Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Xingtao Tang | -- | 898 | 2022-04-22 08:28:12 | | | |

| 2 | Dean Liu | + 116 word(s) | 1014 | 2022-04-24 03:53:20 | | | | |

| 3 | Dean Liu | -2 word(s) | 1012 | 2022-04-24 03:54:15 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Tang, X.; Sun, X.; Yao, M. Position Sensorless Techniques for Switched Reluctance Machine Systems. Encyclopedia. Available online: https://encyclopedia.pub/entry/22154 (accessed on 08 February 2026).

Tang X, Sun X, Yao M. Position Sensorless Techniques for Switched Reluctance Machine Systems. Encyclopedia. Available at: https://encyclopedia.pub/entry/22154. Accessed February 08, 2026.

Tang, Xingtao, Xiaodong Sun, Ming Yao. "Position Sensorless Techniques for Switched Reluctance Machine Systems" Encyclopedia, https://encyclopedia.pub/entry/22154 (accessed February 08, 2026).

Tang, X., Sun, X., & Yao, M. (2022, April 22). Position Sensorless Techniques for Switched Reluctance Machine Systems. In Encyclopedia. https://encyclopedia.pub/entry/22154

Tang, Xingtao, et al. "Position Sensorless Techniques for Switched Reluctance Machine Systems." Encyclopedia. Web. 22 April, 2022.

Copy Citation

Owing to the added advantages of high stability and low cost, the position sensorless method of SRMs has been extensively studied to advance its use in vehicles and construction machinery.

additional components

hybrid detection method

position sensorless control

whole speed

1. Introduction

The switched reluctance motor (SRM) is considered to be one of the best potential motors due to its simple structure, high efficiency, outstanding fault tolerance, and flexible control methods [1][2][3][4][5]. It limits general application in that its doubly salient structure leads to large torque ripple and noise. However, with the rapid development of control theory, finite element analysis (FEA), and power electronics, SRMs are gradually being used in vehicles and other fields [5][6][7][8][9][10].

Switched reluctance motors are widely used in many industrial fields, such as mild-hybrid BSG drives, hybrid vehicles, construction machinery, and aerospace engines, etc., [11][12][13][14][15][16]. To fully discover the potential advantages of SRM, fault-tolerant control research [17][18][19][20], global optimization considering driving cycles and manufacturing fluctuations [21][22][23][24][25], minimum torque ripple control [26][27][28][29], and position sensorless control [30][31][32][33][34] have all been extensively studied. The sensorless approach has attracted much attention because it enables the SRM to have the advantages of low cost, low risk, and is not limited by hardware.

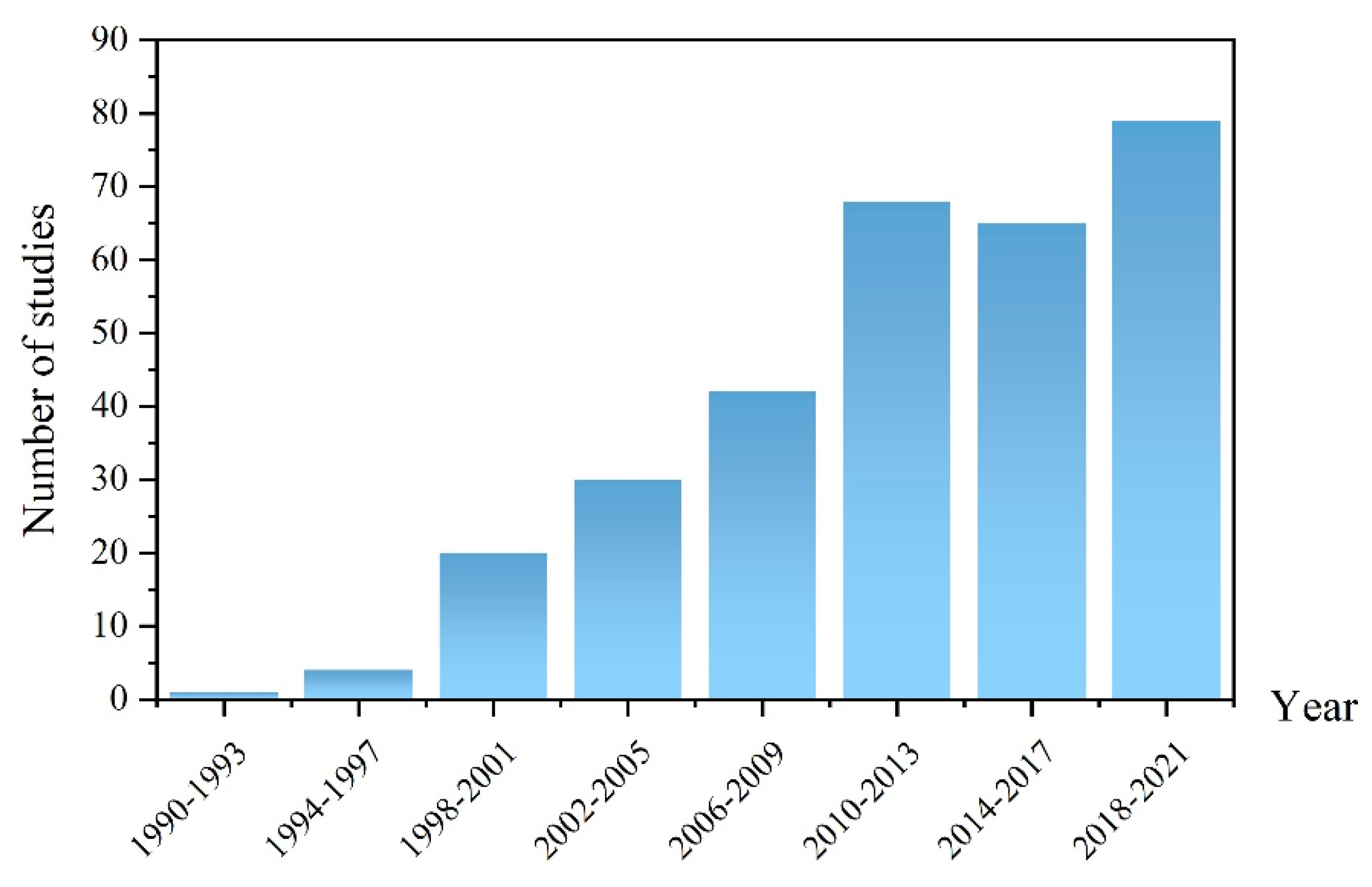

For the SRM drive system, the position signal of the rotor is indispensable. However, the position sensor carries a potential risk of failure and limits the speed regulation performance due to the limitation of the sensor resolution [35][36][37][38][39][40][41][42][43][44][45]. To eliminate the negative effects, increasing position sensorless methods have emerged with the deepening of theoretical research on SRMs. As shown in Figure 1, the number of published articles on SRM position sensorless methods is increasing. Researchers have to admit that this is a hot spot, and it is necessary to analyze and review the related theories and technologies.

Figure 1. Number of studies published before Jan. 2021 that experimentally examined the position sensorless methods for SRM.

2. An Accurate Rotor Estimation Solution in Whole-Speed Range

Position sensorless technology for the full speed range is an ongoing goal. Many methods demonstrate accurate position estimation in part of the velocity range, which is also of great significance for the development of position sensorless methods. However, this limits the practical application of the algorithm in that the motor is required to be in the full speed range. It is necessary to seek rotor position estimation methods in a wider speed range.

3. Reduce Coupling between Position Estimation and Control Methods

For motor motion control, current chopper control (CCC), angle position control (APC), and voltage chopper control (VCC) are relatively mature control algorithms. Many position estimation methods are extremely dependent on these control strategies, which is weak compared with traditional position sensors. Many new controls, such as direct torque control (DTC) and torque sharing function (TSF) [46][47][48][49], have outstanding performance in reducing torque ripple and vibration noise, and the current waveforms produced by these methods are completely different due to different control strategies [50][51]. This forces the position estimation methods to be able to adapt to these new control strategies.

4. Reduce the Need for Prior Parameter Storage

The gradual reduction of the motor a priori parameter requirements can reduce the pressure on microcontrollers with small storage capacity. Of course, researchers also have to realize that some key motor parameters are instructive for estimating rotor position. The validation of prior parameters restricts the application of location-free methods to SRMs with large parameter differences. Moreover, many motor parameters may be changed by the interference from the environment and working conditions, which is a huge risk to the long-term effectiveness of the algorithm.

5. Smooth Switching between Different Speed Stages

The motion process of conventional SRM is mainly divided into the start-up, low-speed, and high-speed stages. How to effectively switch between different sensorless methods is a technical point worth paying attention to [52]. For example, in [53], the pulse injection method is combined as the algorithm for the start-up phase. However, it does not indicate how to switch.

6. High Stability under Heavy and Changing Loads

It is well known that drastic changes in load can challenge the robustness of the control algorithm. In the experiments of some literature, it is easy to observe that the estimation accuracy will be lower than the light load when the load is abruptly changed. How to effectively improve the accuracy of rotor position estimation is a worthy research direction under various working conditions.

The principles of various types of sensorless methods have been introduced in detail, and their development has been teased out. The direction of the entire sensorless development is elucidated based on the current development direction. It is important to see what changes can be made in the future for each type of method. Table 1 presents future applications and future developments of the various methods summarized. From a practical application point of view, hybrid and observer-based methods enable a decoupling of speed/torque control strategies and position estimation in the full speed range.

Table 1. Prediction of the development of existing methods.

| Methods | Features of Application | Future Development |

|---|---|---|

| Pulse injection methods | Outstanding startup performance | Hybrid with other methods |

| Additional components methods | Similar to the novel position sensor | Smaller additional components |

| Flux-current-based methods | Excellent real-time performance | More accurate analytical models |

| Inductance-based methods | Simple detection of special positions | Enhance real-time |

| Intelligent-control-based methods | For the acquisition of electromagnetic values | Mate position sensorless method |

| Observer-based methods | Outstanding real-time performance, decoupling from speed control strategy | Improvements at startup and low speed |

| Hybrid method | Suitable for whole-speed | Smoother mode switching |

7 . Conclusions

It is found that there are many obvious constraints and potential opportunities for the sensorless technology, with the development of advanced control theory and the in-depth study of electromagnetic signature by FEA. Besides the requirements of efficient rotor position estimation in the whole-speed range, there are some challenging objectives for the design of sensorless control, including high detection accuracy, high robustness, and improved algorithm versatility. To address these constraints, some advanced control theories, such as sliding mode observers and hybrid solutions that fuse multiple methods, are used for position estimation. Due to their excellent suitability for modeling nonlinear characteristics, reduced dependence on motor parameters and application in a wider speed range are expected in the future.

References

- Komatsuzaki, A.; Bamba, T.; Miki, I. Estimation of rotor position in a three-phase SRM at standstill and low speeds. Electr. Eng. Jpn. 2012, 178, 55–63.

- Sun, X.; Diao, K.; Lei, G.; Guo, Y.; Zhu, J. Real-Time HIL Emulation for a Segmented-Rotor Switched Reluctance Motor Using a New Magnetic Equivalent Circuit. IEEE Trans. Power Electron. 2020, 35, 3841–3849.

- Namazi, M.M.; Nezhad, S.M.S.; Tabesh, A.; Rashidi, A.; Liserre, M. Passivity-Based Control of Switched Reluctance-Based Wind System Supplying Constant Power Load. IEEE Trans. Ind. Electron. 2018, 65, 9550–9560.

- Wang, I.W.; Kim, Y.S. Rotor speed and position sensorless control of a switched reluctance motor using the binary observer. IEE Proc.-Electr. Power Appl. 2000, 147, 220–226.

- Khalil, A.; Husain, I.; Hossain, S.; Gopalakrishnan, S.; Omekanda, A.; LeQuesne, B.; Klode, H. A hybrid sensorless SRM drive with eight- and six-switch converter topologies. IEEE Trans. Ind. Appl. 2004, 41, 1647–1655.

- Kosaka, T.; Matsui, N.; Saha, S.; Takeda, Y. Sensorless control of SRM based on a simple expression of magnetization characteristics. Electr. Eng. Jpn. 2001, 137, 52–60.

- Diao, K.; Sun, X.; Lei, G.; Guo, Y.; Zhu, J. Multiobjective System Level Optimization Method for Switched Reluctance Motor Drive Systems Using Finite-Element Model. IEEE Trans. Ind. Electron. 2020, 67, 10055–10064.

- Torkaman, H.; Afjei, E.; Toulabi, M.S. New Double-Layer-per-Phase Isolated Switched Reluctance Motor: Concept, Numerical Analysis, and Experimental Confirmation. IEEE Trans. Ind. Electron. 2012, 59, 830–838.

- Nezamabadi, M.M.; Afjei, E.; Torkaman, H. Design, Dynamic Electromagnetic Analysis, FEM, and Fabrication of a New Switched-Reluctance Motor with Hybrid Motion. IEEE Trans. Magn. 2015, 52, 1–8.

- Sato, Y.; Murakami, K.; Tsuboi, Y. Sensorless Torque and Thrust Estimation of a Rotational/Linear Two Degrees-of-Freedom Switched Reluctance Motor. IEEE Trans. Magn. 2016, 52, 1–4.

- Sun, X.; Diao, K.; Yang, Z. Performance improvement of a switched reluctance machine with segmental rotors for hybrid electric vehicles. Comput. Electr. Eng. 2019, 77, 244–259.

- Ma, B.-Y.; Liu, T.-H.; Chen, C.-G.; Shen, T.-J.; Feng, W.-S. Design and implementation of a sensorless switched reluctance drive system. IEEE Trans. Aerosp. Electron. Syst. 1998, 34, 1193–1207.

- Bartolo, J.B.; Degano, M.; Espina, J.; Gerada, C. Design and Initial Testing of a High-Speed 45-kW Switched Reluctance Drive for Aerospace Application. IEEE Trans. Ind. Electron. 2017, 64, 988–997.

- Li, J.-C.; Xin, M.; Fan, Z.-N.; Liu, R. Design and experimental evaluation of a 12 kw large synchronous reluctance motor and control system for elevator traction. IEEE Access 2020, 8, 34256–34264.

- Wang, Q.; Jiang, W.; Jing, X.; Yu, Z. Sensorless Control of Segmented Bilateral Switched Reluctance Linear Motor Based on Coupled Voltage for Long Rail Propulsion Application. IEEE Trans. Energy Convers. 2020, 35, 1348–1359.

- Ullah, S.; McDonald, S.P.; Martin, R.; Benarous, M.; Atkinson, G.J. A Permanent Magnet Assist, Segmented Rotor, Switched Reluctance Drive for Fault Tolerant Aerospace Applications. IEEE Trans. Ind. Appl. 2019, 55, 298–305.

- Sun, X.; Xue, Z.; Han, S.; Chen, L.; Xu, X.; Yang, Z. Comparative study of fault-tolerant performance of a segmented rotor SRM and a conventional SRM. Bull. Pol. Acad. Sci. Tech. Sci. 2017, 65, 375–381.

- Ding, W.; Hu, Y.; Wu, L. Investigation and Experimental Test of Fault-Tolerant Operation of a Mutually Coupled Dual Three-Phase SRM Drive Under Faulty Conditions. IEEE Trans. Power Electron. 2015, 30, 6857–6872.

- Sun, Q.; Lan, T. Maximum Inductance Detection-based Fault-Tolerant Sensorless Control for SRM Drive. In Proceedings of the 2021 IEEE 4th Student Conference on Electric Machines and Systems (SCEMS), Huzhou, China, 1–3 December 2021; pp. 1–5.

- Zhang, L.; Li, P. A fault tolerant sensorless techniques for switched reluctance motor. In Proceedings of the 2017 IEEE 3rd Information Technology and Mechatronics Engineering Conference (ITOEC), Chongqing, China, 3–5 October 2017; pp. 1243–1247.

- Diao, K.; Sun, X.; Yao, M. Robust-Oriented Optimization of Switched Reluctance Motors Considering Manufacturing Fluctuation. IEEE Trans. Transp. Electrif. 2021.

- Omekanda, A.M. Robust torque and torque-per-inertia optimization of a switched reluctance motor using the Taguchi methods. IEEE Trans. Ind. Appl. 2006, 42, 473–478.

- Fan, J.; Jung, I.; Lee, Y. Position Estimation of a Two-Phase Switched Reluctance Motor at Standstill. Machines 2021, 9, 359.

- Chen, H.; Yan, W.; Gu, J.J.; Sun, M. Multiobjective Optimization Design of a Switched Reluctance Motor for Low-Speed Electric Vehicles with a Taguchi–CSO Algorithm. IEEE/ASME Trans. Mechatron. 2018, 23, 1762–1774.

- Diao, K.; Sun, X.; Lei, G.; Bramerdorfer, G.; Guo, Y.; Zhu, J. System-Level Robust Design Optimization of a Switched Reluctance Motor Drive System Considering Multiple Driving Cycles. IEEE Trans. Energy Convers. 2021, 36, 348–357.

- de Paula, M.V.; dos Santos Barros, T.A. A Sliding Mode DITC Cruise Control for SRM with Steepest Descent Minimum Torque Ripple Point Tracking. Trans. Ind. Electron. 2022, 69, 151–159.

- Lin, F.-C.; Yang, S.-M. An Approach to Producing Controlled Radial Force in a Switched Reluctance Motor. IEEE Trans. Ind. Electron. 2007, 54, 2137–2146.

- Husain, I. Minimization of torque ripple in SRM drives. IEEE Trans. Ind. Electron. 2002, 49, 28–39.

- Lee, D.-H.; Liang, J.; Lee, Z.-G.; Ahn, J.-W. A Simple Nonlinear Logical Torque Sharing Function for Low-Torque Ripple SR Drive. IEEE Trans. Ind. Electron. 2009, 56, 3021–3028.

- Cai, J.; Zhao, X. Synthetic Hybrid-Integral-Threshold Logic-Based Position Fault Diagnosis Scheme for SRM Drives. IEEE Trans. Instrum. Meas. 2020, 70, 1–8.

- Ehsani, M.; Fahimi, B. Elimination of position sensors in switched reluctance motor drives: State of the art and future trends. IEEE Trans. Ind. Electron. 2002, 49, 40–47.

- Xue, X.D.; Cheng, K.W.E.; Ho, S.L.; Cheng, E.K.W. A Position Stepping Method for Predicting Performances of Switched Reluctance Motor Drives. IEEE Trans. Energy Convers. 2007, 22, 839–847.

- Han, S.; Liu, C.; Sun, X.; Diao, K. An effective method of verifying poles polarities in switched reluctance motors. COMPEL—Int. J. Comput. Math. Electr. Electron. Eng. 2019, 38, 927–938.

- Gallegos-Lopez, G.; Kjaer, P.; Miller, T. A new sensorless method for switched reluctance motor drives. IEEE Trans. Ind. Appl. 1998, 34, 832–840.

- Wang, W.; Fahimi, B. Fault Resilient Strategies for Position Sensorless Methods of Switched Reluctance Motors Under Single and Multiphase Fault. IEEE J. Emerg. Sel. Top. Power Electron. 2014, 2, 190–200.

- Ge, L.; Ralev, I.; Klein-Hessling, A.; Song, S.; De Doncker, R.W. A Simple Reluctance Calibration Strategy to Obtain the Flux-Linkage Characteristics of Switched Reluctance Machines. IEEE Trans. Power Electron. 2019, 35, 2787–2798.

- Chen, L.; Wang, H.; Sun, X.; Cai, Y.; Li, K.; Diao, K.; Wu, J. Development of digital control system for a belt-driven starter generator SSRM for HEVs. Proc. Inst. Mech. Eng. Part I J. Syst. Control. Eng. 2020, 234, 975–984.

- Sun, X.; Wan, B.; Lei, G.; Tian, X.; Guo, Y.; Zhu, J. Multiobjective and Multiphysics Design Optimization of a Switched Reluctance Motor for Electric Vehicle Applications. IEEE Trans. Energy Convers. 2021, 36, 3294–3304.

- Mihic, D.S.; Terzic, M.; Vukosavic, S.N. A New Nonlinear Analytical Model of the SRM with Included Multiphase Coupling. IEEE Trans. Energy Convers. 2017, 32, 1322–1334.

- Sun, X.; Shen, Y.; Wang, S.; Lei, G.; Yang, Z.; Han, S. Core losses analysis of a novel 16/10 segmented rotor switched reluctance BSG motor for HEVs using nonlinear lumped parameter equivalent circuit model. IEEE/ASME Trans. Mechatron. 2018, 23, 747–757.

- Pillay, P.; Ahmed, M.; Samudio, M. Modeling and performance of a SRM drive with improved ride-through capability. IEEE Trans. Energy Convers. 2001, 16, 165–173.

- Liang, Y.; Chen, H. Circuit-based flux linkage measurement method with the automated resistance correction for SRM sensorless position control. IET Electr. Power Appl. 2018, 12, 1396–1406.

- Sun, X.; Wu, J.; Lei, G.; Cai, Y.; Chen, X.; Guo, Y. Torque Modeling of a Segmented-Rotor SRM Using Maximum-Correntropy-Criterion-Based LSSVR for Torque Calculation of EVs. IEEE J. Emerg. Sel. Top. Power Electron. 2021, 9, 2674–2684.

- Radimov, N.; Ben-Hail, N.; Rabinovici, R. Simple Model of Switched-Reluctance Machine Based only on Aligned and Unaligned Position Data. IEEE Trans. Magn. 2004, 40, 1562–1572.

- Ralev, I.; Max, S.; De Doncker, R.W. Accurate Rotor Position Detection for Low-Speed Operation of Switched Reluctance Drives. In Proceedings of the 2018 IEEE 18th International Power Electronics and Motion Control Conference (PEMC), Budapest, Hungary, 26–30 August 2018; pp. 483–490.

- Feng, L.; Sun, X.; Tian, X.; Diao, K. Direct Torque Control with Variable Flux for an SRM Based on Hybrid Optimization Algorithm. IEEE Trans. Power Electron. 2022, 37, 6688–6697.

- Gan, C.; Chen, Y.; Sun, Q.; Si, J.; Wu, J.; Hu, Y. A Position Sensorless Torque Control Strategy for Switched Reluctance Machines with Fewer Current Sensors. IEEE/ASME Trans. Mechatron. 2021, 26, 1118–1128.

- Sahoo, S.K.; Dasgupta, S.; Panda, S.K.; Xu, J.-X. A Lyapunov function-based robust direct torque controller for a switched reluctance motor drive system. IEEE Trans. Power Electron. 2012, 27, 555–564.

- Sun, X.; Diao, K.; Lei, G.; Guo, Y.; Zhu, J. Direct Torque Control Based on a Fast Modeling Method for a Segmented-Rotor Switched Reluctance Motor in HEV Application. IEEE J. Emerg. Sel. Top. Power Electron. 2021, 9, 232–241.

- Xiao, D.; Ye, J.; Fang, G.; Xia, Z.; Wang, X.; Emadi, A. A Regional Phase-Locked Loop-Based Low-Speed Position-Sensorless Control Scheme for General-Purpose Switched Reluctance Motor Drives. IEEE Trans. Power Electron. 2021, 37, 5859–5873.

- Shi, T.; Cao, Y.; Jiang, G.; Li, X.; Xia, C. A Torque Control Strategy for Torque Ripple Reduction of Brushless DC Motor With Nonideal Back Electromotive Force. IEEE Trans. Ind. Electron. 2017, 64, 4423–4433.

- Zhou, D.; Chen, H. Four-Quadrant Position Sensorless Operation of Switched Reluctance Machine for Electric Vehicles over a Wide Speed Range. IEEE Trans. Transp. Electrif. 2021, 7, 2835–2847.

- Cai, J.; Yan, Y.; Zhang, W.; Zhao, X. A Reliable Sensorless Starting Scheme for SRM with Lowered Pulse Injection Current Influences. IEEE Trans. Instrum. Meas. 2021, 70, 1–9.

More

Information

Subjects:

Engineering, Electrical & Electronic

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

862

Revisions:

3 times

(View History)

Update Date:

24 Apr 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No