| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Md Shahinoor Islam | -- | 1983 | 2022-11-30 14:54:01 | | | |

| 2 | Dean Liu | Meta information modification | 1983 | 2022-12-01 03:23:57 | | |

Video Upload Options

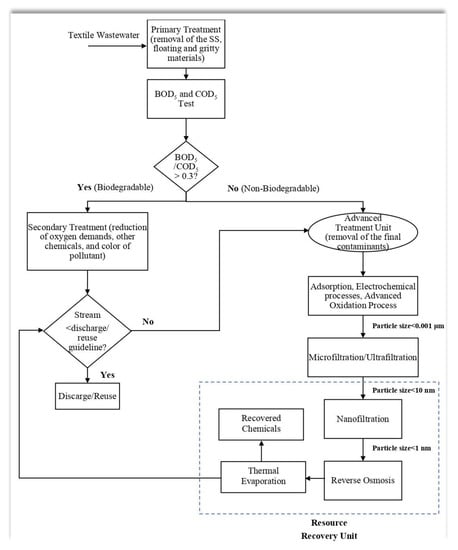

Clothing, one of the basic needs, demands the growth of textile industries worldwide, resulting in higher consumption and pollution of water. Consequently, it requires extensive treatment of textile effluent for environmental protection as well as reuse purposes. Primary treatment, secondary treatment, and tertiary treatment are the three major phases of textile wastewater treatment. Secondary treatment under aerobic and anaerobic circumstances is carried out to decrease BOD, COD, phenol, residual oil, and color, whereas primary treatment is utilized to remove suspended particles, oil, grease, and gritty materials. However, biological treatment is not fully capable of treating water according to discharge/reuse standards. Hence, tertiary treatment is used to remove final contaminants from the wastewater.

1. Introduction

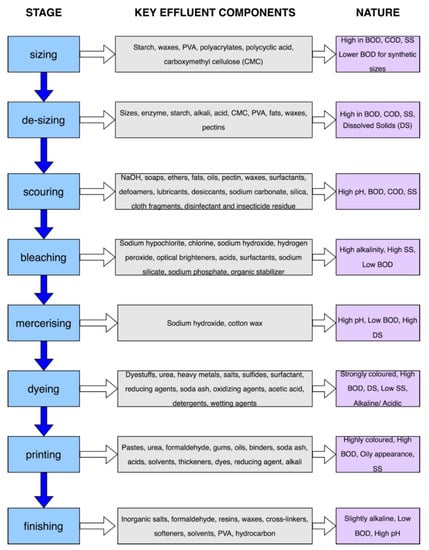

2. Stages of the Textile Processing Operation and Effluent Characteristics

| Wet Processing Stages | ||||||||

|---|---|---|---|---|---|---|---|---|

| Sizing | De-Sizing | Scouring | Bleaching | Mercerizing | Dyeing | Printing | Ref | |

| pH | 7–9.5 | 5.83–8 | 10–13 | 6–11.6 | 5.5–14 | 5–12.5 | 4–9 | [27][41][42][43][44][45] |

| COD (mg/L) |

- | 4600–15,000 | 1470–8000 | 1149–13,500 | 100–2688.5 | 1100–4600 | 785–49,170 | [27][41][42][43][44][45] |

| BOD (mg/L) |

600–2500 | 4400–5060 | 100–2900 | 50–1700 | 20–300 | 10–1800 | 400–1800 | [27][41][42][43][44][45] |

| Sulfate (mg/L) |

- | - | 68.5 | 76.3 | - | 224.9–758.7 | - | [42] |

| Chloride (mg/L) |

- | - | 342.4 | 90–516 | 199.5 | 213.3–26,000 | - | [27][42][43] |

| Copper (mg/L) |

- | - | - | - | - | 0.38–0.43 | - | [42] |

| Chromium (mg/L) |

- | - | - | - | - | 0.39–1.23 | - | [42] |

| TDS (mg/L) |

- | 8700–10,200 | 6323 | 2400–22,000 | 5000–12,000 | 35,000 | 2000 | [27][41] |

| TS (mg/L) |

- | 76,000–32,000 | 7600–17,400 | 2300–14,400 | 600–1900 | 500–50,000 | 2500 | [27][41][44] |

| TSS (mg/L) |

- | 400–4000 | - | 288.5 | 105.2 | 499.4 | 125–9500 | [27][43] |

| SS (mg/L) |

240–260 | 200–270 | 55 | 420–6500 | 2200 | 26,000 | 15,000–20,000 | [41] |

| NO3− (mg/L) |

- | - | - | 5.54 | 9.4 | 6.06 | - | [41][43] |

| NH4+ (mg/L) |

- | - | - | 8.0 | 8.53 | 14.34 | 20–370 | [27][43] |

| H2S (mg/L) |

- | - | - | 5.44 | 1.31 | 1.62 | - | [43] |

3. Treatment Methods

References

- Grant, S.B.; Saphores, J.-D.; Feldman, D.L.; Hamilton, A.J.; Fletcher, T.D.; Cook, P.L.M.; Stewardson, M.; Sanders, B.F.; Levin, L.A.; Ambrose, R.F.; et al. Taking the “Waste” Out of “Wastewater” for Human Water Security and Ecosystem Sustainability. Science 2012, 337, 681–686.

- Vörösmarty, C.J.; McIntyre, P.B.; Gessner, M.O.; Dudgeon, D.; Prusevich, A.; Green, P.; Glidden, S.; Bunn, S.E.; Sullivan, C.A.; Liermann, C.R.; et al. Global threats to human water security and river biodiversity. Nature 2010, 467, 555–561.

- Tong, T.; Elimelech, M. The Global Rise of Zero Liquid Discharge for Wastewater Management: Drivers, Technologies, and Future Directions. Environ. Sci. Technol. 2016, 50, 6846–6855.

- Pervez, M.N.; Balakrishnan, M.; Hasan, S.W.; Choo, K.-H.; Zhao, Y.; Cai, Y.; Zarra, T.; Belgiorno, V.; Naddeo, V. A critical review on nanomaterials membrane bioreactor (NMs-MBR) for wastewater treatment. NPJ Clean. Water 2020, 3, 43.

- Holkar, C.R.; Jadhav, A.J.; Pinjari, D.V.; Mahamuni, N.M.; Pandit, A.B. A critical review on textile wastewater treatments: Possible approaches. J. Environ. Manag. 2016, 182, 351–366.

- Hussain, T.; Wahab, A. A critical review of the current water conservation practices in textile wet processing. J. Clean. Prod. 2018, 198, 806–819.

- Schwarzenbach, R.P.; Egli, T.; Hofstetter, T.B.; von Gunten, U.; Wehrli, B. Global Water Pollution and Human Health. Annu. Rev. Environ. Resour. 2010, 35, 109–136.

- Agarwal, S.; Singh, A.P. Performance evaluation of textile wastewater treatment techniques using sustainability index: An integrated fuzzy approach of assessment. J. Clean. Prod. 2022, 337, 130384.

- Madhav, S.; Ahamad, A.; Singh, P.; Mishra, P.K. A review of textile industry: Wet processing, environmental impacts, and effluent treatment methods. Environ. Qual. Manag. 2018, 27, 31–41.

- Lofrano, G.; Brown, J. Wastewater management through the ages: A history of mankind. Sci. Total Environ. 2010, 408, 5254–5264.

- Eslamian, S.; Eslamian, F.A. Handbook of Drought and Water Scarcity: Management of Drought and Water Scarcity; CRC Press: Boca Raton, FL, USA, 2017.

- Lema, J.M.; Martinez, S.S. Innovative Wastewater Treatment & Resource Recovery Technologies: Impacts on Energy, Economy and Environment; IWA Publishing: London, UK, 2017.

- Voulvoulis, N. Water reuse from a circular economy perspective and potential risks from an unregulated approach. Curr. Opin. Environ. Sci. Health 2018, 2, 32–45.

- Chequer, F.D.; De Oliveira, G.R.; Ferraz, E.A.; Cardoso, J.C.; Zanoni, M.B.; De Oliveira, D.P. Chapter 6—Textile Dyes: Dyeing Process and Environmental Impact. In Eco-Friendly Textile Dyeing and Finishing; Melih, G., Ed.; IntechOpen: Rijeka, Croatia, 2013.

- Gao, B.; Huang, X.; Jiang, T.; Pervez, M.N.; Zhu, W.; Hassan, M.M.; Cai, Y.; Naddeo, V. Sustainable dyeing of ramie fiber with ternary reactive dye mixtures in liquid ammonia. RSC Adv. 2022, 12, 19253–19264.

- Yaseen, D.A.; Scholz, M. Treatment of synthetic textile wastewater containing dye mixtures with microcosms. Environ. Sci. Pollut. Res. 2018, 25, 1980–1997.

- Lin, J.; Ye, W.; Huang, J.; Ricard, B.; Baltaru, M.-C.; Greydanus, B.; Balta, S.; Shen, J.; Vlad, M.; Sotto, A.; et al. Toward Resource Recovery from Textile Wastewater: Dye Extraction, Water and Base/Acid Regeneration Using a Hybrid NF-BMED Process. ACS Sustain. Chem. Eng. 2015, 3, 1993–2001.

- Kesari, K.K.; Soni, R.; Jamal, Q.M.S.; Tripathi, P.; Lal, J.A.; Jha, N.K.; Siddiqui, M.H.; Kumar, P.; Tripathi, V.; Ruokolainen, J. Wastewater Treatment and Reuse: A Review of its Applications and Health Implications. Water Air Soil Pollut. 2021, 232, 208.

- Wang, X.; Jiang, J.; Gao, W. Reviewing textile wastewater produced by industries: Characteristics, environmental impacts, and treatment strategies. Water Sci. Technol. 2022, 85, 2076–2096.

- Ibrahim, Y.; Banat, F.; Naddeo, V.; Hasan, S.W. Numerical modeling of an integrated OMBR-NF hybrid system for simultaneous wastewater reclamation and brine management. Euro-Mediterr. J. Environ. Integr. 2019, 4, 23.

- Muhammad, Y.; Lee, W. Zero-liquid discharge (ZLD) technology for resource recovery from wastewater: A review. Sci. Total Environ. 2019, 681, 551–563.

- Lin, J.; Lin, F.; Chen, X.; Ye, W.; Li, X.; Zeng, H.; Van der Bruggen, B. Sustainable Management of Textile Wastewater: A Hybrid Tight Ultrafiltration/Bipolar-Membrane Electrodialysis Process for Resource Recovery and Zero Liquid Discharge. Ind. Eng. Chem. Res. 2019, 58, 11003–11012.

- Date, M.; Patyal, V.; Jaspal, D.; Malviya, A.; Khare, K. Zero liquid discharge technology for recovery, reuse, and reclamation of wastewater: A critical review. J. Water Process Eng. 2022, 49, 103129.

- Altınay, A.D.; Yazagan, A.; Koseoglu-Imer, D.Y.; Keskinler, B.; Koyuncu, I. Membrane Concentrate Management Model of Biologically Pre-treated Textile Wastewater for Zero-Liquid Discharge. Water Air Soil Pollut. 2022, 233, 303.

- Ricky, R.; Shanthakumar, S.; Ganapathy, G.P.; Chiampo, F. Zero Liquid Discharge System for the Tannery Industry–An Overview of Sustainable Approaches. Recycling 2022, 7, 31.

- Siddique, K.; Rizwan, M.; Shahid, M.J.; Ali, S.; Ahmad, R.; Rizvi, H. Textile Wastewater Treatment Options: A Critical Review. In Enhancing Cleanup of Environmental Pollutants: Volume 2: Non-Biological Approaches; Anjum, N.A., Gill, S.S., Tuteja, N., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 183–207.

- Bisschops, I.; Spanjers, H. Literature review on textile wastewater characterisation. Environ. Technol. 2003, 24, 1399–1411.

- Yaseen, D.A.; Scholz, M. Textile dye wastewater characteristics and constituents of synthetic effluents: A critical review. Int. J. Environ. Sci. Technol. 2019, 16, 1193–1226.

- Ul-Haq, N.; Nasir, H. Cleaner production technologies in desizing of cotton fabric. J. Text. Inst. 2012, 103, 304–310.

- Tanapongpipat, A.; Khamman, C.; Pruksathorm, K.; Hunsom, M. Process modification in the scouring process of textile industry. J. Clean. Prod. 2008, 16, 152–158.

- Li, Q.; Zhao, X.; Quan, H.; Zhou, Y. Establishing an energy-saving scouring/bleaching one-step process for cotton/spandex fabric using UVA-assisted irradiation. RSC Adv. 2022, 12, 9404–9415.

- Inamdar, U.Y.; Pervez, N.; Navik, R.G.; Peng, X.; Cai, Y. Low-temperature bleaching of cotton fabric by activated peroxide system. Emerg. Mater. Res. 2017, 6, 387–395.

- Abdel-Halim, E.S.; Al-Deyab, S.S. Low temperature bleaching of cotton cellulose using peracetic acid. Carbohydr. Polym. 2011, 86, 988–994.

- Wahab, A.; Hussain, T.; Ashraf, M. Water conservation in garment bleaching using aerosol technology. Text. Res. J. 2022, 92, 4629–4638.

- Zhang, Y.; Shao, S.; Yu, W.; Yang, F.; Xu, X. Study on recycling alkali from the wastewater of textile mercerization process by nanofiltration. Ieri Procedia 2014, 9, 71–76.

- Uddin, F. Environmental hazard in textile dyeing wastewater from local textile industry. Cellulose 2021, 28, 10715–10739.

- Samsami, S.; Mohamadizaniani, M.; Sarrafzadeh, M.-H.; Rene, E.R.; Firoozbahr, M. Recent advances in the treatment of dye-containing wastewater from textile industries: Overview and perspectives. Process Saf. Environ. Prot. 2020, 143, 138–163.

- Correia, V.M.; Stephenson, T.; Judd, S.J. Characterisation of textile wastewaters—A review. Environ. Technol. 1994, 15, 917–929.

- Natarajan, P.; Karmegam, P.M.; Madasamy, J.; Somasundaram, S.; Ganesan, S. Effective treatment of domestic sewage to reuse in textile dyeing and catalytic treatment of generated dye wastewater. Int. J. Environ. Sci. Technol. 2022.

- Vasconcelos, M.W.; Gonçalves, S.; de Oliveira, E.C.; Rubert, S.; de Castilhos Ghisi, N. Textile effluent toxicity trend: A scientometric review. J. Clean. Prod. 2022, 366, 132756.

- Periyasamy, A.P.; Ramamoorthy, S.K.; Rwawiire, S.; Zhao, Y. Sustainable Wastewater Treatment Methods for Textile Industry. In Sustainable Innovations in Apparel Production; Muthu, S.S., Ed.; Springer Singapore: Singapore, 2018; pp. 21–87.

- Ahmed, M.A. Reduction of Textile Industrial Waste water Pollution. Gezira J. Eng. Appl. Sci. 2018, 10, 1–12.

- Savin, I.-I.; Butnaru, R. Wastewater characteristics in textile finishing mills. Environ. Eng. Manag. J. (EEMJ) 2008, 7, 859–864.

- Zaharia, C.; Suteu, D. Chapter 3—Textile Organic Dyes—Characteristics, Polluting Effects and Separation/Elimination Procedures from Industrial Effluents—A Critical Overview. In Organic Pollutants Ten Years after the Stockholm Convention; Tomasz, P., Aleksandra, M.-S., Eds.; IntechOpen: Rijeka, Croatia, 2012.

- Ministry of Environment and Forest, Bangladesh. Guide for Assessment of Effluent Treatment Plants; Ministry of Environment and Forest, Bangladesh: Dhaka, Bangladesh, 2008; p. 79.

- Yukseler, H.; Uzal, N.; Sahinkaya, E.; Kitis, M.; Dilek, F.B.; Yetis, U. Analysis of the best available techniques for wastewaters from a denim manufacturing textile mill. J. Environ. Manag. 2017, 203, 1118–1125.

- Katheresan, V.; Kansedo, J.; Lau, S.Y. Efficiency of various recent wastewater dye removal methods: A review. J. Environ. Chem. Eng. 2018, 6, 4676–4697.