Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Rodrigo Pereira | -- | 2341 | 2023-10-13 14:57:28 | | | |

| 2 | Jason Zhu | Meta information modification | 2341 | 2023-10-17 03:20:44 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Pereira, R.; Lima, C.; Pinto, T.; Reis, A. Virtual Assistants in Industry 4.0. Encyclopedia. Available online: https://encyclopedia.pub/entry/50280 (accessed on 07 February 2026).

Pereira R, Lima C, Pinto T, Reis A. Virtual Assistants in Industry 4.0. Encyclopedia. Available at: https://encyclopedia.pub/entry/50280. Accessed February 07, 2026.

Pereira, Rodrigo, Claudio Lima, Tiago Pinto, Arsénio Reis. "Virtual Assistants in Industry 4.0" Encyclopedia, https://encyclopedia.pub/entry/50280 (accessed February 07, 2026).

Pereira, R., Lima, C., Pinto, T., & Reis, A. (2023, October 13). Virtual Assistants in Industry 4.0. In Encyclopedia. https://encyclopedia.pub/entry/50280

Pereira, Rodrigo, et al. "Virtual Assistants in Industry 4.0." Encyclopedia. Web. 13 October, 2023.

Copy Citation

Information and Communication Technologies are driving the improvement of industrial processes. According to the Industry 4.0 (I4.0) paradigm, digital systems provide real-time information to humans and machines, increasing flexibility and efficiency in production environments. Based on the I4.0 Design Principles concept, Virtual Assistants can play a vital role in processing production data and offer contextualized and real-time information to the workers in the production environment.

Virtual Assistants

Industry 4.0

ambient assisted working

Technical Assistance

1. Introduction

In the Industry 4.0 (or Industrie 4.0) (I4.0) paradigm adopted by the German government, the industrial processes are improved through Information and Communication Technologies (ICT). One of the main goals of I4.0 is to provide real-time information to humans and machines, making the production process more efficient and flexible [1]. This industrial environment sensing can be achieved by using concepts such as Ambient Assisted Working (AAW) [2], based on the I4.0 Design Principles [3], which defines Technical Assistance as one of the pivotal areas, split into Physical and Virtual Assistance.

Despite its widespread adoption, there is no unified and universally accepted definition of the “Industry 4.0” concept in the literature. In this perspective, the I4.0 Design Principles, which can be defined as Interconnection, Information Transparency, Decentralization of Decisions, and Technical Assistance, based on [3], represent the possibility to systematize knowledge and support professionals in developing appropriate solutions [4][5]. The Technical Assistance principle considers that, in I4.0 intelligent factories, through Virtual and Physical Assistance, the role of design centered on the human operator [6] is to perform functions with higher added value, enabling strategic decision-making and problem-solving with flexibility [3][7].

In this perspective, Virtual Assistance is a method to provide information quickly and efficiently, based on the ability to filter and interpret information from enormous databases and provide suggestions based on that information [3]. Usually, it can be performed by chatbots or Virtual Assistants. A Virtual Assistant (VA) can be defined as a software agent that can perform tasks or services based on commands or questions [8], an abstraction layer that sits on top of services and/or applications and performs actions using these services and app, with implications of fulfilling the user intent [9]. With the increasing use of VAs in other areas of business such as customer relationship and marketing, e.g., Amazon Echo © or Google Assistant ©, the use of this interaction mode is expanding into I4.0.

The development and use of VAs in many contemporary environments, such as finance, health, education, and production, bring significant advantages: full-time availability, multi-language capability, real-time response, inexpensive maintenance, being easy-to-replicate, extensive knowledge capabilities, and services available via text or speech [10]. On the other hand, despite these positive advances, some issues are posed to the wide adoption of VAs, such as user security and privacy, noisy industrial environments, and ethical issues [10][11].

The research on VAs in I4.0 has gained significant relevance due to their growing and extensive adoption in I4.0 settings, where data-driven decisions play a pivotal role in better-informed decision-making. However, the current literature lacks comprehensive and systematic reviews specifically addressing VA applications in the I4.0 domain, as most-existing reviews focus on other domains such as education [12], health [13], and mobility [14].

2. Characteristics of the Technical Assistance Design Principle Present in the Solutions

The principle of Technical Assistance in Industry 4.0 was divided into two groups: Virtual Assistance and Physical Assistance state that, with the increasing complexity of production systems, humans will transition from mere operators to decision-makers and problem-solvers [3]. To do so, systems need to provide filtered and understandable information to the user for an informed decision (Virtual Assistance). The support of ICT in human tasks (Physical Assistance) is also an important aspect, as with advancements in robotics, it can assist with repetitive or dangerous tasks.

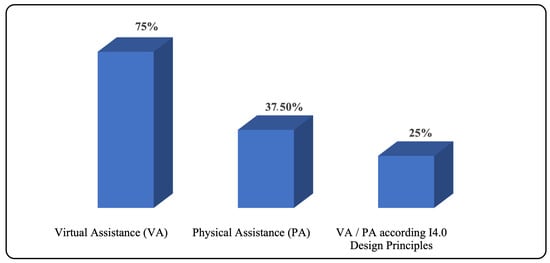

In the following Table 1, the papers are compared taking into consideration the implementation of the Technical Assistance principle in their solutions, in its two modalities—Virtual Assistance and Physical Assistance—and whether they were explicitly based on the Technical Design Principles [3] or not. Figure 1 shows these in a graphical comparison of the three assistance types.

Figure 1. Distribution of papers based on the Technical Assistant Design Principle.

Table 1. Technical Assistance characteristics regarding the type of assistance.

| Virtual Assistance | Physical Assistance | Based on Principles | |

|---|---|---|---|

| Li et al. [15] | ✔ | ✔ | - |

| Trappey et al. [16] | ✔ | - | - |

| Reis et al. [17] | ✔ | - | ✔ |

| Pavlov et al. [18] | - | ✔ | - |

| Casillo et al. [19] | ✔ | - | - |

| Mantravadi et al. [20] | ✔ | - | ✔ |

| Rooein et al. [21] | ✔ | - | - |

| Amendano-Murrillo et al. [22] | - | ✔ | - |

2.1. Virtual Assistance

Virtual Assistance refers to remote support through a digital interface, providing information, guidance, decision-making support, learning, and training, among other features. VAs in the I4.0 paradigm play an important role in providing real-time information so that operators or directors can have accessible and filtered information for better decision-making. Li et al. [15], Reis et al. [17], and Mantravadi et al. [20] presented solutions that enable real-time information retrieval reflecting the status of a machine or factory. Li et al. [15] connected machines and robots through APIs to visualize the state of robots and the tasks they were executing, to monitor machines, and to act quickly in case of failure or breakdown. Reis et al. [17] presented an assistant from the perspective of production directors and managers, where the assistant responds to production status information (recorded stoppages, quantity of produced products, etc.) and performs automatic reports, acting as an interface and automatic filter for factory systems such as an MES or ERP. Similar to [17], Ref. [20] also presented a chatbot that acts as an interface between the MES and the workers.

VAs and chatbots, with their ease of communication with users through natural language techniques, also provide important help in providing static information, with the main goal being teaching and information about production processes. Trappey et al. [16], Casillo et al. [19], and Rooein et al. [21] presented solutions that provide information and answer questions based on an initial Knowledge Base (KB). Trappey et al. [16] presented a framework that can answer various questions based on FAQs and, with the help of VR technologies, can provide information in 3D environments. Casillo et al. [19] presented a chatbot that acts as an assistant in learning and training new workers in manufacturing and serves as a means of providing knowledge to workers during the production process training. Rooein et al. [21] introduced and proposed a chatbot usage framework to adapt and learn from a company’s work processes. A way to adapt to each process was presented through graphs, with the objective of helping, guiding, and teaching new employees about the processes.

2.2. Physical Assistance

On the other hand, Physical Assistance includes on-site help from the worker, either through task execution or through the provision of tools and information to troubleshoot his/her work and problems. VAs in this category can not only act as a request interface for task execution, but also for monitoring.

Li et al. [15] and Amendano-Murrillo et al. [22] presented solutions that allow for the invocation or local execution of tasks, either through API connection with robots, as was the case in [15], where the VA can ask robots to perform tasks requested by the user, or through the solution itself, which has hardware available that allows for task execution, as in the prototype presented in [22], where the robot has cameras and stepper motors that allow for actions to be performed.

Pavlov et al. [18] and also Li et al. [15] allowed for local information about the status of work machines and their production process. In [18], the authors proposed a monitoring system with the help of VR/AR. This solution differs from assistants that are usually based on interaction with chatbots because, with the help of VR and AR, it informs the worker in real-time of problems and also helps him/her with his/her task by informing them of what needs to be done, as well as the factory status. In [15], with the integration of robots with the API, as mentioned earlier, not only does it allow for tasks to be performed, but it also receives the status and logs of tasks and robot problems, helping workers in problem-solving.

3. VA Solutions Oriented toward Services in the Context of Industry 4.0

An assistant is someone or something that helps the user and responds to his/her questions, requiring the knowledge and information necessary to provide the user with the requested answer or execute a task. VAs have some common services and features, mainly in their interface for communicating with the user, as well as mechanisms and services for “translating” user input into language that the computer understands, in order to answer a question or perform a task.

Therefore, VA solutions oriented toward a specific area, in this case the industry, need to add or have specific knowledge or services oriented toward the application area. Regarding these services and modules specifically for I4.0, the analyzed papers presented collaboration in two ways. For dynamic information, these services collaborate with the existing services and legacy systems through the creation of integration services. In another way, for static information, these services build a knowledge base based on real processed data. A synthesis of this kind of services is demonstrated in Table 2.

Table 2. VA solutions oriented toward services in I4.0.

| Dynamic Information | Static Information | |

|---|---|---|

| Li et al. [15] | ✔ | - |

| Trappey et al. [16] | - | ✔ |

| Reis et al. [17] | ✔ | - |

| Pavlov et al. [18] | ✔ | - |

| Casillo et al. [19] | - | ✔ |

| Mantravadi et al. [20] | ✔ | - |

| Rooein et al. [21] | - | ✔ |

| Amendano-Murrillo et al. [22] | ✔ | - |

Li et al. [15], Reis et al. [17], Pavlov et al. [18], and Mantravadi et al. [20] presented integration services that help support their solutions. Li et al. [15] presented an integration service to an API for the control and monitoring of a specific type of robot. Reis et al. [17], with the help of middleware, could extract information from existing services and data, in this case the MES. Pavlov et al. [18] presented integration modules with sensors present in the factory for capturing information, while Mantravadi et al. [20] and Reis et al. [17] presented an integration service with the MES.

Trappey et al. [16], Casillo et al. [19], and Rooein et al. [21], as solutions that do not provide information in a real context, but in providing static information, i.e., [19] or [21], which are training and learning solutions, used a KB, a previously organized database, to provide information to the solutions based on it.

When considering the relevance of real-time information in these environments, it is also possible to relate Physical Assistance to a greater need for real-time information. Comparing Table 1 (types of assistance—Physical or Virtual) with Table 2 (type of information associated with the services—static or dynamic), it is possible to infer that studies based on Physical Assistance relate to services based on dynamic information, while studies related to training and machine operation/maintenance relate to static information. When considering the growth of Cyber–Physical Systems (CPSs) in I4.0, the number of studies related to dynamic information, often in real-time, seems to indicate a growing relevance in the use of services based on dynamic data.

4. Limitations for the Adoption of Virtual Assistance Solutions in Industry 4.0

The introduction of the new paradigm of Industry 4.0 brings new challenges that need to be addressed and solved for its implementation to be efficient and advantageous. Based on [23][24][25], some challenges related to the design and implementation of VAs and information systems in the industrial context have been identified. They are:

-

Environment: adaptation to noisy environments and adverse conditions in factories;

-

Integration: integration with legacy and heterogeneous systems in factories;

-

Security: ensuring the security and privacy of sensitive production data;

-

Personalization: customization and adaptation to meet the specific needs of each industry;

-

Real-time: real-time decision-making, considering the human limitation in processing large volumes of information.

The solutions presented in the papers are analyzed in Table 3, with the objective of understanding if these challenges are considered in their implementation. Adapting to noisy and adverse environments in the factory is important because the solution needs to have all the conditions to communicate and interact with the user in an adverse environment. Among the analyzed papers, only [22] was concerned with adverse environments in factories, such as noise, where the solution presented was subjected to various environments and presented satisfactory results.

Table 3. Limitations addressed by the solutions.

| Environment | Integration | Security | Personalization | Real-Time | |

|---|---|---|---|---|---|

| Li et al. [15] | - | ✔ | - | - | ✔ |

| Trappey et al. [16] | - | - | - | ✔ | - |

| Reis et al. [17] | - | ✔ | ✔ | ✔ | ✔ |

| Pavlov et al. [18] | - | ✔ | - | ✔ | ✔ |

| Casillo et al. [19] | - | - | - | - | - |

| Mantravadi et al. [20] | - | ✔ | - | - | ✔ |

| Rooein et al. [21] | - | - | - | ✔ | ✔ |

| Amendano-Murrillo et al. [22] | ✔ | ✔ | - | ✔ | - |

As discussed earlier, integration with various legacy services and modules of a particular industry is crucial to the execution of the VA’s purpose. The papers [15][17][18][20], as previously presented, offered integration services with APIs or databases.

In the I4.0 paradigm and in other areas, one of the biggest challenges is computer security and data privacy. In the industry environment, data security and privacy are even more of a concern as they deal with very sensitive data, such as customer data or confidential information. Among the analyzed works, only Reis et al. [17] presented a security method and barrier to sensitive factory data, having created an independent database that is updated with factory data through middleware that allows data flow control. The other works that had direct integration with data did not present any kind of data security and filtering. Papers that did not present integration or did not require such integration only need to consider this in the choice of data to populate their databases.

Designing a solution with customization in mind allows the solution to adapt to other industries, not just the one it was created and tested for. In general, all analyzed solutions present characteristics (modules/services) that allow the addition and modification of their area of operation. Casillo et al. [19] and Rooein et al. [21], being training-oriented, were those that had greater customization and adaptation capacity to new environments and processes.

With the transition from operators to decision-makers, the provision of real-time information is critical, as the decisions and actions are taken based on it. The solutions presented that aim to support decision-making and monitoring [15][17][18][20] take into account real-time information to better inform users. The other solutions that are more specific to providing static and training information do not provide this capability.

References

- Lasi, H.; Fettke, P.; Kemper, H.G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242.

- Reis, A.; Rocha, T.; Barroso, J.; Carvalho, D. The Ambient Assisted Working (AAW) concept: Assistance according to I4.0 Technical Assistance Design Principle. In Proceedings of the 15th International Conference on PErvasive Technologies Related to Assistive Environments, Corfu, Greece, 29 June–1 July 2022; pp. 316–318.

- Hermann, M.; Pentek, T.; Otto, B. Design Principles for industrie 4.0 scenarios. In Proceedings of the 2016 49th Hawaii International Conference on System Sciences (HICSS), Koloa, HI, USA, 5–8 January 2016; pp. 3928–3937.

- Gregor, S.D.; Hart, D.N. Information Systems Foundations: Building the Theoretical Base; Australian National University: Canberra, Australia, 2002; pp. 1–20.

- Gregor, S. Building theory in the sciences of the artificial. In Proceedings of the 4th International Conference on Design Science Research in Information Systems and Technology, Philadelphia, PA, USA, 7–8 May 2009; pp. 1–10.

- Nguyen, H.N.; Lasa, G.; Iriarte, I.; Atxa, A.; Unamuno, G.; Galfarsoro, G. Human-centered design for advanced services: A multidimensional design methodology. Adv. Eng. Inform. 2022, 53, 101720.

- Sung, T.K. Industry 4.0: A Korea perspective. Technol. Forecast. Soc. Chang. 2018, 132, 40–45.

- Soofastaei, A. Introductory Chapter: Virtual Assistants. In Virtual Assistant; Soofastaei, A., Ed.; IntechOpen: London, UK, 2021; pp. 1–9.

- Sarikaya, R. The technology behind personal digital assistants: An overview of the system architecture and key components. IEEE Signal Process. Mag. 2017, 34, 67–81.

- Piñeiro-Martín, A.; Garcia-Mateo, C.; Docío-Fernández, L.; López-Pérez, M.d.C. Ethical Challenges in the Development of Virtual Assistants Powered by Large Language Models. Electronics 2023, 12, 3170.

- Bolton, T.; Dargahi, T.; Belguith, S.; Al-Rakhami, M.S.; Sodhro, A.H. On the security and privacy challenges of Virtual Assistants. Sensors 2021, 21, 2312.

- Gubareva, R.; Lopes, R.P. Virtual Assistants for Learning: A Systematic Literature Review. CSEDU 2020, 1, 97–103.

- De Cock, C.; Milne-Ives, M.; van Velthoven, M.H.; Alturkistani, A.; Lam, C.; Meinert, E. Effectiveness of conversational agents (Virtual Assistants) in health care: Protocol for a systematic review. JMIR Res. Protoc. 2020, 9, e16934.

- Lugano, G. Virtual Assistants and self-driving cars. In Proceedings of the 2017 15th International Conference on ITS Telecommunications (ITST), Warsaw, Poland, 29–31 May 2017; pp. 1–5.

- Li, C.; Hansen, A.K.; Chrysostomou, D.; Bøgh, S.; Madsen, O. Bringing a natural language-enabled Virtual Assistant to industrial mobile robots for learning, training and assistance of manufacturing tasks. In Proceedings of the 2022 IEEE/SICE International Symposium on System Integration (SII), Narvik, Norway, 9–12 January 2022; pp. 238–243.

- Trappey, A.J.; Trappey, C.V.; Chao, M.H.; Wu, C.T. VR-enabled engineering consultation chatbot for integrated and intelligent manufacturing services. J. Ind. Inf. Integr. 2022, 26, 100331.

- Reis, A.; Barroso, J.; Santos, A.; Rodrigues, P.; Pereira, R. Virtual Assistance in the Context of the Industry 4.0: A Case Study at Continental Advanced Antenna. In Information Systems and Technologies: WorldCIST 2022; Springer: Berlin/Heidelberg, Germany, 2022; Volume 1, pp. 651–662.

- Pavlov, D.; Sosnovsky, I.; Dimitrov, V.; Melentyev, V.; Korzun, D. Case study of using virtual and augmented reality in industrial system monitoring. In Proceedings of the 2020 26th Conference of Open Innovations Association (FRUCT), Yaroslavl, Russia, 20–24 April 2020; pp. 367–375.

- Casillo, M.; Colace, F.; Fabbri, L.; Lombardi, M.; Romano, A.; Santaniello, D. Chatbot in industry 4.0: An approach for training new employees. In Proceedings of the 2020 IEEE International Conference on Teaching, Assessment, and Learning for Engineering (TALE), Takamatsu, Japan, 8–11 December 2020; pp. 371–376.

- Mantravadi, S.; Jansson, A.D.; Møller, C. User-friendly mes interfaces: Recommendations for an ai-based chatbot assistance in industry 4.0 shop floors. In Proceedings of the Intelligent Information and Database Systems: 12th Asian Conference, ACIIDS 2020, Phuket, Thailand, 23–26 March 2020; Proceedings, Part II 12. Springer: Berlin/Heidelberg, Germany, 2020; pp. 189–201.

- Rooein, D.; Bianchini, D.; Leotta, F.; Mecella, M.; Paolini, P.; Pernici, B. Chatting about processes in digital factories: A model-based approach. In Proceedings of the Enterprise, Business-Process and Information Systems Modeling: 21st International Conference, BPMDS 2020, 25th International Conference, EMMSAD 2020, Held at CAiSE 2020, Grenoble, France, 8–9 June 2020; Proceedings 21. Springer: Berlin/Heidelberg, Germany, 2020; pp. 70–84.

- Amendano-Murrillo, S.; Dután-Gómez, C.; Lema-Condo, E.; Robles-Bykbaev, V. Personal robotic assistants: A proposal based on the intelligent services of the IBM cloud and additive manufacturing. In Proceedings of the 2020 IEEE ANDESCON, Quito, Ecuador, 13–16 October 2020; pp. 1–6.

- Schmidt, B.; Borrison, R.; Cohen, A.; Dix, M.; Gärtler, M.; Hollender, M.; Klöpper, B.; Maczey, S.; Siddharthan, S. Industrial Virtual Assistants: Challenges and opportunities. In Proceedings of the 2018 ACM International Joint Conference and 2018 International Symposium on Pervasive and Ubiquitous Computing and Wearable Computers, Singapore, 8–12 October 2018; pp. 794–801.

- Vaidya, S.; Ambad, P.; Bhosle, S. Industry 4.0—A glimpse. Procedia Manuf. 2018, 20, 233–238.

- Mohamed, M. Challenges and benefits of industry 4.0: An overview. Int. J. Supply Oper. Manag. 2018, 5, 256–265.

More

Information

Subjects:

Computer Science, Information Systems

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

755

Revisions:

2 times

(View History)

Update Date:

17 Oct 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No