Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Xingtao Tang and Version 3 by Dean Liu.

Owing to the added advantages of high stability and low cost, the position sensorless method of SRMs has been extensively studied to advance its use in vehicles and construction machinery.

- additional components

- hybrid detection method

- position sensorless control

- whole speed

1. Introduction

The switched reluctance motor (SRM) is considered to be one of the best potential motors due to its simple structure, high efficiency, outstanding fault tolerance, and flexible control methods [1][2][3][4][5][1,2,3,4,5]. It limits general application in that its doubly salient structure leads to large torque ripple and noise. However, with the rapid development of control theory, finite element analysis (FEA), and power electronics, SRMs are gradually being used in vehicles and other fields [5][6][7][8][9][10][5,6,7,8,9,10].

SAt present, switched reluctance motors are widely used in many industrial fields, such as mild-hybrid BSG drives, hybrid vehicles, construction machinery, and aerospace engines, etc., [11][12][13][14][15][16][11,12,13,14,15,16]. To fully discover the potential advantages of SRM, fault-tolerant control research [17][18][19][20][17,18,19,20], global optimization considering driving cycles and manufacturing fluctuations [21][22][23][24][25][21,22,23,24,25], minimum torque ripple control [26][27][28][29][26,27,28,29], and position sensorless control [30][31][32][33][34][30,31,32,33,34] have all been extensively studied. The sensorless approach has attracted much attention because it enables the SRM to have the advantages of low cost, low risk, and is not limited by hardware.

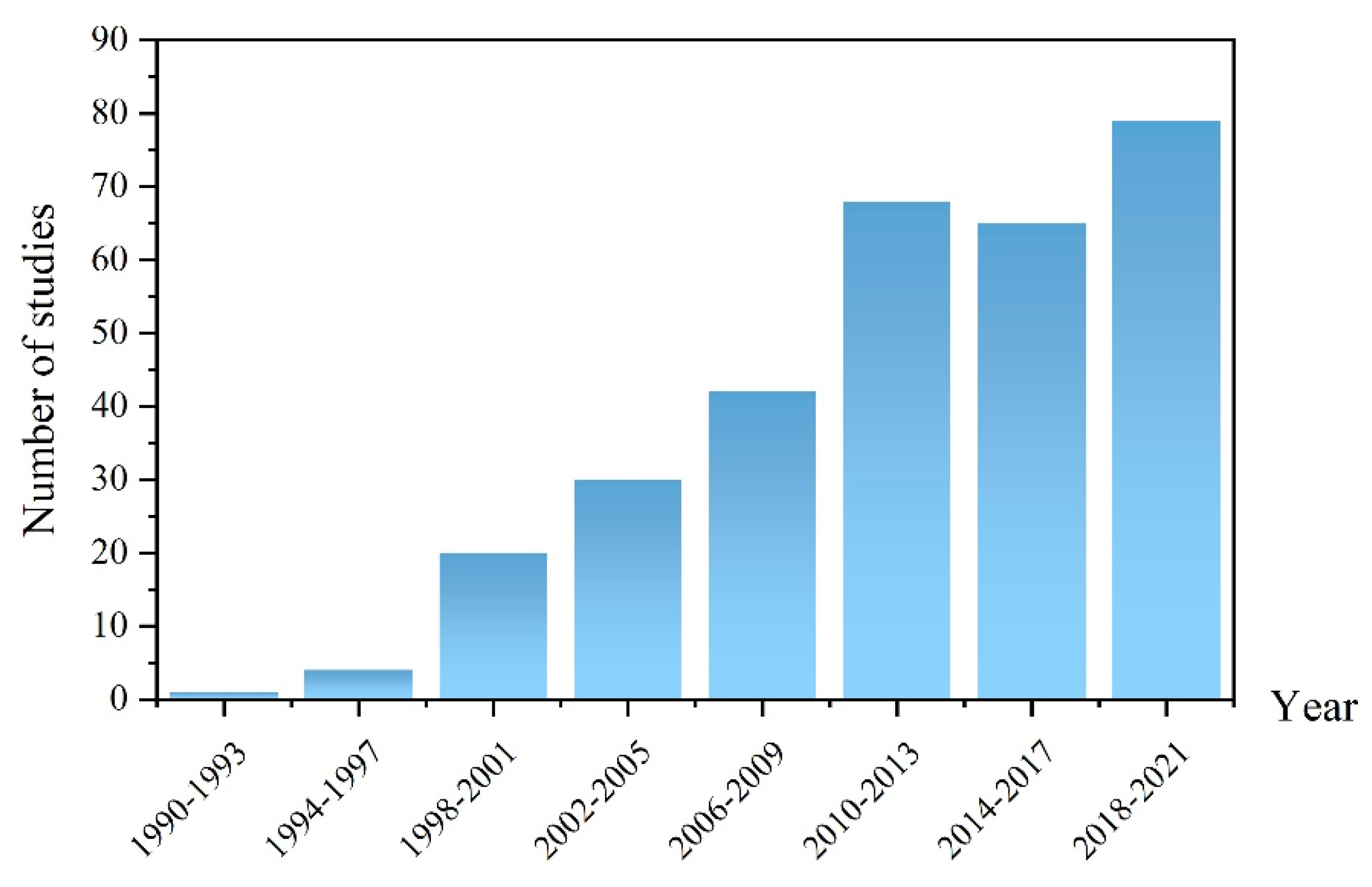

For the SRM drive system, the position signal of the rotor is indispensable. However, the position sensor carries a potential risk of failure and limits the speed regulation performance due to the limitation of the sensor resolution [35][36][37][38][39][40][41][42][43][44][45][35,36,37,38,39,40,41,42,43,44,45]. To eliminate the negative effects, increasing position sensorless methods have emerged with the deepening of theoretical research on SRMs. As shown in Figure 1, the number of published articles on SRM position sensorless methods is increasing. RWesearchers h have to admit that this is a hot spot, and it is necessary to analyze and review the related theories and technologies.

Figure 1.

Number of studies published before Jan. 2021 that experimentally examined the position sensorless methods for SRM.

2. An Accurate Rotor Estimation Solution in Whole-Speed Range

Position sensorless technology for the full speed range is an ongoing goal. Many methods demonstrate accurate position estimation in part of the velocity range, which is also of great significance for the development of position sensorless methods. However, this limits the practical application of the algorithm in that the motor is required to be in the full speed range. It is necessary to seek rotor position estimation methods in a wider speed range.3. Reduce Coupling between Position Estimation and Control Methods

For motor motion control, current chopper control (CCC), angle position control (APC), and voltage chopper control (VCC) are relatively mature control algorithms. Many position estimation methods are extremely dependent on these control strategies, which is weak compared with traditional position sensors. Many new controls, such as direct torque control (DTC) and torque sharing function (TSF) [46][47][48][49][154,160,161,162], have outstanding performance in reducing torque ripple and vibration noise, and the current waveforms produced by these methods are completely different due to different control strategies [50][51][134,135]. This forces the position estimation methods to be able to adapt to these new control strategies.4. Reduce the Need for Prior Parameter Storage

The gradual reduction of the motor a priori parameter requirements can reduce the pressure on microcontrollers with small storage capacity. Of course, reswearchers also have to realize that some key motor parameters are instructive for estimating rotor position. The validation of prior parameters restricts the application of location-free methods to SRMs with large parameter differences. Moreover, many motor parameters may be changed by the interference from the environment and working conditions, which is a huge risk to the long-term effectiveness of the algorithm.5. Smooth Switching between Different Speed Stages

The motion process of conventional SRM is mainly divided into the start-up, low-speed, and high-speed stages. How to effectively switch between different sensorless methods is a technical point worth paying attention to [52][166]. For example, in [53][133], the pulse injection method is combined as the algorithm for the start-up phase. However, it does not indicate how to switch.6. High Stability under Heavy and Changing Loads

It is well known that drastic changes in load can challenge the robustness of the control algorithm. In the experiments of some literature, it is easy to observe that the estimation accuracy will be lower than the light load when the load is abruptly changed. How to effectively improve the accuracy of rotor position estimation is a worthy research direction under various working conditions. The principles of various types of sensorless methods have been introduced in detail, and their development has been teased out. The direction of the entire sensorless development is elucidated based on the current development direction. It is important to see what changes can be made in the future for each type of method. Table 13 presents future applications and future developments of the various methods summarized. From a practical application point of view, hybrid and observer-based methods enable a decoupling of speed/torque control strategies and position estimation in the full speed range.Table 13. Prediction of the development of existing methods.

| Methods | Features of Application | Future Development |

|---|---|---|

| Pulse injection methods | Outstanding startup performance | Hybrid with other methods |

| Additional components methods | Similar to the novel position sensor | Smaller additional components |

| Flux-current-based methods | Excellent real-time performance | More accurate analytical models |

| Inductance-based methods | Simple detection of special positions | Enhance real-time |

| Intelligent-control-based methods | For the acquisition of electromagnetic values | Mate position sensorless method |

| Observer-based methods | Outstanding real-time performance, decoupling from speed control strategy | Improvements at startup and low speed |

| Hybrid method | Suitable for whole-speed | Smoother mode switching |