Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Dongxu Zhu | -- | 1186 | 2022-07-20 06:06:31 | | | |

| 2 | Sirius Huang | Meta information modification | 1186 | 2022-07-20 07:33:14 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Bu, C.; Zhu, D.; Lu, X.; Liu, L.; Sun, Y.; Yu, L.; Xiao, T.; Zhang, W. Waste Rubber Particles. Encyclopedia. Available online: https://encyclopedia.pub/entry/25306 (accessed on 07 February 2026).

Bu C, Zhu D, Lu X, Liu L, Sun Y, Yu L, et al. Waste Rubber Particles. Encyclopedia. Available at: https://encyclopedia.pub/entry/25306. Accessed February 07, 2026.

Bu, Changming, Dongxu Zhu, Xinyu Lu, Lei Liu, Yi Sun, Linwen Yu, Tao Xiao, Wentao Zhang. "Waste Rubber Particles" Encyclopedia, https://encyclopedia.pub/entry/25306 (accessed February 07, 2026).

Bu, C., Zhu, D., Lu, X., Liu, L., Sun, Y., Yu, L., Xiao, T., & Zhang, W. (2022, July 20). Waste Rubber Particles. In Encyclopedia. https://encyclopedia.pub/entry/25306

Bu, Changming, et al. "Waste Rubber Particles." Encyclopedia. Web. 20 July, 2022.

Copy Citation

One of the environmental problems causing concern in the world today is the black pollution caused by the accumulation of waste rubber resources. Rubber concrete can help solve the black pollution problem caused by waste rubber tires, but it is undeniable that rubber particles will reduce the mechanical properties of concrete. Research on waste rubber particles, particle size and properties are needed for the modification of rubberized concrete.

rubber

composition

chemical components

1. Type and Size of Rubber Particles

At present, there are as many as 25 kinds of rubber available on the market [1]. These kinds have different practical application fields. Automobile tires mainly use natural rubber, or natural rubber and carbon black composite materials, so the waste tire rubber involved in rubber concrete research is generally natural rubber or more complex synthetic rubber material. The utilization of waste tire rubber produced every year is shown in Table 1. Table 1 shows that 30% of the rubber is directly crushed and then landfilled. This treatment method not only wastes rubber resources, but also pollutes the environment.

Table 1. Statistics for world waste rubber resource utilization [1].

| Percentage | |

|---|---|

| Recovery | 3–15% |

| Reutilization | 5–23% |

| Recovery (energy) | 25–60% |

| Stacking | 20–30% |

Forrest [2] pointed out that rubber can be recycled in many ways, but it cannot be widely used due to the high energy consumption caused by technology shortages at present. Forrest thinks it is possible to simply reprocess rubber for reuse, such as turning it into coarse particles that can be used as aggregate in concrete [3]. Roychand [4] found that rubber particles often play an unfavorable role in the failure process of rubberized concrete. He believes that this is due to the soft and elastic properties of rubber. The larger the size of the rubber particles, the more space they occupy in the rubber concrete, and the more severe the failure response of the structure under load [5].

2. Properties of Rubber Particles

When conducting the test of rubber concrete, scholars choose different types and sizes of rubber particles, which are summarized in Table 2 for the convenience of readers.

Table 2. Rubber particle size statistics table.

| Reference | CR Size | Reference | CR Size | Reference | CR Size |

|---|---|---|---|---|---|

| Steyn et al. [6] | <4.75 mm (fine) | Taak et al. [7] | 10–20 mm (coarse) | Dehdezi et al. [8] | 2–4 mm (fine) |

| Tiwari et al. [9] | <4.75 mm (fine) | Mhaya et al. [10] | 1–4 mm (fine), 5–8 mm (coarse) | Abdelmonem et al. [11] | 0–4 mm (fine) |

| Ramdani et al. [12] | 0.2–4 mm (fine) | Karunarathna et al. [5] | 2–4 mm (fine), 15 mm(coarse) | Othman et al. [13] | 180 µm (fine) |

| Ossola. [14] | 420–840 µm (fine) | Rahim et al. [15] | 2–4 mm (fine) | Mousavimehr et al. [16] | 0–4.75 mm (fine) |

| Barrera et al. [17] | 0.85–2.8 mm (fine) | Habib et al. [18] | 0.075–10 mm (fine) | Liu et al. [19] | <0.42 mm (fine) |

| Su et al. [20] | 0.3 mm, 0.5 mm, 3 mm (fine) | Chaikaew et al. [21] | 3.36 mm (fine) | Eisa et al. [22] | 2–3 mm (fine) |

| Zhu et al. [23] | 1–2 mm (fine) | Aslani et al. [24] | 2–5 mm (fine) | Shahjalal et al. [25] | 4.75–19 mm (fine\coarse) |

| Li et al. [26] | 0–4 mm (fine) | Wang et al. [27] | 1.19–19 mm (fine\coarse) | Gerges et al. [28] | 710 µm (fine) |

| Aureliano et al. [29] | 0–1.18 mm (fine) | He et al. [30] | <0.088 mm (fine) | Liu et al. [31] | 0.178, 1.11, 2 mm (fine) |

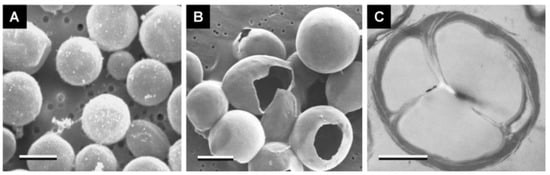

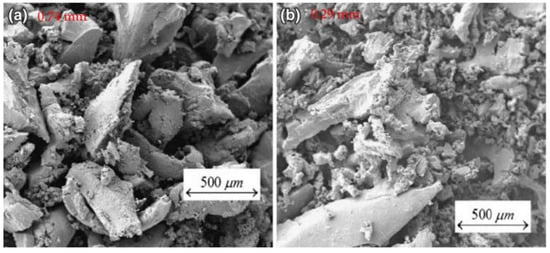

The smoothness of rubber prevents it from bonding effectively to cementitious substrates. Delilah [32] put rubber particles into a 0.1 m sodium carbonate buffer containing 3% glutaraldehyde and 2% formaldehyde for special treatment, and the surface of the rubber particles after the removal of impurities was smooth, as shown in Figure 1. In fact, if no special treatment is performed, but only after pulverization, the surface of the rubber particles will appear to be not smooth [33], as shown in Figure 2. The impurities remaining on the surface of the rubber particles after crushing will fall off when combined with the cement matrix, and there is no tight bond between the rubber particles and the impurities. Deliah’s research revealed the true appearance of rubber particles, and Segre [34] also observed the same phenomenon.

Figure 1. Microscopic image of elastic rubber particles. (A) Conventional SEM. (B) Field emission SEM at room temperature. (C) Transmission electron micrograph (TEM) of single rubber particles [32].

Figure 2. SEM of crumb rubber [33]. (a) 0.74 mm (b) 0.29 mm.

Delilah [32] pointed out that these impurities include acidic substances and carboxyl groups, which are derived from various admixtures added during the preparation of rubber tires. Rubber tires go through an intensive refining process during the production process, in which oils, additives, accelerators, carbon black and other substances are added. The composition of rubber tires is shown in Table 3, and the substances added during this process cannot be removed by simple mechanical crushing [4], as shown in Figure 3. Xiao et al. [35] found that low temperature plasma treatment roughened the surface of rubber particles and greatly reduced the water contact angle of rubber. The rough surface of the rubber was able to bond with the cement matrix better.

Figure 3. Different stages of tire shredding [4].

Table 3. Basic composition of reclaimed rubber particles [4].

| Material | Main Ingredients | Composition |

|---|---|---|

| Rubber | Natural rubber, synthetic rubber | 51% |

| Reinforcing agent | Carbon black, silica | 25% |

| Softener | Petroleum process oil, petroleum synthetic resin, etc. | 19.5% |

| Vulcanizing agent | Sulphur, organic vulcanizers | 1.0% |

| Vulcanizing accelerator | Thiazole accelerators, sulfenic amide accelerator | 1.5% |

| Vulcanizing accelerator aid | Zinc oxide, stearic acid | 0.5% |

| Antioxidant | Amine antioxidants, phenol antioxidants, wax | 1.5% |

| Filler | Calcium carbonate, clay |

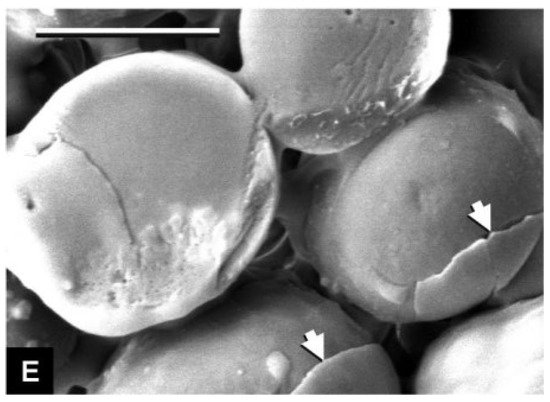

Rubber is a highly elastic material that can recover when subjected to external forces. The high elastic properties of rubber can make up for the high brittleness of concrete, while the low elastic modulus of concrete has always been the focus of research. The work of Karunarathna [5] shows that the elastic modulus of concrete is obviously reduced after the incorporation of rubber, and rubber can delay the development of structural cracks. Meanwhile, rubber particles can also act as bridges between cracks when concrete is damaged by force, as shown in Figure 4.

Figure 4. Crack bridging by tire shreds [5].

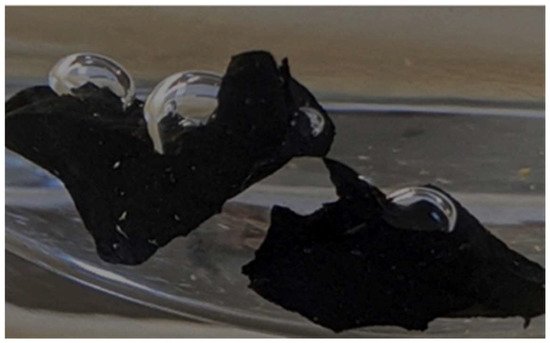

Rubber is a kind of porous material. Karunarathna confirmed the high gas content of rubber through research and photographed overflow bubbles on rubber surfaces when soaked in water, as shown in Figure 5. The porous structure of rubber allows it to contain more air, resulting in weak adhesion between rubber and cement matrix when mixed with concrete. Roychand [4] expressed that the problem of high gas content in rubber can be effectively improved by soaking the rubber in advance. Roychand believes that the porous structure in rubber is derived from the linear structure of the internal material composition, which guarantees the high elastic properties of the rubber.

Figure 5. Trapped air bubbles on tire shreds submerged in water [5].

Through Fourier transform infrared and X-ray fluorescence analysis, Jusli et al. [36] found that the main chemical components of broken tire rubber particles were carbon, zinc, silicon, magnesium and calcium. The main chemical components are shown in Table 4. According to Table 4, except for SBR, carbon black accounts for the vast majority. In addition, there are admixtures such as oil that cause crushed tire rubber to act differently to rubber alone. This is also a factor to consider when recycling scrap tire rubber. Delilah et al. [32] purified natural rubber using lactic acid bacteria and latex and concluded that natural rubber is composed of a rubber core and a protein coating by low-temperature plasma monorail scanning and protein chemical analysis, as shown in Figure 6.

Figure 6. Rubber structure diagram: low-temperature field-emission SEM (at 4 kV) of frozen-hydrated fractured particles; magnification bar = 2 mm [32].

Table 4. Rubber chemical composition [36].

| Chemical Composition | Percentage (%) |

|---|---|

| SBR | 48.0 |

| Carbon black | 47.0 |

| Extender oil | 1.9 |

| Zinc oxide | 1.1 |

| Stearic acid | 0.5 |

| Sulfur | 0.8 |

| Accelerator | 0.7 |

References

- Nuzaimah, M.; Sapuan, S.M.; Nadlene, R.; Jawaid, M. Recycling of waste rubber as fillers: A review. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 368, p. 012016.

- Forrest, M.J. Recycling and Re-Use of Waste Rubber; de Gruyter: Berlin, Germany, 2019.

- Stallings, K.A.; Durham, S.A.; Chorzepa, M.G. Effect of cement content and recycled rubber particle size on the performance of rubber-modified concrete. Int. J. Sustain. Eng. 2019, 12, 189–200.

- Roychand, R.; Gravina, R.J.; Zhuge, Y.; Ma, X.; Youssf, O.; Mills, J.E. A comprehensive review on the mechanical properties of waste tire rubber concrete. Constr. Build. Mater. 2020, 237, 117651.

- Karunarathna, S.; Linforth, S.; Kashani, A.; Liu, X.; Ngo, T. Effect of recycled rubber aggregate size on fracture and other mechanical properties of structural concrete. J. Clean. Prod. 2021, 314, 128230.

- Steyn, Z.C.; Babafemi, A.J.; Fataar, H.; Combrinck, R. Concrete containing waste recycled glass, plastic and rubber as sand replacement. Constr. Build. Mater. 2021, 269, 121242.

- Taak, N.; Sharma, L. Influence of compression casting technique and chipped rubber usage on the strength parameters of concrete. Mater. Today Proc. 2021, 45, 3462–3468.

- Dehdezi, P.K.; Erdem, S.; Blankson, M.A. Physico-mechanical, microstructural and dynamic properties of newly developed artificial fly ash based lightweight aggregate–Rubber concrete composite. Compos. Part B Eng. 2015, 79, 451–455.

- Tiwari, S.; Gangwar, P. Evaluate the effect of acid attack on rubberised concrete using crumb tyre rubber and replacement of cement by alccofine. Mater. Today Proc. 2021, 47, 3778–3782.

- Mhaya, A.M.; Huseien, G.F.; Faridmehr, I.; Abidin, A.R.Z.; Alyousef, R.; Ismail, M. Evaluating mechanical properties and impact resistance of modified concrete containing ground Blast Furnace slag and discarded rubber tire crumbs. Constr. Build. Mater. 2021, 295, 123603.

- Abdelmonem, A.; El-Feky, M.S.; Nasr, E.S.A.; Kohail, M. Performance of high strength concrete containing recycled rubber. Constr. Build. Mater. 2019, 227, 116660.

- Ramdani, S.; Guettala, A.; Benmalek, M.L.; Aguiar, J.B. Physical and mechanical performance of concrete made with waste rubber aggregate, glass powder and silica sand powder. J. Build. Eng. 2019, 21, 302–311.

- Othman, R.; Chong, B.W.; Jaya, R.P.; Hasan, M.R.M.; Abdullah, M.M.A.B.; Ibrahim, M.H.W. Evaluation on the rheological and mechanical properties of concrete incorporating eggshell with tire powder. J. Mater. Res. Technol. 2021, 14, 439–451.

- Ossola, G.; Wojcik, A. UV modification of tire rubber for use in cementitious composites. Cem. Concr. Compos. 2014, 52, 34–41.

- Rahim, N.L.; Ibrahim, N.M.; Tajri, S.A.N.; Zainol Abidin, M.Z. The Behaviour of Rubber Tyre as Fine Aggregate in Concrete Mix. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Bäch, Switzerland, 2015; Volume 754, pp. 427–431.

- Mousavimehr, M.; Nematzadeh, M. Post-heating flexural behavior and durability of hybrid PET–Rubber aggregate concrete. Constr. Build. Mater. 2020, 265, 120359.

- Martínez-Barrera, G.; del Coz-Díaz, J.J.; Álvarez-Rabanal, F.P.; Gayarre, F.L.; Martínez-López, M.; Cruz-Olivares, J. Waste tire rubber particles modified by gamma radiation and their use as modifiers of concrete. Case Stud. Constr. Mater. 2020, 12, e00321.

- Habib, A.; Yildirim, U.; Eren, O. Mechanical and dynamic properties of high strength concrete with well graded coarse and fine tire rubber. Constr. Build. Mater. 2020, 246, 118502.

- Liu, R.; Li, H.; Jiang, Q.; Meng, X. Experimental investigation on flexural properties of directional steel fiber reinforced rubberized concrete. In Structures; Elsevier: Amsterdam, The Netherlands, 2020; Volume 27, pp. 1660–1669.

- Su, H.; Yang, J.; Ling, T.C.; Ghataora, G.S.; Dirar, S. Properties of concrete prepared with waste tyre rubber particles of uniform and varying sizes. J. Clean. Prod. 2015, 91, 288–296.

- Chaikaew, C.; Sukontasukkul, P.; Chaisakulkiet, U.; Sata, V.; Chindaprasirt, P. Properties of concrete pedestrian blocks containing crumb rubber from recycle waste tyres reinforced with steel fibres. Case Stud. Constr. Mater. 2019, 11, e00304.

- Eisa, A.S.; Elshazli, M.T.; Nawar, M.T. Experimental investigation on the effect of using crumb rubber and steel fibers on the structural behavior of reinforced concrete beams. Constr. Build. Mater. 2020, 252, 119078.

- Zhu, H.; Rong, B.; Xie, R.; Yang, Z. Experimental investigation on the floating of rubber particles of crumb rubber concrete. Constr. Build. Mater. 2018, 164, 644–654.

- Aslani, F.; Kelin, J. Assessment and development of high-performance fibre-reinforced lightweight self-compacting concrete including recycled crumb rubber aggregates exposed to elevated temperatures. J. Clean. Prod. 2018, 200, 1009–1025.

- Shahjalal, M.; Islam, K.; Rahman, J.; Ahmed, K.S.; Karim, M.R.; Billah, A.M. Flexural response of fiber reinforced concrete beams with waste tires rubber and recycled aggregate. J. Clean. Prod. 2021, 278, 123842.

- Li, N.; Long, G.; Ma, C.; Fu, Q.; Zeng, X.; Ma, K.; Luo, B. Properties of self-compacting concrete (SCC) with recycled tire rubber aggregate: A comprehensive study. J. Clean. Prod. 2019, 236, 117707.

- Wang, J.; Dai, Q.; Si, R.; Guo, S. Investigation of properties and performances of Polyvinyl Alcohol (PVA) fiber-reinforced rubber concrete. Constr. Build. Mater. 2018, 193, 631–642.

- Gerges, N.N.; Issa, C.A.; Fawaz, S.A. Rubber concrete: Mechanical and dynamical properties. Case Stud. Constr. Mater. 2018, 9, e00184.

- Aureliano, F.D.S.; Ariellen Ap, F.C.; Júnior, I.F.; Pedroso, R.D.O. Manufacture of structural blocks of concrete with waste tire rubbers. Procedia Manuf. 2019, 38, 464–470.

- He, T.; Xu, R.; Da, Y.; Yang, R.; Chen, C.; Liu, Y. Experimental study of high-performance autoclaved aerated concrete produced with recycled wood fibre and rubber powder. J. Clean. Prod. 2019, 234, 559–567.

- Liu, F.; Chen, G.; Li, L.; Guo, Y. Study of impact performance of rubber reinforced concrete. Constr. Build. Mater. 2012, 36, 604–616.

- Wood, D.F.; Cornish, K. Microstructure of purified rubber particles. Int. J. Plant Sci. 2000, 161, 435–445.

- Navarro, F.J.; Partal, P.; Martınez-Boza, F.; Valencia, C.; Gallegos, C. Rheological characteristics of ground tire rubber-modified bitumens. Chem. Eng. J. 2002, 89, 53–61.

- Segre, N.; Joekes, I. Use of tire rubber particles as addition to cement paste. Cem. Concr. Res. 2000, 30, 1421–1425.

- Xiao, F.; Yao, S.; Wang, J.; Wei, J.; Amirkhanian, S. Physical and chemical properties of plasma treated crumb rubbers and high temperature characteristics of their rubberised asphalt binders. Road Mater. Pavement Des. 2020, 21, 587–606.

- Jusli, E.; Nor, H.M.; Jaya, R.P.; Zaiton, H. Chemical properties of waste tyre rubber granules. In Advanced Materials Research; Trans Tech Publications Ltd.: Bäch, Switzerland, 2014; Volume 911, pp. 77–81.

More

Information

Subjects:

Materials Science, Composites

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.6K

Revisions:

2 times

(View History)

Update Date:

22 Jul 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No