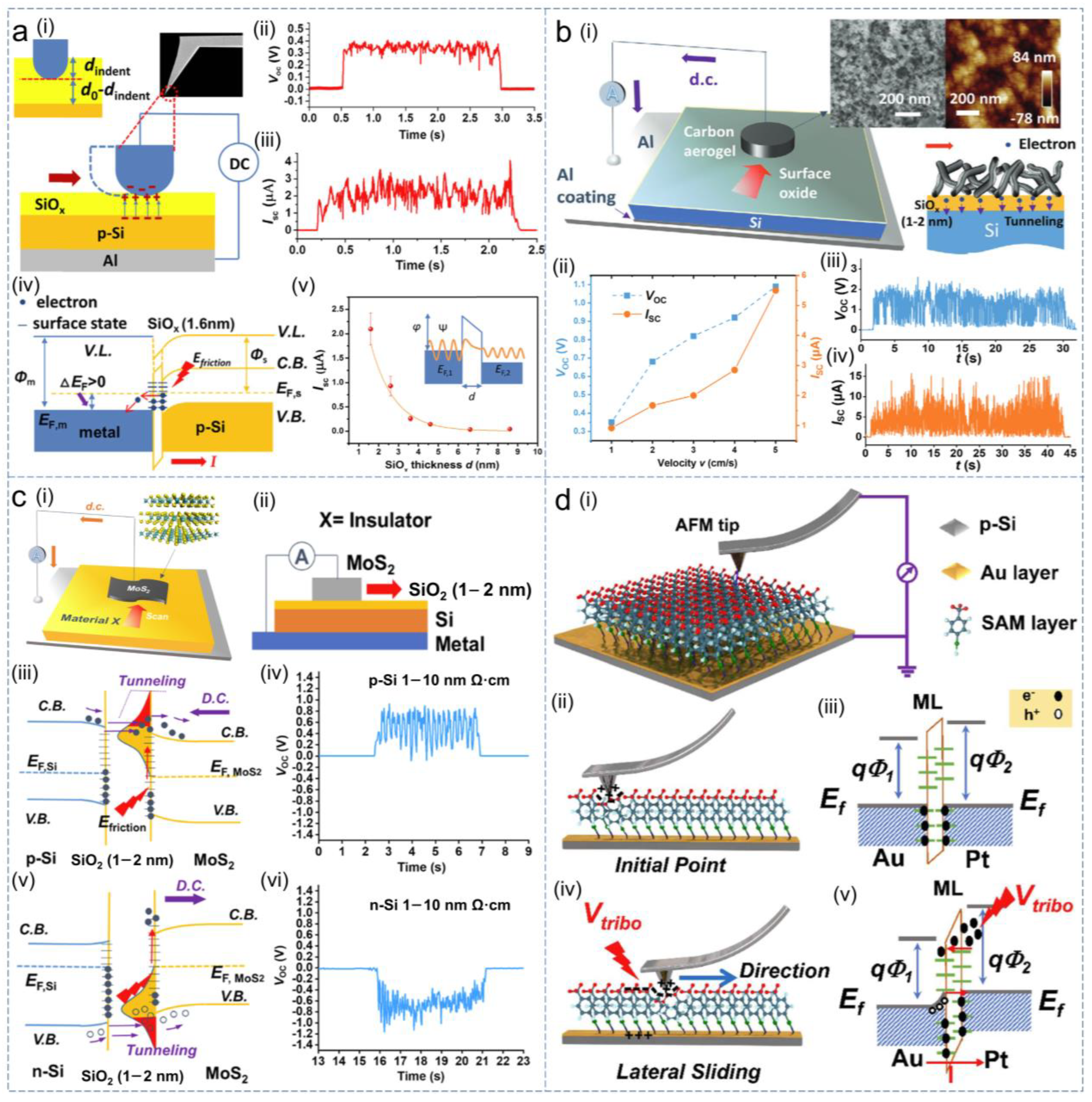

2.3.2. Metal–Semiconductor Contact

2.3.3. Metal/Semiconductor–Insulator–Metal/Semiconductor Contact

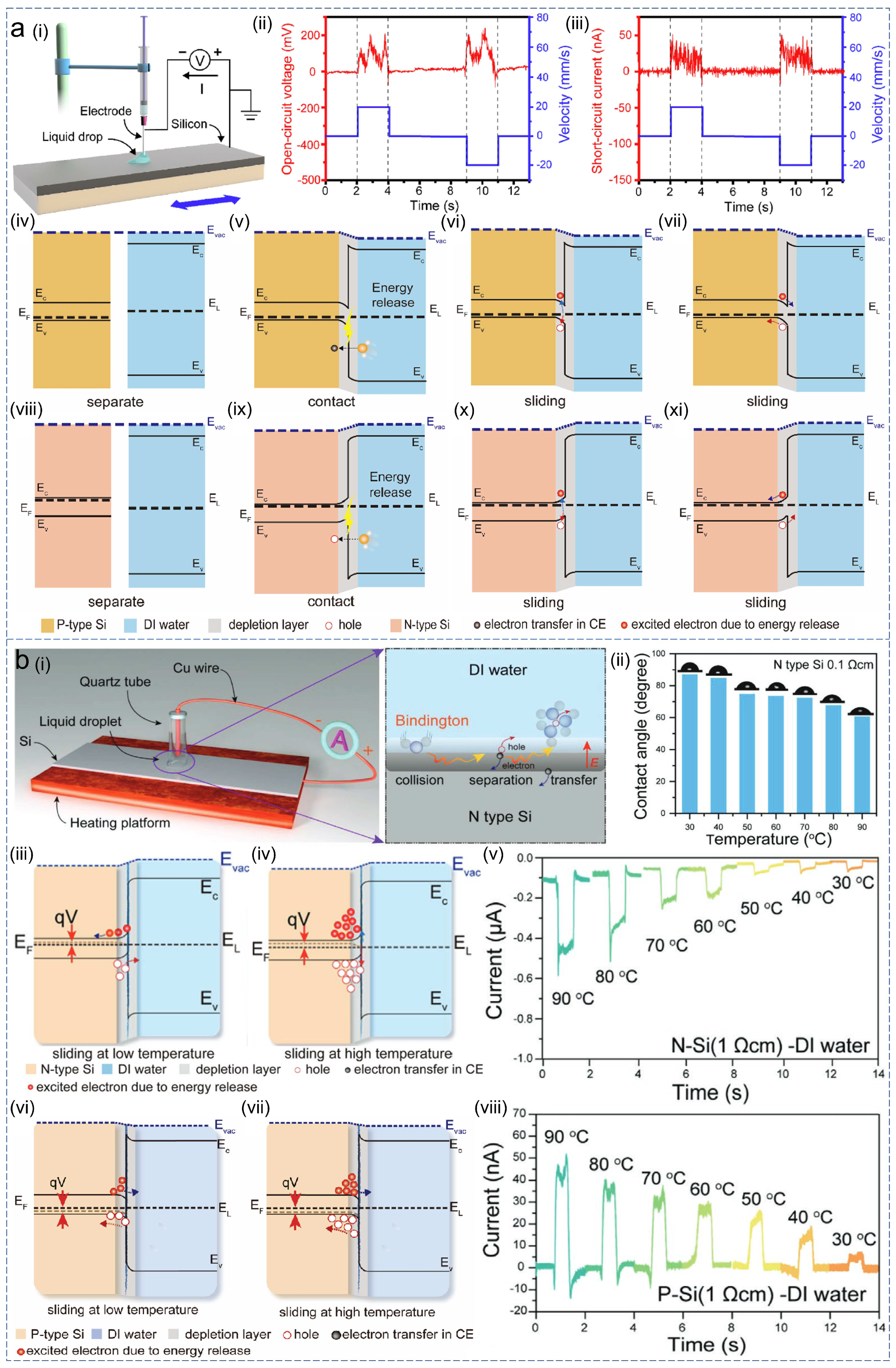

2.3.4. Liquid–Semiconductor Contact

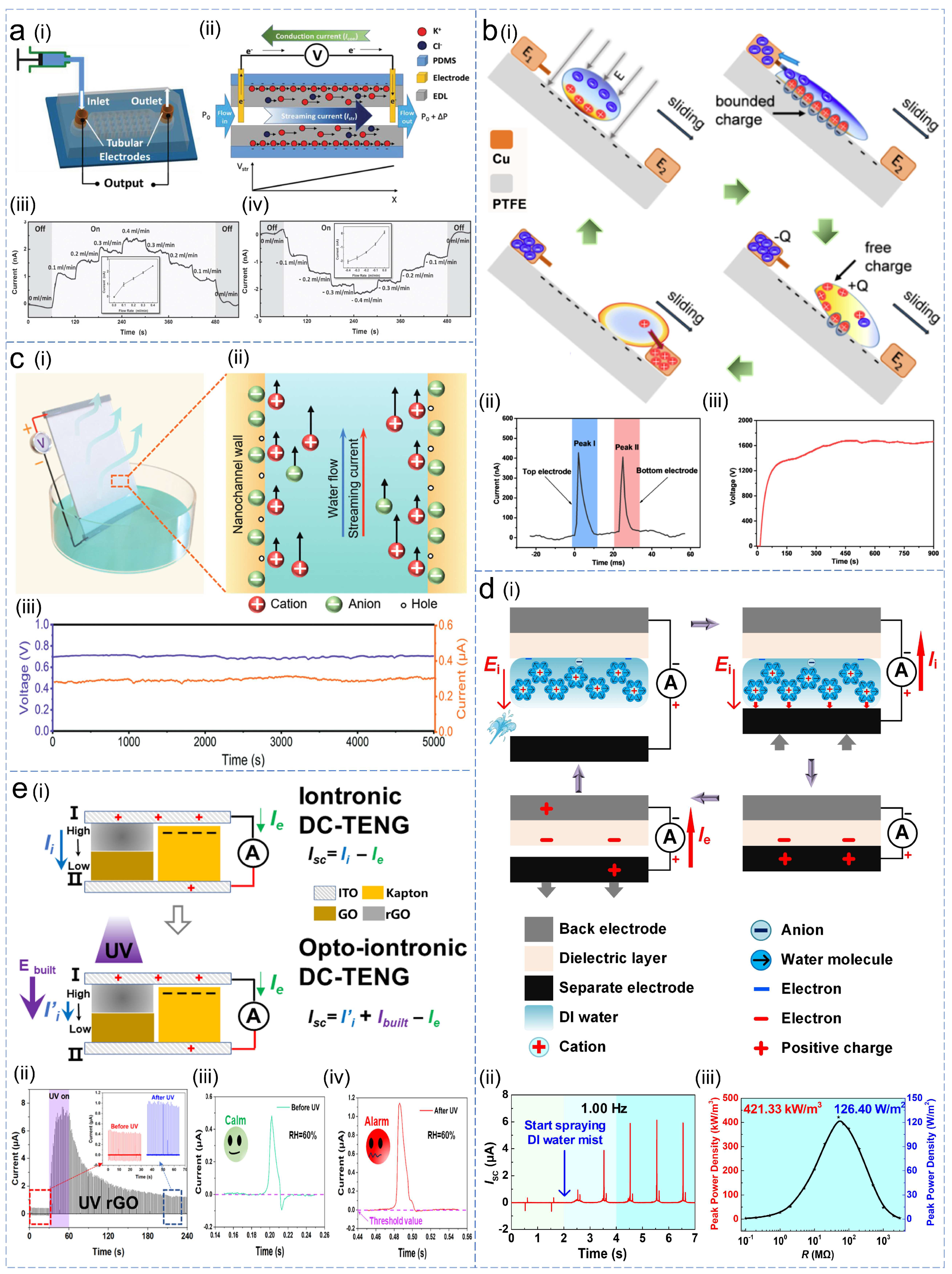

2.4. DC-TENGs Based on Materials for Iontronic Rectification

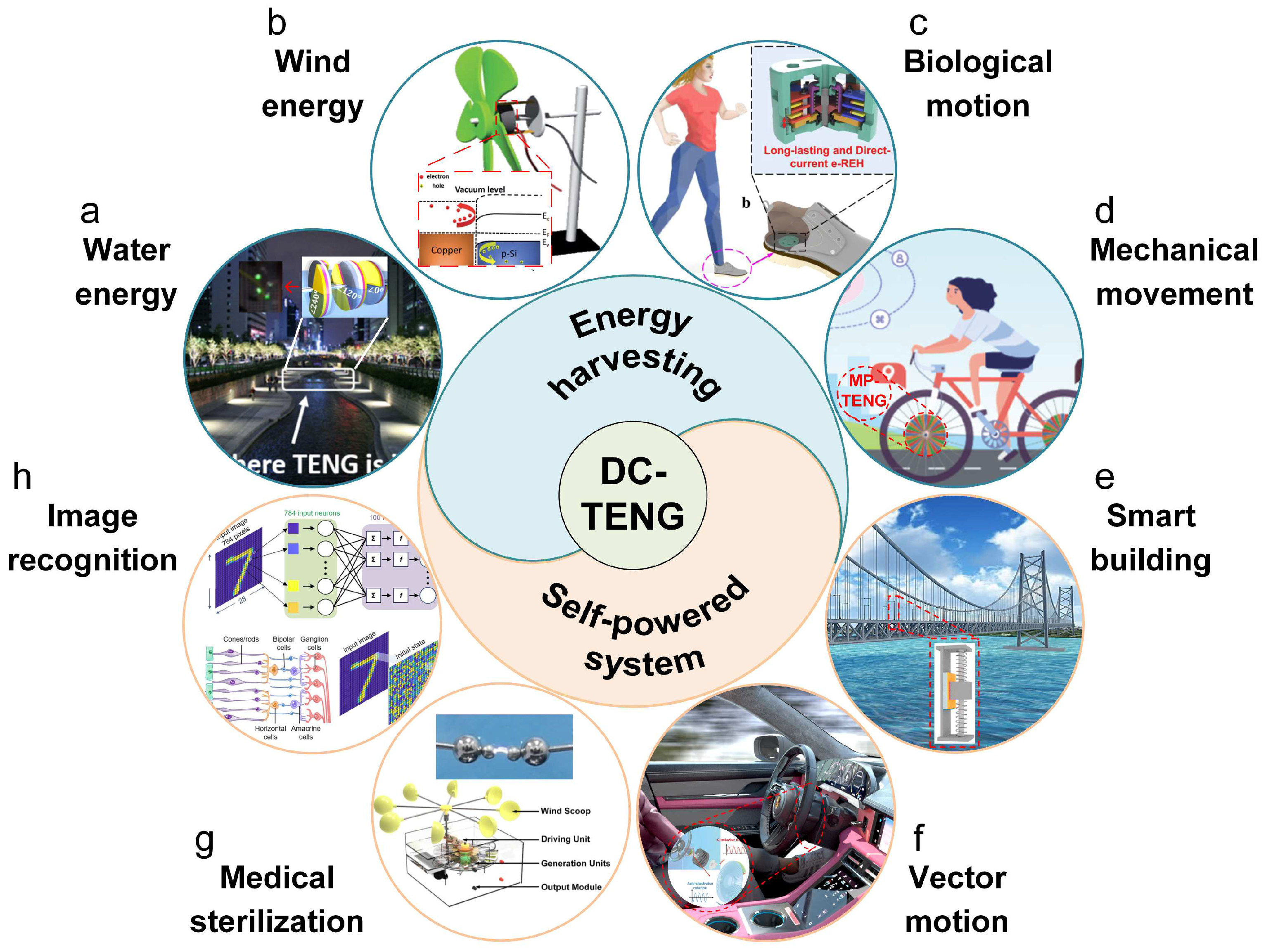

3. Various Applications of DC-TENGs

| Advantages | Disadvantages | |

|---|---|---|

| DC-TENGs based on dielectric materials | higher voltage output | higher internal resistance prone to friction and wear |

| DC-TENGs based on semiconductor materials | higher current density lower internal resistance |

prone to friction and wear depletion of space charge |

| DC-TENGs based on materials for iontronic rectifications | free from friction and wear suppletion of surface charge |

additional ionic source |

References

- Kennedy, C. The energy embodied in the first and second industrial revolutions. J. Ind. Ecol. 2020, 24, 887–898.

- Balat, M. Status of fossil energy resources: A global perspective. Energy Sources Part B 2007, 2, 31–47.

- Wrigley, E.A. Energy and the English industrial revolution. Philos. Trans. R. Soc. A 2013, 371, 20110568.

- Qiao, S.; Dang, Y.J.; Ren, Z.Y.; Zhang, K.Q. The dynamic spillovers among carbon, fossil energy and electricity markets based on a TVP-VAR-SV method. Energy 2023, 266, 126344.

- Gong, X.; Shi, R.; Xu, J.; Lin, B. Analyzing spillover effects between carbon and fossil energy markets from a time-varying perspective. Appl. Energy 2021, 285, 116384.

- Fernández, A.M.; Ferrándiz, E.; Medina, J. The diffusion of energy technologies. Evidence from renewable, fossil, and nuclear energy patents. Technol. Forecast. Soc. 2022, 178, 121566.

- Tollefson, J. Carbon emissions hit new high: Warning from COP27. Nature 2022.

- Su, C.W.; Pang, L.D.; Qin, M.; Lobont, O.R.; Umar, M. The spillover effects among fossil fuel, renewables and carbon markets: Evidence under the dual dilemma of climate change and energy crises. Energy 2023, 274, 127304.

- Perera, F.P. Multiple threats to child health from fossil fuel combustion: Impacts of air pollution and climate change. Environ. Health Perspect. 2017, 125, 141–148.

- Slamersak, A.; Kallis, G.; O’Neill, D.W. Energy requirements and carbon emissions for a low-carbon energy transition. Nat. Commun. 2022, 13, 6932.

- Guan, Y.; Yan, J.; Shan, Y.; Zhou, Y.; Hang, Y.; Li, R.; Liu, Y.; Liu, B.; Nie, Q.; Bruckner, B.; et al. Burden of the global energy price crisis on households. Nat. Energy 2023, 8, 304–316.

- Long, C.; Jiang, Z.; Shangguan, J.; Qing, T.; Zhang, P.; Feng, B. Applications of carbon dots in environmental pollution control: A review. Chem. Eng. J. 2021, 406, 126848.

- Fahrenkamp-Uppenbrink, J. Cost of the “Internet of Things”. Science 2019, 364, 347–349.

- Silva, J.S.; Zhang, P.; Pering, T.; Boavida, F.; Hara, T.; Liebau, N.C. People-centric Internet of Things. IEEE Commun. Mag. 2017, 55, 18–19.

- Siow, E.; Tiropanis, T.; Hall, W. Analytics for the Internet of Things. ACM Comput. Surv. 2018, 51, 1–36.

- Andreev, S.; Dobre, C.; Misra, P. The Internet of Things and sensor networks. IEEE Commun. Mag. 2019, 57, 64.

- Pikul, J.H.; Ning, H. Powering the Internet of Things. Joule 2018, 2, 1036–1038.

- Sisinni, E.; Saifullah, A.; Han, S.; Jennehag, U.; Gidlund, M. Industrial Internet of Things: Challenges, opportunities, and directions. IEEE Trans. Ind. Inform. 2018, 14, 4724–4734.

- Boyes, H.; Hallaq, B.; Cunningham, J.; Watson, T. The industrial internet of things (IIoT): An analysis framework. Comput. Ind. 2018, 101, 1–12.

- Zhang, X.; Ge, Z. Local parameter optimization of LSSVM for industrial soft sensing with Big Data and cloud implementation. IEEE Trans. Ind. Inform. 2020, 16, 2917–2928.

- Sengupta, J.; Ruj, S.; Bit, S.D. A secure fog-based architecture for industrial Internet of Things and Industry 4.0. IEEE Trans. Ind. Inform. 2021, 17, 2316–2324.

- Ojha, T.; Misra, S.; Raghuwanshi, N.S. Internet of things for agricultural applications: The state of the art. IEEE Internet Things J. 2021, 8, 10973–10997.

- Ruan, J.; Jiang, H.; Zhu, C.; Hu, X.; Shi, Y.; Liu, T.; Rao, W.; Chan, F.T.S. Agriculture IoT: Emerging trends, cooperation networks, and outlook. IEEE Wirel. Commun. 2019, 26, 56–63.

- Misra, N.N.; Dixit, Y.; Al-Mallahi, A.; Bhullar, M.S.; Upadhyay, R.; Martynenko, A. IoT, Big Data, and artificial intelligence in agriculture and food industry. IEEE Internet Things J. 2022, 9, 6305–6324.

- Zhu, Z.; Bai, Y.; Dai, W.; Liu, D.; Hu, Y. Quality of e-commerce agricultural products and the safety of the ecological environment of the origin based on 5G Internet of Things technology. Environ. Technol. Innov. 2021, 22, 101462.

- Zhu, F.; Lv, Y.; Chen, Y.; Wang, X.; Xiong, G.; Wang, F.-Y. Parallel transportation systems: Toward IoT-enabled smart urban traffic control and management. IEEE Trans. Intell. Transp. Syst. 2020, 21, 4063–4071.

- Kim, B.-S.; Kim, K.-I.; Shah, B.; Chow, F.; Kim, K.H. Wireless sensor networks for Big Data systems. Sensors 2019, 19, 1565.

- Dai, H.-N.; Zheng, Z.; Zhang, Y. Blockchain for Internet of Things: A Survey. IEEE Internet Things 2019, 6, 8076–8094.

- Yao, L.; Sheng, Q.Z.; Ngu, A.H.H.; Li, X. Things of interest recommendation by leveraging heterogeneous relations in the Internet of Things. ACM Trans. Internet Technol. 2016, 16, 1–25.

- Haight, R.; Haensch, W.; Friedman, D. Solar-powering the Internet of Things. Science 2016, 353, 124–125.

- Facchini, A. Distributed energy resources: Planning for the future. Nat. Energy 2017, 2, 17129.

- Hittinger, E.; Jaramillo, P. Internet of Things: Energy boon or bane? Science 2019, 364, 326–328.

- Zhang, H.; Li, Y.; Gao, D.W.; Zhou, J. Distributed optimal energy management for energy internet. IEEE Trans. Ind. Inform. 2017, 13, 3081–3097.

- Leicester, R.J.; Newman, V.G.; Wright, J.K. Renewable energy sources and storage. Nature 1978, 272, 518–521.

- Kammen, D.M.; Sunter, D.A. City-integrated renewable energy for urban sustainability. Science 2016, 352, 922–928.

- Chu, S.; Majumdar, A. Opportunities and challenges for a sustainable energy future. Nature 2012, 488, 294–303.

- Kittner, N.; Lill, F.; Kammen, D.M. Energy storage deployment and innovation for the clean energy transition. Nat. Energy 2017, 2, 17125.

- Mitchell, C. Momentum is increasing towards a flexible electricity system based on renewables. Nat. Energy 2016, 1, 15030.

- Bossink, B.A.G. Demonstrating sustainable energy: A review based model of sustainable energy demonstration projects. Renew. Sustain. Energy Rev. 2017, 77, 1349–1362.

- Kurt, E.; Gör, H.; Döner, U. Electromagnetic design of a new axial and radial flux generator with the rotor back-irons. Int. J. Hydrogen Energy 2016, 41, 7019–7026.

- Wang, X.; Pang, W.; Gao, P.; Zhao, X. Electromagnetic design and analysis of axial flux permanent magnet generator with unequal-width PCB winding. IEEE Access 2019, 7, 164696–164707.

- Wang, X.; Zhang, Y.; Xue, S.; Wang, T.; Fu, G.; Mao, X.; Lu, C. Bi-stable electromagnetic generator with asymmetrical potential wells for low frequency vibration energy harvesting. Mech. Syst. Signal Process. 2023, 199, 110478.

- Fan, F.-R.; Tian, Z.-Q.; Wang, Z.L. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334.

- Wang, Z.L. Triboelectric nanogenerators as new energy technology and self-powered sensors—Principles, problems and perspectives. Faraday Discuss. 2014, 176, 447–458.

- Cui, X.; Zhang, Y.; Hu, G.; Zhang, L.; Zhang, Y. Dynamical charge transfer model for high surface charge density triboelectric nanogenerators. Nano Energy 2020, 70, 104513.

- Liu, L.; Li, J.; Ou-Yang, W.; Guan, Z.; Hu, X.; Xie, M.; Tian, Z. Ferromagnetic-assisted Maxwell’s displacement current based on iron/polymer composite for improving the triboelectric nanogenerator output. Nano Energy 2022, 96, 107139.

- Zi, Y.; Guo, H.; Wen, Z.; Yeh, M.-H.; Hu, C.; Wang, Z.L. Harvesting low-frequency (<5 Hz) irregular mechanical energy: A possible killer application of triboelectric nanogenerator. ACS Nano 2016, 10, 4797–4805.

- Xing, F.; Jie, Y.; Cao, X.; Li, T.; Wang, N. Natural triboelectric nanogenerator based on soles for harvesting low-frequency walking energy. Nano Energy 2017, 42, 138–142.

- Zhang, D.; Shi, J.; Si, Y.; Li, T. Multi-grating triboelectric nanogenerator for harvesting low-frequency ocean wave energy. Nano Energy 2019, 61, 132–140.

- Fan, K.; Wei, D.; Zhang, Y.; Wang, P.; Tao, K.; Yang, R. A whirligig-inspired intermittent-contact triboelectric nanogenerator for efficient low-frequency vibration energy harvesting. Nano Energy 2021, 90, 106576.

- Wang, Z.; Liu, W.; He, W.; Guo, H.; Long, L.; Xi, Y.; Wang, X.; Liu, A.; Hu, C. Ultrahigh electricity generation from low-frequency mechanical energy by efficient energy management. Joule 2021, 5, 441–455.

- Barrows, S.E.; Homer, J.S.; Orrell, A.C. Valuing wind as a distributed energy resource: A literature review. Renew. Sustain. Energy Rev. 2021, 152, 111678.

- Zhang, L.; Meng, B.; Tian, Y.; Meng, X.; Lin, X.; He, Y.; Xing, C.; Dai, H.; Wang, L. Vortex-induced vibration triboelectric nanogenerator for low speed wind energy harvesting. Nano Energy 2022, 95, 107029.

- Cheng, B.; Qi, C.; Ding, Y.; Jia, X.; Bai, S.; Xu, Q.; Yu, Y.; Wen, J.; Qin, Y. High output performance flutter-driven triboelectric nanogenerator. Nano Energy 2023, 106, 108106.

- Ren, Z.; Wu, L.; Pang, Y.; Zhang, W.; Yang, R. Strategies for effectively harvesting wind energy based on triboelectric nanogenerators. Nano Energy 2022, 100, 107522.

- Hu, J.; Pu, X.; Yang, H.; Zeng, Q.; Tang, Q.; Zhang, D.; Hu, C.; Xi, Y. A flutter-effect-based triboelectric nanogenerator for breeze energy collection from arbitrary directions and self-powered wind speed sensor. Nano Res. 2019, 12, 3018–3023.

- Wang, Z.L. Catch wave power in floating nets. Nature 2017, 542, 159–160.

- Cheng, J.; Zhang, X.; Jia, T.; Wu, Q.; Dong, Y.; Wang, D. Triboelectric nanogenerator with a seesaw structure for harvesting ocean energy. Nano Energy 2022, 102, 107622.

- Ahn, J.; Kim, J.S.; Jeong, Y.; Hwang, S.; Yoo, H.; Jeong, Y.; Gu, J.; Mahato, M.; Ko, J.; Jeon, S.; et al. All-recyclable triboelectric nanogenerator for sustainable ocean monitoring systems. Adv. Energy Mater. 2022, 12, 2201341.

- Sun, W.; Zheng, Y.; Li, T.; Feng, M.; Cui, S.; Liu, Y.; Chen, S.; Wang, D. Liquid-solid triboelectric nanogenerators array and its applications for wave energy harvesting and self-powered cathodic protection. Energy 2021, 217, 119388.

- Xu, Q.; Shang, C.; Ma, H.; Hong, Q.; Li, C.; Ding, S.; Xue, L.; Sun, X.; Pan, Y.; Sugahara, T.; et al. A guided-liquid-based hybrid triboelectric nanogenerator for omnidirectional and high-performance ocean wave energy harvesting. Nano Energy 2023, 109, 108240.

- Dassanayaka, D.G.; Alves, T.M.; Wanasekara, N.D.; Dharmasena, I.G.; Ventura, J. Recent progresses in wearable triboelectric nanogenerators. Adv. Funct. Mater. 2022, 32, 2205438.

- Wang, H.; Han, M.; Song, Y.; Zhang, H. Design, manufacturing and applications of wearable triboelectric nanogenerators. Nano Energy 2021, 81, 105627.

- Xiao, X.; Chen, G.; Libanori, A.; Chen, J. Wearable triboelectric nanogenerators for therapeutics. Trends Chem. 2021, 3, 279–290.

- Mariello, M. Heart energy harvesting and cardiac bioelectronics: Technologies and perspectives. Nanoenergy Adv. 2022, 2, 344–385.

- Quan, Y.; Wu, X.; Zhu, S.; Zeng, X.; Zeng, Z.; Zheng, Q. Triboelectric nanogenerators for clinical diagnosis and therapy: A report of recent progress. Med. Nov. Technol. Devices 2022, 16, 100195.

- Naval, S.; Jain, A.; Mallick, D. Direct current triboelectric nanogenerators: A review. J. Micromech. Microeng. 2022, 33, 013001.

- Zhang, R.; Hummelgård, M.; Örtegren, J.; Olsen, M.; Andersson, H.; Olin, H. Interaction of the human body with triboelectric nanogenerators. Nano Energy 2019, 57, 279–292.

- Yu, B.; Yu, H.; Wang, H.; Zhang, Q.; Zhu, M. High-power triboelectric nanogenerator prepared from electrospun mats with spongy parenchyma-like structure. Nano Energy 2017, 34, 69–75.

- Thakur, V.N.; Han, J.I. Triboelectric nanogenerator for smart traffic monitoring and safety. J. Ind. Eng. Chem. 2023, 124, 89–101.

- Hu, Y.Q.; Wang, X.L.; Qin, Y.C.; Li, Z.H.; Wang, C.F.; Wu, H. A robust hybrid generator for harvesting vehicle suspension vibration energy from random road excitation. Appl. Energy 2022, 309, 118506.

- Zhong, W.; Xu, B.; Gao, Y. Engraved pattern spacer triboelectric nanogenerators for mechanical energy harvesting. Nano Energy 2022, 92, 106782.

- Cao, J.; Lin, Y.; Fu, X.; Wang, Z.; Liu, G.; Zhang, Z.; Qin, Y.; Zhou, H.; Dong, S.; Cheng, G.; et al. Self-powered overspeed wake-up alarm system based on triboelectric nanogenerators for intelligent transportation. Nano Energy 2023, 107, 108150.

- Pang, Y.; Zhu, X.; Jin, Y.; Yang, Z.; Liu, S.; Shen, L.; Li, X.; Lee, C. Textile-inspired triboelectric nanogenerator as intelligent pavement energy harvester and self-powered skid resistance sensor. Appl. Energy 2023, 348, 121515.

- Shi, Q.; Yang, J.; Gui, H.; Gui, Y.; Tang, C.; Yu, Y.; Zhao, Z. Self-powered circular-honeycomb triboelectric nanogenerator for vibration energy harvesting and resonance detection of synchronous machine. Sens. Actuators A Phys. 2023, 354, 114291.

- Yang, C.; Liu, G.; Wang, X.; Liu, B.; Xiao, L.; Wan, L.; Yao, H. Harvesting wide frequency micromechanical vibration energy and wind energy with a multi-mode triboelectric nanogenerator for traffic monitoring and warning. Adv. Mater. Technol. 2022, 8, 2200465.

- Chen, Y.; Zhang, H.; Xu, C.; Deng, L.; Yang, Q.; Zhang, H.; Xing, J.; Xie, L. Characteristic of solid-ferrofluid triboelectric nanogenerator for ultra-low-frequency vibration energy harvesting. Nano Energy 2023, 111, 108395.

- Tan, D.; Zhou, J.; Wang, K.; Zhang, C.; Li, Z.; Xu, D. Wearable bistable triboelectric nanogenerator for harvesting torsional vibration energy from human motion. Nano Energy 2023, 109, 108315.

- Qi, Y.; Liu, G.; Gao, Y.; Bu, T.; Zhang, X.; Xu, C.; Lin, Y.; Zhang, C. Frequency band characteristics of a triboelectric nanogenerator and ultra-wide-band vibrational energy harvesting. ACS Appl. Mater. Interfaces 2021, 13, 26084–26092.

- Zheng, Y.; Liu, T.; Wu, J.; Xu, T.; Wang, X.; Han, X.; Cui, H.; Xu, X.; Pan, C.; Li, X. Energy conversion analysis of multilayered triboelectric nanogenerators for synergistic rain and solar energy harvesting. Adv. Mater. 2022, 34, e2202238.

- Im, B.; Lee, S.-K.; Kang, G.; Moon, J.; Byun, D.; Cho, D.-H. Electrohydrodynamic jet printed silver-grid electrode for transparent raindrop energy-based triboelectric nanogenerator. Nano Energy 2022, 95, 107049.

- Cheng, B.; Niu, S.; Xu, Q.; Wen, J.; Bai, S.; Qin, Y. Gridding triboelectric nanogenerator for raindrop energy harvesting. ACS Appl. Mater. Interfaces 2021, 13, 59975–59982.

- Liu, X.; Yu, A.; Qin, A.; Zhai, J. Highly integrated triboelectric nanogenerator for efficiently harvesting raindrop energy. Adv. Mater. Technol. 2019, 4, 1900608.

- Zhang, Q.; Jiang, C.; Li, X.; Dai, S.; Ying, Y.; Ping, J. Highly efficient raindrop energy-based triboelectric nanogenerator for self-powered intelligent greenhouse. ACS Nano 2021, 15, 12314–12323.

- Cheng, B.; Xu, Q.; Ding, Y.; Bai, S.; Jia, X.; Yu, Y.; Wen, J.; Qin, Y. High performance temperature difference triboelectric nanogenerator. Nat. Commun. 2021, 12, 4782.

- Guo, W.; Long, Y.; Bai, Z.; Wang, X.; Liu, H.; Guo, Z.; Tan, S.; Guo, H.; Wang, Y.; Miao, Y. Variable stiffness triboelectric nano-generator to harvest high-speed railway bridge’s vibration energy. Energy Convers. Manag. 2022, 268, 115969.

- Li, X.; Zhang, D.; Zhang, D.; Li, Z.; Wu, H.; Zhou, Y.; Wang, B.; Guo, H.; Peng, Y. Solid-liquid triboelectric nanogenerator based on vortex-induced resonance. Nanomaterials 2023, 13, 1036.

- Huang, L.-b.; Xu, W.; Bai, G.; Wong, M.-C.; Yang, Z.; Hao, J. Wind energy and blue energy harvesting based on magnetic-assisted noncontact triboelectric nanogenerator. Nano Energy 2016, 30, 36–42.

- Zhang, Q.; Liang, Q.; Liao, Q.; Ma, M.; Gao, F.; Zhao, X.; Song, Y.; Song, L.; Xun, X.; Zhang, Y. An amphiphobic hydraulic triboelectric nanogenerator for a self-cleaning and self-charging power system. Adv. Funct. Mater. 2018, 28, 1803117.

- Li, Z.; Jiang, X.; Xu, W.; Gong, Y.; Peng, Y.; Zhong, S.; Xie, S. Performance comparison of electromagnetic generators based on different circular magnet arrangements. Energy 2022, 258, 124759.

- Cabrera-Tobar, A.; Bullich-Massagué, E.; Aragüés-Peñalba, M.; Gomis-Bellmunt, O. Review of advanced grid requirements for the integration of large scale photovoltaic power plants in the transmission system. Renew. Sustain. Energy Rev. 2016, 62, 971–987.

- Hu, C.J.; Lin, Y.H.; Tang, C.W.; Tsai, M.Y.; Hsu, W.K.; Kuo, H.F. ZnO-coated carbon nanotubes: Flexible piezoelectric generators. Adv. Mater. 2011, 23, 2941–2945.

- Wang, Z.L.; Wang, A.C. On the origin of contact-electrification. Mater. Today 2019, 30, 34–51.

- Zhang, Z.; Yin, N.; Wu, Z.; Pan, S.; Wang, D. Research methods of contact electrification: Theoretical simulation and experiment. Nano Energy 2021, 79, 105501.

- Shi, K.; Chai, B.; Zou, H.; Wen, Z.; He, M.; Chen, J.; Jiang, P.; Huang, X. Contact electrification at adhesive interface: Boosting charge transfer for high-performance triboelectric nanogenerators. Adv. Funct. Mater. 2023, 2307678.

- Wu, J.; Wang, X.; Li, H.; Wang, F.; Yang, W.; Hu, Y. Insights into the mechanism of metal-polymer contact electrification for triboelectric nanogenerator via first-principles investigations. Nano Energy 2018, 48, 607–616.

- Xu, W.; Zheng, H.; Liu, Y.; Zhou, X.; Zhang, C.; Song, Y.; Deng, X.; Leung, M.; Yang, Z.; Xu, R.X.; et al. A droplet-based electricity generator with high instantaneous power density. Nature 2020, 578, 392–396.

- Wu, H.; Wang, S.; Wang, Z.; Zi, Y. Achieving ultrahigh instantaneous power density of 10 MW/m2 by leveraging the opposite-charge-enhanced transistor-like triboelectric nanogenerator (OCT-TENG). Nat. Commun. 2021, 12, 5470.

- Cao, V.A.; Lee, S.; Kim, M.; Alam, M.M.; Park, P.; Nah, J. Output power density enhancement of triboelectric nanogenerators via ferroelectric polymer composite interfacial layers. Nano Energy 2020, 67, 104300.

- Kim, M.; Park, D.; Alam, M.M.; Lee, S.; Park, P.; Nah, J. Remarkable output power density enhancement of triboelectric nanogenerators via polarized ferroelectric polymers and bulk MoS2 composites. ACS Nano 2019, 13, 4640–4646.

- Yu, Y.; Li, H.; Zhao, D.; Gao, Q.; Li, X.; Wang, J.; Wang, Z.L.; Cheng, T. Material’s selection rules for high performance triboelectric nanogenerators. Mater. Today 2023, 64, 61–71.

- Zhou, Y.; Deng, W.; Xu, J.; Chen, J. Engineering materials at the nanoscale for triboelectric nanogenerators. Cell Rep. Phys. Sci. 2020, 1, 100142.

- Haider, Z.; Haleem, A.; Ahmad, R.u.S.; Farooq, U.; Shi, L.; Claver, U.P.; Memon, K.; Fareed, A.; Khan, I.; Mbogba, M.K.; et al. Highly porous polymer cryogel based tribopositive material for high performance triboelectric nanogenerators. Nano Energy 2020, 68, 104294.

- Candido, I.C.M.; Oliveira, G.d.S.; Ribeiro, S.J.L.; Cavicchioli, M.; Barud, H.S.; Silva, L.G.; de Oliveira, H.P. PVA-silk fibroin bio-based triboelectric nanogenerator. Nano Energy 2023, 105, 108035.

- Mao, R.; Zhang, D.; Wang, Z.; Zhang, H.; Wang, D.; Tang, M.; Zhou, L.; Cai, H.; Xia, H. Deep-learning-assisted low-cost flexible cotton yarn-based triboelectric nanogenerator for ultra-sensitive human-computer merging interfaces. Nano Energy 2023, 111, 108418.

- Fan, J.-C.; Tang, X.-G.; Sun, Q.-J.; Jiang, Y.-P.; Li, W.-H.; Liu, Q.-X. Low-cost composite film triboelectric nanogenerators for a self-powered touch sensor. Nanoscale 2023, 15, 6263–6272.

- Peng, F.; Liu, D.; Zhao, W.; Zheng, G.; Ji, Y.; Dai, K.; Mi, L.; Zhang, D.; Liu, C.; Shen, C. Facile fabrication of triboelectric nanogenerator based on low-cost thermoplastic polymeric fabrics for large-area energy harvesting and self-powered sensing. Nano Energy 2019, 65, 104068.

- Bukhari, M.U.; Khan, A.; Maqbool, K.Q.; Arshad, A.; Riaz, K.; Bermak, A. Waste to energy: Facile, low-cost and environment-friendly triboelectric nanogenerators using recycled plastic and electronic wastes for self-powered portable electronics. Energy Rep. 2022, 8, 1687–1695.

- Jiang, C.M.; Wu, C.; Li, X.J.; Yao, Y.; Lan, L.Y.; Zhao, F.N.; Ye, Z.Z.; Ying, Y.B.; Ping, J.F. All-electrospun flexible triboelectric nanogenerator based on metallic MXene nanosheets. Nano Energy 2019, 59, 268–276.

- Dharmasena, R.D.I.G.; Silva, S.R.P. Towards optimized triboelectric nanogenerators. Nano Energy 2019, 62, 530–549.

- Wang, Z.L.; Wu, W. Nanotechnology-enabled energy harvesting for self-powered micro-/nanosystems. Angew. Chem. 2012, 51, 11700–11721.

- Zhao, Z.; Lu, Y.; Mi, Y.; Meng, J.; Cao, X.; Wang, N. Structural flexibility in triboelectric nanogenerators: A review on the adaptive design for self-powered systems. Micromachines 2022, 13, 1586.

- Xia, X.; Wang, H.; Basset, P.; Zhu, Y.; Zi, Y. Inductor-free output multiplier for power promotion and management of triboelectric nanogenerators toward self-powered systems. ACS Appl. Mater. Interfaces 2020, 12, 5892–5900.

- Hurtado, C.; Lyu, X.; Ferrie, S.; Le Brun, A.P.; MacGregor, M.; Ciampi, S. Organic Monolayers on Si(211) for Triboelectricity Generation: Etching Optimization and Relationship between the Electrochemistry and Current Output. ACS Appl. Nano Mater. 2022, 5, 14263–14274.

- Chang, A.; Uy, C.; Xiao, X.; Xiao, X.; Chen, J. Self-powered environmental monitoring via a triboelectric nanogenerator. Nano Energy 2022, 98, 107282.

- Qin, Y.; Fu, X.; Lin, Y.; Wang, Z.; Cao, J.; Zhang, C. Self-powered Internet of Things sensing node based on triboelectric nanogenerator for sustainable environmental monitoring. Nano Res. 2023, 16, 11878–11884.

- Xia, K.; Xu, Z.; Hong, Y.; Wang, L. A free-floating structure triboelectric nanogenerator based on natural wool ball for offshore wind turbine environmental monitoring. Mater. Today Sustain. 2023, 24, 100467.

- Wang, D.; Zhang, D.; Tang, M.; Zhang, H.; Sun, T.; Yang, C.; Mao, R.; Li, K.; Wang, J. Ethylene chlorotrifluoroethylene/hydrogel-based liquid-solid triboelectric nanogenerator driven self-powered MXene-based sensor system for marine environmental monitoring. Nano Energy 2022, 100, 107509.

- Yang, Y.; Guo, X.; Zhu, M.; Sun, Z.; Zhang, Z.; He, T.; Lee, C. Triboelectric nanogenerator enabled wearable sensors and electronics for sustainable Internet of Things integrated green earth. Adv. Energy Mater. 2022, 13, 2203040.

- Sun, F.; Zhu, Y.; Jia, C.; Zhao, T.; Chu, L.; Mao, Y. Advances in self-powered sports monitoring sensors based on triboelectric nanogenerators. J. Energy Chem. 2023, 79, 477–488.

- Wang, T.; Shen, Y.; Chen, L.; Wang, K.; Niu, L.; Liu, G.; He, H.; Cong, H.; Jiang, G.; Zhang, Q.; et al. Large-scale production of the 3D warp knitted terry fabric triboelectric nanogenerators for motion monitoring and energy harvesting. Nano Energy 2023, 109, 108309.

- Zhao, Z.; Zhang, Z.; Xu, L.; Gao, F.; Zhao, B.; Kang, Z.; Liao, Q.; Zhang, Y. Tumbler-shaped hybrid triboelectric nanogenerators for amphibious self-powered environmental monitoring. Nano Energy 2020, 76, 104960.

- So, M.Y.; Xu, B.; Li, Z.; Lai, C.L.; Jiang, C. Flexible corrugated triboelectric nanogenerators for efficient biomechanical energy harvesting and human motion monitoring. Nano Energy 2023, 106, 108033.

- Zhou, Q.; Pan, J.; Deng, S.; Xia, F.; Kim, T. Triboelectric nanogenerator-based sensor systems for chemical or biological detection. Adv. Mater. 2021, 33, e2008276.

- Huang, L.; Shi, Y.; Ren, Y.; Yang, D.; Huang, F.; Liu, Z.; Chen, Y.; Li, H.; Chen, X.; Bian, Z. Sustainable electrochemical gold dissolution process based on triboelectric nanogenerator. Nano Energy 2023, 113, 108531.

- Jiang, Q.; Jie, Y.; Han, Y.; Gao, C.; Zhu, H.; Willander, M.; Zhang, X.; Cao, X. Self-powered electrochemical water treatment system for sterilization and algae removal using water wave energy. Nano Energy 2015, 18, 81–88.

- Su, Y.; Chen, G.; Chen, C.; Gong, Q.; Xie, G.; Yao, M.; Tai, H.; Jiang, Y.; Chen, J. Self-powered respiration monitoring enabled by a triboelectric nanogenerator. Adv. Mater. 2021, 33, e2101262.

- Li, X.; Jiang, C.; Zhao, F.; Lan, L.; Yao, Y.; Yu, Y.; Ping, J.; Ying, Y. Fully stretchable triboelectric nanogenerator for energy harvesting and self-powered sensing. Nano Energy 2019, 61, 78–85.

- Haghayegh, M.; Cao, R.; Zabihi, F.; Bagherzadeh, R.; Yang, S.; Zhu, M. Recent advances in stretchable, wearable and bio-compatible triboelectric nanogenerators. J. Mater. Chem. C 2022, 10, 11439–11471.

- Xi, Y.; Hua, J.; Shi, Y. Noncontact triboelectric nanogenerator for human motion monitoring and energy harvesting. Nano Energy 2020, 69, 104390.

- Che, Z.; O’Donovan, S.; Xiao, X.; Wan, X.; Chen, G.; Zhao, X.; Zhou, Y.; Yin, J.; Chen, J. Implantable Triboelectric Nanogenerators for Self-Powered Cardiovascular Healthcare. Small 2023, 2207600.

- Chen, C.; Wen, Z.; Shi, J.; Jian, X.; Li, P.; Yeow, J.T.W.; Sun, X. Micro triboelectric ultrasonic device for acoustic energy transfer and signal communication. Nat. Commun. 2020, 11, 4143.

- Wang, S.; Xu, P.; Wang, X.; Zheng, J.; Liu, X.; Liu, J.; Chen, T.; Wang, H.; Xie, G.; Tao, J.; et al. Underwater bionic whisker sensor based on triboelectric nanogenerator for passive vortex perception. Nano Energy 2022, 97, 107210.

- Shi, X.; Han, K.; Pang, Y.; Mai, W.; Luo, J. Triboelectric nanogenerators as self-powered sensors for biometric authentication. Nanoscale 2023, 15, 9635–9651.

- Wen, Z.; Fu, J.; Han, L.; Liu, Y.; Peng, M.; Zheng, L.; Zhu, Y.; Sun, X.; Zi, Y. Toward self-powered photodetection enabled by triboelectric nanogenerators. J. Mater. Chem. C 2018, 6, 11893–11902.

- Wang, Z.L. On the expanded Maxwell’s equations for moving charged media system—General theory, mathematical solutions and applications in TENG. Mater. Today 2022, 52, 348–363.

- Liu, X.; Zhang, M.; Yang, Z.; Wang, H.; Chen, J.; Wang, Z.; Lu, Y.; Chen, Y.; Ji, L.; Cheng, J. Alternating current electroluminescent device powered by triboelectric nanogenerator with capacitively driven circuit strategy. Adv. Funct. Mater. 2021, 32, 2106411.

- Song, Y.; Wang, N.; Wang, Y.; Zhang, R.; Olin, H.; Yang, Y. Direct current triboelectric nanogenerators. Adv. Energy Mater. 2020, 10, 2002756.

- Shan, C.; Li, K.; Cheng, Y.; Hu, C. Harvesting environment mechanical energy by direct current triboelectric nanogenerators. Nano-micro Lett. 2023, 15, 127.

- Shi, Q.; He, T.; Lee, C. More than energy harvesting—Combining triboelectric nanogenerator and flexible electronics technology for enabling novel micro-/nano-systems. Nano Energy 2019, 57, 851–871.

- Li, Z.B.; Li, H.Y.; Fan, Y.J.; Liu, L.; Chen, Y.H.; Zhang, C.; Zhu, G. Small-sized, lightweight, and flexible triboelectric nanogenerator enhanced by PTFE/PDMS nanocomposite electret. ACS Appl. Mater. Interfaces 2019, 11, 20370–20377.

- Wang, S.; Lin, L.; Wang, Z.L. Triboelectric nanogenerators as self-powered active sensors. Nano Energy 2015, 11, 436–462.

- Zhang, C.; Zhou, T.; Tang, W.; Han, C.; Zhang, L.; Wang, Z.L. Rotating-disk-based direct-current triboelectric nanogenerator. Adv. Energy Mater. 2014, 4, 1301798.

- Wang, J.; Wu, Z.; Pan, L.; Gao, R.; Zhang, B.; Yang, L.; Guo, H.; Liao, R.; Wang, Z.L. Direct-current rotary-tubular triboelectric nanogenerators based on liquid-dielectrics contact for sustainable energy harvesting and chemical composition analysis. ACS Nano 2019, 13, 2587–2598.

- Qiao, G.; Wang, J.; Yu, X.; Jia, R.; Cheng, T.; Wang, Z.L. A bidirectional direct current triboelectric nanogenerator with the mechanical rectifier. Nano Energy 2021, 79, 105408.

- Fu, S.; He, W.; Wu, H.; Shan, C.; Du, Y.; Li, G.; Wang, P.; Guo, H.; Chen, J.; Hu, C. High output performance and ultra-durable DC output for triboelectric nanogenerator inspired by primary cell. Nano-Micro Lett. 2022, 14, 155.

- Du, Y.; Fu, S.; Shan, C.; Wu, H.; He, W.; Wang, J.; Guo, H.; Li, G.; Wang, Z.; Hu, C. A novel design based on mechanical time-delay switch and charge space accumulation for high output performance direct-current triboelectric nanogenerator. Adv. Funct. Mater. 2022, 32, 2208783.

- Ryu, H.; Lee, J.H.; Khan, U.; Kwak, S.S.; Hinchet, R.; Kim, S.-W. Sustainable direct current powering a triboelectric nanogenerator via a novel asymmetrical design. Energy Environ. Sci. 2018, 11, 2057–2063.

- Dharmasena, R.D.I.G.; Cronin, H.M.; Dorey, R.A.; Silva, S.R.P. Direct current contact-mode triboelectric nanogenerators via systematic phase shifting. Nano Energy 2020, 75, 104887.

- Wang, J.; Li, Y.; Xie, Z.; Xu, Y.; Zhou, J.; Cheng, T.; Zhao, H.; Wang, Z.L. Cylindrical direct-current triboelectric nanogenerator with constant output current. Adv. Energy Mater. 2020, 10, 1904227.

- Hu, Y.; Li, X.; Zhao, Z.; Zhang, C.; Zhou, L.; Li, Y.; Liu, Y.; Wang, J.; Wang, Z.L. Triboelectric nanogenerator with low crest factor via precise phase difference design realized by 3D printing. Small Methods 2021, 5, e2100936.

- Li, X.; Zhang, C.; Gao, Y.; Zhao, Z.; Hu, Y.; Yang, O.; Liu, L.; Zhou, L.; Wang, J.; Wang, Z.L. A highly efficient constant-voltage triboelectric nanogenerator. Energy Environ. Sci. 2022, 15, 1334–1345.

- Yang, Y.; Zhang, H.; Wang, Z.L. Direct-current triboelectric generator. Adv. Funct. Mater. 2014, 24, 3745–3750.

- Chen, C.; Guo, H.; Chen, L.; Wang, Y.-C.; Pu, X.; Yu, W.; Wang, F.; Du, Z.; Wang, Z.L. Direct current fabric triboelectric nanogenerator for biomotion energy harvesting. ACS Nano 2020, 14, 4585–4594.

- Li, G.; Wu, S.; Sha, Z.; Zhou, Y.; Wang, C.-H.; Peng, S. Dual-breakdown direct-current triboelectric nanogenerator with synergistically enhanced performance. Nano Energy 2022, 99, 107355.

- Liu, D.; Yin, X.; Guo, H.; Zhou, L.; Li, X.; Zhang, C.; Wang, J.; Wang, Z.L. A constant current triboelectric nanogenerator arising from electrostatic breakdown. Sci. Adv. 2019, 5, eaav6437.

- Zhao, Z.; Dai, Y.; Liu, D.; Zhou, L.; Li, S.; Wang, Z.L.; Wang, J. Rationally patterned electrode of direct-current triboelectric nanogenerators for ultrahigh effective surface charge density. Nat. Commun. 2020, 11, 6186.

- Gao, Y.; Liu, D.; Zhou, L.; Li, S.; Zhao, Z.; Yin, X.; Chen, S.; Wang, Z.L.; Wang, J. A robust rolling-mode direct-current triboelectric nanogenerator arising from electrostatic breakdown effect. Nano Energy 2021, 85, 106014.

- Chen, J.; Gong, S.; Gong, T.; Yang, X.; Guo, H. Stackable direct current triboelectric-electromagnetic hybrid nanogenerator for self-powered air purification and quality monitoring. Adv. Energy Mater. 2023, 13, 2203689.

- Mariello, M. Recent advances on hybrid piezo-triboelectric bio-nanogenerators: Materials, architectures and circuitry. Nanoenergy Adv. 2022, 2, 64–109.

- Zhang, Y.; Zeng, Q.; Wu, Y.; Wu, J.; Yuan, S.; Tan, D.; Hu, C.; Wang, X. An ultra-durable windmill-like hybrid nanogenerator for steady and efficient harvesting of low-speed wind energy. Nano-Micro Lett. 2020, 12, 175.

- Zhang, J.-H.; Zhou, Z.; Li, J.; Shen, B.; Zhu, T.; Gao, X.; Tao, R.; Guo, X.; Hu, X.; Shi, Y.; et al. Coupling enhanced performance of triboelectric–piezoelectric hybrid nanogenerator based on nanoporous film of poly(vinylidene fluoride)/BaTiO3 composite electrospun fibers. ACS Mater. Lett. 2022, 4, 847–852.

- Lin, S.; Lin Wang, Z. The tribovoltaic effect. Mater. Today 2023, 62, 111–128.

- Xu, R.; Zhang, Q.; Wang, J.Y.; Liu, D.; Wang, J.; Wang, Z.L. Direct current triboelectric cell by sliding an n–type semiconductor on a p–type semiconductor. Nano Energy 2019, 66, 104185.

- Chen, Y.; Zhang, Z.; Wang, Z.; Bu, T.; Dong, S.; Wei, W.; Chen, Z.; Lin, Y.; Lv, Y.; Zhou, H.; et al. Friction-dominated carrier excitation and transport mechanism for GaN-based direct-current triboelectric nanogenerators. ACS Appl. Mater. Interfaces 2022, 14, 24020–24027.

- Wang, Z.; Zhang, Z.; Chen, Y.; Gong, L.; Dong, S.; Zhou, H.; Lin, Y.; Lv, Y.; Liu, G.; Zhang, C. Achieving an ultrahigh direct-current voltage of 130 V by semiconductor heterojunction power generation based on the tribovoltaic effect. Energy Environ. Sci. 2022, 15, 2366–2373.

- Zhang, Z.; Wang, Z.; Chen, Y.; Feng, Y.; Dong, S.; Zhou, H.; Wang, Z.L.; Zhang, C. Semiconductor contact-electrification-dominated tribovoltaic effect for ultrahigh power generation. Adv. Mater. 2022, 34, e2200146.

- Lee, Y.-S.; Jeon, S.; Kim, D.; Lee, D.-M.; Kim, D.; Kim, S.-W. High performance direct current-generating triboelectric nanogenerators based on tribovoltaic p-n junction with ChCl-passivated CsFAMA perovskite. Nano Energy 2023, 106, 108066.

- Zhang, Z.; Jiang, D.; Zhao, J.; Liu, G.; Bu, T.; Zhang, C.; Wang, Z.L. Tribovoltaic effect on metal–semiconductor interface for direct-current low-impedance triboelectric nanogenerators. Adv. Energy Mater. 2020, 10, 1903713.

- Meng, J.; Guo, Z.H.; Pan, C.; Wang, L.; Chang, C.; Li, L.; Pu, X.; Wang, Z.L. Flexible textile direct-current generator based on the tribovoltaic effect at dynamic metal-semiconducting polymer interfaces. ACS Energy Lett. 2021, 6, 2442–2450.

- Huang, X.; Xiang, X.; Nie, J.; Peng, D.; Yang, F.; Wu, Z.; Jiang, H.; Xu, Z.; Zheng, Q. Microscale Schottky superlubric generator with high direct-current density and ultralong life. Nat. Commun. 2021, 12, 2268.

- Yuan, H.; Xiao, Z.; Wan, J.; Xiang, Y.; Dai, G.; Li, H.; Yang, J. A rolling-mode Al/CsPbBr3 Schottky junction direct-current triboelectric nanogenerator for harvesting mechanical and solar energy. Adv. Energy Mater. 2022, 12, 2200550.

- Liu, J.; Miao, M.; Jiang, K.; Khan, F.; Goswami, A.; McGee, R.; Li, Z.; Nguyen, L.; Hu, Z.; Lee, J.; et al. Sustained electron tunneling at unbiased metal-insulator-semiconductor triboelectric contacts. Nano Energy 2018, 48, 320–326.

- Liu, J.; Cheikh, M.I.; Bao, R.; Peng, H.; Liu, F.; Li, Z.; Jiang, K.; Chen, J.; Thundat, T. Tribo-tunneling DC generator with carbon aerogel/silicon multi-nanocontacts. Adv. Electron. Mater. 2019, 5, 1900464.

- Liu, J.; Liu, F.; Bao, R.; Jiang, K.; Khan, F.; Li, Z.; Peng, H.; Chen, J.; Alodhayb, A.; Thundat, T. Scaled-up direct-current generation in MoS2 multilayer-based moving heterojunctions. ACS Appl. Mater. Interfaces 2019, 11, 35404–35409.

- Zhang, L.; Shalabny, A.; Su, C.; Cui, X.; Sweedan, A.; Zhang, K.; Harilal, S.; Sadhujan, S.; Bashouti, M.Y. Dynamic molecular tunnel junctions based on self-assembled monolayers for high tunneling current triboelectricity generation. J. Mater. Chem. A 2023, 11, 4946–4956.

- Lin, S.; Chen, X.; Wang, Z.L. The tribovoltaic effect and electron transfer at a liquid-semiconductor interface. Nano Energy 2020, 76, 105070.

- Zheng, M.; Lin, S.; Zhu, L.; Tang, Z.; Wang, Z.L. Effects of temperature on the tribovoltaic effect at liquid-solid interfaces. Adv. Mater. Interfaces 2021, 9, 2101757.

- Zhang, R.; Wang, S.; Yeh, M.-H.; Pan, C.; Lin, L.; Yu, R.; Zhang, Y.; Zheng, L.; Jiao, Z.; Wang, Z.L. A streaming potential/current-based microfluidic direct current generator for self-powered nanosystems. Adv. Mater. 2015, 27, 6482–6487.

- Dong, J.; Xu, C.; Zhu, L.; Zhao, X.; Zhou, H.; Liu, H.; Xu, G.; Wang, G.; Zhou, G.; Zeng, Q.; et al. A high voltage direct current droplet-based electricity generator inspired by thunderbolts. Nano Energy 2021, 90, 106567.

- Chi, J.; Liu, C.; Che, L.; Li, D.; Fan, K.; Li, Q.; Yang, W.; Dong, L.; Wang, G.; Wang, Z.L. Harvesting Water-Evaporation-Induced Electricity Based on Liquid-Solid Triboelectric Nanogenerator. Adv. Sci. 2022, 9, e2201586.

- Li, X.; Li, S.; Guo, X.; Shao, J.; Wang, Z.L.; Wei, D. Triboiontronics for efficient energy and information flow. Matter 2023, 6, 1–15.

- Ouyang, Y.; Li, X.; Peng, P.; Yang, F.; Wang, Z.L.; Wei, D. Opto-iontronic coupling in triboelectric nanogenerator. Nano Energy 2023, 116, 108796.

- Kim, T.; Kim, D.Y.; Yun, J.; Kim, B.; Lee, S.H.; Kim, D.; Lee, S. Direct-current triboelectric nanogenerator via water electrification and phase control. Nano Energy 2018, 52, 95–104.

- Yu, X.; Zheng, H.; Lu, Y.; Shen, R.; Yan, Y.; Hao, Z.; Yang, Y.; Lin, S. Wind driven semiconductor electricity generator with high direct current output based on a dynamic Schottky junction. RSC Adv. 2021, 11, 19106–19112.

- Tao, K.; Zhao, Z.; Mao, X.; Shen, W.; Qiu, C.; Qi, H.; Ye, T.; Zhang, X.; Wu, J.; Fan, K.; et al. Direct-current, long-lasting and highly efficient electret energy harvesting from ultra-low-frequency motions using toothed clutch mechanism. Nano Energy 2023, 105, 107998.

- Chen, P.; An, J.; Cheng, R.; Shu, S.; Berbille, A.; Jiang, T.; Wang, Z.L. Rationally segmented triboelectric nanogenerator with a constant direct-current output and low crest factor. Energy Environ. Sci. 2021, 14, 4523–4532.

- Li, S.; Liu, D.; Zhao, Z.; Zhou, L.; Yin, X.; Li, X.; Gao, Y.; Zhang, C.; Zhang, Q.; Wang, J.; et al. A fully self-powered vibration monitoring system driven by dual-mode triboelectric nanogenerators. ACS Nano 2020, 14, 2475–2482.

- Li, S.; Zhao, Z.; Liu, D.; An, J.; Gao, Y.; Zhou, L.; Li, Y.; Cui, S.; Wang, J.; Wang, Z.L. A self-powered dual–type signal vector sensor for smart robotics and automatic vehicles. Adv. Mater. 2022, 34, e2110363.

- Wang, Y.; Huang, T.; Gao, Q.; Li, J.; Wen, J.; Wang, Z.L.; Cheng, T. High-voltage output triboelectric nanogenerator with DC/AC optimal combination method. Nano Res. 2021, 15, 3239–3245.

- Yu, J.R.; Yang, X.X.; Gao, G.Y.; Xiong, Y.; Wang, Y.F.; Han, J.; Chen, Y.H.; Zhang, H.; Sun, Q.J.; Wang, Z.L. Bioinspired mechano-photonic artificial synapse based on graphene/MoS2 heterostructure. Sci. Adv. 2021, 7, eabd9117.

- Qiao, W.; Zhao, Z.; Zhou, L.; Liu, D.; Li, S.; Yang, P.; Li, X.; Liu, J.; Wang, J.; Wang, Z.L. Simultaneously enhancing direct-current density and lifetime of tribovotaic nanogenerator via interface lubrication. Adv. Funct. Mater. 2022, 32, 2208544.