| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Bahman Amini Horri | + 2664 word(s) | 2664 | 2022-02-21 07:29:06 | | | |

| 2 | Camila Xu | -39 word(s) | 2625 | 2022-03-01 02:06:16 | | | | |

| 3 | Camila Xu | -39 word(s) | 2625 | 2022-03-01 02:11:44 | | |

Video Upload Options

The thermochemical water-splitting method is a promising technology for efficiently converting renewable thermal energy sources into green hydrogen. Thermochemical water splitting uses a high-temperature source, e.g., nuclear energy, waste heat, or concentrated solar systems, to convert water into hydrogen and oxygen through cyclic chemical reactions. Several promising routes have been proposed for hydrogen production through green technologies such as biological processes (such as CO gas-fermentation, dark fermentation, etc.), electrical (such as alkaline electrolysis cell, anion exchange membrane electrolysis cell, proton exchange membrane electrolysis cell, solid oxide electrolysis cell, etc.), photonic (bio-photolysis, photofermentation, etc.), thermochemical, etc.

1. Introduction

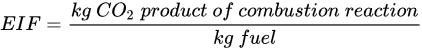

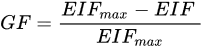

(1)

(1) (2)

(2) (3)

(3) Figure 1. HCF, GF, and EIF of coal, oil, natural gas, and hydrogen (Reproduced with permission from [17], Elsevier: 2015).

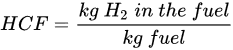

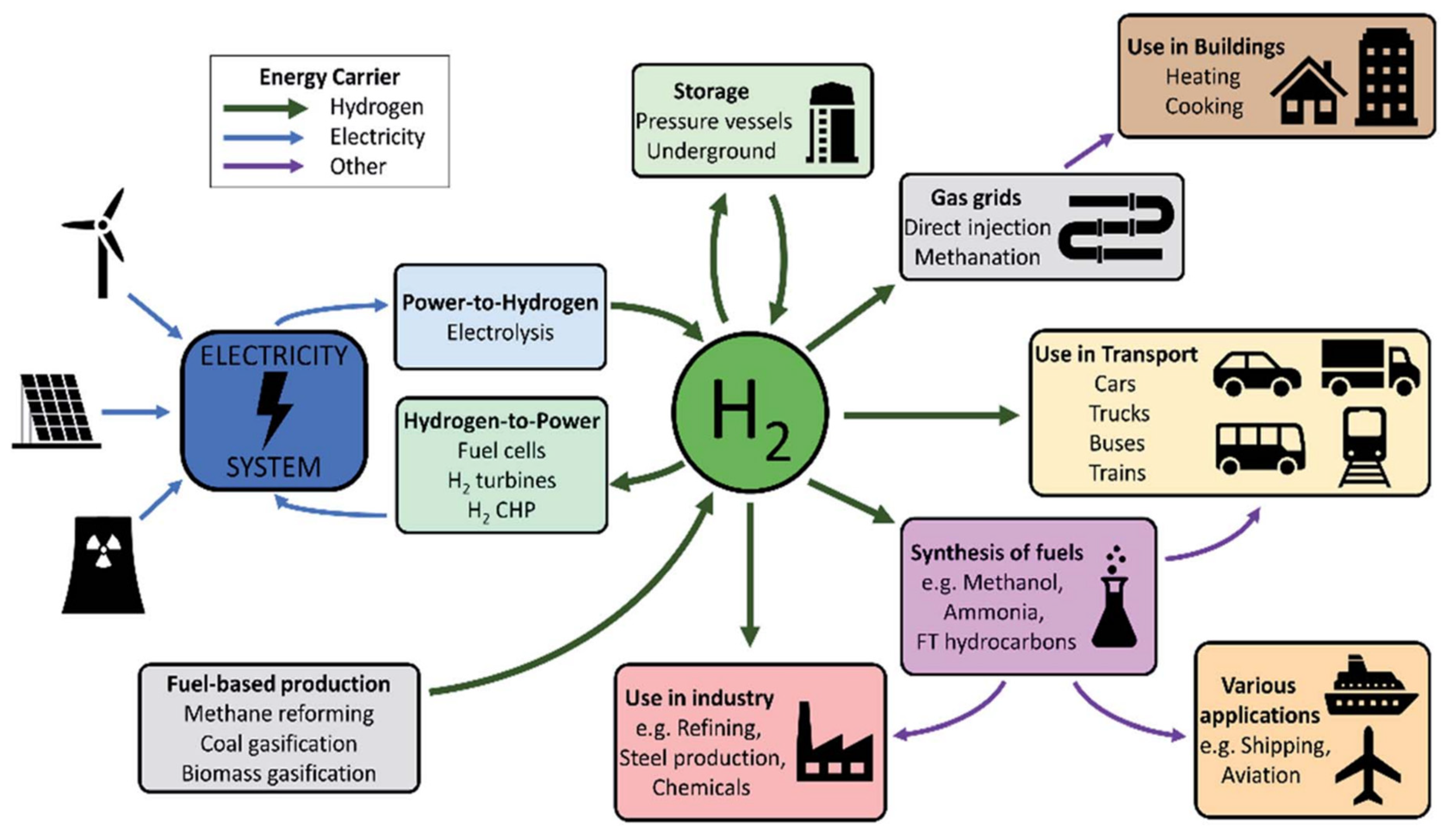

Figure 1. HCF, GF, and EIF of coal, oil, natural gas, and hydrogen (Reproduced with permission from [17], Elsevier: 2015). Figure 2. A summary of hydrogen applications [30].

Figure 2. A summary of hydrogen applications [30].2. Green Hydrogen Technologies

- -Low-temperature cycles with an operating temperature below 1100 °C, such as sulfur-iodine, hybrid sulfur, hybrid copper chloride, etc.

- -High-temperature cycles with an operating temperature above 1100 °C, such as Zn/ZnO, FeO/Fe3O4, manganese oxide-based, ferrite cycles, etc. [48]

-

3. Summary

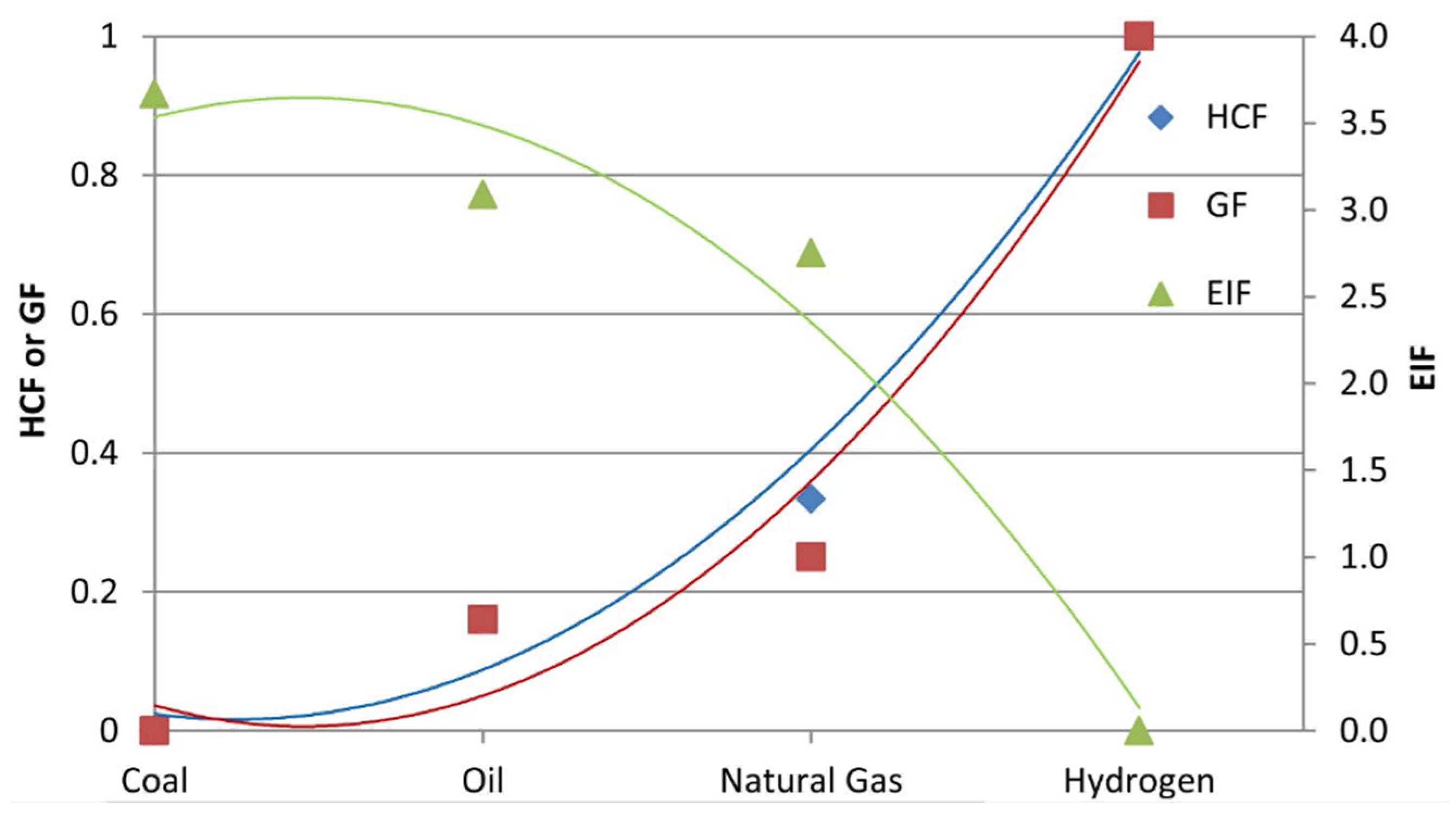

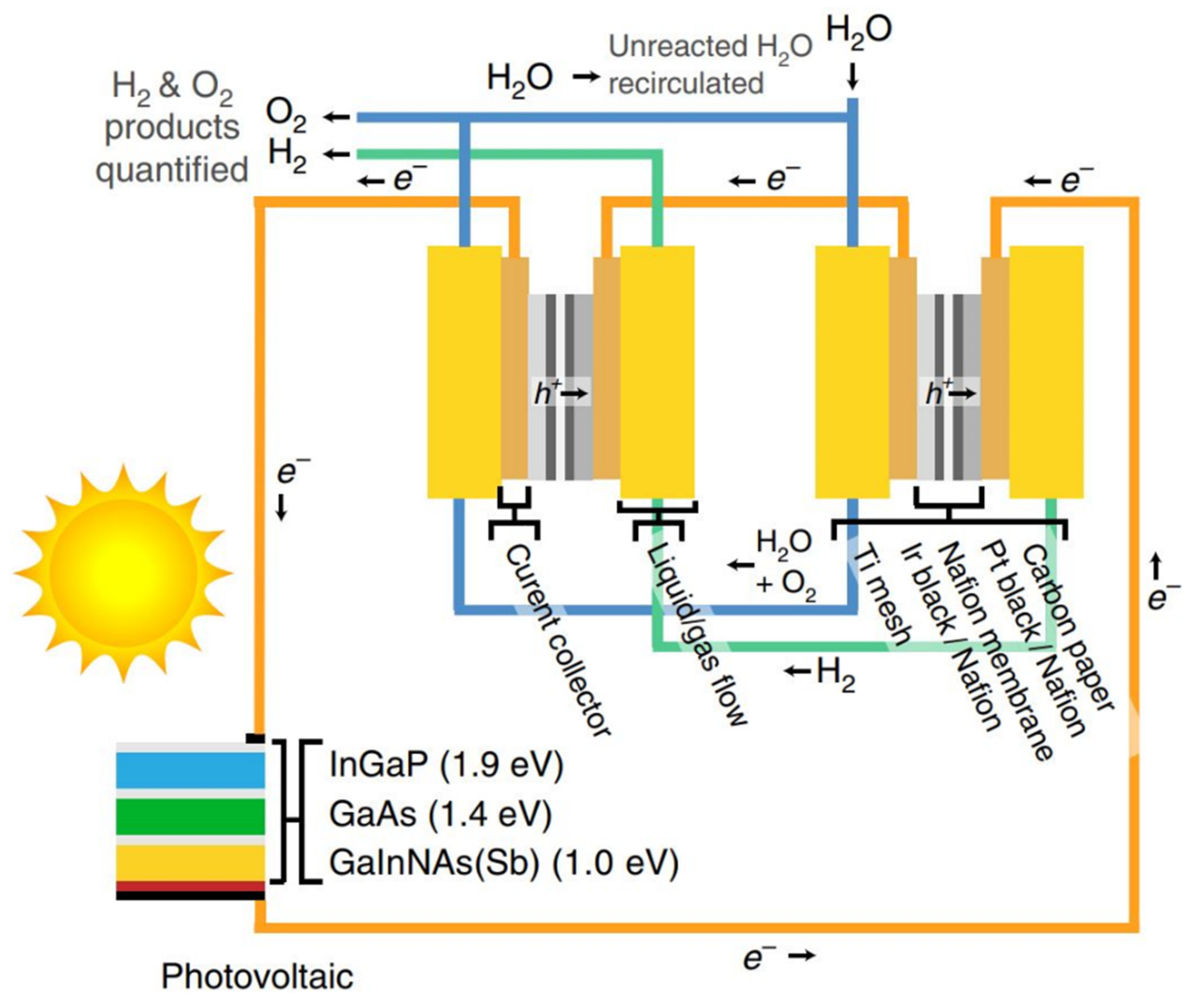

Optimal energy strategy plays an essential role in improving process optimization to increase lifetime and cost-effectiveness. Energy and exergy analysis of an S-I cycle coupled with HI-I2-H2O electrolysis has been conducted by Ying et al. [49]. The whole cycle was divided into three sections, i.e., Bunsen reaction, sulfuric acid decomposition, and HI-I2-H2O electrolysis. According to the results, the energy and exergy efficiencies of the system were about 15.3–31.0% and 32.8%, respectively. Due to the transformation of electricity to exergy in an electrolytic cell, sulfuric acid decomposer and condenser and Bunsen reaction sections accounted for about 93.0% and 63.4% of the exergy destruction, respectively. The highest exergy efficiency of the proposed S-I cycle was about 32.8% which was lower than the four-step Cu-Cl cycle (75.7% [50]) and Zn/ZnO cycle (~40%) [51]. The highest energy efficiency was also about 31.0%, which was lower than the Cu-Cl (41.9% [50]) and Zn/ZnO cycles (~40% [52]), implying that more studies should be conducted to improve the overall energy and exergy efficiencies of the proposed cycle such as appropriate waste heat recovery and internal heat exchange was recommended by the authors.Juárez-Martínez et al. [41] optimized the energy efficiency of an S-I cycle using a new network consisting of four heat exchangers and a heuristic-ruled method. The effect of the new network of heat exchangers on the system’s efficiency was analyzed, and it was found that the energy needed for cooling decreased. Thus, the overall thermal energy efficiency improved by about 10%.Wang et al. [53] analyzed the energy efficiency of direct solar hydrogen using low-cost materials. As the current hydrogen production systems suffer from either low efficiencies or expensive materials, they claimed that their proposed hydrogen generation system comprised of catalysts and low-cost light-absorbers could reach 20% efficiency of solar-to-hydrogen (STH) conversion by coupling high-performance perovskite-Si tandem cells with earth-abundant catalysts. The electrodes were made of high-density NiMo with flower-stem morphology with minimal reaction overpotential (~6 mV at 10 mA·cm−2) and increased reaction sites. Enhancing the performance of perovskite cells with an open-circuit voltage of 1.271 V can improve surface passivation and, consequently, surge the overall efficiency from 20% to 25%. In another attempt, Jia et al. [54] reported a higher hydrogen efficiency of over 30% using photovoltaic-electrolysis technology for water splitting. The system includes an InGaP/GaAs/GaInNAsSb triple-junction solar cell in series with two polymeric electrolyte membrane electrolyzers. Since the mentioned assembly produced a high voltage to drive the electrolyzers, no extra input power was used in the system. The operating capacity of the electrolyzers was well matched to the maximum output power of the photovoltaic cell by adjusting the solar concentration. A schematic of the PV-electrolysis is shown in Figure 3. High STH efficiency of about 30% was reported for the PV-electrolysis system. It is interesting to note that using two electrolyzers in series with a high-efficiency solar cell minimized the required additional voltage, thus improving the water splitting efficiency. Figure 3. Schematic of PV-electrolysis system for hydrogen production [54].According to the techno-economic assessments in 2009, the cost of hydrogen production using the HyS process with nuclear reactor is $5.34–6.18 per kg [55]. On the other hand, the costs of solar-driven hydrogen production are approximately in the range of $2.64–7.58 per kg depending on the solar plant efficiency, heliostat cost, location, thermochemical efficiency, etc. [56][57][58]. It has been reported that the sulfur dioxide depolarized electrolyzer (SDE) can significantly reduce the costs and electrical power required for the process [59]. It should also be noted that the realistic thermochemical efficiency of the S-I cycle is in the range of 35–38% based on hydrogen LHV, and costs of hydrogen production with an S-I cycle equipped with a nuclear reactor is in the range of $3.50–12.0 per kg [60][61]. As listed in Table 1, D’Souza [62] estimated the overall cost of hydrogen production (per kg hydrogen) in different cycles in 2015 and 2025. US DOE chose these technologies in collaboration with the TIAX laboratory as the most promising thermochemical water-splitting cycles. As has been established by the US DOE, hydrogen production costs should be in the range of $6 and $2–3 per kg H2 in 2015 and 2025, respectively. As can be seen in this table, the ferrite cycle (Ni ferrite thin film) shows great potential for hydrogen production, followed by the HyS cycle. However, further developments are required to satisfy the long-term stability and efficiency of these cycles to decrease capital expenditures (CAPEX) and operating expenses (OPEX).Table 1. Hydrogen production costs ($ per kg H2) of different thermochemical water splitting cycles [62].

Figure 3. Schematic of PV-electrolysis system for hydrogen production [54].According to the techno-economic assessments in 2009, the cost of hydrogen production using the HyS process with nuclear reactor is $5.34–6.18 per kg [55]. On the other hand, the costs of solar-driven hydrogen production are approximately in the range of $2.64–7.58 per kg depending on the solar plant efficiency, heliostat cost, location, thermochemical efficiency, etc. [56][57][58]. It has been reported that the sulfur dioxide depolarized electrolyzer (SDE) can significantly reduce the costs and electrical power required for the process [59]. It should also be noted that the realistic thermochemical efficiency of the S-I cycle is in the range of 35–38% based on hydrogen LHV, and costs of hydrogen production with an S-I cycle equipped with a nuclear reactor is in the range of $3.50–12.0 per kg [60][61]. As listed in Table 1, D’Souza [62] estimated the overall cost of hydrogen production (per kg hydrogen) in different cycles in 2015 and 2025. US DOE chose these technologies in collaboration with the TIAX laboratory as the most promising thermochemical water-splitting cycles. As has been established by the US DOE, hydrogen production costs should be in the range of $6 and $2–3 per kg H2 in 2015 and 2025, respectively. As can be seen in this table, the ferrite cycle (Ni ferrite thin film) shows great potential for hydrogen production, followed by the HyS cycle. However, further developments are required to satisfy the long-term stability and efficiency of these cycles to decrease capital expenditures (CAPEX) and operating expenses (OPEX).Table 1. Hydrogen production costs ($ per kg H2) of different thermochemical water splitting cycles [62].Years HyS CuCl Ferrite SA ZnO MnO S-I 2015 5.68 6.83 4.06 7.78 6.07 - - 2025 3.85 5.39 2.42 4.71 4.18 4.63 4.68 Hydrogen production through thermochemical water-splitting cycles is a clean and attractive method for addressing the global hydrogen energy demand. Currently, the most common methods for hydrogen generation are fossil-based technologies, and they result in air pollution and greenhouse gas emissions, resulting in global warming. Clean hydrogen can be produced using thermochemical cycles, but these cycles need to be studied to improve efficiency and lower the overall operation costs. A number of the recent studies and their significant findings has been summarised in Table 2. As listed in this table, each technology has weaknesses and strengths compared to the other ones. Overall, it is suggested that future studies should focus on improving the overall efficiency of the cycles, especially the Cu-Cl low-temperature cycle as well as zinc oxide and ferrite high-temperature cycles, by using the most cost-effective catalysts, optimizing structural and microstructural properties, removing impurities from the cycles, promoting the redox reactions and conversion rates, doping, handling the byproducts, etc. Since catalysts can enhance reaction rates and help improve the hydrogen yield, a cost-effective catalyst selection will be helpful. Nanomaterials can also improve the efficiency of the cycles, but their weaknesses, such as agglomeration, grain growth, and costs, should be addressed efficiently. Non-stoichiometry can facilitate the reactions and promote hydrogen production in metal oxide cycles. The potent combination between the thermodynamics and kinetic properties of the reactions and the structural/microstructural properties of the materials such as structure, morphology, composition, etc. and possible new synthesis routes should be considered in the subsequent studies to improve the cost-effectiveness of the cycles further. Implementing simulations for predicting the results of using new materials, new synthesis conditions, rate of reactions in each step, etc., can be beneficial.Table 2. Summary of the significant discoveries of some of the essential thermochemical water-splitting cycles.Cycle Major Discovery Ref. S-I Optimization of the Bunsen section for liquid–liquid separation.

Increasing iodine content improved separation characteristics.

The optimum I2/H2SO4 ratio was in the range of 2.45–3.99 at 70–85 °C[63] S-I Developed a microporous membrane resistant to sulfur trioxide composed of α-alumina support, ZrO2-SiO2 intermediate layer, and organosilica sol top layer. High Si:Zr ratio and large pore of the ZrO2-SiO2 showed higher O2/SO3 selectivity and higher chemical stability against SO3 [64] S-I Developed a modified cycle with fewer steps and used a steam boiler. The modified cycle has a higher HI decomposition rate, and the Bunsen reaction happened at lower temperatures. [65] S-I Catalysts with hierarchical pore structure and higher specific surface area and micropore proportion of about 50% showed higher catalytic activity. [66] S-I N doping promotes HI decomposition rate [67] HyS Increasing Fe content in Fe/Al and Fe/Ti binary metal oxide catalysts improved catalytic activity [68] HyS Cr, Ce, U, Mn, and Ni form stable sulphates and are not suitable catalysts for sulfuric acid decomposition. t/BaSO4-TiO2, Pt/TiO2, Pt/ZrO2, and Pt/SiO2 are the most suitable catalysts for the HyS cycle. [69] HyS PtxPdy thin film deposited on a Si wafer showed high catalytic activity [70] HyS Increasing Ni dopant in PtxNiy/C catalysts increased electron vacancies and improved catalytic performance [71] HyS Incorporating ceria in Pt/C composite catalyst increased catalyst active area and improved its performance [72] Cu-Cl Developing a novel integrated system for producing nitrogen, methane, ammonia, oxygen, and carbon dioxide [73] Cu-Cl Optimizing the temperature of the hydrolysis step can minimize the number of byproducts. [74] Cu-Cl Cu-Cl is the most promising cycle for large-scale hydrogen production. [75] ZnO/Zn Partially reduced ZnO showed higher catalytic performance at elevated temperatures (R = 57.2%) [76] ZnO/Zn Hindered recombination and lowered the reaction temperature of the first step (methane or carbon as reducing agent) [77] ZnO/Zn A negative axial temperature gradient reduced the steam and inert gas proportion [78][79] SnO2/SnO Reducing O2 partial pressure to about 10−3 bar decreased thermal reduction temperature [80] Fe3O4/FeO Non-stoichiometric wustite have higher defect densities and showed higher reaction rates [81] Ferrite Zirconia support enhances the energy radiation absorption and lowers the temperature [82] Ferrite Ceramics nanoparticles can slightly increase hydrogen yield and hinder grain growth [83] Ferrite ZrO2 can reduce the high-temperature sintering and improve catalytic activity [84] Ferrite Calcium-stabilized zirconia forms calcium zirconate promotes high active phase dispersion and improves hydrogen yield [85] Ferrite Sacrificial (carbon black and PEG) and zirconia plates improved the thermal stability of Ni-ferrite samples [84] Ferrite Core-shell NiFe2O4/Y2O3 nanoparticles showed stable hydrogen volume, but lower rates of hydrogen production than that of mixed powders [83] Ferrite Hercynite formation in alumina and cobalt ferrite decreased ferrite reduction temperature [86]

References

- Fallah Vostakola, M.; Mirkazemi, S.M.; Eftekhari Yekta, B. Structural, morphological, and optical properties of W-doped VO2 thin films prepared by sol-gel spin coating method. Int. J. Appl. Ceram. Technol. 2019, 16, 943–950.

- Nguyen, V.H.; Do, H.H.; Van Nguyen, T.; Singh, P.; Raizada, P.; Sharma, A.; Sana, S.S.; Grace, A.N.; Shokouhimehr, M.; Ahn, S.H.; et al. Perovskite oxide-based photocatalysts for solar-driven hydrogen production: Progress and perspectives. Sol. Energy 2020, 211, 584–599.

- Fallah Vostakola, M.; Amini Horri, B. Progress in Material Development for Low-Temperature Solid Oxide Fuel Cells: A Review. Energies 2021, 14, 1280.

- Dincer, I.; Zamfirescu, C. Potential options to greenize energy systems. Energy 2012, 46, 5–15.

- Choolaei, M.; Bull, T.; Ramirez Reina, T.; Amini Horri, B. Synthesis and characterisation of nanocrystalline CuO–Fe2O3/GDC anode powders for solid oxide fuel cells. Ceram. Int. 2020, 46, 14776–14786.

- Clemente, A.; Costa-Castelló, R. Redox flow batteries: A literature review oriented to automatic control. Energies 2020, 13, 4514.

- Schoden, F.; Dotter, M.; Knefelkamp, D.; Blachowicz, T.; Hellkamp, E.S. Review of State of the Art Recycling Methods in the Context of Dye Sensitized Solar Cells. Energies 2021, 14, 3741.

- Rajpar, A.H.; Ali, I.; Eladwi, A.E.; Bashir, M.B.A. Recent Development in the Design of Wind Deflectors for Vertical Axis Wind Turbine: A Review. Energies 2021, 14, 5140.

- Moska, R.; Labus, K.; Kasza, P. Hydraulic Fracturing in Enhanced Geothermal Systems—Field, Tectonic and Rock Mechanics Conditions—A Review. Energies 2021, 14, 5725.

- Le Saché, E.; Johnson, S.; Pastor-Pérez, L.; Horri, B.A.; Reina, T.R. Biogas upgrading via dry reforming over a Ni-Sn/CeO2-Al2O3 catalyst: Influence of the biogas source. Energies 2019, 12, 1007.

- Price, C.A.H.; Arnold, W.; Pastor-Pérez, L.; Amini-Horri, B.; Reina, T.R. Catalytic Upgrading of a Biogas Model Mixture via Low Temperature DRM Using Multicomponent Catalysts. Top. Catal. 2020, 63, 281–293.

- Rezaei, S.E.; Zebarjadi, M.; Esfarjani, K. Effect of exchange-correlation functional type and spin-orbit coupling on thermoelectric properties of ZrTe2. J. Solid State Chem. 2021, 302, 122414.

- Amini Horri, B.; Choolaei, M.; Chaudhry, A.; Qaalib, H. A highly efficient hydrogen generation electrolysis system using alkaline zinc hydroxide solution. Int. J. Hydrogen Energy 2019, 44, 72–81.

- Rafique, M.; Mubashar, R.; Irshad, M.; Gillani, S.S.A.; Tahir, M.B.; Khalid, N.R.; Yasmin, A.; Shehzad, M.A. A Comprehensive Study on Methods and Materials for Photocatalytic Water Splitting and Hydrogen Production as a Renewable Energy Resource. J. Inorg. Organomet. Polym. Mater. 2020, 30, 3837–3861.

- Hooshyari, K.; Amini Horri, B.; Abdoli, H.; Fallah Vostakola, M.; Kakavand, P.; Salarizadeh, P. A Review of Recent Developments and Advanced Applications of High-Temperature Polymer Electrolyte Membranes for PEM Fuel Cells. Energies 2021, 14, 5440.

- Acar, C.; Dincer, I.; Naterer, G.F. Review of photocatalytic water-splitting methods for sustainable hydrogen production. Int. J. Energy Res. 2016, 40, 1449–1473.

- Dincer, I.; Acar, C. Review and evaluation of hydrogen production methods for better sustainability. Int. J. Hydrogen Energy 2015, 40, 11094–11111.

- Brau, J.-F.; Morandin, M.; Berntsson, T. Hydrogen for oil refining via biomass indirect steam gasification: Energy and environmental targets. Clean Technol. Environ. Policy 2013, 15, 501–512.

- Brau, J.F.; Morandin, M. Biomass-based hydrogen for oil refining: Integration and performances of two gasification concepts. Int. J. Hydrogen Energy 2014, 39, 2531–2542.

- Liu, W.; Zuo, H.; Wang, J.; Xue, Q.; Ren, B.; Yang, F. The production and application of hydrogen in steel industry. Int. J. Hydrogen Energy 2021, 46, 10548–10569.

- Dodds, P.E.; Staffell, I.; Hawkes, A.D.; Li, F.; Grünewald, P.; McDowall, W.; Ekins, P. Hydrogen and fuel cell technologies for heating: A review. Int. J. Hydrogen Energy 2015, 40, 2065–2083.

- Felseghi, R.A.; Carcadea, E.; Raboaca, M.S.; Trufin, C.N.; Filote, C. Hydrogen fuel cell technology for the sustainable future of stationary applications. Energies 2019, 12, 4593.

- Bellosta von Colbe, J.; Ares, J.R.; Barale, J.; Baricco, M.; Buckley, C.; Capurso, G.; Gallandat, N.; Grant, D.M.; Guzik, M.N.; Jacob, I.; et al. Application of hydrides in hydrogen storage and compression: Achievements, outlook and perspectives. Int. J. Hydrogen Energy 2019, 44, 7780–7808.

- Cernat, A.; Pana, C.; Negurescu, N.; Lazaroiu, G.; Nutu, C.; Fuiorescu, D. Hydrogen—An alternative fuel for automotive diesel engines used in transportation. Sustainability 2020, 12, 9321.

- Renau, J.; García, V.; Domenech, L.; Verdejo, P.; Real, A.; Giménez, A.; Sánchez, F.; Lozano, A.; Barreras, F. Novel use of green hydrogen fuel cell-based combined heat and power systems to reduce primary energy intake and greenhouse emissions in the building sector. Sustainability 2021, 13, 1776.

- Parra, D.; Valverde, L.; Pino, F.J.; Patel, M.K. A review on the role, cost and value of hydrogen energy systems for deep decarbonisation. Renew. Sustain. Energy Rev. 2019, 101, 279–294.

- Muradov, N.Z.; Veziroǧlu, T.N. From hydrocarbon to hydrogen-carbon to hydrogen economy. Int. J. Hydrogen Energy 2005, 30, 225–237.

- Tang, J.; Liu, T.; Miao, S.; Cho, Y. Emerging energy harvesting technology for electro/photo-catalytic water splitting application. Catalysts 2021, 11, 142.

- Yilanci, A.; Dincer, I.; Ozturk, H.K. A review on solar-hydrogen/fuel cell hybrid energy systems for stationary applications. Prog. Energy Combust. Sci. 2009, 35, 231–244.

- Quarton, C.J.; Tlili, O.; Welder, L.; Mansilla, C.; Blanco, H.; Heinrichs, H.; Leaver, J.; Samsatli, N.J.; Lucchese, P.; Robinius, M.; et al. The curious case of the conflicting roles of hydrogen in global energy scenarios. Sustain. Energy Fuels 2019, 4, 80–95.

- Minh, D.P.; Siang, T.J.; Vo, D.V.N.; Phan, T.S.; Ridart, C.; Nzihou, A.; Grouset, D. Hydrogen production from biogas reforming: An overview of steam reforming, dry reforming, dual reforming, and tri-reforming of methane. In Hydrogen Supply Chain: Design, Deployment and Operation; Azzaro-Pantel, C., Ed.; Academic Press: Cambridge, MA, USA, 2018; pp. 111–166. ISBN 9780128111970.

- Howarth, R.W.; Jacobson, M.Z. How green is blue hydrogen? Energy Sci. Eng. 2021, 9, 1676–1687.

- Evers, A.A. A Proposal To Future Energy Supplies: Your Personal Power Provider (3P+) Virtual Power Plants with Direct Solar Hydrogen and Fuel Cells. I ECS Trans. 2009, 17, 691–696.

- Luo, M.; Yi, Y.; Wang, S.; Wang, Z.; Du, M.; Pan, J.; Wang, Q. Review of hydrogen production using chemical-looping technology. Renew. Sustain. Energy Rev. 2018, 81, 3186–3214.

- Wang, Z.; Fan, W.; Zhang, G.; Dong, S. Exergy analysis of methane cracking thermally coupled with chemical looping combustion for hydrogen production. Appl. Energy 2016, 168, 1–12.

- Yang, W.; Moon, J. Recent Advances in Earth-Abundant Photocathodes for Photoelectrochemical Water Splitting. ChemSusChem 2019, 12, 1889–1899.

- Wang, T. An overview of IGCC systems. In Integrated Gasification Combined Cycle (IGCC) Technologies; Wang, T., Stiegel, G., Eds.; Elsevier Ltd.: New Orleans, LA, USA, 2017; pp. 1–80. ISBN 9780081001851.

- Full, J.; Merseburg, S.; Miehe, R.; Sauer, A. A new perspective for climate change mitigation— introducing carbon-negative hydrogen production from biomass with carbon capture and storage (Hybeccs). Sustainability 2021, 13, 4026.

- Tyagi, D.; Shirsat, A.N.; Varma, S. Carbon derived from rice: Application as a support for platinum catalysts for hydrogen generation by HI decomposition. Bull. Mater. Sci. 2021, 44, 172.

- Martino, M.; Ruocco, C.; Meloni, E.; Pullumbi, P.; Palma, V. Main hydrogen production processes: An overview. Catalysts 2021, 11, 547.

- Juárez-Martínez, L.C.; Espinosa-Paredes, G.; Vázquez-Rodríguez, A.; Romero-Paredes, H. Energy optimization of a Sulfur–Iodine thermochemical nuclear hydrogen production cycle. Nucl. Eng. Technol. 2021, 53, 2066–2073.

- Lassouane, F.; Menia, S.; Khellaf, A. An overview of the hybrid sulfur cycle process for solar hydrogen production. In Proceedings of the 3rd International Symposium on Environment Friendly Energies and Applications, EFEA 2014; IEEE: Paris, France, 2014; pp. 1–6.

- Vagia, E.C.; Muradov, N.; Kalyva, A.; T-Raissi, A.; Qin, N.; Srinivasa, A.R.; Kakosimos, K.E. Solar hybrid photo-thermochemical sulfur-ammonia water-splitting cycle: Photocatalytic hydrogen production stage. Int. J. Hydrogen Energy 2017, 42, 20608–20624.

- Dincer, I.; Zamfirescu, C. Other Hydrogen Production Methods. In Sustainable Hydrogen Production; Elsevier Inc.: Amsterdam, The Netherlands, 2016; pp. 411–439. ISBN 9780128015636.

- Acar, C.; Dincer, I. Hydrogen Production. In Comprehensive Energy Systems; Elsevier: Amsterdam, The Netherlands, 2018; Volume 3, pp. 1–40. ISBN 9780128095973.

- Abanades, S. Metal Oxides Applied to Thermochemical Water-Splitting for Hydrogen Production Using Concentrated Solar Energy. ChemEngineering 2019, 3, 63.

- Steinfeld, A. Solar thermochemical production of hydrogen℄A review. Sol. Energy 2005, 78, 603–615.

- Perkins, C.; Weimer, A.W. Solar-Thermal Production of Renewable Hydrogen. AIChE J. 2009, 55, 286–293.

- Ying, Z.; Yang, J.; Zheng, X.; Wang, Y.; Dou, B. Energy and exergy analyses of a novel sulfur–iodine cycle assembled with HI–I2–H2O electrolysis for hydrogen production. Int. J. Hydrogen Energy 2021, 46, 23139–23148.

- Ishaq, H.; Dincer, I. A comparative evaluation of three Cu-Cl cycles for hydrogen production. Int. J. Hydrogen Energy 2019, 44, 7958–7968.

- Murmura, M.A.; Vilardi, G. Energy and exergy analysis of the zinc/zinc oxide thermochemical cycle for hydrogen production and fuel cell power generation. Energy Convers. Manag. 2021, 247, 114761.

- Haltiwanger, J.F.; Davidson, J.H.; Wilson, E.J. Renewable hydrogen from the Zn/ZnO solar thermochemical cycle: A cost and policy analysis. J. Sol. Energy Eng. Trans. ASME 2010, 132, 041011.

- Wang, Y.; Sharma, A.; Duong, T.; Arandiyan, H.; Zhao, T.; Zhang, D.; Su, Z.; Garbrecht, M.; Beck, F.J.; Karuturi, S.; et al. Direct Solar Hydrogen Generation at 20% Efficiency Using Low-Cost Materials. Adv. Energy Mater. 2021, 11, 2101053.

- Jia, J.; Seitz, L.C.; Benck, J.D.; Huo, Y.; Chen, Y.; Ng, J.W.D.; Bilir, T.; Harris, J.S.; Jaramillo, T.F. Solar water splitting by photovoltaic-electrolysis with a solar-to-hydrogen efficiency over 30%. Nat. Commun. 2016, 7, 13237.

- Gorensek, M.; Summers, W.; Boltrunis, C.; Lahoda, E.; Allen, D.; Greyvenstein, R. Hybrid Sulfur Process Reference Design and Cost Analysis; Report No. SRNL-L1200-2008-00002; Savannah River National Laboratory: Jackson, SC, USA, 2009.

- Corgnale, C.; Summers, W.A. Solar hydrogen production by the Hybrid Sulfur process. Int. J. Hydrogen Energy 2011, 36, 11604–11619.

- Kromer, M.; Roth, K.; Takata, R.; Chin, P. Support for Cost Analyses on Solar-Driven High Temperature Thermochemical Water-Splitting Cycles; Final Report to Department of Energy, Order DE-DT0000951; TIAX LLC: Lexington, MA, USA, 2011.

- U.S. Department of Energy HydroGEN Program.

- Roeb, M.; Monnerie, N.; Houaijia, A.; Thomey, D.; Sattler, C. Solar Thermal Water Splitting. In Renewable Hydrogen Technologies: Production, Purification, Storage, Applications and Safety; Elsevier: Amsterdam, The Netherlands, 2013; pp. 63–86. ISBN 9780444563521.

- Leybros, J.; Gilardi, T.; Saturnin, A.; Mansilla, C.; Carles, P. Plant sizing and evaluation of hydrogen production costs from advanced processes coupled to a nuclear heat source. Part I: Sulphur-iodine cycle. Int. J. Hydrogen Energy 2010, 35, 1008–1018.

- Le Duigou, A.; Borgard, J.M.; Larousse, B.; Doizi, D.; Allen, R.; Ewan, B.C.; Priestman, G.H.; Elder, R.; Devonshire, R.; Ramos, V.; et al. HYTHEC: An EC funded search for a long term massive hydrogen production route using solar and nuclear technologies. Int. J. Hydrogen Energy 2007, 32, 1516–1529.

- D’Souza, L. Thermochemical hydrogen production from water using reducible oxide materials: A critical review. Mater. Renew. Sustain. Energy 2013, 2, 7.

- Zhu, Q.; Zhang, Y.; Zhou, C.; Wang, Z.; Zhou, J.; Cen, K. Optimization of liquid-liquid phase separation characteristics in the Bunsen section of the sulfur-iodine hydrogen production process. Int. J. Hydrogen Energy 2012, 37, 6407–6414.

- Yu, X.; Meng, L.; Nagasawa, H.; Kanezashi, M.; Machida, M.; Tsuru, T. Evaluating the chemical stability of metal oxides in SO3 and applications of SiO2-based membranes to O2/SO3 separation. J. Am. Ceram. Soc. 2019, 102, 6946–6956.

- Park, J.K.; Ifaei, P.; Ba-Alawi, A.H.; Safder, U.; Yoo, C.K. Hydrogen production through the sulfur–iodine cycle using a steam boiler heat source for risk and techno-socio-economic cost (RSTEC) reduction. Int. J. Hydrogen Energy 2020, 45, 14578–14593.

- Rong, S.; Zhang, R.; Zhu, X.; Zhang, M.; Li, J.; Zhang, L. Exploring the relationship between the physical properties of activated carbon catalysts and their efficiency in catalyzing hydrogen iodide decomposition to produce hydrogen. Int. J. Hydrogen Energy 2021, 46, 18207–18223.

- Li, X.; Zhang, R.; Zhu, X.; Zhang, L. Effect of N-doping on the catalytic decomposition of hydrogen iodide over activated carbon: Experimental and DFT studies. Int. J. Hydrogen Energy 2020, 45, 4511–4520.

- Kim, T.H.; Gong, G.T.; Lee, B.G.; Lee, K.Y.; Jeon, H.Y.; Shin, C.H.; Kim, H.; Jung, K.D. Catalytic decomposition of sulfur trioxide on the binary metal oxide catalysts of Fe/Al and Fe/Ti. Appl. Catal. A Gen. 2006, 305, 39–45.

- Corgnale, C.; Gorensek, M.B.; Summers, W.A. Review of sulfuric acid decomposition processes for sulfur-based thermochemical hydrogen production cycles. Processes 2020, 8, 1383.

- Falch, A.; Lates, V.; Kriek, R.J. Combinatorial Plasma Sputtering of PtxPdy Thin Film Electrocatalysts for Aqueous SO2 Electro-oxidation. Electrocatalysis 2015, 6, 322–330.

- Zhang, S.; Huang, B.; He, Y.; Zhu, Y.; Zhang, Y.; Wang, Z. Demetallized PtxNiy/C catalyst for SO2 electrochemical oxidation in the SI/HyS hydrogen production cycles. Int. J. Hydrogen Energy 2021, 46, 10161–10171.

- Xu, F.; Cheng, K.; Yu, Y.; Mu, S. One-pot synthesis of Pt/CeO2/C catalyst for enhancing the SO2 electrooxidation. Electrochim. Acta 2017, 229, 253–260.

- Izanloo, M.; Mehrpooya, M. Investigation of a hybrid thermochemical Cu–Cl cycle, carbon capturing, and ammonia production process. J. Therm. Anal. Calorim. 2021, 144, 1907–1923.

- Farsi, A.; Dincer, I.; Naterer, G.F. Review and evaluation of clean hydrogen production by the copper–chlorine thermochemical cycle. J. Clean. Prod. 2020, 276, 123833.

- Safari, F.; Dincer, I. A review and comparative evaluation of thermochemical water splitting cycles for hydrogen production. Energy Convers. Manag. 2020, 205, 112182.

- Bhosale, R.R. Solar hydrogen production via ZnO/Zn based thermochemical water splitting cycle: Effect of partial reduction of ZnO. Int. J. Hydrogen Energy 2021, 46, 4739–4748.

- Wieckert, C.; Steinfeld, A. Solar thermal reduction of ZnO using CH4:ZnO and C:ZnO molar ratios less than 1. J. Sol. Energy Eng. Trans. ASME 2002, 124, 55–62.

- Lindemer, M.D.; Advani, S.G.; Prasad, A.K. Experimental investigation of heterogeneous hydrolysis with Zn vapor under a temperature gradient. Int. J. Hydrogen Energy 2017, 42, 7847–7856.

- Lindemer, M.D.; Advani, S.G.; Prasad, A.K. Hydrogen production via the heterogeneous hydrolysis of Zn vapor under a temperature gradient: Modeling and efficiency analysis. Int. J. Hydrogen Energy 2016, 41, 10557–10567.

- Bhosale, R.R.; Kumar, A.; Sutar, P. Thermodynamic analysis of solar driven SnO2/SnO based thermochemical water splitting cycle. Energy Convers. Manag. 2017, 135, 226–235.

- Charvin, P.; Abanades, S.; Flamant, G.; Lemort, F. Two-step water splitting thermochemical cycle based on iron oxide redox pair for solar hydrogen production. Energy 2007, 32, 1124–1133.

- Marugán, J.; Botas, J.A.; Martín, M.; Molina, R.; Herradón, C. Study of the first step of the Mn2O3/MnO thermochemical cycle for solar hydrogen production. Int. J. Hydrogen Energy 2012, 37, 7017–7025.

- Amar, V.S.; Puszynski, J.A.; Shende, R.V. H2 generation from thermochemical water-splitting using yttria stabilized NiFe2O4 core-shell nanoparticles. J. Renew. Sustain. Energy 2015, 7, 023113.

- Teknetzi, I.; Nessi, P.; Zaspalis, V.; Nalbandian, L. Ni-ferrite with structural stability for solar thermochemical H2O/CO2 splitting. Int. J. Hydrogen Energy 2017, 42, 26231–26242.

- Reñones, P.; Alvarez-Galvan, M.C.; Ruiz-Matas, L.; Retuerto, M.; Navarro, R.M.; Fierro, J.L.G. Nickel ferrite supported on calcium-stabilized zirconia for solar hydrogen production by two-step thermochemical water splitting. Mater. Today Energy 2017, 6, 248–254.

- Scheffe, J.R.; Li, J.; Weimer, A.W. A spinel ferrite/hercynite water-splitting redox cycle. Int. J. Hydrogen Energy 2010, 35, 3333–3340.