With the global energy shortages, sustainable energy scavenging from the natural environment is desperately needed. Unlike solar cell or wind power, which depends heavily on weather conditions, triboelectric nanogenerator (TENG) has received extensive attention as an efficient all–weather energy–harvesting technology. Based on the coupling principle of contact electrification (CE) and electrostatic induction, conventional TENGs convert mechanical energy into an alternating current (AC) output. However, the typically distributed sensor systems in the ubiquitous Internet of Things (IoTs) request a direct current (DC) input. Direct current triboelectric nanogenerators (DC-TENGs) with the constant output characteristic are critical to satisfy the above requirements.

- direct current triboelectric nanogenerator

- dielectric material

- semiconductor material

1. Introduction

2. DC-TENGs Based on Different Types of Materials

2.1. Operating Mechanism of TENG

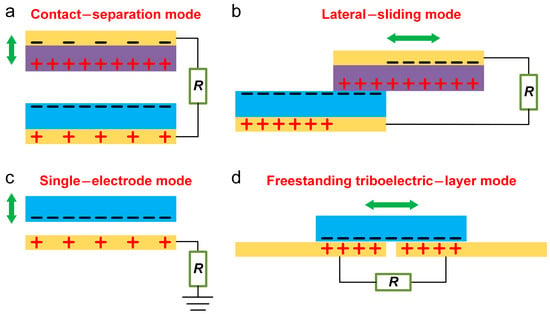

When the surfaces of two dissimilar materials were separated by mechanical force, the electrostatic charges generated by their physical contact could generate a potential drop. It could drive electrons to flow between the two electrodes on the top and bottom surfaces of the two materials. TENGs based on the above theory have four basic modes [167][142]: the contact–separation mode, the lateral–sliding mode, the single–electrode mode, and the freestanding triboelectric–layer mode, as elaborated in Figure 21a–d, respectively. Generally speaking, physical contact between the two dielectric films creates oppositely charged surfaces. During the regular relative motion between dielectric layers and electrodes, electrons are driven to continuously transfer alternately between the electrode and electrode or electrode and earth to form the AC output. To avoid the energy dissipation caused by the rectifier bridge and improve the practicality of TENG as a flexible energy–harvesting and self–powered sensing device, DC-TENGs based on different mechanisms with various materials properties were developed.

2.2. DC-TENGs Based on Dielectric Materials

2.2.1. Mechanical Rectification

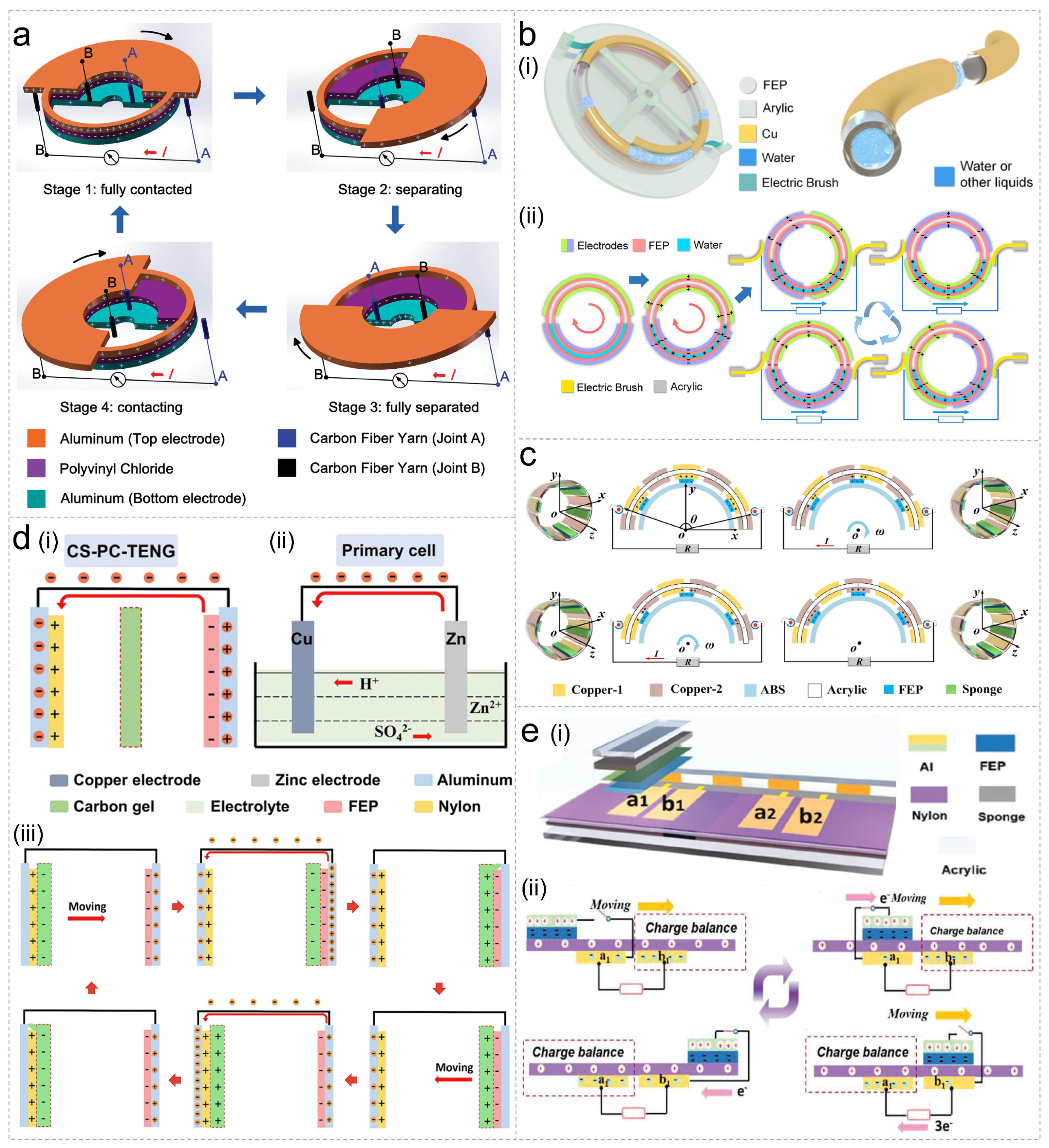

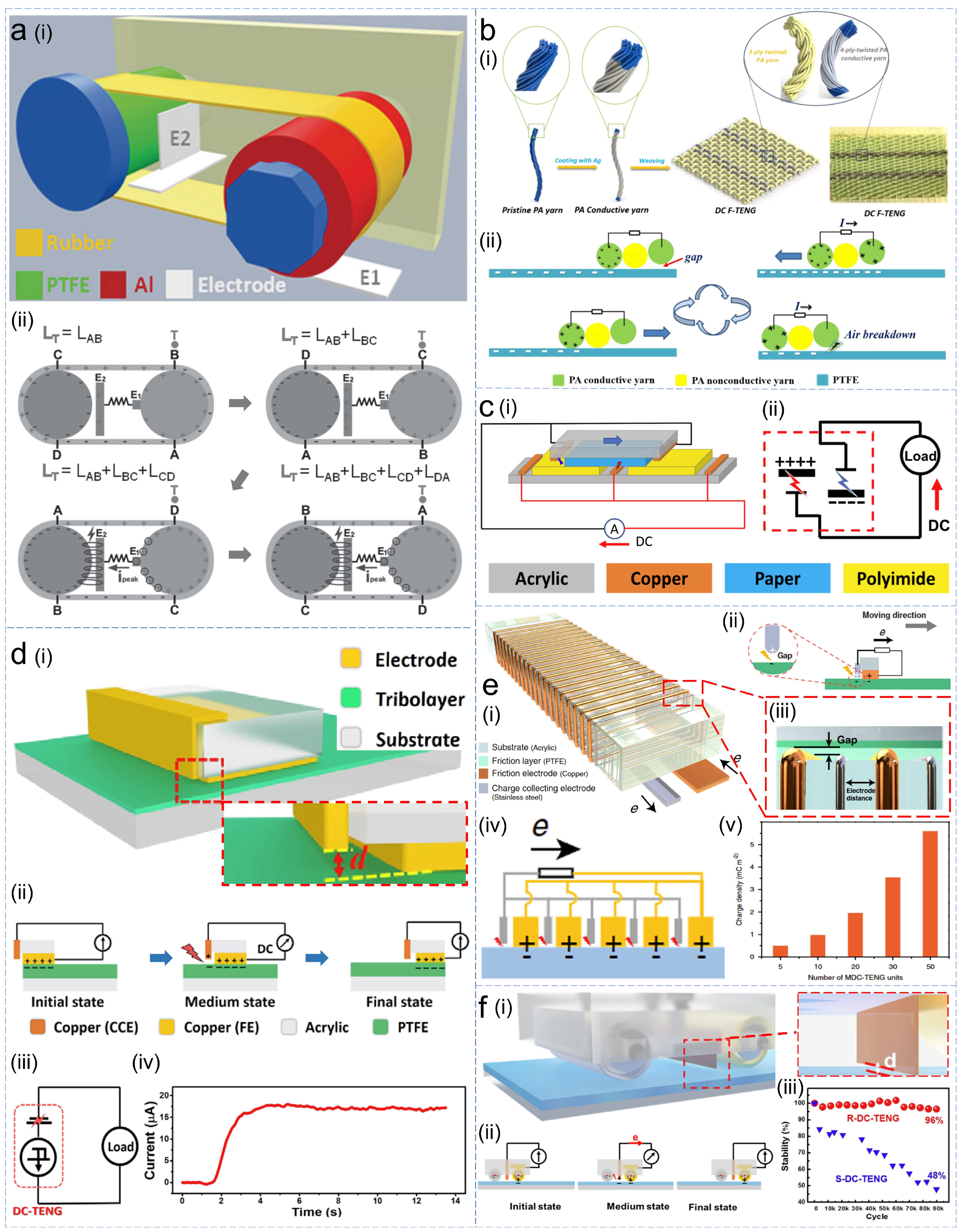

DC-TENGs based on dielectric materials can be obtained by the current commutation units, in which the alternating contact with the electrode is ensured to realize the mechanical rectification. It is equivalent to continuously exchanging the position between two electrodes as the direction of electron flow changes, ensuring the unidirectional flow of charge carriers between the two current commutation units. In 2014, a rotating–disk–based DC-TENG [166][143] was reported by Zhang et al. shown in Figure 32a, in which two pairs of parallel flexible electric brushes were designed as the current commutation units. During the operation of the DC-TENG, as the top friction electrode (aluminum, Al) continued to rotate, it constantly contacted and separated from the dielectric layer (polyvinyl chloride, PVC), driving electrons to alternately transfer between the top friction electrode and the bottom charge–collecting electrode (Al) to generate AC output. In the second half cycle of the generated AC signal, the contact relationship between the two pairs of electric brushes and the electrodes was exchanged. So the current direction between the two electric brushes was converted to the same direction as the first half cycle to generate the DC output. The peak power density of the DC-TENG reached 25 mW/m2 at the rotating speed of 750 r/min. In the kind of DC-TENG with the electric brush as the commutation unit, the friction and wear between brush and electrode is an important factor affecting the stability of device operation. To deal with this problem, the carbon fiber material was selected to make the flexible electric brush in the rotating–disk–based DC-TENG. Converting the fixed sliding friction between electric brushes and electrodes to free sliding friction was another effective way to reduce friction and wear, as rotary–tubular DC-TENG was reported by Wang et al. in 2019 [168][144]. Its prototype structure was mainly composed of a fluorinated ethylene propylene (FEP) ring tube and copper (Cu) charge–collecting electrodes as shown in Figure 32b(i). When the DC-TENG started to operate, the pre–filled liquid was in full contact with the tube, and the negative charge in the liquid was transferred to the inner surface of the tube. As the device continued to rotate, Cu electric brushes fixed on both sides of the tube alternately swept across the surface of charge–collecting electrodes to ensure that the current direction between brushes remained unchanged, forming the DC output [Figure 32b(ii)]. In this DC-TENG, not only the free sliding mode was used to effectively reduce the friction and wear between the electric brushes and the charge–collecting electrodes, but also the use of liquid friction materials could completely avoid faster friction and wear between solid materials. Furthermore, in terms of friction reduction, rolling friction is undoubtedly better than sliding friction. In 2021, Qiao et al. reported a bidirectional DC-TENG [169][145] (Figure 32c), in which the rolling electric brushes were used as the current commutation units. During the operation of DC-TENG, the electric brushes alternately rolled through the friction electrode surfaces, which made the equipment produce DC output and effectively reduce friction and wear between the electric brushes and friction electrode to improve durability. In addition, the FEP dielectric layer was designed to the arched structure, which allowed the DC-TENG can harvest efficiently bidirectional rotating mechanical energy. At the rotation speed of 180 r/min, it could obtain a peak output power of 0.96 W/m2.

2.2.2. Phase Coupling

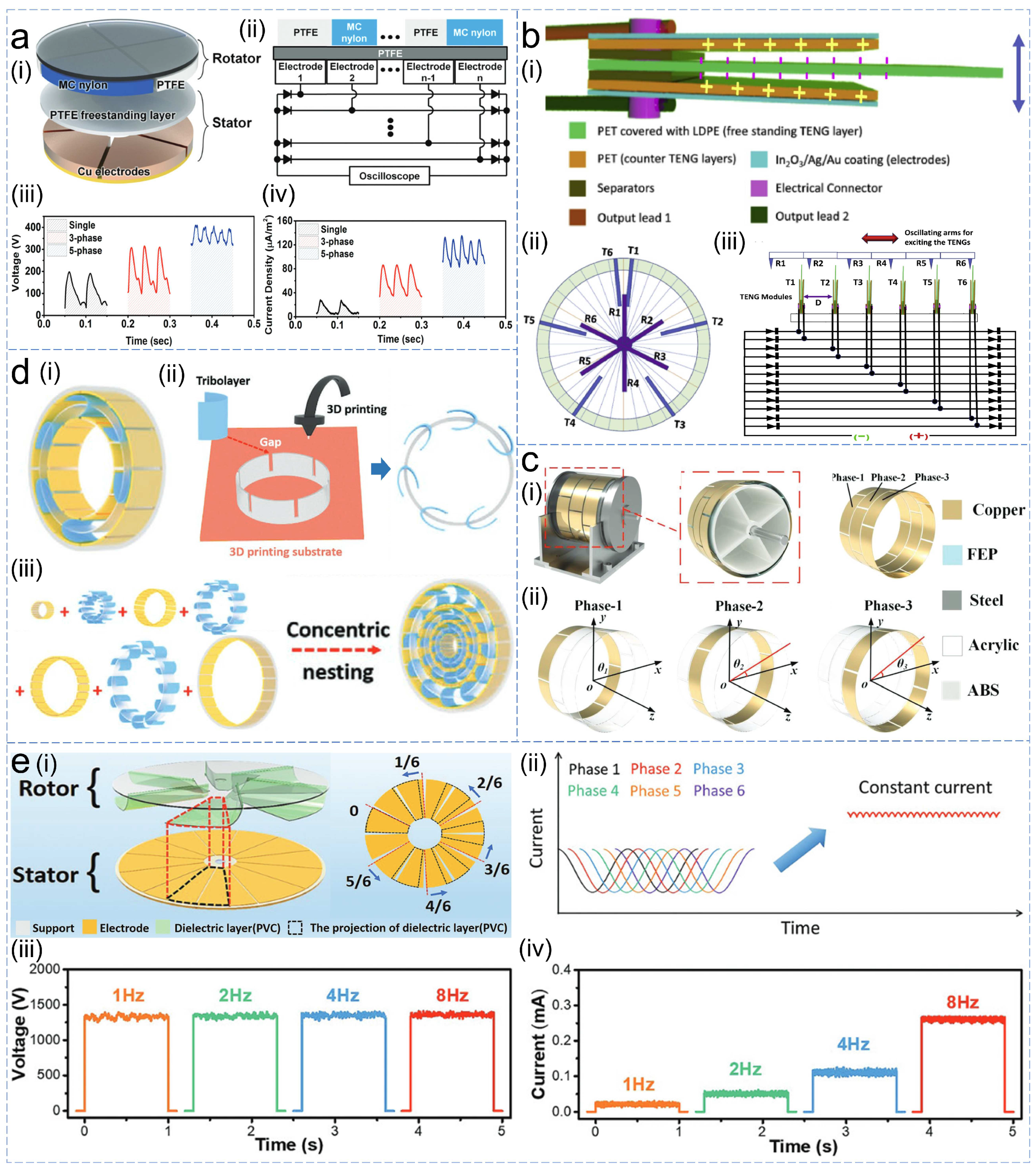

Although DC-TENGs from mechanical rectification could generate DC output without the assistance of the rectifier bridge, the current signals were generally pulsed with a high crest factor, which cannot constantly power electronics. To further reduce the crest factor of the DC signal and enable the device to achieve more stable output, the principle of phase coupling began to be explored. Ryu et al. invented a multiphase rotating DC-TENG in 2018 [145][148] [Figure 43a(i)], in which the rotator was made of alternating polytetrafluoroethylene (PTFE) and nylon dielectric layers, and the stator was composed of PTFE dielectric layers and charge–collecting electrodes on its lower surface. In the physical structure of DC-TENG, by adjusting the quantitative relationship between the dielectric layers in the rotor and the charge–collecting electrodes in the stator, a regular phase difference was constructed between them. The charge–collecting electrodes were connected according to the equivalent rectifier circuit shown in Figure 43a(ii). During the operation of the DC-TENG, as the rotor continued to rotate, each charge–collecting electrode generated a similar AC signal with the regular phase difference. These AC signals were converted into constant DC signals by the equivalent rectifier circuit, including the constant open–circuit voltage and constant short–circuit current, as shown in Figure 43a(iii,iv). Experiments showed that with the increase in the number of phases, the output was more stable, and the crest factor was closer to 1. When the phase number was 5, the current crest factor of the multiphase rotating DC-TENG was 1.26. In addition to the sliding mode DC-TENG from phase coupling, the constant output could also be achieved by using multiple contact–separation mode TENGs, as Dharmasena et al. developed the DC-TENG in 2020 [172][149] [Figure 43b(i)]. In the DC-TENG, multiple contact–separated TENGs were installed in the device shell according to the regular angle difference [Figure 43b(ii)], and they were connected to the equivalent rectifier circuit in the way shown in Figure 43b(iii). Each contact–separated TENGs could generate similar AC electrical signals with regular phase differences when they were sequentially excited, which was finally converted into a constant output by the equivalent rectifier circuit. After testing, the current crest factor of this contact-mode DC-TENG with six phases was 1.08 at an oscillation frequency of 5 Hz.

2.2.3. Dielectric Breakdown

In addition to mechanical rectification and phase coupling, DC-TENG based on dielectric materials could also achieve constant DC output in a much simpler structure by the introduction of the electrostatic breakdown effect. In terms of pulsed DC output, Yang et al. developed a rotating DC-TENG based on the dielectric breakdown effect in 2014 [148][153], which consisted of two rotating wheels connected by a rubber belt [Figure 54a(i)]. Its operating mechanism was shown in Figure 54a(ii). During the DC-TENG operation, electrons on the surface of Al wheels were first transferred to the inner surface of the belt and then to the surface of PTFE wheels due to the difference in material electronegativity. The charge–collecting electrode surface continuously accumulated positive charges thanks to the electrostatic induction effect. When the electrostatic potential between charge–collecting electrode and the PTFE wheel reached the breakdown voltage, the air medium was broken down to produce pulse discharge, which would drive electrons from the charge–collecting electrode to the friction electrode, resulting in a DC pulse signal. It could generate an open–circuit voltage of approximately 3200 V at the rotation speed of 1000 r/min, so the DC-TENG from the dielectric breakdown was an important means to produce a high voltage output. In addition to rigid physical devices, DC-TENG from dielectric breakdown could also operate normally when it was made into wearable fabrics as a flexible energy–harvesting device. In 2020, Chen et al. developed a fabric DC-TENG [176][154], which used flexible conductive yarn to generate the dielectric breakdown effect to harvest biological motion energy [Figure 54b(i)]. As demonstrated in Figure 54b(ii), when the fabric slid forward on the PTFE dielectric surface, the left yarn as the friction electrode contacted the dielectric layer and transferred electrons to the dielectric layer surface. Then, the fabric moved in the opposite direction, based on the electrostatic induction effect, and the right yarn as the charge–collecting electrode continued to accumulate positive charges on the surface. When the electrostatic breakdown occurred between the charge–collecting electrode and the dielectric layer, the breakdown current drove electrons to flow unidirectionally between the friction electrode and the charge–collecting electrode to generate the DC pulse output. A small fabric DC-TENG (15 mm × 35 mm) could generate an open–circuit voltage of 4500 V, which was enough to light more than 400 light–emitting diodes (LEDs). The rapid accumulation of charge density on the surface of the charge–collecting electrode was an important factor in the dielectric breakdown effect. Compared with the CE between metal and dielectric materials, there was no doubt that the two dielectric materials with greater electronegativity difference have more electron transfer and faster potential difference growth during contact. So, Li et al. developed a dual–breakdown DC-TENG in 2022 [177][155], which uses dielectric materials with different electronegativity as friction materials shown in Figure 54c(i). As shown in the equivalent circuit of Figure 54c(ii), the DC-TENG consisted of two dielectric materials as charge sources and corresponding charge–collecting electrodes. When the two dielectric layers contacted each other, based on the difference in material electronegativity, an equal amount of different electric charges was generated on their contact surfaces. When they were separated from each other, electrostatic breakdown effects were generated between them and the corresponding charge–collecting electrodes to exert a synergistic enhancement effect. It led to the unidirectional flow of electrons in the external circuit between the two charge–collecting electrodes, resulting in a synergistic pulsed DC output.

2.3. DC-TENGs Based on Semiconductor Materials

In DC-TENGs based on dielectric materials, the insulation characteristics of the dielectric layer caused higher internal resistance, which would reduce the short–circuit current density and its energy supply for electronic devices. To effectively improve the current density of the DC-TENGs, they could be combined with the electromagnetic or piezoelectric nanogenerator. However, such hybrid nanogenerators [181,182,183,184][159][160][161][162] inevitably led to the complexity of the device structure and affected its robustness. In particular when the internal resistance between different types of generators was not in the same order of magnitude, it resulted in unsatisfactory output performance. To effectively reduce the internal resistance of TENG to increase the output current, DC-TENG based on semiconductor materials had been developed. The DC output was realized based on the tribovoltaic effect between different types of friction materials, which was mainly divided into four types—semiconductor–semiconductor contact, metal–semiconductor contact, metal/semiconductor–insulator–metal/semiconductor contact, and liquid–semiconductor contact.2.3.1. Semiconductor–Semiconductor Contact

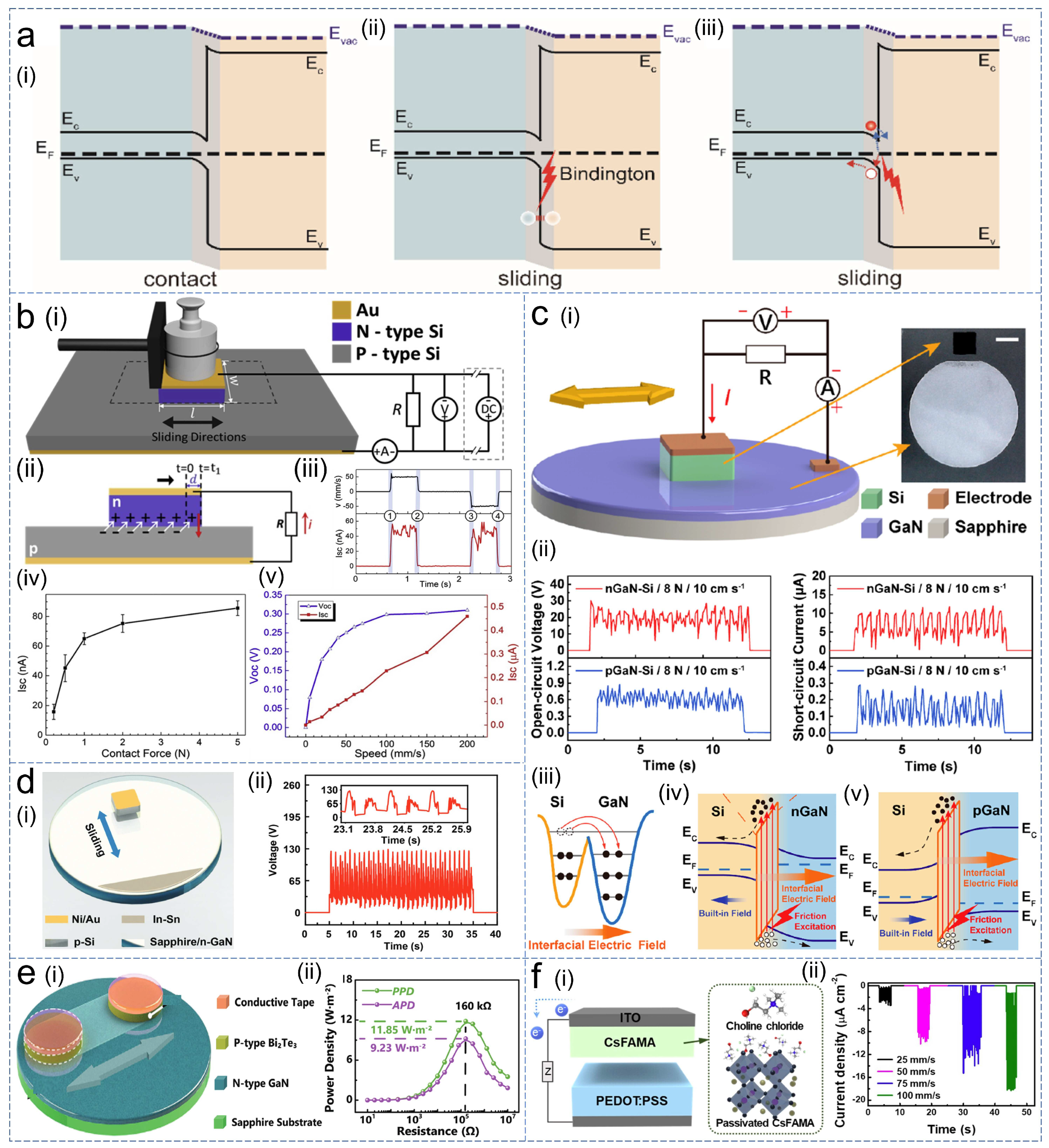

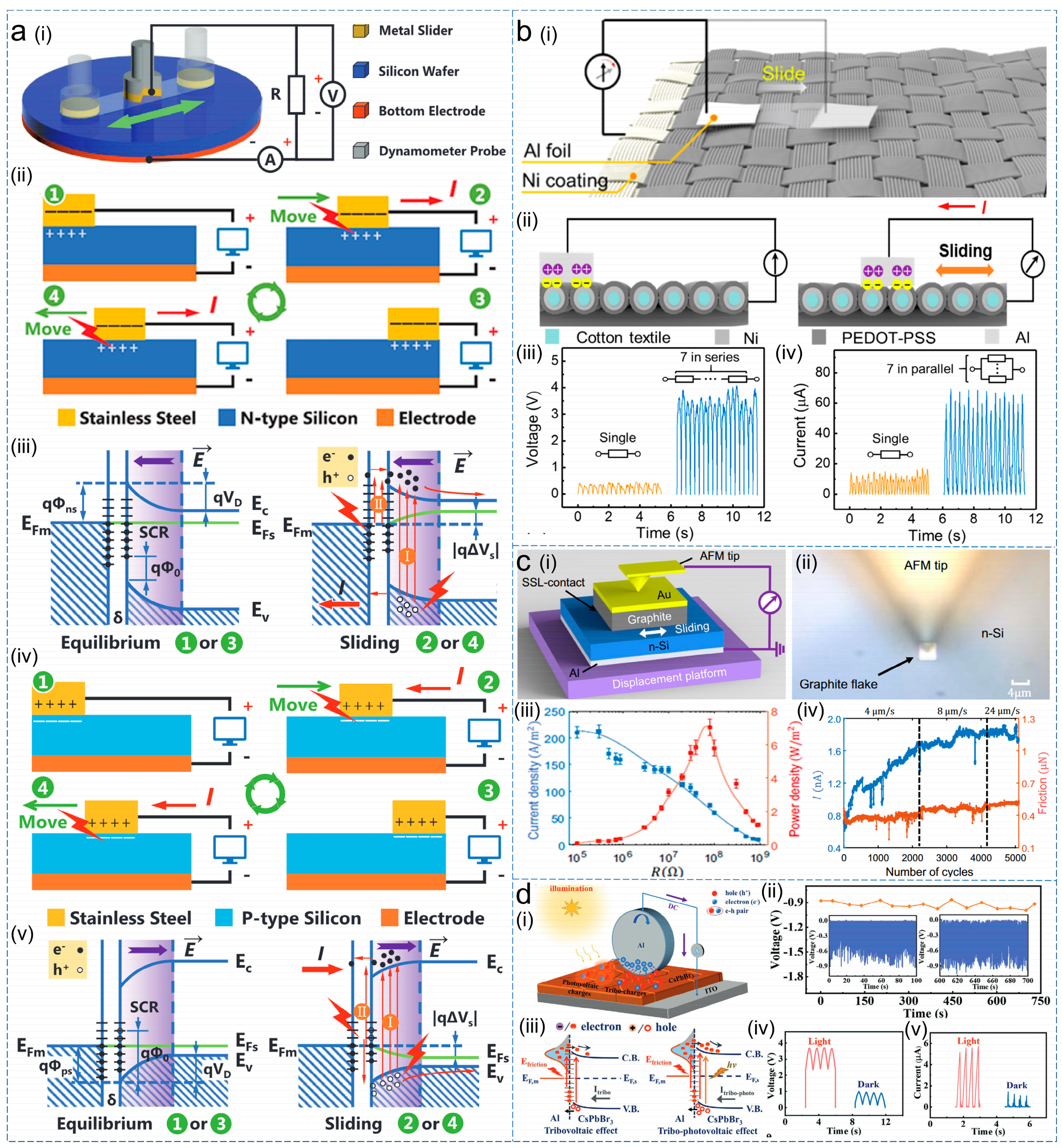

The tribovoltaic effect generated by the sliding of the semiconductor materials could directly generate constant signals [150][163], and the specific output mechanism was shown in Figure 65a. When the p–type silicon (Si) and n–type Si were in contact with each other, based on the Fermi energy level difference, electrons were transferred from n–type semiconductors to p–type semiconductors, and holes were transferred in the opposite direction. So, a built–in electric field in the direction from the n–type semiconductor to the p–type semiconductor was generated at the contact surface to form a p–n junction, as demonstrated in [Figure 65a(i)]. When the relative motion occurred between the two semiconductors, the atoms on the two surfaces interacted to form the new chemical bonds and release the frictional energy (“Bindington”) [Figure 65a(ii)]. The frictional energy (“Bindington”) in the tribovoltaic effect was similar to the role of the excitions in the photovoltaic effect, which excited the electron–hole pair at the contact interface to move along/against the built–in electric field, thereby forming the constant output in the external circuit [Figure 65a(iii)]. Based on this principle, Xu et al. reported a DC-TENG based on the mutual sliding between p-n type Si in 2019 [151][164], as shown in Figure 65b(i). Experiments showed that in the tribovoltaic effect between the two, the direction of the constant current was the same as that of the built-in electric field [Figure 65b(ii)] and was independent of the relative sliding direction [Figure 65b(iii)]. During the DC-TENG operation, as the contact force between semiconductors increased, they were contacted more fully so that the output performance was increased [Figure 65b(iv)]. Similarly, as the relative sliding speed increased, the transfer speed of charge carriers in DC-TENG continued to increase, so the short–circuit current was increased, as shown in Figure 65b(v).

2.3.2. Metal–Semiconductor Contact

There was a wide choice of friction materials in the tribovoltaic effect. In addition to the p–n junction between semiconductor–semiconductor materials, the DC-TENG based on the Schottky junction between metal–semiconductor materials could also achieve the DC output. In 2020, Zhang et al. invented low–impedance DC-TENG based on the contact between stainless steel metal and Si semiconductor [154][169] [Figure 76a(i)], and the specific working mechanism was shown in Figure 76a(ii). The Schottky junction was constructed when the stainless steel with a large work function was in static contact with the n–type Si with a small work function, and electrons transferred from the semiconductor side to the metal side, forming a built–in electric field. Then, the friction energy released by the formation of atomic bonds during the sliding process of the metal on the semiconductor surface could excite non–equilibrium carriers, which included the excited electron–hole pairs in the semiconductor space charge region and the excited electron composition of the metal and semiconductor surface states. Under the action of the built–in electric field, the non–equilibrium carriers could drift along or against the direction of the built–in electric field, generating constant output in the external circuit. Correspondingly, the energy band diagram between the stainless steel and n–type Si was shown in Figure 76a(iii) at different operating stages of the DC-TENG. On the other hand, when the stainless steel and p–type Si slid with each other [Figure 76a(iv)], electrons transferred from the metal side to the p–type Si side, and a reverse built–in electric field was constructed, due to a higher work function and a lower Fermi level of p–type Si. With the relative sliding of stainless steel and p–type Si, the reverse built–in electric field drove the electrons to flow unidirectionally in the external circuit to generate reverse DC output, and the change process of the energy band diagram was shown in Figure 76a(v). The tribovoltaic effect could also occur when the metal and the flexible organic semiconductor polymers slide relatively. In 2021, Meng et al. proposed a flexible textile DC-TENG based on the contact between the metal Al and the conducting polymer PEDOT [189][170], as shown in Figure 76b(i). In this DC-TENG, The direction of the built–in electric field was from Al to PEDOT, which drove the non–equilibrium carriers generated during the sliding process to move along or against the direction of the built–in electric field to generate constant output [Figure 76b(ii)]. Through the way of increasing voltage in series and increasing current in parallel of multiple power generation units, the open–circuit voltage of 3.5V [Figure 76b(iii)] and the short–circuit current of 70 μA [Figure 7b(iv)] could be generated, respectively, by two integration methods from seven DC-TENGs.

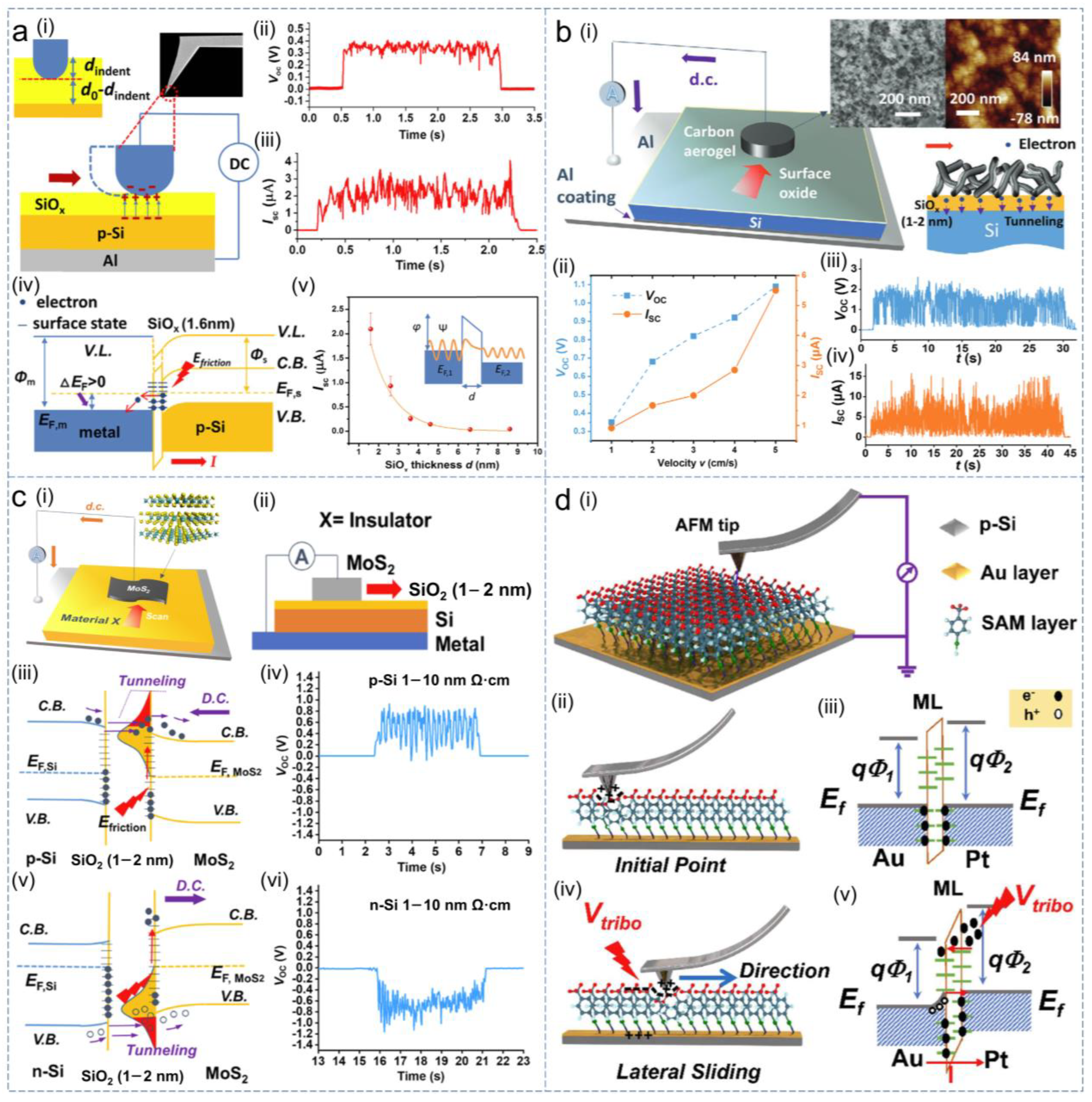

2.3.3. Metal/Semiconductor–Insulator–Metal/Semiconductor Contact

To further reduce the rapid friction and wear in DC-TENG based on semiconductor materials, a thin insulating layer was introduced between the semiconductor–semiconductor contact or metal–semiconductor contact to form the tribo–tunneling effect. In 2018, Liu et al. developed a DC-TENG based on metal–insulator–semiconductor contact [157][173] shown in Figure 87a(i). When the probe (platinum, Pt) of the electrical–atomic force microscopy contacted with the silicon oxide of p–type Si, under the action of Schottky junction, electrons tunneled through the insulating layer from the metal side with a high Fermi level to the semiconductor side with a low Fermi level, forming a built–in electric field. When the relative sliding occurs between the Pt and the insulating layer, the released friction energy stimulated the non–equilibrium carriers to tunnel through the insulating layer along or against the built–in electric field, driving a constant open–circuit voltage and short–circuit current generated as shown in Figure 87a(ii,iii), and the energy band diagram between Pt and p–type Si was shown in Figure 87a(iv). Experiments showed that the output performance of DC-TENG based on the tribo–tunneling effect decreased with the increase in insulating layer thickness due to the hindrance of the insulating layer to charge carriers, as shown in Figure 87a(v). In this DC-TENG based on the AFM probe sliding on the insulating surface of the semiconductor, a high current density (1–10 A/m2) was generated, but the manufacturing process of the probe was more complicated, and it could cause strong material wear. To solve such problems, Liu et al. proposed a DC-TENG based on the tribo–tunneling effect of carbon aerogel–insulator–semiconductor contact [192][174] in 2019, as shown in Figure 87b(i). The built–in electric field formed by the Schottky junction between carbon aerogel and p–type Si drove the charge carriers to tunnel through the insulating layer to form a constant output in the external circuit. Experiments showed that the open–circuit voltage and short–circuit current of the DC-TENG increased with the increase in relative sliding speed, as shown in Figure 87b(ii). Particularly, based on the material properties of carbon aerogel, when it contacted the insulating layer, not only the friction and wear between the materials were effectively reduced, but also a large number of nano–contact points on the contact interface were constructed acting as the superposition of multiple power generation units to effectively improve the output performance of DC-TENG. The open–circuit voltage reached 2 V [Figure 87b(iii)], short–circuit current reached 15 μA [Figure 87b(iv)], and the theoretical current density reached 100 A/m2.

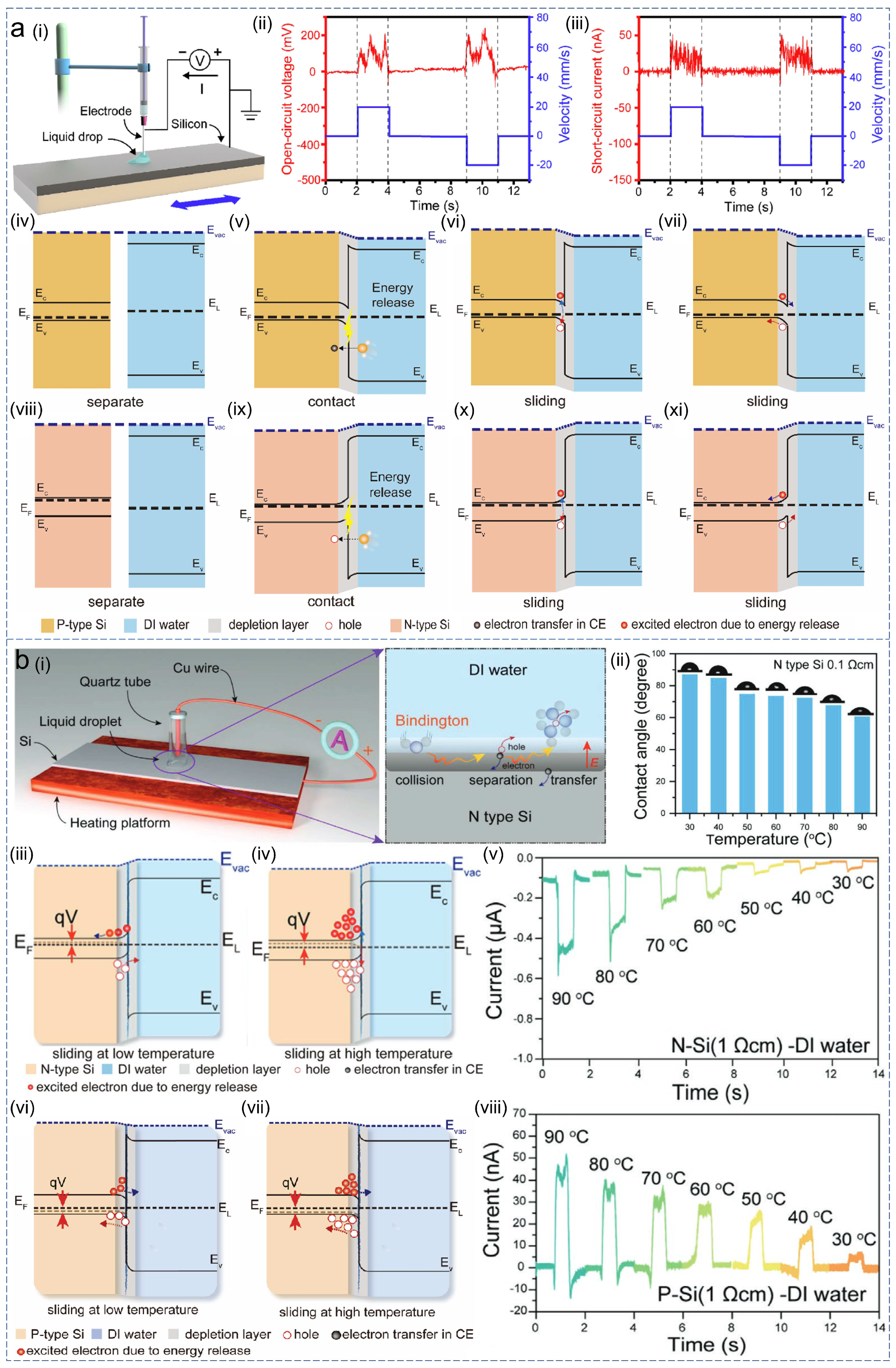

2.3.4. Liquid–Semiconductor Contact

The tribovoltaic effect could also be generated between liquid and semiconductor, which could effectively reduce friction and wear. In 2020, Lin et al. invented a DC-TENG by driving droplets to slide on the Si surface [160][177], as shown in Figure 98a(i). When the deionized (DI) water droplets slid on the p–type silicon surface, the DC-TENG generated constant open–circuit voltage and short–circuit current, which was independent of the relative sliding direction [Figure 98a(ii,iii)]. The Fermi level of water was higher than that of p–type Si, and when they were separated from each other, the energy band diagram was shown in Figure 98a(iv). When the droplet contacted the p–type Si, the electrons were transferred from the droplet to the Si surface, forming a built–in electric field. At the same time, new chemical bonds might be formed at the contact interface, and the energy band diagram was shown in Figure 98a(v). Electrons transfer and the formation of new chemical bonds both led to the release of friction energy at the contact interface, which could excite the generation of electron–hole pairs on the p–type Si surface [Figure 98a(vi)]. Under the action of the built–in electric field, the electron–hole pairs would transfer along/against the electric field direction, forming the constant output in the external circuit [Figure 98a(vii)]. When the DI water droplet contacted with n–type Si with a higher Fermi level, the electrons were transferred from the Si surface to the droplet, forming a reverse built–in electric field. It drove the electron–hole pairs to perform directional motion to form a reverse constant output, and the energy band diagrams at different operating stages were shown in Figure 98a(viii–xi).

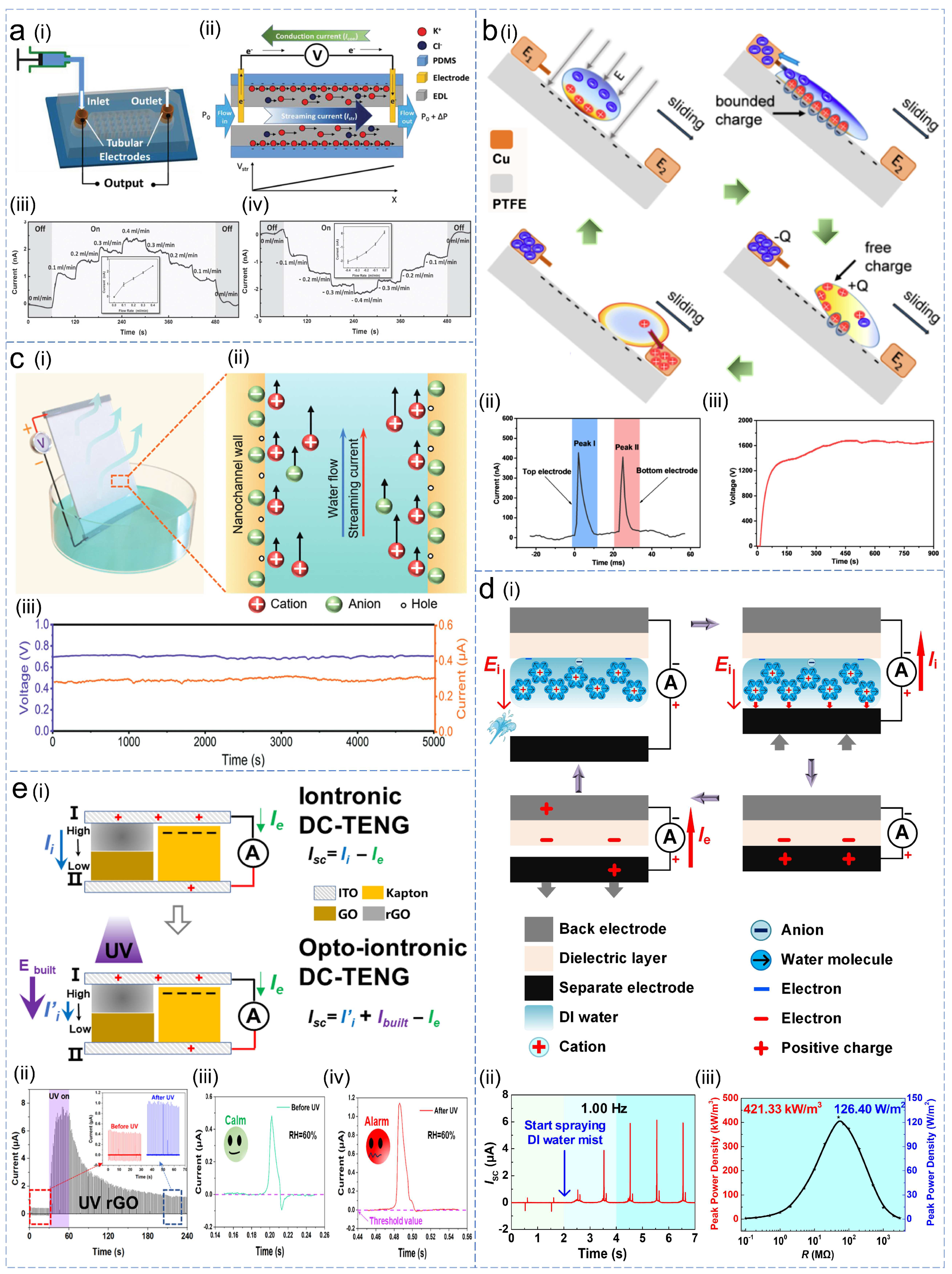

2.4. DC-TENGs Based on Materials for Iontronic Rectification

In DC-TENGs based on solid dielectric/semiconductor materials, the friction and wear between solid materials were an inevitable problem. The DC output mechanism formed by the unidirectional flow of ionic charge based on materials for iontronic rectification could avoid the above challenges. In 2015, Zhang et al. invented a microfluidic DC-TENG [162][179] [Figure 109a(i)], which could effectively convert liquid flow energy into constant electric output. When the 1 μmol/L KCl solution contacted the polydimethylsiloxane (PDMS) replica, based on the CE principle, the electrons were transferred from the liquid to the PDMS surface to form the electrical double layer (EDL), and the cation concentration was higher than that of the anion in the liquid. As the liquid was pushed through the PDMS surface, the net positive charge was transmitted to form the streaming current. The induced electric field generated by the charge distribution along the liquid flow direction led to the streaming potential, which drove the unidirectional flow of electrons in the external circuit to form the constant output, as shown in Figure 109a(ii). As demonstrated in Figure 109a(iii), with the continuous change in liquid flow rate, the amplitude of the short–circuit current generated by the DC-TENG altered accordingly. Once the flow direction of the liquid was changed, the direction of the output current altered accordingly, as shown in Figure 109a(iv). To effectively improve the output performance of this type of DC generator, Dong et al. invented a high–voltage DC-TENG [196][180] by using a pre–negative charged dielectric layer [Figure 109b(i)]. In the falling process of the water droplet, the electric field constructed by negative charges on the PTFE dielectric layer drove the cations and anions in the water droplet to move along and against the electric field, respectively. When the droplet contacted the PTFE surface, the anions in the upper layer of the droplet contacted and transferred to the top Cu electrode, and it drove electrons to transfer from the top electrode to the bottom Cu electrode in the external circuit, forming the current Peak I. When the droplet slid along the dielectric layer and contacted with bottom electrode, the cations were transferred to the bottom electrode, which drove electrons to move in the same direction in the external circuit, forming the current Peak II. The two current signals in the same direction of DC-TENG were shown in Figure 109b(ii). When the droplets were dropped at a frequency of 2.5 Hz, a constant voltage output of more than 1600 V could be generated in this high–voltage DC-TENG [Figure 109b(iii)].To further achieve an effective constant output, Chi et al. developed a DC-TENG [197][181] in 2022 [Figure 109c(i)], which could produce constant electricity based on the action of water evaporation and capillary force. It consisted of a superhydrophilic porous aluminum oxide (Al2O3) ceramic sheet and electrodes arranged, respectively, at the top and bottom of the sheet. When the bottom electrode on the ceramic sheet was immersed in water, under the combined action of water evaporation and capillary force, the water continuously flowed upward along the nanopores inside the ceramic sheet and evaporated at the top of the sheet. In the process of liquid flow, electrons in water were transferred to the ceramic surface to form an EDL, and the net cations in the liquid continued to flow with the liquid to form a streaming current. It drove electrons to transfer from the top electrode to the bottom electrode to form the DC output in the external circuit, as shown in Figure 109c(ii). Experiments showed that the DC-TENG could work normally only when the liquid could evaporate. It had stronger stability and could produce stable output (0.7 V and 0.3 μA) for at least 5000 s [Figure 109c(iii)].

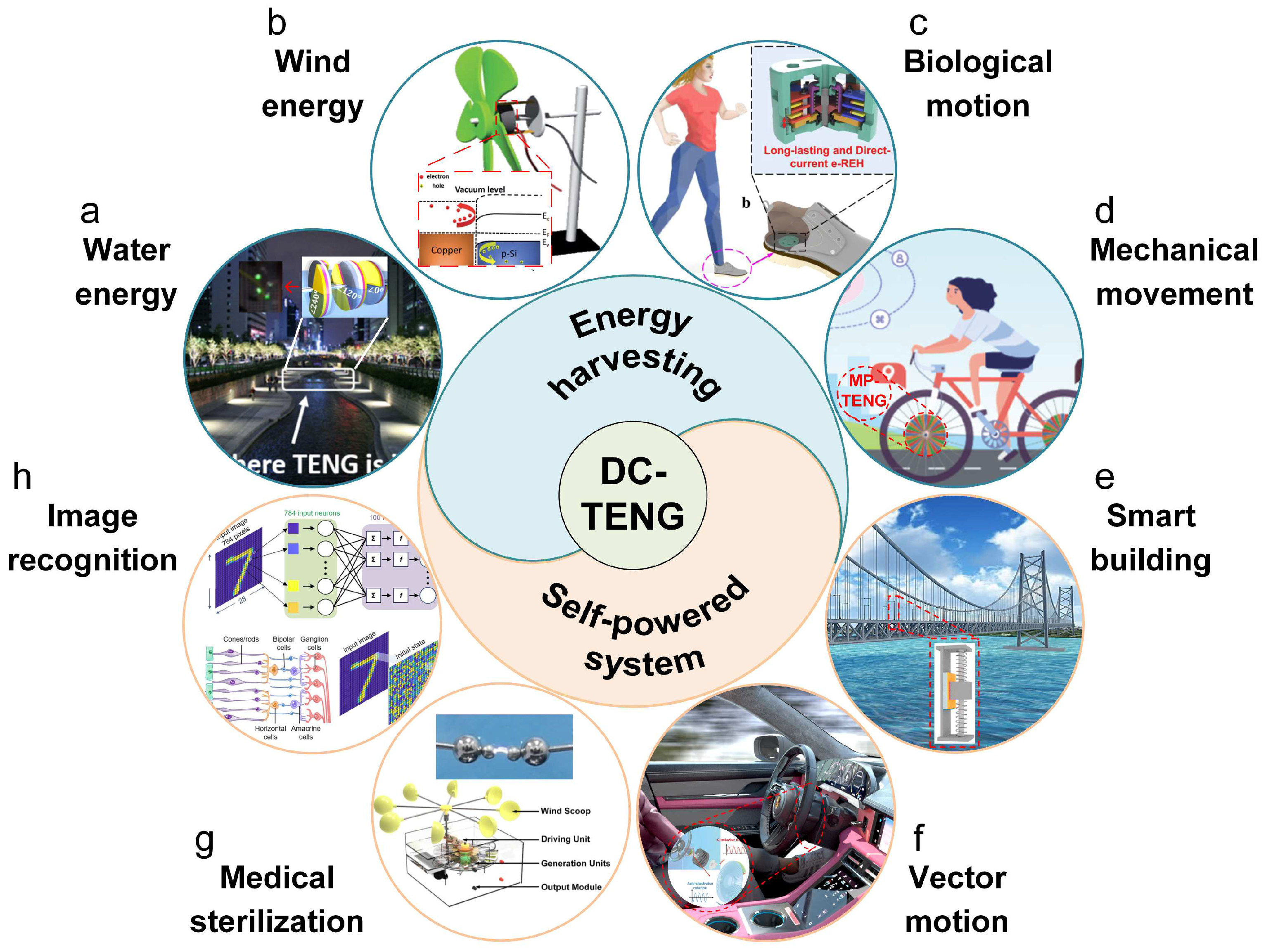

3. Various Applications of DC-TENGs

The advantages and disadvantages of DC-TENGs based on different material types have been summarized. To show them more intuitively, a comparison Table 1 was constructed. Based on these advantages, DC-TENGs had a wide range of application fields in energy–harvesting and the self–powered system, as shown in Figure 110. The mechanical energy from water, wind, biological motion, mechanical movement, raindrops, and many others could be effectively harvested by DC-TENGs. In 2018, Lim et al. designed a DC-TENG [200][184] based on the phase coupling principle, which could effectively harvest the water flow energy with the assistance of the propeller to drive the LED board to operate normally [Figure 110a]. Its practical application in the natural river environment proved that the TENG has good environmental adaptability and operational stability. In terms of wind energy harvesting, Yu et al. developed a DC-TENG based on the tribovoltaic effect between the Cu and p–type Si [201][185] in 2021 [Figure 110b]. It could output a constant current with an average of 4.4 mA (the maximum value was 8.4 mA), several orders of magnitude over previous generators based on the metal and semiconductor contact. In addition to natural resources, to effectively collect biological movement energy, Tao et al. developed a DC-TENG from the phase coupling [202][186] in 2023 shown in [Figure 110c]. Due to the advantages of the lightweight and small size of TENG, it could be installed in shoes to convert the low–frequency motion energy of the human walking into an approximately constant output with an average power of approximately 3.95 mW for supplying the micro biosensors. In addition, DC-TENG also could effectively harvest the mechanical movement energy widely existing in human life, such as vehicle operation and mechanical vibration. In 2021, the DC-TENG based on the phase coupling principle developed by Chen et al. [203][187] [Figure 110d], which was mounted on a bicycle to harvest the rotational energy of the wheels. It could effectively drive the relevant sensor nodes to work normally for collecting information on motion speed, real–time position, and energy consumption, thus opening the era of green travel. In the future, the DC-TENGs based on dielectric materials are generally more suitable for building large–scale energy–harvesting devices due to their cost–effectiveness, especially for harvesting large–scale high–entropy energy sources, such as ocean energy, wind energy, and mechanical movement energy. The DC-TENGs based on semiconductor materials could generate higher energy density caused by lower internal resistance, and their simpler structure design makes them more suitable to harvest biological motion energy for wearable electronics. Furthermore, the DC-TENGs based on the materials for iontronic rectification could generate higher energy due to the lowest resistance. It could overcome the challenges for traditional TENGs, such as materials friction and wear, and depletion of surface charge. It could extend the applications of DC-TENG for more power–hungry applications.

| Advantages | Disadvantages | |

|---|---|---|

| DC-TENGs based on dielectric materials | higher voltage output | higher internal resistance prone to friction and wear |

| DC-TENGs based on semiconductor materials | higher current density lower internal resistance |

prone to friction and wear depletion of space charge |

| DC-TENGs based on materials for iontronic rectifications | free from friction and wear suppletion of surface charge |

additional ionic source |

References

- Kennedy, C. The energy embodied in the first and second industrial revolutions. J. Ind. Ecol. 2020, 24, 887–898.

- Balat, M. Status of fossil energy resources: A global perspective. Energy Sources Part B 2007, 2, 31–47.

- Wrigley, E.A. Energy and the English industrial revolution. Philos. Trans. R. Soc. A 2013, 371, 20110568.

- Qiao, S.; Dang, Y.J.; Ren, Z.Y.; Zhang, K.Q. The dynamic spillovers among carbon, fossil energy and electricity markets based on a TVP-VAR-SV method. Energy 2023, 266, 126344.

- Gong, X.; Shi, R.; Xu, J.; Lin, B. Analyzing spillover effects between carbon and fossil energy markets from a time-varying perspective. Appl. Energy 2021, 285, 116384.

- Fernández, A.M.; Ferrándiz, E.; Medina, J. The diffusion of energy technologies. Evidence from renewable, fossil, and nuclear energy patents. Technol. Forecast. Soc. 2022, 178, 121566.

- Tollefson, J. Carbon emissions hit new high: Warning from COP27. Nature 2022.

- Su, C.W.; Pang, L.D.; Qin, M.; Lobont, O.R.; Umar, M. The spillover effects among fossil fuel, renewables and carbon markets: Evidence under the dual dilemma of climate change and energy crises. Energy 2023, 274, 127304.

- Perera, F.P. Multiple threats to child health from fossil fuel combustion: Impacts of air pollution and climate change. Environ. Health Perspect. 2017, 125, 141–148.

- Slamersak, A.; Kallis, G.; O’Neill, D.W. Energy requirements and carbon emissions for a low-carbon energy transition. Nat. Commun. 2022, 13, 6932.

- Guan, Y.; Yan, J.; Shan, Y.; Zhou, Y.; Hang, Y.; Li, R.; Liu, Y.; Liu, B.; Nie, Q.; Bruckner, B.; et al. Burden of the global energy price crisis on households. Nat. Energy 2023, 8, 304–316.

- Long, C.; Jiang, Z.; Shangguan, J.; Qing, T.; Zhang, P.; Feng, B. Applications of carbon dots in environmental pollution control: A review. Chem. Eng. J. 2021, 406, 126848.

- Fahrenkamp-Uppenbrink, J. Cost of the “Internet of Things”. Science 2019, 364, 347–349.

- Silva, J.S.; Zhang, P.; Pering, T.; Boavida, F.; Hara, T.; Liebau, N.C. People-centric Internet of Things. IEEE Commun. Mag. 2017, 55, 18–19.

- Siow, E.; Tiropanis, T.; Hall, W. Analytics for the Internet of Things. ACM Comput. Surv. 2018, 51, 1–36.

- Andreev, S.; Dobre, C.; Misra, P. The Internet of Things and sensor networks. IEEE Commun. Mag. 2019, 57, 64.

- Pikul, J.H.; Ning, H. Powering the Internet of Things. Joule 2018, 2, 1036–1038.

- Sisinni, E.; Saifullah, A.; Han, S.; Jennehag, U.; Gidlund, M. Industrial Internet of Things: Challenges, opportunities, and directions. IEEE Trans. Ind. Inform. 2018, 14, 4724–4734.

- Boyes, H.; Hallaq, B.; Cunningham, J.; Watson, T. The industrial internet of things (IIoT): An analysis framework. Comput. Ind. 2018, 101, 1–12.

- Zhang, X.; Ge, Z. Local parameter optimization of LSSVM for industrial soft sensing with Big Data and cloud implementation. IEEE Trans. Ind. Inform. 2020, 16, 2917–2928.

- Sengupta, J.; Ruj, S.; Bit, S.D. A secure fog-based architecture for industrial Internet of Things and Industry 4.0. IEEE Trans. Ind. Inform. 2021, 17, 2316–2324.

- Ojha, T.; Misra, S.; Raghuwanshi, N.S. Internet of things for agricultural applications: The state of the art. IEEE Internet Things J. 2021, 8, 10973–10997.

- Ruan, J.; Jiang, H.; Zhu, C.; Hu, X.; Shi, Y.; Liu, T.; Rao, W.; Chan, F.T.S. Agriculture IoT: Emerging trends, cooperation networks, and outlook. IEEE Wirel. Commun. 2019, 26, 56–63.

- Misra, N.N.; Dixit, Y.; Al-Mallahi, A.; Bhullar, M.S.; Upadhyay, R.; Martynenko, A. IoT, Big Data, and artificial intelligence in agriculture and food industry. IEEE Internet Things J. 2022, 9, 6305–6324.

- Zhu, Z.; Bai, Y.; Dai, W.; Liu, D.; Hu, Y. Quality of e-commerce agricultural products and the safety of the ecological environment of the origin based on 5G Internet of Things technology. Environ. Technol. Innov. 2021, 22, 101462.

- Zhu, F.; Lv, Y.; Chen, Y.; Wang, X.; Xiong, G.; Wang, F.-Y. Parallel transportation systems: Toward IoT-enabled smart urban traffic control and management. IEEE Trans. Intell. Transp. Syst. 2020, 21, 4063–4071.

- Kim, B.-S.; Kim, K.-I.; Shah, B.; Chow, F.; Kim, K.H. Wireless sensor networks for Big Data systems. Sensors 2019, 19, 1565.

- Dai, H.-N.; Zheng, Z.; Zhang, Y. Blockchain for Internet of Things: A Survey. IEEE Internet Things 2019, 6, 8076–8094.

- Yao, L.; Sheng, Q.Z.; Ngu, A.H.H.; Li, X. Things of interest recommendation by leveraging heterogeneous relations in the Internet of Things. ACM Trans. Internet Technol. 2016, 16, 1–25.

- Haight, R.; Haensch, W.; Friedman, D. Solar-powering the Internet of Things. Science 2016, 353, 124–125.

- Facchini, A. Distributed energy resources: Planning for the future. Nat. Energy 2017, 2, 17129.

- Hittinger, E.; Jaramillo, P. Internet of Things: Energy boon or bane? Science 2019, 364, 326–328.

- Zhang, H.; Li, Y.; Gao, D.W.; Zhou, J. Distributed optimal energy management for energy internet. IEEE Trans. Ind. Inform. 2017, 13, 3081–3097.

- Leicester, R.J.; Newman, V.G.; Wright, J.K. Renewable energy sources and storage. Nature 1978, 272, 518–521.

- Kammen, D.M.; Sunter, D.A. City-integrated renewable energy for urban sustainability. Science 2016, 352, 922–928.

- Chu, S.; Majumdar, A. Opportunities and challenges for a sustainable energy future. Nature 2012, 488, 294–303.

- Kittner, N.; Lill, F.; Kammen, D.M. Energy storage deployment and innovation for the clean energy transition. Nat. Energy 2017, 2, 17125.

- Mitchell, C. Momentum is increasing towards a flexible electricity system based on renewables. Nat. Energy 2016, 1, 15030.

- Bossink, B.A.G. Demonstrating sustainable energy: A review based model of sustainable energy demonstration projects. Renew. Sustain. Energy Rev. 2017, 77, 1349–1362.

- Kurt, E.; Gör, H.; Döner, U. Electromagnetic design of a new axial and radial flux generator with the rotor back-irons. Int. J. Hydrogen Energy 2016, 41, 7019–7026.

- Wang, X.; Pang, W.; Gao, P.; Zhao, X. Electromagnetic design and analysis of axial flux permanent magnet generator with unequal-width PCB winding. IEEE Access 2019, 7, 164696–164707.

- Wang, X.; Zhang, Y.; Xue, S.; Wang, T.; Fu, G.; Mao, X.; Lu, C. Bi-stable electromagnetic generator with asymmetrical potential wells for low frequency vibration energy harvesting. Mech. Syst. Signal Process. 2023, 199, 110478.

- Fan, F.-R.; Tian, Z.-Q.; Wang, Z.L. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334.

- Wang, Z.L. Triboelectric nanogenerators as new energy technology and self-powered sensors—Principles, problems and perspectives. Faraday Discuss. 2014, 176, 447–458.

- Cui, X.; Zhang, Y.; Hu, G.; Zhang, L.; Zhang, Y. Dynamical charge transfer model for high surface charge density triboelectric nanogenerators. Nano Energy 2020, 70, 104513.

- Liu, L.; Li, J.; Ou-Yang, W.; Guan, Z.; Hu, X.; Xie, M.; Tian, Z. Ferromagnetic-assisted Maxwell’s displacement current based on iron/polymer composite for improving the triboelectric nanogenerator output. Nano Energy 2022, 96, 107139.

- Zi, Y.; Guo, H.; Wen, Z.; Yeh, M.-H.; Hu, C.; Wang, Z.L. Harvesting low-frequency (<5 Hz) irregular mechanical energy: A possible killer application of triboelectric nanogenerator. ACS Nano 2016, 10, 4797–4805.

- Xing, F.; Jie, Y.; Cao, X.; Li, T.; Wang, N. Natural triboelectric nanogenerator based on soles for harvesting low-frequency walking energy. Nano Energy 2017, 42, 138–142.

- Zhang, D.; Shi, J.; Si, Y.; Li, T. Multi-grating triboelectric nanogenerator for harvesting low-frequency ocean wave energy. Nano Energy 2019, 61, 132–140.

- Fan, K.; Wei, D.; Zhang, Y.; Wang, P.; Tao, K.; Yang, R. A whirligig-inspired intermittent-contact triboelectric nanogenerator for efficient low-frequency vibration energy harvesting. Nano Energy 2021, 90, 106576.

- Wang, Z.; Liu, W.; He, W.; Guo, H.; Long, L.; Xi, Y.; Wang, X.; Liu, A.; Hu, C. Ultrahigh electricity generation from low-frequency mechanical energy by efficient energy management. Joule 2021, 5, 441–455.

- Barrows, S.E.; Homer, J.S.; Orrell, A.C. Valuing wind as a distributed energy resource: A literature review. Renew. Sustain. Energy Rev. 2021, 152, 111678.

- Zhang, L.; Meng, B.; Tian, Y.; Meng, X.; Lin, X.; He, Y.; Xing, C.; Dai, H.; Wang, L. Vortex-induced vibration triboelectric nanogenerator for low speed wind energy harvesting. Nano Energy 2022, 95, 107029.

- Cheng, B.; Qi, C.; Ding, Y.; Jia, X.; Bai, S.; Xu, Q.; Yu, Y.; Wen, J.; Qin, Y. High output performance flutter-driven triboelectric nanogenerator. Nano Energy 2023, 106, 108106.

- Ren, Z.; Wu, L.; Pang, Y.; Zhang, W.; Yang, R. Strategies for effectively harvesting wind energy based on triboelectric nanogenerators. Nano Energy 2022, 100, 107522.

- Hu, J.; Pu, X.; Yang, H.; Zeng, Q.; Tang, Q.; Zhang, D.; Hu, C.; Xi, Y. A flutter-effect-based triboelectric nanogenerator for breeze energy collection from arbitrary directions and self-powered wind speed sensor. Nano Res. 2019, 12, 3018–3023.

- Wang, Z.L. Catch wave power in floating nets. Nature 2017, 542, 159–160.

- Cheng, J.; Zhang, X.; Jia, T.; Wu, Q.; Dong, Y.; Wang, D. Triboelectric nanogenerator with a seesaw structure for harvesting ocean energy. Nano Energy 2022, 102, 107622.

- Ahn, J.; Kim, J.S.; Jeong, Y.; Hwang, S.; Yoo, H.; Jeong, Y.; Gu, J.; Mahato, M.; Ko, J.; Jeon, S.; et al. All-recyclable triboelectric nanogenerator for sustainable ocean monitoring systems. Adv. Energy Mater. 2022, 12, 2201341.

- Sun, W.; Zheng, Y.; Li, T.; Feng, M.; Cui, S.; Liu, Y.; Chen, S.; Wang, D. Liquid-solid triboelectric nanogenerators array and its applications for wave energy harvesting and self-powered cathodic protection. Energy 2021, 217, 119388.

- Xu, Q.; Shang, C.; Ma, H.; Hong, Q.; Li, C.; Ding, S.; Xue, L.; Sun, X.; Pan, Y.; Sugahara, T.; et al. A guided-liquid-based hybrid triboelectric nanogenerator for omnidirectional and high-performance ocean wave energy harvesting. Nano Energy 2023, 109, 108240.

- Dassanayaka, D.G.; Alves, T.M.; Wanasekara, N.D.; Dharmasena, I.G.; Ventura, J. Recent progresses in wearable triboelectric nanogenerators. Adv. Funct. Mater. 2022, 32, 2205438.

- Wang, H.; Han, M.; Song, Y.; Zhang, H. Design, manufacturing and applications of wearable triboelectric nanogenerators. Nano Energy 2021, 81, 105627.

- Xiao, X.; Chen, G.; Libanori, A.; Chen, J. Wearable triboelectric nanogenerators for therapeutics. Trends Chem. 2021, 3, 279–290.

- Mariello, M. Heart energy harvesting and cardiac bioelectronics: Technologies and perspectives. Nanoenergy Adv. 2022, 2, 344–385.

- Quan, Y.; Wu, X.; Zhu, S.; Zeng, X.; Zeng, Z.; Zheng, Q. Triboelectric nanogenerators for clinical diagnosis and therapy: A report of recent progress. Med. Nov. Technol. Devices 2022, 16, 100195.

- Naval, S.; Jain, A.; Mallick, D. Direct current triboelectric nanogenerators: A review. J. Micromech. Microeng. 2022, 33, 013001.

- Zhang, R.; Hummelgård, M.; Örtegren, J.; Olsen, M.; Andersson, H.; Olin, H. Interaction of the human body with triboelectric nanogenerators. Nano Energy 2019, 57, 279–292.

- Yu, B.; Yu, H.; Wang, H.; Zhang, Q.; Zhu, M. High-power triboelectric nanogenerator prepared from electrospun mats with spongy parenchyma-like structure. Nano Energy 2017, 34, 69–75.

- Thakur, V.N.; Han, J.I. Triboelectric nanogenerator for smart traffic monitoring and safety. J. Ind. Eng. Chem. 2023, 124, 89–101.

- Hu, Y.Q.; Wang, X.L.; Qin, Y.C.; Li, Z.H.; Wang, C.F.; Wu, H. A robust hybrid generator for harvesting vehicle suspension vibration energy from random road excitation. Appl. Energy 2022, 309, 118506.

- Zhong, W.; Xu, B.; Gao, Y. Engraved pattern spacer triboelectric nanogenerators for mechanical energy harvesting. Nano Energy 2022, 92, 106782.

- Cao, J.; Lin, Y.; Fu, X.; Wang, Z.; Liu, G.; Zhang, Z.; Qin, Y.; Zhou, H.; Dong, S.; Cheng, G.; et al. Self-powered overspeed wake-up alarm system based on triboelectric nanogenerators for intelligent transportation. Nano Energy 2023, 107, 108150.

- Pang, Y.; Zhu, X.; Jin, Y.; Yang, Z.; Liu, S.; Shen, L.; Li, X.; Lee, C. Textile-inspired triboelectric nanogenerator as intelligent pavement energy harvester and self-powered skid resistance sensor. Appl. Energy 2023, 348, 121515.

- Shi, Q.; Yang, J.; Gui, H.; Gui, Y.; Tang, C.; Yu, Y.; Zhao, Z. Self-powered circular-honeycomb triboelectric nanogenerator for vibration energy harvesting and resonance detection of synchronous machine. Sens. Actuators A Phys. 2023, 354, 114291.

- Yang, C.; Liu, G.; Wang, X.; Liu, B.; Xiao, L.; Wan, L.; Yao, H. Harvesting wide frequency micromechanical vibration energy and wind energy with a multi-mode triboelectric nanogenerator for traffic monitoring and warning. Adv. Mater. Technol. 2022, 8, 2200465.

- Chen, Y.; Zhang, H.; Xu, C.; Deng, L.; Yang, Q.; Zhang, H.; Xing, J.; Xie, L. Characteristic of solid-ferrofluid triboelectric nanogenerator for ultra-low-frequency vibration energy harvesting. Nano Energy 2023, 111, 108395.

- Tan, D.; Zhou, J.; Wang, K.; Zhang, C.; Li, Z.; Xu, D. Wearable bistable triboelectric nanogenerator for harvesting torsional vibration energy from human motion. Nano Energy 2023, 109, 108315.

- Qi, Y.; Liu, G.; Gao, Y.; Bu, T.; Zhang, X.; Xu, C.; Lin, Y.; Zhang, C. Frequency band characteristics of a triboelectric nanogenerator and ultra-wide-band vibrational energy harvesting. ACS Appl. Mater. Interfaces 2021, 13, 26084–26092.

- Zheng, Y.; Liu, T.; Wu, J.; Xu, T.; Wang, X.; Han, X.; Cui, H.; Xu, X.; Pan, C.; Li, X. Energy conversion analysis of multilayered triboelectric nanogenerators for synergistic rain and solar energy harvesting. Adv. Mater. 2022, 34, e2202238.

- Im, B.; Lee, S.-K.; Kang, G.; Moon, J.; Byun, D.; Cho, D.-H. Electrohydrodynamic jet printed silver-grid electrode for transparent raindrop energy-based triboelectric nanogenerator. Nano Energy 2022, 95, 107049.

- Cheng, B.; Niu, S.; Xu, Q.; Wen, J.; Bai, S.; Qin, Y. Gridding triboelectric nanogenerator for raindrop energy harvesting. ACS Appl. Mater. Interfaces 2021, 13, 59975–59982.

- Liu, X.; Yu, A.; Qin, A.; Zhai, J. Highly integrated triboelectric nanogenerator for efficiently harvesting raindrop energy. Adv. Mater. Technol. 2019, 4, 1900608.

- Zhang, Q.; Jiang, C.; Li, X.; Dai, S.; Ying, Y.; Ping, J. Highly efficient raindrop energy-based triboelectric nanogenerator for self-powered intelligent greenhouse. ACS Nano 2021, 15, 12314–12323.

- Cheng, B.; Xu, Q.; Ding, Y.; Bai, S.; Jia, X.; Yu, Y.; Wen, J.; Qin, Y. High performance temperature difference triboelectric nanogenerator. Nat. Commun. 2021, 12, 4782.

- Guo, W.; Long, Y.; Bai, Z.; Wang, X.; Liu, H.; Guo, Z.; Tan, S.; Guo, H.; Wang, Y.; Miao, Y. Variable stiffness triboelectric nano-generator to harvest high-speed railway bridge’s vibration energy. Energy Convers. Manag. 2022, 268, 115969.

- Li, X.; Zhang, D.; Zhang, D.; Li, Z.; Wu, H.; Zhou, Y.; Wang, B.; Guo, H.; Peng, Y. Solid-liquid triboelectric nanogenerator based on vortex-induced resonance. Nanomaterials 2023, 13, 1036.

- Huang, L.-b.; Xu, W.; Bai, G.; Wong, M.-C.; Yang, Z.; Hao, J. Wind energy and blue energy harvesting based on magnetic-assisted noncontact triboelectric nanogenerator. Nano Energy 2016, 30, 36–42.

- Zhang, Q.; Liang, Q.; Liao, Q.; Ma, M.; Gao, F.; Zhao, X.; Song, Y.; Song, L.; Xun, X.; Zhang, Y. An amphiphobic hydraulic triboelectric nanogenerator for a self-cleaning and self-charging power system. Adv. Funct. Mater. 2018, 28, 1803117.

- Li, Z.; Jiang, X.; Xu, W.; Gong, Y.; Peng, Y.; Zhong, S.; Xie, S. Performance comparison of electromagnetic generators based on different circular magnet arrangements. Energy 2022, 258, 124759.

- Cabrera-Tobar, A.; Bullich-Massagué, E.; Aragüés-Peñalba, M.; Gomis-Bellmunt, O. Review of advanced grid requirements for the integration of large scale photovoltaic power plants in the transmission system. Renew. Sustain. Energy Rev. 2016, 62, 971–987.

- Hu, C.J.; Lin, Y.H.; Tang, C.W.; Tsai, M.Y.; Hsu, W.K.; Kuo, H.F. ZnO-coated carbon nanotubes: Flexible piezoelectric generators. Adv. Mater. 2011, 23, 2941–2945.

- Wang, Z.L.; Wang, A.C. On the origin of contact-electrification. Mater. Today 2019, 30, 34–51.

- Zhang, Z.; Yin, N.; Wu, Z.; Pan, S.; Wang, D. Research methods of contact electrification: Theoretical simulation and experiment. Nano Energy 2021, 79, 105501.

- Shi, K.; Chai, B.; Zou, H.; Wen, Z.; He, M.; Chen, J.; Jiang, P.; Huang, X. Contact electrification at adhesive interface: Boosting charge transfer for high-performance triboelectric nanogenerators. Adv. Funct. Mater. 2023, 2307678.

- Wu, J.; Wang, X.; Li, H.; Wang, F.; Yang, W.; Hu, Y. Insights into the mechanism of metal-polymer contact electrification for triboelectric nanogenerator via first-principles investigations. Nano Energy 2018, 48, 607–616.

- Xu, W.; Zheng, H.; Liu, Y.; Zhou, X.; Zhang, C.; Song, Y.; Deng, X.; Leung, M.; Yang, Z.; Xu, R.X.; et al. A droplet-based electricity generator with high instantaneous power density. Nature 2020, 578, 392–396.

- Wu, H.; Wang, S.; Wang, Z.; Zi, Y. Achieving ultrahigh instantaneous power density of 10 MW/m2 by leveraging the opposite-charge-enhanced transistor-like triboelectric nanogenerator (OCT-TENG). Nat. Commun. 2021, 12, 5470.

- Cao, V.A.; Lee, S.; Kim, M.; Alam, M.M.; Park, P.; Nah, J. Output power density enhancement of triboelectric nanogenerators via ferroelectric polymer composite interfacial layers. Nano Energy 2020, 67, 104300.

- Kim, M.; Park, D.; Alam, M.M.; Lee, S.; Park, P.; Nah, J. Remarkable output power density enhancement of triboelectric nanogenerators via polarized ferroelectric polymers and bulk MoS2 composites. ACS Nano 2019, 13, 4640–4646.

- Yu, Y.; Li, H.; Zhao, D.; Gao, Q.; Li, X.; Wang, J.; Wang, Z.L.; Cheng, T. Material’s selection rules for high performance triboelectric nanogenerators. Mater. Today 2023, 64, 61–71.

- Zhou, Y.; Deng, W.; Xu, J.; Chen, J. Engineering materials at the nanoscale for triboelectric nanogenerators. Cell Rep. Phys. Sci. 2020, 1, 100142.

- Haider, Z.; Haleem, A.; Ahmad, R.u.S.; Farooq, U.; Shi, L.; Claver, U.P.; Memon, K.; Fareed, A.; Khan, I.; Mbogba, M.K.; et al. Highly porous polymer cryogel based tribopositive material for high performance triboelectric nanogenerators. Nano Energy 2020, 68, 104294.

- Candido, I.C.M.; Oliveira, G.d.S.; Ribeiro, S.J.L.; Cavicchioli, M.; Barud, H.S.; Silva, L.G.; de Oliveira, H.P. PVA-silk fibroin bio-based triboelectric nanogenerator. Nano Energy 2023, 105, 108035.

- Mao, R.; Zhang, D.; Wang, Z.; Zhang, H.; Wang, D.; Tang, M.; Zhou, L.; Cai, H.; Xia, H. Deep-learning-assisted low-cost flexible cotton yarn-based triboelectric nanogenerator for ultra-sensitive human-computer merging interfaces. Nano Energy 2023, 111, 108418.

- Fan, J.-C.; Tang, X.-G.; Sun, Q.-J.; Jiang, Y.-P.; Li, W.-H.; Liu, Q.-X. Low-cost composite film triboelectric nanogenerators for a self-powered touch sensor. Nanoscale 2023, 15, 6263–6272.

- Peng, F.; Liu, D.; Zhao, W.; Zheng, G.; Ji, Y.; Dai, K.; Mi, L.; Zhang, D.; Liu, C.; Shen, C. Facile fabrication of triboelectric nanogenerator based on low-cost thermoplastic polymeric fabrics for large-area energy harvesting and self-powered sensing. Nano Energy 2019, 65, 104068.

- Bukhari, M.U.; Khan, A.; Maqbool, K.Q.; Arshad, A.; Riaz, K.; Bermak, A. Waste to energy: Facile, low-cost and environment-friendly triboelectric nanogenerators using recycled plastic and electronic wastes for self-powered portable electronics. Energy Rep. 2022, 8, 1687–1695.

- Jiang, C.M.; Wu, C.; Li, X.J.; Yao, Y.; Lan, L.Y.; Zhao, F.N.; Ye, Z.Z.; Ying, Y.B.; Ping, J.F. All-electrospun flexible triboelectric nanogenerator based on metallic MXene nanosheets. Nano Energy 2019, 59, 268–276.

- Dharmasena, R.D.I.G.; Silva, S.R.P. Towards optimized triboelectric nanogenerators. Nano Energy 2019, 62, 530–549.

- Wang, Z.L.; Wu, W. Nanotechnology-enabled energy harvesting for self-powered micro-/nanosystems. Angew. Chem. 2012, 51, 11700–11721.

- Zhao, Z.; Lu, Y.; Mi, Y.; Meng, J.; Cao, X.; Wang, N. Structural flexibility in triboelectric nanogenerators: A review on the adaptive design for self-powered systems. Micromachines 2022, 13, 1586.

- Xia, X.; Wang, H.; Basset, P.; Zhu, Y.; Zi, Y. Inductor-free output multiplier for power promotion and management of triboelectric nanogenerators toward self-powered systems. ACS Appl. Mater. Interfaces 2020, 12, 5892–5900.

- Hurtado, C.; Lyu, X.; Ferrie, S.; Le Brun, A.P.; MacGregor, M.; Ciampi, S. Organic Monolayers on Si(211) for Triboelectricity Generation: Etching Optimization and Relationship between the Electrochemistry and Current Output. ACS Appl. Nano Mater. 2022, 5, 14263–14274.

- Chang, A.; Uy, C.; Xiao, X.; Xiao, X.; Chen, J. Self-powered environmental monitoring via a triboelectric nanogenerator. Nano Energy 2022, 98, 107282.

- Qin, Y.; Fu, X.; Lin, Y.; Wang, Z.; Cao, J.; Zhang, C. Self-powered Internet of Things sensing node based on triboelectric nanogenerator for sustainable environmental monitoring. Nano Res. 2023, 16, 11878–11884.

- Xia, K.; Xu, Z.; Hong, Y.; Wang, L. A free-floating structure triboelectric nanogenerator based on natural wool ball for offshore wind turbine environmental monitoring. Mater. Today Sustain. 2023, 24, 100467.

- Wang, D.; Zhang, D.; Tang, M.; Zhang, H.; Sun, T.; Yang, C.; Mao, R.; Li, K.; Wang, J. Ethylene chlorotrifluoroethylene/hydrogel-based liquid-solid triboelectric nanogenerator driven self-powered MXene-based sensor system for marine environmental monitoring. Nano Energy 2022, 100, 107509.

- Yang, Y.; Guo, X.; Zhu, M.; Sun, Z.; Zhang, Z.; He, T.; Lee, C. Triboelectric nanogenerator enabled wearable sensors and electronics for sustainable Internet of Things integrated green earth. Adv. Energy Mater. 2022, 13, 2203040.

- Sun, F.; Zhu, Y.; Jia, C.; Zhao, T.; Chu, L.; Mao, Y. Advances in self-powered sports monitoring sensors based on triboelectric nanogenerators. J. Energy Chem. 2023, 79, 477–488.

- Wang, T.; Shen, Y.; Chen, L.; Wang, K.; Niu, L.; Liu, G.; He, H.; Cong, H.; Jiang, G.; Zhang, Q.; et al. Large-scale production of the 3D warp knitted terry fabric triboelectric nanogenerators for motion monitoring and energy harvesting. Nano Energy 2023, 109, 108309.

- Zhao, Z.; Zhang, Z.; Xu, L.; Gao, F.; Zhao, B.; Kang, Z.; Liao, Q.; Zhang, Y. Tumbler-shaped hybrid triboelectric nanogenerators for amphibious self-powered environmental monitoring. Nano Energy 2020, 76, 104960.

- So, M.Y.; Xu, B.; Li, Z.; Lai, C.L.; Jiang, C. Flexible corrugated triboelectric nanogenerators for efficient biomechanical energy harvesting and human motion monitoring. Nano Energy 2023, 106, 108033.

- Zhou, Q.; Pan, J.; Deng, S.; Xia, F.; Kim, T. Triboelectric nanogenerator-based sensor systems for chemical or biological detection. Adv. Mater. 2021, 33, e2008276.

- Huang, L.; Shi, Y.; Ren, Y.; Yang, D.; Huang, F.; Liu, Z.; Chen, Y.; Li, H.; Chen, X.; Bian, Z. Sustainable electrochemical gold dissolution process based on triboelectric nanogenerator. Nano Energy 2023, 113, 108531.

- Jiang, Q.; Jie, Y.; Han, Y.; Gao, C.; Zhu, H.; Willander, M.; Zhang, X.; Cao, X. Self-powered electrochemical water treatment system for sterilization and algae removal using water wave energy. Nano Energy 2015, 18, 81–88.

- Su, Y.; Chen, G.; Chen, C.; Gong, Q.; Xie, G.; Yao, M.; Tai, H.; Jiang, Y.; Chen, J. Self-powered respiration monitoring enabled by a triboelectric nanogenerator. Adv. Mater. 2021, 33, e2101262.

- Li, X.; Jiang, C.; Zhao, F.; Lan, L.; Yao, Y.; Yu, Y.; Ping, J.; Ying, Y. Fully stretchable triboelectric nanogenerator for energy harvesting and self-powered sensing. Nano Energy 2019, 61, 78–85.

- Haghayegh, M.; Cao, R.; Zabihi, F.; Bagherzadeh, R.; Yang, S.; Zhu, M. Recent advances in stretchable, wearable and bio-compatible triboelectric nanogenerators. J. Mater. Chem. C 2022, 10, 11439–11471.

- Xi, Y.; Hua, J.; Shi, Y. Noncontact triboelectric nanogenerator for human motion monitoring and energy harvesting. Nano Energy 2020, 69, 104390.

- Che, Z.; O’Donovan, S.; Xiao, X.; Wan, X.; Chen, G.; Zhao, X.; Zhou, Y.; Yin, J.; Chen, J. Implantable Triboelectric Nanogenerators for Self-Powered Cardiovascular Healthcare. Small 2023, 2207600.

- Chen, C.; Wen, Z.; Shi, J.; Jian, X.; Li, P.; Yeow, J.T.W.; Sun, X. Micro triboelectric ultrasonic device for acoustic energy transfer and signal communication. Nat. Commun. 2020, 11, 4143.

- Wang, S.; Xu, P.; Wang, X.; Zheng, J.; Liu, X.; Liu, J.; Chen, T.; Wang, H.; Xie, G.; Tao, J.; et al. Underwater bionic whisker sensor based on triboelectric nanogenerator for passive vortex perception. Nano Energy 2022, 97, 107210.

- Shi, X.; Han, K.; Pang, Y.; Mai, W.; Luo, J. Triboelectric nanogenerators as self-powered sensors for biometric authentication. Nanoscale 2023, 15, 9635–9651.

- Wen, Z.; Fu, J.; Han, L.; Liu, Y.; Peng, M.; Zheng, L.; Zhu, Y.; Sun, X.; Zi, Y. Toward self-powered photodetection enabled by triboelectric nanogenerators. J. Mater. Chem. C 2018, 6, 11893–11902.

- Wang, Z.L. On the expanded Maxwell’s equations for moving charged media system—General theory, mathematical solutions and applications in TENG. Mater. Today 2022, 52, 348–363.

- Liu, X.; Zhang, M.; Yang, Z.; Wang, H.; Chen, J.; Wang, Z.; Lu, Y.; Chen, Y.; Ji, L.; Cheng, J. Alternating current electroluminescent device powered by triboelectric nanogenerator with capacitively driven circuit strategy. Adv. Funct. Mater. 2021, 32, 2106411.

- Song, Y.; Wang, N.; Wang, Y.; Zhang, R.; Olin, H.; Yang, Y. Direct current triboelectric nanogenerators. Adv. Energy Mater. 2020, 10, 2002756.

- Shan, C.; Li, K.; Cheng, Y.; Hu, C. Harvesting environment mechanical energy by direct current triboelectric nanogenerators. Nano-micro Lett. 2023, 15, 127.

- Shi, Q.; He, T.; Lee, C. More than energy harvesting—Combining triboelectric nanogenerator and flexible electronics technology for enabling novel micro-/nano-systems. Nano Energy 2019, 57, 851–871.

- Li, Z.B.; Li, H.Y.; Fan, Y.J.; Liu, L.; Chen, Y.H.; Zhang, C.; Zhu, G. Small-sized, lightweight, and flexible triboelectric nanogenerator enhanced by PTFE/PDMS nanocomposite electret. ACS Appl. Mater. Interfaces 2019, 11, 20370–20377.

- Wang, S.; Lin, L.; Wang, Z.L. Triboelectric nanogenerators as self-powered active sensors. Nano Energy 2015, 11, 436–462.

- Zhang, C.; Zhou, T.; Tang, W.; Han, C.; Zhang, L.; Wang, Z.L. Rotating-disk-based direct-current triboelectric nanogenerator. Adv. Energy Mater. 2014, 4, 1301798.

- Wang, J.; Wu, Z.; Pan, L.; Gao, R.; Zhang, B.; Yang, L.; Guo, H.; Liao, R.; Wang, Z.L. Direct-current rotary-tubular triboelectric nanogenerators based on liquid-dielectrics contact for sustainable energy harvesting and chemical composition analysis. ACS Nano 2019, 13, 2587–2598.

- Qiao, G.; Wang, J.; Yu, X.; Jia, R.; Cheng, T.; Wang, Z.L. A bidirectional direct current triboelectric nanogenerator with the mechanical rectifier. Nano Energy 2021, 79, 105408.

- Fu, S.; He, W.; Wu, H.; Shan, C.; Du, Y.; Li, G.; Wang, P.; Guo, H.; Chen, J.; Hu, C. High output performance and ultra-durable DC output for triboelectric nanogenerator inspired by primary cell. Nano-Micro Lett. 2022, 14, 155.

- Du, Y.; Fu, S.; Shan, C.; Wu, H.; He, W.; Wang, J.; Guo, H.; Li, G.; Wang, Z.; Hu, C. A novel design based on mechanical time-delay switch and charge space accumulation for high output performance direct-current triboelectric nanogenerator. Adv. Funct. Mater. 2022, 32, 2208783.

- Ryu, H.; Lee, J.H.; Khan, U.; Kwak, S.S.; Hinchet, R.; Kim, S.-W. Sustainable direct current powering a triboelectric nanogenerator via a novel asymmetrical design. Energy Environ. Sci. 2018, 11, 2057–2063.

- Dharmasena, R.D.I.G.; Cronin, H.M.; Dorey, R.A.; Silva, S.R.P. Direct current contact-mode triboelectric nanogenerators via systematic phase shifting. Nano Energy 2020, 75, 104887.

- Wang, J.; Li, Y.; Xie, Z.; Xu, Y.; Zhou, J.; Cheng, T.; Zhao, H.; Wang, Z.L. Cylindrical direct-current triboelectric nanogenerator with constant output current. Adv. Energy Mater. 2020, 10, 1904227.

- Hu, Y.; Li, X.; Zhao, Z.; Zhang, C.; Zhou, L.; Li, Y.; Liu, Y.; Wang, J.; Wang, Z.L. Triboelectric nanogenerator with low crest factor via precise phase difference design realized by 3D printing. Small Methods 2021, 5, e2100936.

- Li, X.; Zhang, C.; Gao, Y.; Zhao, Z.; Hu, Y.; Yang, O.; Liu, L.; Zhou, L.; Wang, J.; Wang, Z.L. A highly efficient constant-voltage triboelectric nanogenerator. Energy Environ. Sci. 2022, 15, 1334–1345.

- Yang, Y.; Zhang, H.; Wang, Z.L. Direct-current triboelectric generator. Adv. Funct. Mater. 2014, 24, 3745–3750.

- Chen, C.; Guo, H.; Chen, L.; Wang, Y.-C.; Pu, X.; Yu, W.; Wang, F.; Du, Z.; Wang, Z.L. Direct current fabric triboelectric nanogenerator for biomotion energy harvesting. ACS Nano 2020, 14, 4585–4594.

- Li, G.; Wu, S.; Sha, Z.; Zhou, Y.; Wang, C.-H.; Peng, S. Dual-breakdown direct-current triboelectric nanogenerator with synergistically enhanced performance. Nano Energy 2022, 99, 107355.

- Liu, D.; Yin, X.; Guo, H.; Zhou, L.; Li, X.; Zhang, C.; Wang, J.; Wang, Z.L. A constant current triboelectric nanogenerator arising from electrostatic breakdown. Sci. Adv. 2019, 5, eaav6437.

- Zhao, Z.; Dai, Y.; Liu, D.; Zhou, L.; Li, S.; Wang, Z.L.; Wang, J. Rationally patterned electrode of direct-current triboelectric nanogenerators for ultrahigh effective surface charge density. Nat. Commun. 2020, 11, 6186.

- Gao, Y.; Liu, D.; Zhou, L.; Li, S.; Zhao, Z.; Yin, X.; Chen, S.; Wang, Z.L.; Wang, J. A robust rolling-mode direct-current triboelectric nanogenerator arising from electrostatic breakdown effect. Nano Energy 2021, 85, 106014.

- Chen, J.; Gong, S.; Gong, T.; Yang, X.; Guo, H. Stackable direct current triboelectric-electromagnetic hybrid nanogenerator for self-powered air purification and quality monitoring. Adv. Energy Mater. 2023, 13, 2203689.

- Mariello, M. Recent advances on hybrid piezo-triboelectric bio-nanogenerators: Materials, architectures and circuitry. Nanoenergy Adv. 2022, 2, 64–109.

- Zhang, Y.; Zeng, Q.; Wu, Y.; Wu, J.; Yuan, S.; Tan, D.; Hu, C.; Wang, X. An ultra-durable windmill-like hybrid nanogenerator for steady and efficient harvesting of low-speed wind energy. Nano-Micro Lett. 2020, 12, 175.

- Zhang, J.-H.; Zhou, Z.; Li, J.; Shen, B.; Zhu, T.; Gao, X.; Tao, R.; Guo, X.; Hu, X.; Shi, Y.; et al. Coupling enhanced performance of triboelectric–piezoelectric hybrid nanogenerator based on nanoporous film of poly(vinylidene fluoride)/BaTiO3 composite electrospun fibers. ACS Mater. Lett. 2022, 4, 847–852.

- Lin, S.; Lin Wang, Z. The tribovoltaic effect. Mater. Today 2023, 62, 111–128.

- Xu, R.; Zhang, Q.; Wang, J.Y.; Liu, D.; Wang, J.; Wang, Z.L. Direct current triboelectric cell by sliding an n–type semiconductor on a p–type semiconductor. Nano Energy 2019, 66, 104185.

- Chen, Y.; Zhang, Z.; Wang, Z.; Bu, T.; Dong, S.; Wei, W.; Chen, Z.; Lin, Y.; Lv, Y.; Zhou, H.; et al. Friction-dominated carrier excitation and transport mechanism for GaN-based direct-current triboelectric nanogenerators. ACS Appl. Mater. Interfaces 2022, 14, 24020–24027.

- Wang, Z.; Zhang, Z.; Chen, Y.; Gong, L.; Dong, S.; Zhou, H.; Lin, Y.; Lv, Y.; Liu, G.; Zhang, C. Achieving an ultrahigh direct-current voltage of 130 V by semiconductor heterojunction power generation based on the tribovoltaic effect. Energy Environ. Sci. 2022, 15, 2366–2373.

- Zhang, Z.; Wang, Z.; Chen, Y.; Feng, Y.; Dong, S.; Zhou, H.; Wang, Z.L.; Zhang, C. Semiconductor contact-electrification-dominated tribovoltaic effect for ultrahigh power generation. Adv. Mater. 2022, 34, e2200146.

- Lee, Y.-S.; Jeon, S.; Kim, D.; Lee, D.-M.; Kim, D.; Kim, S.-W. High performance direct current-generating triboelectric nanogenerators based on tribovoltaic p-n junction with ChCl-passivated CsFAMA perovskite. Nano Energy 2023, 106, 108066.

- Zhang, Z.; Jiang, D.; Zhao, J.; Liu, G.; Bu, T.; Zhang, C.; Wang, Z.L. Tribovoltaic effect on metal–semiconductor interface for direct-current low-impedance triboelectric nanogenerators. Adv. Energy Mater. 2020, 10, 1903713.

- Meng, J.; Guo, Z.H.; Pan, C.; Wang, L.; Chang, C.; Li, L.; Pu, X.; Wang, Z.L. Flexible textile direct-current generator based on the tribovoltaic effect at dynamic metal-semiconducting polymer interfaces. ACS Energy Lett. 2021, 6, 2442–2450.

- Huang, X.; Xiang, X.; Nie, J.; Peng, D.; Yang, F.; Wu, Z.; Jiang, H.; Xu, Z.; Zheng, Q. Microscale Schottky superlubric generator with high direct-current density and ultralong life. Nat. Commun. 2021, 12, 2268.

- Yuan, H.; Xiao, Z.; Wan, J.; Xiang, Y.; Dai, G.; Li, H.; Yang, J. A rolling-mode Al/CsPbBr3 Schottky junction direct-current triboelectric nanogenerator for harvesting mechanical and solar energy. Adv. Energy Mater. 2022, 12, 2200550.

- Liu, J.; Miao, M.; Jiang, K.; Khan, F.; Goswami, A.; McGee, R.; Li, Z.; Nguyen, L.; Hu, Z.; Lee, J.; et al. Sustained electron tunneling at unbiased metal-insulator-semiconductor triboelectric contacts. Nano Energy 2018, 48, 320–326.

- Liu, J.; Cheikh, M.I.; Bao, R.; Peng, H.; Liu, F.; Li, Z.; Jiang, K.; Chen, J.; Thundat, T. Tribo-tunneling DC generator with carbon aerogel/silicon multi-nanocontacts. Adv. Electron. Mater. 2019, 5, 1900464.

- Liu, J.; Liu, F.; Bao, R.; Jiang, K.; Khan, F.; Li, Z.; Peng, H.; Chen, J.; Alodhayb, A.; Thundat, T. Scaled-up direct-current generation in MoS2 multilayer-based moving heterojunctions. ACS Appl. Mater. Interfaces 2019, 11, 35404–35409.

- Zhang, L.; Shalabny, A.; Su, C.; Cui, X.; Sweedan, A.; Zhang, K.; Harilal, S.; Sadhujan, S.; Bashouti, M.Y. Dynamic molecular tunnel junctions based on self-assembled monolayers for high tunneling current triboelectricity generation. J. Mater. Chem. A 2023, 11, 4946–4956.

- Lin, S.; Chen, X.; Wang, Z.L. The tribovoltaic effect and electron transfer at a liquid-semiconductor interface. Nano Energy 2020, 76, 105070.

- Zheng, M.; Lin, S.; Zhu, L.; Tang, Z.; Wang, Z.L. Effects of temperature on the tribovoltaic effect at liquid-solid interfaces. Adv. Mater. Interfaces 2021, 9, 2101757.

- Zhang, R.; Wang, S.; Yeh, M.-H.; Pan, C.; Lin, L.; Yu, R.; Zhang, Y.; Zheng, L.; Jiao, Z.; Wang, Z.L. A streaming potential/current-based microfluidic direct current generator for self-powered nanosystems. Adv. Mater. 2015, 27, 6482–6487.

- Dong, J.; Xu, C.; Zhu, L.; Zhao, X.; Zhou, H.; Liu, H.; Xu, G.; Wang, G.; Zhou, G.; Zeng, Q.; et al. A high voltage direct current droplet-based electricity generator inspired by thunderbolts. Nano Energy 2021, 90, 106567.

- Chi, J.; Liu, C.; Che, L.; Li, D.; Fan, K.; Li, Q.; Yang, W.; Dong, L.; Wang, G.; Wang, Z.L. Harvesting Water-Evaporation-Induced Electricity Based on Liquid-Solid Triboelectric Nanogenerator. Adv. Sci. 2022, 9, e2201586.

- Li, X.; Li, S.; Guo, X.; Shao, J.; Wang, Z.L.; Wei, D. Triboiontronics for efficient energy and information flow. Matter 2023, 6, 1–15.

- Ouyang, Y.; Li, X.; Peng, P.; Yang, F.; Wang, Z.L.; Wei, D. Opto-iontronic coupling in triboelectric nanogenerator. Nano Energy 2023, 116, 108796.

- Kim, T.; Kim, D.Y.; Yun, J.; Kim, B.; Lee, S.H.; Kim, D.; Lee, S. Direct-current triboelectric nanogenerator via water electrification and phase control. Nano Energy 2018, 52, 95–104.

- Yu, X.; Zheng, H.; Lu, Y.; Shen, R.; Yan, Y.; Hao, Z.; Yang, Y.; Lin, S. Wind driven semiconductor electricity generator with high direct current output based on a dynamic Schottky junction. RSC Adv. 2021, 11, 19106–19112.

- Tao, K.; Zhao, Z.; Mao, X.; Shen, W.; Qiu, C.; Qi, H.; Ye, T.; Zhang, X.; Wu, J.; Fan, K.; et al. Direct-current, long-lasting and highly efficient electret energy harvesting from ultra-low-frequency motions using toothed clutch mechanism. Nano Energy 2023, 105, 107998.

- Chen, P.; An, J.; Cheng, R.; Shu, S.; Berbille, A.; Jiang, T.; Wang, Z.L. Rationally segmented triboelectric nanogenerator with a constant direct-current output and low crest factor. Energy Environ. Sci. 2021, 14, 4523–4532.

- Li, S.; Liu, D.; Zhao, Z.; Zhou, L.; Yin, X.; Li, X.; Gao, Y.; Zhang, C.; Zhang, Q.; Wang, J.; et al. A fully self-powered vibration monitoring system driven by dual-mode triboelectric nanogenerators. ACS Nano 2020, 14, 2475–2482.

- Li, S.; Zhao, Z.; Liu, D.; An, J.; Gao, Y.; Zhou, L.; Li, Y.; Cui, S.; Wang, J.; Wang, Z.L. A self-powered dual–type signal vector sensor for smart robotics and automatic vehicles. Adv. Mater. 2022, 34, e2110363.

- Wang, Y.; Huang, T.; Gao, Q.; Li, J.; Wen, J.; Wang, Z.L.; Cheng, T. High-voltage output triboelectric nanogenerator with DC/AC optimal combination method. Nano Res. 2021, 15, 3239–3245.

- Yu, J.R.; Yang, X.X.; Gao, G.Y.; Xiong, Y.; Wang, Y.F.; Han, J.; Chen, Y.H.; Zhang, H.; Sun, Q.J.; Wang, Z.L. Bioinspired mechano-photonic artificial synapse based on graphene/MoS2 heterostructure. Sci. Adv. 2021, 7, eabd9117.

- Qiao, W.; Zhao, Z.; Zhou, L.; Liu, D.; Li, S.; Yang, P.; Li, X.; Liu, J.; Wang, J.; Wang, Z.L. Simultaneously enhancing direct-current density and lifetime of tribovotaic nanogenerator via interface lubrication. Adv. Funct. Mater. 2022, 32, 2208544.