Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Mohammed M. Farid | + 7883 word(s) | 7883 | 2022-02-22 04:54:03 | | | |

| 2 | Rita Xu | -4830 word(s) | 3053 | 2022-03-09 05:12:51 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Farid, M. Effect of Temperatures on Polyphenols during Extraction. Encyclopedia. Available online: https://encyclopedia.pub/entry/20352 (accessed on 07 February 2026).

Farid M. Effect of Temperatures on Polyphenols during Extraction. Encyclopedia. Available at: https://encyclopedia.pub/entry/20352. Accessed February 07, 2026.

Farid, Mohammed. "Effect of Temperatures on Polyphenols during Extraction" Encyclopedia, https://encyclopedia.pub/entry/20352 (accessed February 07, 2026).

Farid, M. (2022, March 09). Effect of Temperatures on Polyphenols during Extraction. In Encyclopedia. https://encyclopedia.pub/entry/20352

Farid, Mohammed. "Effect of Temperatures on Polyphenols during Extraction." Encyclopedia. Web. 09 March, 2022.

Copy Citation

Polyphenols are a set of bioactive compounds commonly found in plants. These compounds are of great interest, as they have shown high antioxidant power and are correlated to many health benefits. Hence, traditional methods of extraction such as solvent extraction, Soxhlet extraction and novel extraction technologies such as ultrasound-assisted extraction and subcritical water extraction (SWE) have been investigated for the extraction of polyphenols.

polyphenols

antioxidant

bioactive compounds

pressurised liquid extraction

1. Introduction

Polyphenols are naturally occurring substances found primarily in fruits, vegetables and most plant materials. Polyphenol is an umbrella term, so phenolic acids, flavonoids, stilbenes and lignans are all types of polyphenols. These substances show high antioxidant activity and are correlated to many positive health benefits [1][2]. Polyphenols are attributed with having protective effects against diabetes, cancer and cardiovascular diseases (CVD) [3]. The most well-studied subclass of polyphenols are flavonoids [4]. Some of the most important flavonoids are catechins, hesperidin, naringenin and quercetin. While the exact mechanism behind how these substances provide these health benefits is not well understood, studies show a clear positive correlation. Many of these positive benefits have been attributed to their antioxidant capacity, and the global market for antioxidants has grown to about US$3000 million [5]. With such a rise, there has recently been a growing number of studies investigating various extraction techniques.

The extraction techniques can be broadly divided into traditional (conventional) and novel (emerging) technologies. The traditional extractions include solvent extraction, Soxhlet extraction and maceration. The disadvantages of these extractions are the long extraction times, high energy consumption, the need for expensive, high-quality organic solvents, evaporation of the solvents during treatment and the use of these potentially toxic solvents, which then poses problems with disposal and possible loss of functionality [6]. The novel technologies include ultrasound-assisted extraction (UAE), enzymatic extraction, microwave-assisted extraction (MAE) and pulsed electric field (PEF) extraction. These emerging technologies are non-thermal, do not use any hazardous chemicals, provide a shorter extraction time and have high energy and extraction efficiency. Most of these novel extraction technologies are considered “green”, as they fit the criteria set by the Environmental Protection Agency (EPA) [7][8].

Supercritical/subcritical fluid extraction is another prominent technique in the field. This technology is often categorised as both a novel and traditional technology depending on the individual user. However, unlike other emerging technologies, this process does sometimes include treatment at high temperatures. The fluid chosen is also of importance for categorisation, as the critical temperature of the different fluids varies widely. In the case of supercritical CO2 extraction, the treatment may be considered non-thermal (around 40–60 °C); for example, the critical point for CO2 is around 31.2 °C [9]. As this technique may also use propane, methanol and other chemicals as solvents, it is sometimes categorised as a traditional extraction technology. On the other hand, subcritical water extraction is known by many names—pressurised liquid extraction (PLE), pressurised hot water extraction (PHWE) and superheated water extraction (SHWE). As water is a low-cost, non-toxic and environmentally friendly solvent, this extraction technique is very beneficial [10]. However, pressurised liquid extraction (hereafter referred to as PLE) often requires high temperatures between 100 °C and 300 °C and, hence, a very high-pressure vessel for treatment.

In traditional extractions, the highest polyphenol yield is observed around 60–80 °C, and the most common solvents used for these extractions are ethanol, methanol and acetone [10][11][12][13][14][15][16][17][18][19][20][21][22][23][24][25][26][27]. As there is solvent loss at temperatures above 60–80 °C, studies investigating the impact of extraction temperatures did not include higher treatment temperatures (>80–90 °C). Studies that investigated the impact of drying temperature on polyphenolic yields have provided insight into the behaviour of polyphenols at these temperatures. Many studies have shown that at drying temperatures above 80 °C, the polyphenolic yield decreases [19][28][29][30][31][32][33][34][35]. For this reason, polyphenols are regularly regarded as heat-labile compounds.

However, pressurised liquid extraction (PLE) studies have shown high phenolic yield at temperatures well above 100 °C. Generally, an increase in extraction temperature (up to 180–200 °C) correlates to an increase in phenolic content and antioxidant activity [36][37][38][39][40][41][42][43][44][45][46][47][48][49][50][51][52][53]. As this conflicts with findings from studies using traditional extractions, this topic requires further investigation.

2. Thermal Degradation

Maillard and Berset [54] used three mechanisms to explain the behaviour of polyphenols at high temperatures. First, the insoluble phenolic compounds may be released when the lignin bonds to phenolic acids are broken. It has been shown that the quantity of bound phenolic acids (measured after hydrolysis of plant tissue) is twice that of free phenolic compounds [54]. Secondly, lignin itself may be degraded at high temperatures, giving rise to more phenolic acids. This could explain the increase in phenolic yield with increasing temperature in PLE extractions. Lastly, at high temperatures, thermal degradation of the polyphenols may occur. Thermal degradation is the most common mechanism used to explain the fall in polyphenol yield during high-temperature extractions. However, thermal degradation alone does not explain the behaviour of polyphenols, as conventional extraction studies have shown that thermal degradation occurs at 80 °C compared with 150–200 °C in PLE. The other two mechanisms discussed above could be attributed to the conflicting results in the literature. The increase in TPC observed at high temperatures in PLE extractions could be due to the lignin–phenolic acid bonds breaking or due to the breakdown of lignin itself, giving rise to more phenolic acid.

Larrauri et al. [35] reported a significant drop in total phenolic content when the plant material was dried at temperatures above 100 °C, also showing a decrease in antioxidant activity along with a decrease in TPC and suggesting that thermal degradation of the polyphenols may have occurred. Another study was conducted by the same authors to investigate the effect of drying temperatures between 20 °C and 120 °C. They observed that antioxidant activity at 20 °C was 1.7 times higher than the AOA observed at 120 °C. They suggested that the oxidation of polyphenols at high temperatures may also lead to a loss in observed antioxidant activity [28].

Ross et al. [34] studied the effect of heating grape seed flour at various temperatures (120–240 °C) on polyphenols extracted with ethanol. The study found that the TPC yield dropped when the temperature was raised beyond 180 °C, while total flavonoid content (TFC) dropped at a lower temperature of 120 °C, suggesting that flavonoids are more sensitive to temperatures. A significant increase in TPC was observed at 150 °C, which could be due to the liberation of phenolic compounds from the plant matrix and/or the breakdown of lignin. At an extremely high temperature of 180 °C, similar to Larrauri et al. [35], the authors suggested that the main mechanism behind the reduction is thermal degradation. When yields of specific polyphenols are calculated by HPLC, it is observed that (1) catechin drops at above 150 °C, (2) gallocatechin increases massively with increasing time and temperature, (3) epicatechin is not highly affected at 120 °C but drops at above 150 °C and (4) gallic acid increases massively with time and temperature [34]. Other studies have also found that flavonoids are more heat sensitive, and the degradation of flavones and flavanols/flavanones are observed at lower temperatures [39][40][54][55][56][57][58][59].

Anthocyanins are one of the most abundant flavonoid constituents found in fruits and vegetables [60][61]. One study tested the thermal effects between 20–60 °C and observed that, initially, an increase in temperature causes an increase in anthocyanin extraction [16]; however, a sharp decrease in anthocyanin extraction was observed at 45 °C. The anthocyanin content in the TPC dropped from 70% to 54% with an increase in temperature beyond 45 °C. The initial increase in yield with temperature could be due to the increase in solubility of anthocyanins in ethanol. However, the TPC showed the opposite trend and increased with temperature. The contrast in the yield of TPC and anthocyanins could be due to anthocyanins being more sensitive to high temperatures. Ju and Howard [62] investigated the impact of temperature on both anthocyanins and TPC. They also found that the optimal extraction temperature for anthocyanins occurred at lower temperatures (80–100 °C) compared with TPC (120 °C). Volden et al. [63] found that blanching (94–96 °C, 3 min) and boiling (10 min) red cabbage increased the total polyphenols while the anthocyanin content decreased by 59% and 41% for the blanched and boiled red cabbage, respectively, suggesting that the anthocyanins were degraded by heat. Another study found that the anthocynanin content of elderberry, strawberry and black carrot reduced with heating at 95 °C for 1 h. The anthocyanin content in elderberry decreased by 50% after 3 h of heating [64].

Table 1 provides a summary of the findings of the papers discussed above.

Table 1. Thermal Degradation.

| Source | Extraction | Temperatures Tested | Effect on Polyphenols | Reference |

|---|---|---|---|---|

| Red grape pomace peels | TSE | Dried at 60, 100 and 140 °C; freeze-dried samples served as controls | TPC ↓ at 100 °C | [35] |

| Grape seed flour (GSF) | TSE | Heated at 120, 150, 180, 210 or 240 °C | TPC ↓ above 180 °C TFC ↓ above 120 °C |

[34] |

| Black rice | TSE | Dried at 20, 40, 60, 80 and 100 °C | TFC ↓ above 40 °C TPC ↓ above 80 °C |

[30] |

| Spinach | PLE | Extractions between 50–190 °C | Flavonoids ↓ at 130 °C No decrease in TPC |

[41] |

| Black currants | TSE | Extractions between 20–60 °C | T ↑, TPC ↑ Anthocyanins ↓ above 45 °C. |

[16] |

| Hemp, flax, canola seed cakes | TSE | Extractions at 40, 50, 60, 70 °C | T ↑, TPC ↑ TFC ↓ above 60 °C in flax and canola seed cake TFC ↓ above 70 °C in hempseed cake |

[57] |

| Peach | TSE | Extractions between 25–70 °C | TFC ↓ above 60 °C TPC remains same between 25–70 °C |

[55] |

| Mango peels and seed | TSE | Extractions at 25, 50, and 75 °C | TFC ↓ at 50 and 75 °C | [58] |

| Red grape skin | PLE | Extractions between 20 to 140 °C | Anthocyanins ↓ above 100 °C TPC ↓ above 120 °C |

[62] |

| Elderberry, strawberry and black carrot | TSE | Heated at 95 °C | Anthocyanins ↓ | [64] |

| Red cabbage | TSE | Blanched at 94–96 °C | TPC ↑ at 94–96 °C Anthocyanins ↓ at 94–96 °C |

[63] |

3. Effects of Other Parameters on Traditional and PLE Extractions, i.e., Oxidation, Light Sensitivity, Heating Time and Enzymes

3.1. Extraction Conditions

The duration of heating, storage conditions prior to extraction and exposure to oxygen are all factors that play an important role in determining the effect of temperature on the polyphenols [63][65]. PLE and traditional extraction are performed in very different environments. PLE is performed inside a cell with no exposure to light, mostly in the absence of oxygen (usually the cell is purged with nitrogen) for a shorter period compared with traditional extraction performed for long hours in a beaker. Long extraction times leave the partially extracted polyphenols exposed to light and oxygen, which has been reported to degrade the extractants [36]. This is further supported by studies conducted on the impact of various methods used for drying the plant material before extraction. Chan et al. [66] found that sun-drying ginger leaves caused significant loss in polyphenol yield compared with other drying methods that do not expose the leaves to light. Hot air or conventional drying has been shown to significantly decrease polyphenol yield compared with drying in a vacuum or nitrogen [30][67][68].

Ibañez et al. [37] performed a PLE extraction of polyphenols from dried rosemary leaves at 100, 150 and 200 °C. The study also found that when the temperature increased, the TPC increased. As the TPC and AOA were maximum at 200 °C, the authors suggested that thermal decomposition did not occur. As deoxygenated water was used and no exposure to air occurred during the process, it was suggested that a low level of oxidation occurred. Carnosic acid is said to be more sensitive to the presence of oxygen than temperature, which could explain why a PLE at 200 °C showed the highest yield of carnosic acid.

Palma et al. [36] studied the stability of phenolic compounds, specifically the impact of temperature and other conditions on individual polyphenol standards (gallic acid, cis-coumaric acid, caftaric acid, catechin, epicatechin and epigallocatechin gallate). The samples were subject to a superheated methanol treatment at 40, 50, 100 and 150 °C, while methanol extraction at 65 °C (boiling point of methanol) for 45 min was conducted as a control. The recovery rates of individual polyphenols were calculated using HPLC. Ninety per cent of all phenolic compounds were recovered at all temperatures except for catechin and epicatechin, which saw a drop in recovery rate above 150 °C. The results of the boiling methanol extraction showed that the recovery rates were much lower than the PLE extraction. In fact, catechin saw a reduction of 40% in its concentration.

The highest degradation observed in superheated methanol treatment was for catechins, but it was only 14%. The authors suggested that this degradation happened at moderate temperatures (around 65 °C) during boiling methanol extraction due to light exposure and oxidation by the oxygen present in the air. As no such degradation was observed in dark and oxygen-free environments during superheated methanol extraction, it was concluded that the lower recovery rates in methanol extraction were not due to thermal degradation. As catechins are known to be the most oxidisable compound among the ones tested, the 40% loss of catechins in methanol extraction compared with only 10% in PLE provides more evidence that the degradation is due to the presence of oxygen.

3.2. Enzymes

Enzymes such as glycosidases, polyphenol oxidases (PPO) and peroxidases found in plant tissue can cause degradation of polyphenols [61]. Glycosidases can break down anthocyanins to anthocyanidins and sugars that are chemically unstable and rapidly degrade [61]. In the presence of oxygen, PPO can catalyse the oxidation of o-dihydrophenols diphenols (e.g., chlorogenic acid) into o-quinone (e.g., chlorogenoquinone) [60]. In the presence of H2O2, peroxidase can catalyse the same reaction [69].

The thermal stability of this enzyme is heavily influenced by the source of the enzyme but also depends on the pH [70]. Even PPO from the same source may have different thermostabilities depending on the different molecular forms of PPO [70]. However, in general, PPO is not considered an extremely heat-stable enzyme. PPO can be inactivated with mild heating, such as a blanching treatment for fruits and vegetables [60]. In most cases, a temperature of 70–90 °C inactivates the enzyme [70].

Rossi et al. [71] found that blanching blueberries led to the doubling of anthocyanin content in its juice compared to unblanched samples. The blanching treatment completely inactivated the native PPO and thus increased the anthocyanin recovery [71]. Additionally, another study found that the addition of unblanched blueberry-pulp extract to blueberry juice caused a 50% loss in anthocyanins while the addition of blanched extract did not result in any degradation [72].

3.3. Solvent Concentration and pH

The solvent concentration also has a significant impact on the optimal extraction temperature [16][41]. Cacace and Mazza [16] studied the impact of ethanol concentration on the optimal extraction temperature of polyphenols from blackcurrants. They found that extraction could be performed at lower temperatures when low ethanol concentration was used. For example, at 85% ethanol concentration (wt basis), the maximum anthocyanin extraction is between 30–35 °C, while at 20% ethanol (wt basis), the highest anthocyanin yield was observed at 25 °C.

The pH of the extraction media also plays an important role in determining the effect of temperature. Havlíková and Míková [65] investigated the stability of anthocyanins under various pH and temperatures. At lower temperatures (50–60 °C), pH plays a significant role in anthocyanin’s thermal stability, but at temperatures above 70 °C, the pH does not have a significant effect. The pH during extraction did not affect the stability of the anthocyanins when the oxygen concentration during treatment was negligible.

4. Effects of Extraction Temperature on the Profiles of Polyphenols Extracted

Many studies have found that the extraction temperature significantly impacts the type of polyphenols extracted since various polyphenols degrade at different temperatures [36][39][41][47][51][55][58][62][73][74][75].

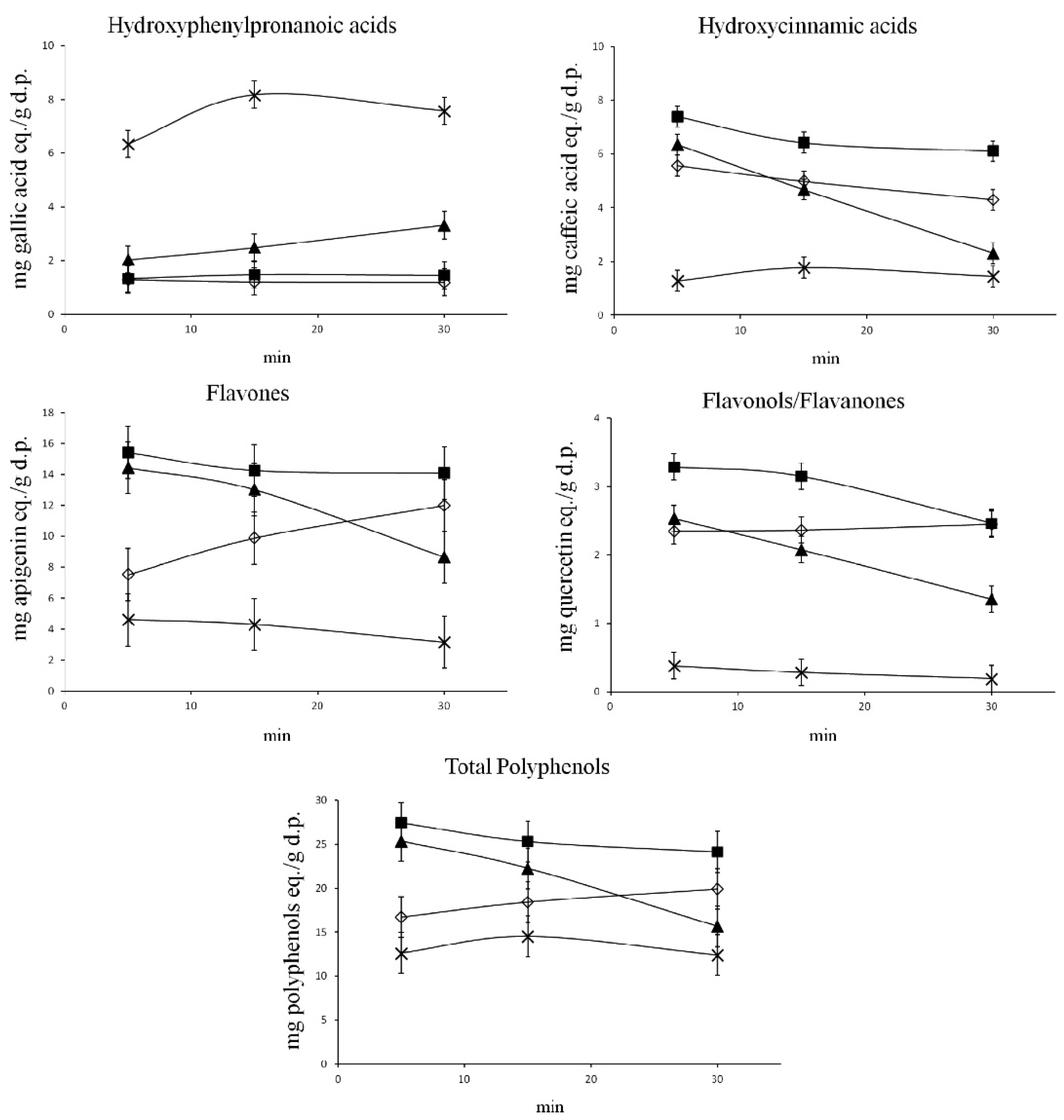

Vergara-Salinas et al. [47] performed pressurised liquid extraction (PLE) on dried thyme and studied the effect of temperatures between 50 and 200 °C and the profile of polyphenols being extracted at each temperature using HPLC. The results showed that temperature had a significant effect on the polyphenol subclasses (Figure 1, Table 2). Hydroxyphenylpronanoic acid (HPPA) concentration increased by almost three times when the extraction temperature was 200 °C, while 100 °C was optimal for hydroxycinnamic acids, flavones, flavonols and total polyphenols. Additionally, higher extraction temperatures showed less diversity in the types of polyphenols extracted.

Figure 1. Impact of temperature on polyphenols and subclasses. Extraction temperatures: (◇) 50 °C; (■) 100 °C; (▲) 150 °C; (×) 200 °C. Reprinted with permission from {Vergara-Salinas, J.R.; Pérez-Jiménez, J.; Torres, J.L.; Agosin, E.; Pérez-Correa, J.R. Effects of temperature and time on polyphenolic content and antioxidant activity in the pressurized hot water extraction of deodorized thyme (Thymus vulgaris). J. Agric. Food Chem. 2012, 60, 10920–10929, doi:10.1021/jf3027759.}. Copyright {2012} American Chemical Society.

Table 2. Impact on individual phenolic compounds.

| Source | Extraction | Effect | Reference |

|---|---|---|---|

| Thyme | PLE | T ↑, hydroxyphenyl propanoic acids (HPPA) ↑, hydroxycinnamic acids ↓, flavones ↓, and flavanols ↓ | [47] |

| Rosemary | PLE | T ↑, rosmanol ↓, carnosol ↓, carnosic acid ↑ | [37] |

| Mint | TSE followed by acid hydrolysis | All phenolic increased massively after hydrolysis, except caffeic acid | [73] |

| Buckthorn | TSE followed by acid hydrolysis | Ferulic acid, myricetin, quercetin, naringenin, luteolin and apigenin appeared after hydrolysis. The content of the phenolics also increased with the exception of gallic acid, which slightly decreased. Vanillic acid was present in the normal extract but not present after hydrolysis | [73] |

| Birch | TSE followed by acid hydrolysis | Myricetin, quercetin and kaempferol appeared after hydrolysis. Hydrolysis caused an increase in the content of gallic acid, protocatechuic acid and apigenin but a decrease in the content of caffeic acid and chlorogenic acid | [73] |

| Caraway | TSE followed by acid hydrolysis | Protocatechuic acid was found in the normal extract but not found after hydrolysis. Caffeic acid decreased after hydrolysis | [73] |

| Parsley | TSE followed by acid hydrolysis | Quercetin appeared after hydrolysis. Increase in concentrations of all other phenolics after hydrolysis. Increase in gallic acid again explained by hydrolysis of galotannins | [73] |

Ibañez et al. [37] performed a sequential extraction at 100, 150 and 200 °C and analysed the extracts using HPLC; they found that polar phenolic compounds were extracted at low temperatures while less polar phenolics were extracted at higher temperatures. The polarity of water was reduced at higher temperatures, allowing it to solvate the nonpolar compounds and extract them. As a result, depending on the extraction temperature, phenolic compounds can be extracted with high selectivity. Hossain et al. [45] studied the extraction of polyphenols from rosemary, oregano and marjoram and found that TPC increased as the temperature increased from 66 °C to 200 °C. However, at temperatures above 150 °C, rosmarinic acid and carnosic acid decreases (Table 2). As the AOA remained very high, the authors suggested that rosmarinic and carnosic acid broke down to compounds with higher antioxidant power.

Palma et al. [36] performed a PLE for polyphenols from grape peels and seeds. For grape seed extracts, compounds were detected at 150 °C that were not present at 50 °C and 100 °C. Mišan et al. [73] extracted polyphenols from parsley, buckthorn, mint, caraway and birch and also performed acid hydrolysis (HCL in 50% aqueous methanol heated to 90 °C for 2 h) and compared the results to unhydrolysed samples. With the assumption that hydrolysis of the phenols occurs at high temperatures, researchers can compare the results of this study to other papers performing extractions at high temperatures. The results show that depending on the plant, many polyphenols appear or disappear after hydrolysis. Table 2 below summarises studies that showed a shifting profile of phenolics depending on extraction conditions.

References

- Pandey, K.B.; Rizvi, S.I. Plant polyphenols as dietary antioxidants in human health and disease. Oxid. Med. Cell. Longev. 2009, 2, 270–278.

- Zia-Ul-Haq, M. Historical and Introductory Aspects of Carotenoids. In Carotenoids: Structure and Function in the Human Body; Zia-Ul-Haq, M., Dewanjee, S., Riaz, M., Eds.; Springer: Cham, Switzerland, 2021; pp. 1–42. ISBN 978-3-030-46459-2.

- Cory, H.; Passarelli, S.; Szeto, J.; Tamez, M.; Mattei, J. The Role of Polyphenols in Human Health and Food Systems: A Mini-Review. Front. Nutr. 2018, 5, 87.

- Arts, I.C.W.; Hollman, P.C.H. Polyphenols and disease risk in epidemiologic studies. Am. J. Clin. Nutr. 2005, 81, 317S–325S.

- Todd, R.; Baroutian, S. A techno-economic comparison of subcritical water, supercritical CO2 and organic solvent extraction of bioactives from grape marc. J. Clean. Prod. 2017, 158, 349–358.

- Nayak, A.; Bhushan, B. An overview of the recent trends on the waste valorization techniques for food wastes. J. Environ. Manag. 2019, 233, 352–370.

- Azmir, J.; Zaidul, I.S.M.; Rahman, M.M.; Sharif, K.M.; Mohamed, A.; Sahena, F.; Jahurul, M.H.A.; Ghafoor, K.; Norulaini, N.A.N.; Omar, A.K.M. Techniques for extraction of bioactive compounds from plant materials: A review. J. Food Eng. 2013, 117, 426–436.

- Galanakis, C.M. Recovery of high added-value components from food wastes: Conventional, emerging technologies and commercialized applications. Trends Food Sci. Technol. 2012, 26, 68–87.

- Soquetta, M.B.; Terra, L.D.M.; Bastos, C.P. Green technologies for the extraction of bioactive compounds in fruits and vegetables. CYTA J. Food 2018, 16, 400–412.

- Zakaria, S.M.; Kamal, S.M.M. Subcritical Water Extraction of Bioactive Compounds from Plants and Algae: Applications in Pharmaceutical and Food Ingredients. Food Eng. Rev. 2016, 8, 23–34.

- Dent, M.; Dragović-Uzelac, V.; Penić, M.; Brñić, M.; Bosiljkov, T.; Levaj, B. The effect of extraction solvents, temperature and time on the composition and mass fraction of polyphenols in dalmatian wild sage (Salvia officinalis L.) extracts. Food Technol. Biotechnol. 2013, 51, 84–91.

- Bucić-Kojić, A.; Planinić, M.; Tomas, S.; Bilić, M.; Velić, D. Study of solid-liquid extraction kinetics of total polyphenols from grape seeds. J. Food Eng. 2007, 81, 236–242.

- Jokic, S.; Velic, D.; Bilic, M.; Bucic-Kojic, A.; Planinic, M.; Tomasa, S. Modelling of the process of solid-liquid extraction of total polyphenols from soybeans. Czech J. Food Sci. 2010, 28, 206–212.

- Durling, N.E.; Catchpole, O.J.; Grey, J.B.; Webby, R.F.; Mitchell, K.A.; Foo, L.Y.; Perry, N.B. Extraction of phenolics and essential oil from dried sage (Salvia officinalis) using ethanol-water mixtures. Food Chem. 2007, 101, 1417–1424.

- Thoo, Y.Y.; Ho, S.K.; Liang, J.Y.; Ho, C.W.; Tan, C.P. Effects of binary solvent extraction system, extraction time and extraction temperature on phenolic antioxidants and antioxidant capacity from mengkudu (Morinda citrifolia). Food Chem. 2010, 120, 290–295.

- Cacace, J.E.; Mazza, G. Optimization of extraction of anthocyanins from black currants with aqueous ethanol. J. Food Sci. 2003, 68, 240–248.

- Jeong, S.M.; Kim, S.Y.; Kim, D.R.; Jo, S.C.; Nam, K.C.; Ahn, D.U.; Lee, S.C. Effect of heat treatment on the antioxidant activity of extracts from citrus peels. J. Agric. Food Chem. 2004, 52, 3389–3393.

- Spigno, G.; Tramelli, L.; De Faveri, D.M. Effects of extraction time, temperature and solvent on concentration and antioxidant activity of grape marc phenolics. J. Food Eng. 2007, 81, 200–208.

- Akowuah, G.A.; Mariam, A.; Chin, J.H. The effect of extraction temperature on total phenols and antioxidant activity of Gynura procumbens leaf. Pharmacogn. Mag. 2009, 4, 81–85.

- Hernández-Carranza, P.; Ávila-Sosa, R.; Guerrero-Beltrán, J.A.; Navarro-Cruz, A.R.; Corona-Jiménez, E.; Ochoa-Velasco, C.E. Optimization of Antioxidant Compounds Extraction from Fruit By-Products: Apple Pomace, Orange and Banana Peel. J. Food Process. Preserv. 2016, 40, 103–115.

- Li, B.B.; Smith, B.; Hossain, M.M. Extraction of phenolics from citrus peels: I. Solvent extraction method. Sep. Purif. Technol. 2006, 48, 182–188.

- Shi, J.; Yu, J.; Pohorly, J.; Young, J.C.; Bryan, M.; Wu, Y. Optimization of the extraction of polyphenols from grape seed meal by aqueous ethanol solution. J. Food Agric. Environ. 2003, 1, 42–47.

- Jeganathan, P.M.; Venkatachalam, S.; Karichappan, T.; Ramasamy, S. Model development and process optimization for solvent extraction of polyphenols from red grapes using box-behnken design. Prep. Biochem. Biotechnol. 2014, 44, 56–67.

- Gironi, F.; Piemonte, V. Temperature and solvent effects on polyphenol extraction process from chestnut tree wood. Chem. Eng. Res. Des. 2011, 89, 857–862.

- Čepo, D.V.; Albahari, P.; Končić, M.Z.; Radić, K.; Jurmanović, S.; Jug, M. Solvent Extraction and Chromatographic Determination of Polyphenols in Olive Pomace. Food Health Dis. 2017, 6, 7–14.

- Rajbhar, K.; Dawda, H.; Mukundan, U. Polyphenols: Methods of Extraction. Sci. Rev. Chem. Commun 2015, 5, 1–6.

- Bucić-Kojić, A.; Planinić, M.; Tomas, S.; Jakobek, L.; Šeruga, M. Influence of solvent and temperature on extraction of phenolic compounds from grape seed, antioxidant activity and colour of extract. Int. J. Food Sci. Technol. 2009, 44, 2394–2401.

- Larrauri, J.A.; Sánchez-Moreno, C.; Saura-Calixto, F. Effect of Temperature on the Free Radical Scavenging Capacity of Extracts from Red and White Grape Pomace Peels. J. Agric. Food Chem. 1998, 46, 2694–2697.

- Al Juhaimi, F.; Özcan, M.M.; Uslu, N.; Ghafoor, K. The effect of drying temperatures on antioxidant activity, phenolic compounds, fatty acid composition and tocopherol contents in citrus seed and oils. J. Food Sci. Technol. 2018, 55, 190–197.

- Lang, G.H.; Lindemann, I.D.S.; Ferreira, C.D.; Hoffmann, J.F.; Vanier, N.L.; de Oliveira, M. Effects of drying temperature and long-term storage conditions on black rice phenolic compounds. Food Chem. 2019, 287, 197–204.

- Daniel, D.L.; Huerta, B.E.B.; Sosa, I.A.; Mendoza, M.G.V. Effect of fixed bed drying on the retention of phenolic compounds, anthocyanins and antioxidant activity of roselle (Hibiscus sabdariffa L.). Ind. Crops Prod. 2012, 40, 268–276.

- Vega-Gálvez, A.; Di Scala, K.; Rodríguez, K.; Lemus-Mondaca, R.; Miranda, M.; López, J.; Perez-Won, M. Effect of air-drying temperature on physico-chemical properties, antioxidant capacity, colour and total phenolic content of red pepper (Capsicum annuum, L. var. Hungarian). Food Chem. 2009, 117, 647–653.

- Miranda, M.; Vega-Gálvez, A.; López, J.; Parada, G.; Sanders, M.; Aranda, M.; Uribe, E.; Di Scala, K. Impact of air-drying temperature on nutritional properties, total phenolic content and antioxidant capacity of quinoa seeds (Chenopodium quinoa Willd.). Ind. Crops Prod. 2010, 32, 258–263.

- Ross, C.F.; Hoye, C.; Fernandez-Plotka, V.C. Influence of Heating on the Polyphenolic Content and Antioxidant Activity of Grape Seed Flour. J. Food Sci. 2011, 76, 884–890.

- Larrauri, J.A.; Rupérez, P.; Saura-Calixto, F. Effect of Drying Temperature on the Stability of Polyphenols and Antioxidant Activity of Red Grape Pomace Peels. J. Agric. Food Chem. 1997, 45, 1390–1393.

- Palma, M.; Piñeiro, Z.; Barroso, C.G. Stability of phenolic compounds during extraction with superheated solvents. J. Chromatogr. A 2001, 921, 169–174.

- Ibañez, E.; Kubátová, A.; Señoráns, F.J.; Cavero, S.; Reglero, U.; Hawthorne, S.B. Subcritical water extraction of antioxidant compounds from rosemary plants. J. Agric. Food Chem. 2003, 51, 375–382.

- Zeković, Z.; Vidović, S.; Vladić, J.; Radosavljević, R.; Cvejin, A.; Elgndi, M.A.; Pavlić, B. Optimization of subcritical water extraction of antioxidants from Coriandrum sativum seeds by response surface methodology. J. Supercrit. Fluids 2014, 95, 560–566.

- Casazza, A.A.; Aliakbarian, B.; Sannita, E.; Perego, P. High-pressure high-temperature extraction of phenolic compounds from grape skins. Int. J. Food Sci. Technol. 2012, 47, 399–405.

- Santos, D.T.; Veggi, P.C.; Meireles, M.A.A. Optimization and economic evaluation of pressurized liquid extraction of phenolic compounds from jabuticaba skins. J. Food Eng. 2012, 108, 444–452.

- Howard, L.; Pandjaitan, N. Pressurized liquid extraction of flavonoids from spinach. J. Food Sci. 2008, 73.

- Andrew, J.; Masetlwa, J.; Tesfaye, T.; Sithole, B. Beneficiation of eucalyptus tree barks in the context of an integrated biorefinery—Optimisation of accelerated solvent extraction (ASE) of polyphenolic compounds using response surface methodology. Sustain. Chem. Pharm. 2020, 18, 100327.

- Ollanketo, M.; Peltoketo, A.; Hartonen, K.; Hiltunen, R.; Riekkola, M.L. Extraction of sage (Salvia officinalis L.) by pressurized hot water and conventional methods: Antioxidant activity of the extracts. Eur. Food Res. Technol. 2002, 215, 158–163.

- Nandasiri, R.; Eskin, N.A.M.; Thiyam-Höllander, U. Antioxidative Polyphenols of Canola Meal Extracted by High Pressure: Impact of Temperature and Solvents. J. Food Sci. 2019, 84, 3117–3128.

- Hossain, M.B.; Barry-Ryan, C.; Martin-Diana, A.B.; Brunton, N.P. Optimisation of accelerated solvent extraction of antioxidant compounds from rosemary (Rosmarinus officinalis L.), marjoram (Origanum majorana L.) and oregano (Origanum vulgare L.) using response surface methodology. Food Chem. 2011, 126, 339–346.

- Rodríguez-Meizoso, I.; Marin, F.R.; Herrero, M.; Señorans, F.J.; Reglero, G.; Cifuentes, A.; Ibáñez, E. Subcritical water extraction of nutraceuticals with antioxidant activity from oregano. Chemical and functional characterization. J. Pharm. Biomed. Anal. 2006, 41, 1560–1565.

- Vergara-Salinas, J.R.; Pérez-Jiménez, J.; Torres, J.L.; Agosin, E.; Pérez-Correa, J.R. Effects of temperature and time on polyphenolic content and antioxidant activity in the pressurized hot water extraction of deodorized thyme (Thymus vulgaris). J. Agric. Food Chem. 2012, 60, 10920–10929.

- Budrat, P.; Shotipruk, A. Enhanced recovery of phenolic compounds from bitter melon (Momordica charantia) by subcritical water extraction. Sep. Purif. Technol. 2009, 66, 125–129.

- Repajić, M.; Cegledi, E.; Kruk, V.; Pedisić, S.; Çinar, F.; Kovačević, D.B.; Žutić, I.; Dragović-Uzelac, V. Accelerated solvent extraction as a green tool for the recovery of polyphenols and pigments fromwild nettle leaves. Processes 2020, 8, 803.

- Barros, F.; Dykes, L.; Awika, J.M.; Rooney, L.W. Accelerated solvent extraction of phenolic compounds from sorghum brans. J. Cereal Sci. 2013, 58, 305–312.

- Álvarez-Casas, M.; García-Jares, C.; Llompart, M.; Lores, M. Effect of experimental parameters in the pressurized solvent extraction of polyphenolic compounds from white grape marc. Food Chem. 2014, 157, 524–532.

- Rajha, H.N.; Ziegler, W.; Louka, N.; Hobaika, Z.; Vorobiev, E.; Boechzelt, H.G.; Maroun, R.G. Effect of the drying process on the intensification of phenolic compounds recovery from grape pomace using accelerated solvent extraction. Int. J. Mol. Sci. 2014, 15, 18640–18658.

- Duba, K.S.; Casazza, A.A.; Mohamed, H.B.; Perego, P.; Fiori, L. Extraction of polyphenols from grape skins and defatted grape seeds using subcritical water: Experiments and modeling. Food Bioprod. Process. 2015, 94, 29–38.

- Maillard, M.N.; Berset, C. Evolution of Antioxidant Activity during Kilning: Role of Insoluble Bound Phenolic Acids of Barley and Malt. J. Agric. Food Chem. 1995, 43, 1789–1793.

- Mokrani, A.; Madani, K. Effect of solvent, time and temperature on the extraction of phenolic compounds and antioxidant capacity of peach (Prunus persica L.) fruit. Sep. Purif. Technol. 2016, 162, 68–76.

- Chen, M.L.; Yang, D.J.; Liu, S.C. Effects of drying temperature on the flavonoid, phenolic acid and antioxidative capacities of the methanol extract of citrus fruit (Citrus sinensis (L.) Osbeck) peels. Int. J. Food Sci. Technol. 2011, 46, 1179–1185.

- Teh, S.S.; Birch, E.J. Effect of ultrasonic treatment on the polyphenol content and antioxidant capacity of extract from defatted hemp, flax and canola seed cakes. Ultrason. Sonochem. 2014, 21, 346–353.

- Dorta, E.; Lobo, M.G.; Gonzalez, M. Reutilization of mango byproducts: Study of the effect of extraction solvent and temperature on their antioxidant properties. J. Food Sci. 2012, 77, C80–C88.

- Wang, L.F.; Kim, D.M.; Lee, C.Y. Effects of heat processing and storage on flavanols and sensory qualities of green tea beverage. J. Agric. Food Chem. 2000, 48, 4227–4232.

- Patras, A.; Brunton, N.P.; O’Donnell, C.; Tiwari, B.K. Effect of thermal processing on anthocyanin stability in foods; mechanisms and kinetics of degradation. Trends Food Sci. Technol. 2010, 21, 3–11.

- Alvarez-Suarez, J.M.; Cuadrado, C.; Redondo, I.B.; Giampieri, F.; González-Paramás, A.M.; Santos-Buelga, C. Novel approaches in anthocyanin research—Plant fortification and bioavailability issues. Trends Food Sci. Technol. 2021, 117, 92–105.

- Ju, Z.Y.; Howard, L.R. Effects of solvent and temperature on pressurized liquid extraction of anthocyanins and total phenolics from dried red grape skin. J. Agric. Food Chem. 2003, 51, 5207–5213.

- Volden, J.; Borge, G.I.A.; Bengtsson, G.B.; Hansen, M.; Thygesen, I.E.; Wicklund, T. Effect of thermal treatment on glucosinolates and antioxidant-related parameters in red cabbage (Brassica oleracea L. ssp. capitata f. rubra). Food Chem. 2008, 109, 595–605.

- Sadilova, E.; Stintzing, F.C.; Carle, R. Thermal degradation of acylated and nonacylated anthocyanins. J. Food Sci. 2006, 71, C504–C512.

- Havlíková, L.; Míková, K. Heat Stability of Anthocyanins. Z. Lebensm. Unters. Forsch. 1985, 181, 427–432.

- Chan, E.W.C.; Lim, Y.Y.; Wong, S.K.; Lim, K.K.; Tan, S.P.; Lianto, F.S.; Yong, M.Y. Effects of different drying methods on the antioxidant properties of leaves and tea of ginger species. Food Chem. 2009, 113, 166–172.

- Tran, T.M.K.; Kirkman, T.; Nguyen, M.; Van Vuong, Q. Effects of drying on physical properties, phenolic compounds and antioxidant capacity of Robusta wet coffee pulp (Coffea canephora). Heliyon 2020, 6, e04498.

- Valadez-Carmona, L.; Plazola-Jacinto, C.P.; Hernández-Ortega, M.; Hernández-Navarro, M.D.; Villarreal, F.; Necoechea-Mondragón, H.; Ortiz-Moreno, A.; Ceballos-Reyes, G. Effects of microwaves, hot air and freeze-drying on the phenolic compounds, antioxidant capacity, enzyme activity and microstructure of cacao pod husks (Theobroma cacao L.). Innov. Food Sci. Emerg. Technol. 2017, 41, 378–386.

- Kader, F.; Irmouli, M.; Nicolas, J.P.; Metche, M. Involvement of blueberry peroxidase in the mechanisms of anthocyanin degradation in blueberry juice. J. Food Sci. 2002, 67, 910–915.

- Vamos-Vigyázó, L. Polyphenol Oxidase and Peroxidase in Fruits and Vegetables. Crit. Rev. Food Sci. Nutr. 1981, 15, 49–127.

- Rossi, M.; Giussani, E.; Morelli, R.; Lo Scalzo, R.; Nanic, R.C.; Torreggiani, D. Effect of fruit blanching on phenolics and radical scavenging activity of highbush blueberry juice. Food Res. Int. 2003, 36, 999–1005.

- Skrede, G.; Wrolstad, R.E.; Durst, R.W. Changes in anthocyanins and polyphenolics during juice processing of highbush blueberries (Vaccinium corymbosum L.). J. Food Sci. 2000, 65, 357–364.

- Mišan, A.Č.; Mimica-Dukić, N.M.; Mandić, A.I.; Sakač, M.B.; Milovanović, I.L.; Sedej, I.J. Development of a Rapid Resolution HPLC method for the separation and determination of 17 phenolic compounds in crude plant extracts. Cent. Eur. J. Chem. 2011, 9, 133–142.

- Jablonský, M.; Vernarecová, M.; Ház, A.; Dubinyová, L.; Škulcová, A.; Sladková, A.; Šurina, I. Extraction of phenolic and lipophilic compounds from spruce (picea abies) bark using accelerated solvent extraction by ethanol. Wood Res. 2015, 60, 583–590.

- Mustafa, A.; Turner, C. Pressurized liquid extraction as a green approach in food and herbal plants extraction: A review. Anal. Chim. Acta 2011, 703, 8–18.

More

Information

Subjects:

Engineering, Chemical; Food Science & Technology

Contributor

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

9.2K

Entry Collection:

Extraction Techniques in Sample Preparation

Revisions:

2 times

(View History)

Update Date:

09 Mar 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No