Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Egle Klumbyte | -- | 1633 | 2022-05-11 13:46:39 | | | |

| 2 | Dean Liu | -13 word(s) | 1620 | 2022-05-12 03:10:48 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Klumbyte, E.; Šadauskienė, J.; Ramanauskas, J.; Krawczyk, D.; Fokaides, P. Thermal Bridges. Encyclopedia. Available online: https://encyclopedia.pub/entry/22816 (accessed on 07 February 2026).

Klumbyte E, Šadauskienė J, Ramanauskas J, Krawczyk D, Fokaides P. Thermal Bridges. Encyclopedia. Available at: https://encyclopedia.pub/entry/22816. Accessed February 07, 2026.

Klumbyte, Egle, Jolanta Šadauskienė, Juozas Ramanauskas, Dorota Krawczyk, Paris Fokaides. "Thermal Bridges" Encyclopedia, https://encyclopedia.pub/entry/22816 (accessed February 07, 2026).

Klumbyte, E., Šadauskienė, J., Ramanauskas, J., Krawczyk, D., & Fokaides, P. (2022, May 11). Thermal Bridges. In Encyclopedia. https://encyclopedia.pub/entry/22816

Klumbyte, Egle, et al. "Thermal Bridges." Encyclopedia. Web. 11 May, 2022.

Copy Citation

Thermal bridges are caused by full or partial penetration of the building envelope by materials with different thermal conductivities, changes in fabric thickness, and/or differences between internal and external areas, such as those found at wall/floor/ceiling junctions).

thermal bridges

thermal transmittance

thermal insulation

1. Introduction

The universal climate change problem has made it crucial for the European Union to invest in energy-saving methods. For this reason, members of the European Union have created an integrated national energy and climate plan from 2021 to 2030 [1]. The Energy Union and the Energy and Climate Policy Framework for 2030 pledge to reduce the amount of emitted gas, which is known to cause the greenhouse effect, by at least 40% compared to the amount emitted in 1990. According to the data of 2014, buildings used approximately 40% of all the energy generated in the EU countries. They emitted more than a third of the universally emitted amount of CO2 gas [2]. Hence, it was concluded that the buildings sector has much potential to save energy.

Legal requirements for the new generation of buildings are stated in the renewed Directive (EU) 2018/844 [3], which focuses on the energy performance of buildings and energy efficiency. The Union’s goal to develop an effective energy system by 2050 is difficult, since breakthroughs in energy efficiency move slowly. In 2014, about 3% of European buildings were Nearly Zero Energy Buildings (NZEB). That means 97% of the buildings were of low energy efficiency [4]. Currently, about 75% of buildings in the European Union are not energy efficient, but in 2050, 85–95% of them will still be in use.

Much effort is being put into renewing and supplementing the buildings’ funds, because countless buildings were previously built following low energy usage efficiency standards. Nevertheless, only 1% of buildings are being efficiently renovated each year. For this reason, decisive action is required in order to achieve Europe’s climate-neutral (net zero emissions) goals by 2050. According to the European Commission’s 17 September Communication, due to Europe’s 2030 climate ambitions [5], this norm must increase twice in order to achieve a more ambitious 2030 climate target of at least 55%. The Commission determined that renovation would be needed at an average rate of 3% annually in order to cost-effectively implement the Union’s energy efficiency ambitions. For this reason, on 14 October 2020, the Commission presented a new renovation strategy called “A Renovation Wave for Europe—Greening buildings, creating jobs, improving lives” [6].

In most European cities, buildings appeared during the past few decades and have not been properly taken care of for a long time. In most cases, buildings cannot satisfy modern requirements related to the quality of accommodation, energy usage efficiency, economy, and environmental protection. Doubtlessly, to achieve sustainability, one must emphasize the modern integrated renovation of already-built buildings and take notice of the usage of renewable energy and building insulation, heating, ventilation, and air conditioning (HVAC).

2. Thermal Bridge

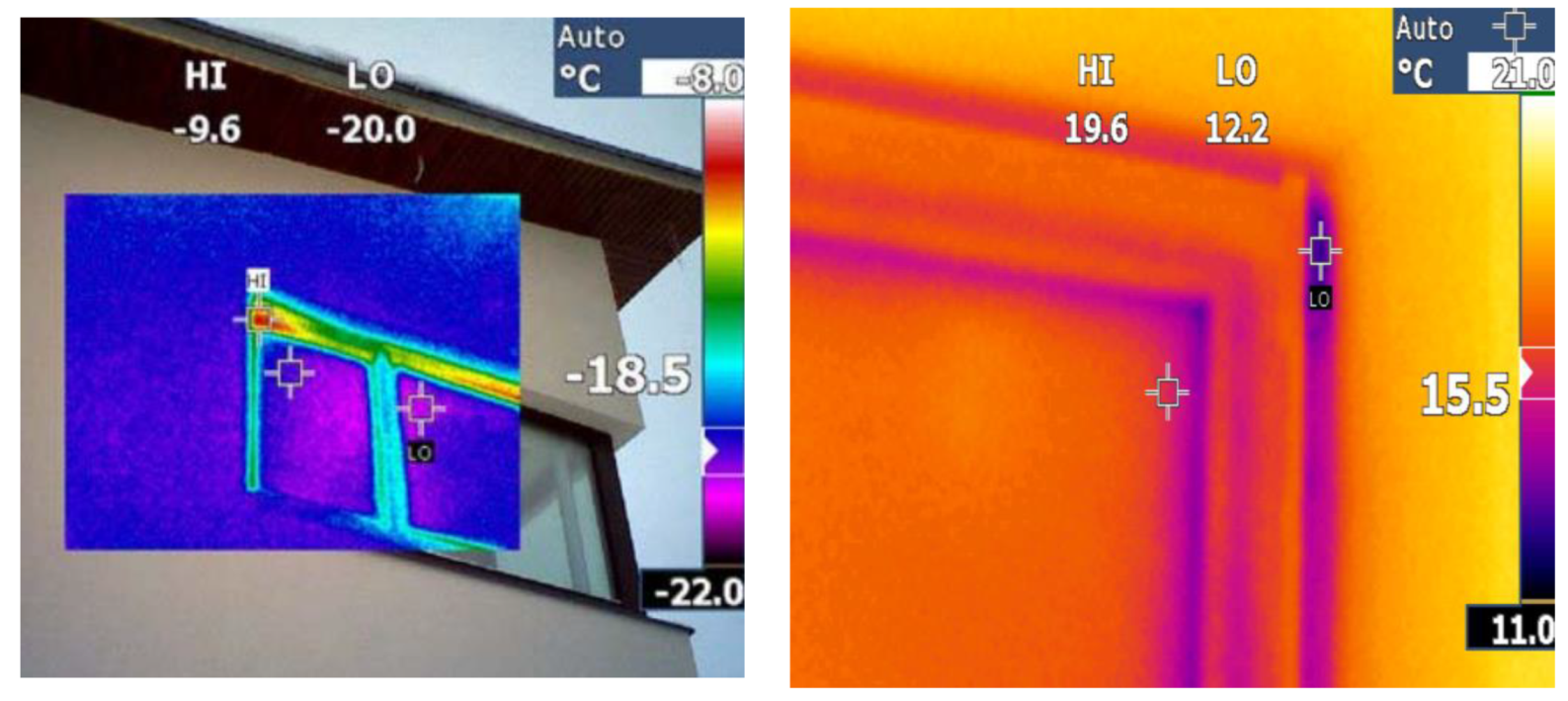

One of the ways to effectively renovate buildings is to apply new high-performance windows. However, judging from experience, the low energy efficiency is often related to low quality of construction. Correct window installation is still one of the most difficult hurdles that must be overcome to achieve a higher energy efficiency in buildings [7]. Thermal imaging performed by professionals clearly shows thermal bridges at window openings (Figure 1) [8].

Figure 1. Thermal images of thermal bridges at window openings.

Thermal bridges are caused by full or partial penetration of the building envelope by materials with different thermal conductivities, changes in fabric thickness, and/or differences between internal and external areas, such as those found at wall/floor/ceiling junctions) [9]. The total impact of thermal bridges on heating energy demand is generally significant, ranging from 5% to 39% [10][11][12][13]. The factors mentioned above are determined by weather conditions, insulation level, thermal bridge constructive solution, building type (use and geometry), and the method used to implement its effect within the calculation of the building energy demand [14].

Thermal bridges can impact a single point, a linear area, or an entire spatial configuration. Typically, the linear thermal bridges (LTB) that occur at the junction of two or more building envelope elements are evaluated in the calculations of the building’s energy demand. Several scientific studies have been conducted in which LTB was investigated using various calculation and simulation methodologies, such as static/dynamic and 1D/2D/3D [15][16][17][18].

The majority of studies present empirical LTB dependences, which determine the linear thermal transmittance value of a specific construction element [19]. On these foundations, numerical calculation software and catalogues have been developed. The European Standard EN ISO 14683 contains seventy-six cases referring to eight thermal bridge typologies (roofs, corners, intermediate floors, internal walls, slab-on-ground floors, suspended ground floors, pillars, window and door openings), and is one of the most widely used atlases. On the other hand, these atlases provide thermal bridge values calculated using the 2-D method. These calculations exclude point thermal bridges (PTB), which are formed by thermally conductive fasteners such as waxes, varnishes, etc. In terms of PTB, the effect of PTB is often neglected in analyses aimed at defining a building’s energy performance. Researchers also addresses the significance of PTB in the calculation of thermal losses from thermal bridges in window installations.

3. A New High-Performance Window Installation

To partly resolve this problem, a new requirement was included in the Lithuanian national document [20], which stated that the thermal transmittance of a linear thermal bridge (LTB) of an NZEB or passive house must be a maximum of 0.05 W/(m·K). However, attaining this value presents a severe difficulty for project designers and builders [21]. However, a new method of installing window frames directly onto thermal insulation layers has been found to reduce the effect of LTB [22].

Nowadays, a few alternative installation solutions are applied in the practical area of construction. Most window frameworks are pendent on reinforced anchor brackets (Figure 2a) or on rectangular wooden frames (chipboard) (Figure 2b) that are installed on a wall. However, these different cases of window mounting do not ensure that thermal bridges at the junction of wall and window will be avoided. Insufficiently isolated joints of window frames and facade walls increase the impact of building thermal leaks, and it does not ensure the required value of the airtightness of passive house, which must be equal to 0.6 air change rate at 50 Pa per hour. Furthermore, it is important to mention that the possibility of condensation and humidity increases when using the mentioned window mounting methods [23][24]. In this way, the building may lose its passive house status because of window installation defects [25][26].

It is often incorrectly thought that by installing a window in the isolation layer, the thermal bridge will have no impact on the building’s energy consumption. The value of the thermal bridge of the openings depends on the length from the load-bearing layer and the mounting place of the window, and on the materials used to mount the window, such as installing foam, framework, fasteners and finishing elements. The longer the length between the wall and the window, the higher the required number of anchor brackets attached directly to the window frame and the outer wall retaining layer. However, point thermal bridges (PTB) appear at the points where the anchor brackets are attached. Thus, using a lot of them is not efficient.

Anchor holders are often made of plastic, which has a much lower thermal conductivity value than metal, to reduce energy loss due to point thermal bridges. However, the support force of this type of bracket has drawbacks: plastic is flexible. It may not withstand heavy high-performance windows in the thermal insulation layer that have a greater length than the load-bearing layer. The weight of the opening parts of such glass systems is a minimum of 130 kg. Therefore, only steel brackets, whose thermal transmittance value is 50 (W/(m·K)), are suitable for installing windows in passive houses. This means the material of anchor brackets has a huge impact on the efficiency of high-energy-performance buildings. To assess the real energy consumption, buildings must evaluate the additional heat losses due to PTB. Otherwise, the energy efficiency calculations for the building might be incorrect.

Designers and builders are looking for new ways to reduce the impact of PTB on a building’s energy costs [29]. A new method for installing windows in a thermal insulation layer is currently being applied in practice. A prefabricated frame, made of higher-density stone wool boards (SWB) and auxiliary elements, is being used for the installation of window frames (Figure 3). Practice shows that such window installation is not complicated due to the lightness of the thermal insulation board and the simplicity of the fastening elements. Moreover, it is suitable for installation on any retaining wall, and the thermal conductivity of the frame made of thermal insulation material is low. Such a frame’s static properties are sufficient for installing a high-performance window up to 350 mm away from the retaining wall layer. Since metal fasteners do not connect, it is unlikely to create a PTB effect. However, installing windows in this way is little studied compared to the general thermal research context. Therefore, researchers investigated the thermal properties of windows installed in the thermal insulation layer in detail and to compare different installation methods and thermal bridge evaluation methodologies from the point of view of thermal physics.

A major concern regarding the design and manufacturing of advanced windows is related to their sound insulation performance. Studies have demonstrated the effectiveness of porous absorbent materials in the cavity perimeter of windows [30], as well as the effect of ventilation-enabling façade noise control devices for congested high-rise cities [31]. Active noise control, which uses a secondary sound to cancel unwanted noise, has been successfully implemented and is considered to be an established technique for enhancing the sound insulation of windows [32].

References

- National Energy and Climate Plans (NECPs). European Commission. Available online: https://ec.europa.eu/energy/topics/energy-strategy/national-energy-climate-plans_en (accessed on 27 July 2021).

- Building Performance Institute Europe (BPIE). Renovation Strategies of Selected EU Countries. A Status Report on Compliance with Article 4 of the Energy Efficiency Directive; BPIE: Brussels, Belgium, 2014; Available online: Renovation-Strategies-EU-BPIE-2014.pdf (accessed on 1 March 2022).

- EN. Directive (EU) 2018/844 of the European Parliament and of the Council of 30 May 2018 amending Directive 2010/31/EU on the energy performance of buildings and Directive 2012/27/EU on energy efficiency; the European Parliament and the Council of the European Union. Off. J. Eur. Union 2018, 35, L156–L175.

- Building Performance Institute Europe (BPIE). Future-Proof Buildings for All Europeans; BPIE: Brussels, Belgium, 2019; Available online: https://globalabc.org/resources/publications/bpie-future-proof-buildings-all-europeans (accessed on 1 March 2022).

- COM/2020/562 Final. Investing in a Climate-Neutral Future for the Benefit of Our People. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. Stepping up Europe’s 2030 Climate Ambition Brussels. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52020DC0562 (accessed on 1 March 2022).

- Renovation Wave|Energy. Available online: https://ec.europa.eu/energy/topics/energy-efficiency/energy-efficient-buildings/renovation-wave_en (accessed on 1 March 2022).

- Bergero, S.; Cavalletti, P.; Chiari, A. Energy refurbishment in existing buildings: Thermal bridge correction according to DM 26/06/2015 limit values. Energy Procedia 2017, 140, 127–140.

- O’Grady, M.; Lechowska, A.A.; Harte, A.M. Application of infrared thermography technique to the thermal assessment of multiple thermal bridges and windows. Energy Build. 2018, 168, 347–362.

- ISO. EN ISO 10211:2017; Thermal Bridges in Building Construction—Heat Flows and Surface Temperatures—Detailed Calculations. CEN Committee ISO/TC 163/SC; International Organization for Standardization: Geneva, Switzerland, 2017.

- Theodosiou, T.; Tsikaloudaki, K.; Bikas, D.; Aravantinos, D.; Kontoleon, K.N. Assessing the use of simplilied and analytical methods for approaching thermal bridges with regard to their impact on the thermal performance of the building envelope. In Proceedings of the World SB 14 Conference on the Sustainable Building: Result, Barcelona, Spain, 28–30 October 2014; Available online: http://wsb14barcelona.org/programme/pdf_poster/P-059.pdf (accessed on 1 March 2022).

- Theodosiou, T.G.; Papadopoulos, A.M. The impact of thermal bridges on the energy demand of buildings with double brick wall constructions. Energy Build. 2008, 40, 2083–2089.

- Citterio, M.; Cocco, M.; Erhorn-Klutting, H. Thermal bridges in the EPBD context: Overview on MS approaches in regulations. In ASIEPI Information Paper. 2008. Available online: https://www.buildup.eu/sites/default/files/P064_EN_ASIEPI_WP4_IP1_p3073.pdf (accessed on 1 March 2022).

- Evola, G.; Margani, G.; Marletta, L. Energy and cost evaluation of thermal bridge correction in Mediterranean climate. Energy Build. 2011, 43, 2385–2393.

- Martin, K.; Escudero, C.; Erkoreka, A.; Flores, I.; Sala, J.M. Equivalent wall method for dynamic characterization of thermal bridges. Energy Build. 2012, 55, 704–714.

- Gao, Y.; Roux, J.J.; Zhao, L.H.; Jiang, Y. Dinamical building simulation: A low order model for thermal bridges losses. Energy Build. 2008, 40, 2236–2243.

- Tadeu, A.; Simoes, I.; Simoes, N.; Prata, J. Simulation of dynamic liner thermal bridges using a boundary element method model in the frequency domain. Energy Build. 2011, 43, 3685–3695.

- Berggren, B.; Wall, M. Calculation of thermal bridges in (Nordic) building envelopes—Risk of performance failure due to inconsistent use of methodology. Energy Build. 2013, 65, 331–339.

- Ascione, F.; Bianco, N.; de Rossi, F.; Turni, G.; Vanoli, G.P. Different metchods for the modeling of thermal bridges into energy simulation programs: Comparisons of accuracy for flat heterogeneous roofs in Italian climates. Appl. Energy 2012, 97, 405–418.

- Capozzoli, A.; Gorrino, A.; Corrado, V. A building thermal bridges sensitivity analysis. Appl. Energy 2013, 107, 229–243.

- Construction Technical Regulation STR 2.01.02: 2016; Design and Certification of Energy Performance of Buildings; Ministry of Environment: Vilnius, Lithuania, 2020.

- Cerneckiene, J.; Zdankus, T.; Valancius, R.; Fokaides, P.A. Numerical Investigation of the impact of longitudinal thermal bridging on energy efficient buildings under humid continental climate conditions: The Case of Lithuania. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2020; Volume 410, p. 012105.

- Fokaides, P.A.; Apanaviciene, R.; Černeckiene, J.; Jurelionis, A.; Klumbyte, E.; Kriauciunaite-Neklejonoviene, V.; Pupeikis, D.; Rekus, D.; Sadauskiene, J.; Seduikyte, L.; et al. Research Challenges and Advancements in the field of Sustainable Energy Technologies in the Built Environment. Sustainability 2020, 12, 8417.

- De Angelis, E.; Serra, E. Light steel-frame walls: Thermal insulation performances and thermal bridges. Energy Procedia 2014, 45, 362–371.

- Grudzińska, M.; Brzyski, P. The Occurrence of Thermal Bridges in Hemp-lime Construction Junctions. Period. Polytech. Civ. Eng. 2019, 63, 377–387.

- Udrea, I.; Popa, R.T.; Mladin, E.C.; Georgescu, M.S.; Ochinciuc, C.V. Thermal bridges evaluation for a Passive House building in Romanian Southern climate. In Proceedings of the 2017 8th International Conference on Energy and Environment (CIEM), Bucharest, Romania, 19–20 October 2017; Proceedings Paper: International Conference on Energy and Environment. pp. 456–459.

- Sadauskiene, J.; Ramanauskas, J.; Seduikyte, L.; Dauksys, M.; Vasylius, A. A simplified methodology for evaluating the impact of point thermal bridges on the high-energy performance of a passive house. Sustainability 2015, 7, 16687–16702.

- Rruumala. Available online: https://www.ruumala.com/lt/metaliniai-ankeriai/ploksti-kronsteinai/ (accessed on 1 March 2022).

- Lithuanian Passive House. Available online: https://www.pasyvusnamas.lt/langu-montavimas-siltinimo-sluoksnyje/langu-dezes (accessed on 1 March 2022).

- Hallik, J.; Kalamees, T. A new method to estimate point thermal transmittance based on combined two-dimensional heat flow calculation. In Proceedings of the 12th Nordic Symposium on Building Physics (nsb 2020), E3SWeb of Conferences, Tallinn, Estonia, 6–9 September 2020; Volume 172, p. 08005.

- Tsukamoto, Y.; Tomikawa, Y.; Sakagami, K.; Okuzono, T.; Maikawa, H.; Komoto, Y. Experimental assessment of sound insulation performance of a double window with porous absorbent materials its cavity perimeter. Appl. Acoust. 2020, 165, 107317.

- Tang, S.K. A review on natural ventilation-enabling façade noise control devices for congested high-rise cities. Appl. Sci. 2017, 7, 175.

- Huang, H.; Qiu, X.; Kang, J. Active noise attenuation in ventilation windows. J. Acoust. Soc. Am. 2011, 130, 176–188.

More

Information

Subjects:

Engineering, Civil

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.3K

Entry Collection:

Environmental Sciences

Revisions:

2 times

(View History)

Update Date:

12 May 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No