| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Denesh Mohan | + 2293 word(s) | 2293 | 2020-08-26 10:31:52 | | | |

| 2 | Denesh Mohan | Meta information modification | 2293 | 2020-09-01 14:30:18 | | | | |

| 3 | Denesh Mohan | Meta information modification | 2293 | 2020-09-02 01:54:30 | | | | |

| 4 | Denesh Mohan | + 1 word(s) | 2294 | 2020-09-02 02:13:40 | | | | |

| 5 | Catherine Yang | Meta information modification | 2293 | 2020-09-02 03:04:29 | | |

Video Upload Options

The materials for additive manufacturing (AM) technology have grown substantially over the last few years to fulfill industrial needs. Despite that, the use of bio-based composites for improved mechanical properties and biodegradation is still not fully explored. This limits the universal expansion of AM-fabricated products due to the incompatibility of the products made from petroleum-derived resources. The development of naturally-derived polymers for AM materials is promising with the increasing number of studies in recent years owing to their biodegradation and biocompatibility. Cellulose is the most abundant biopolymer that possesses many favorable properties to be incorporated into AM materials, which have been continuously focused on in recent years. This critical review discusses the development of AM technologies and materials, cellulose-based polymers, cellulose-based three-dimensional (3D) printing filaments, liquid deposition modeling of cellulose, and four-dimensional (4D) printing of cellulose-based materials. Cellulose-based AM material applications and the limitations with future developments are also reviewed.

1. Introduction

The world population increases by 227,400 people a day, and this situation increases the burden on the earth as the world population is expected to reach 10.74 billion by 2100, which can be extremely detrimental from an environmental perspective[1]. Due to the increase in population, intense research has been done to cope with the manufacturing demands; consequently, unsustainable production from non-renewable resources resulted in significant global pollution and climate changes. Only 10% of plastics are recycled, 60% is dumped in landfills, and 30% are unaccounted for, which can be discarded in any part of the environment, thus resulting in environmental issues [2]. By 2050, the plastic industry may need 20% of the crude oil supply to accommodate plastic production if the trend remains unchanged [3]. The decrease in fossil fuel resources and the increase in plastic consumption drive the search for alternative resources and technologies for more sustainable and environmentally friendly plastic production. Sustainable plastic materials should be produced from renewable resources without damaging the environment, easily recycled, and biodegradable under certain environmental conditions with low energy consumption. Cellulose as a sustainable material is known to be the most abundantly available component of biomass that covers up to 50 wt. % of lignocellulosic biomass [4]. Various types of cellulose can be used to synthesize nanocellulose from the cellulose, such as cellulose nanofibrils (CNF), cellulose nanocrystals (CNC), and bacterial nanocellulose (BNC). These nanocellulose products vary in terms of properties, morphology, and crystallinity, depending on the extraction method and biomass used [5][6]. The utilization of cellulose fiber as the feedstock for injection molding has now expanded to AM, which is among the coveted industries in the world.

AM is the process of manufacturing materials layer by layer to fabricate precise three-dimensional (3D) models using data from computer-aided design (CAD) software [7]. AM has expanded to various industries, including metal, ceramic, and medical applications, and the current focus of this technique is bioprinting cardiovascular application, which involves 3D-printed heart valves [8][9][10]. Therefore, many naturally derived polymers are used in current studies for the preparation of scaffolds by 3D printing due to the large potential in biomedical applications, particularly the replacement and regeneration of cells, tissues, or organs. AM of cellulose-based materials is a promising option due to the renewable source and low cost of extraction with lower environmental degradation.

2. Polymer-Based Additive Manufacturing

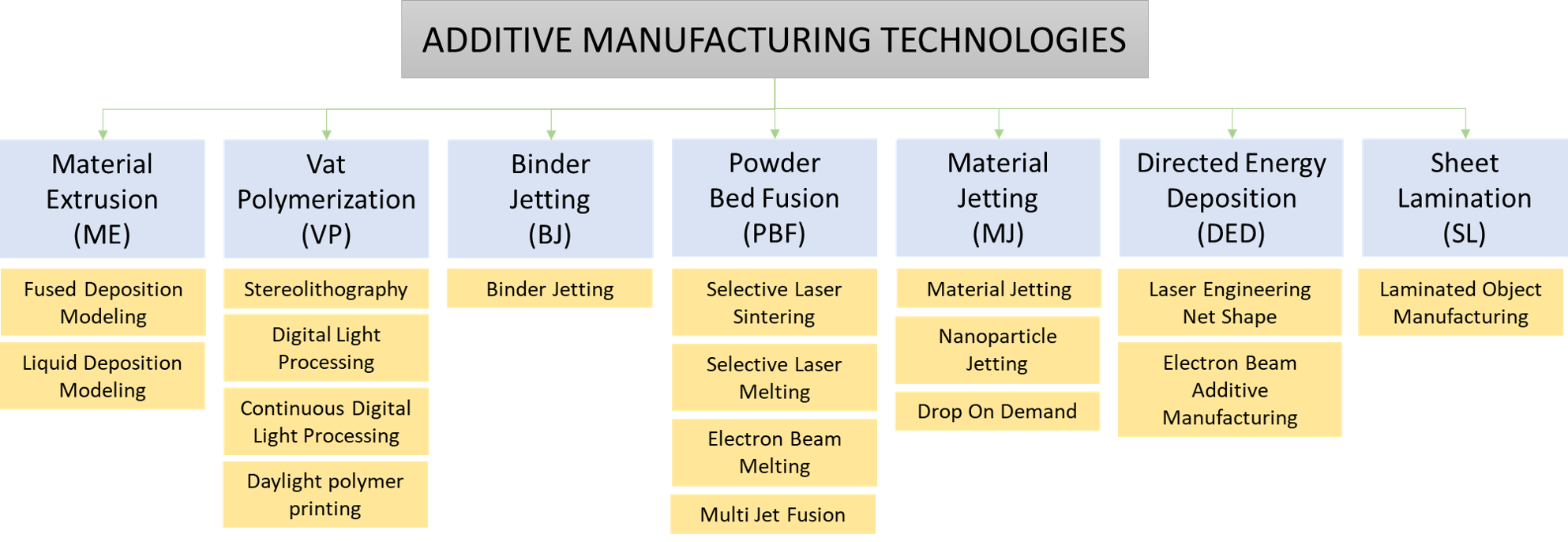

AM technologies are the essential part of the whole 3D printing, bridging the 3D models, materials, and final applications based on the products needed by the industry. Originally, 3D printers were used to produce one or two fast prototype models to help developers fix faults and change the product as a fast prototyping solution. Different technologies have been developed by varying the technique of printing product on the build platform and the materials used for printing. By referring to ASTM Standard F2792, the American Society for Testing and Materials (ASTM) has documented 3D printing technologies into seven categories, namely material extrusion, powder bed fusion, vat photopolymerization, direct energy deposition, binder jetting, material jetting, and sheet lamination, as shown in Figure 1. [11]

Polymer shows a major contribution in AM, whereby parts produced from the polymer are recorded with 51% contribution, 29% metal and polymer, and 19.8% is metal product [12]. Among the many available AM techniques producing 3D-printed polymers, Fused Deposition Modeling (FDM) is mainly used for fabrication. Due to the feasibility of this technology, it has been used as part of educational kits, prototypes, visual aids, and presentation models. However, due to the lack of technical skills and quality of the 3D printer, the end-user tends to produce massive waste from supportive material, failed products, and broken plastic parts. Thus, modifications are needed to be done to have a biodegradable based polymer in 3D printing industry to enhance the properties and reducing the burden on fossil fuel industry. Table 1 shows the recent study done to incorporate different types of fillers in commercial 3D printing polylactic acid (PLA) FDM filament.

Table 1: The modification approaches on the biodegradable of PLA

|

Filler |

Filler Fraction (%) |

Composite Tensile Strength (MPa) |

Difference (%) |

Ref |

|

Modified carbon fiber |

34 |

91.0 |

+225.0 |

[13] |

|

Carbon fiber |

28 |

61.4 |

+36.8 |

[14] |

|

Graphene nanoplatelets |

10 |

40.2 |

+27.2 |

[15] |

|

Rice husk |

20 |

53.0 |

+18.3 |

[16] |

|

Ceramics |

40 |

43.2 |

+1.9 |

[17] |

3. Cellulose-Based Polymers in 3D Printing Technology

The main principles of both green chemistry and green engineering is focusing on the prevention of new generation waste. The prevention can be started in this new emerging technology by introducing sustainable and biodegradable materials in 3D printing applications. As early as possible, the polymer-based material used in the AM should pursue cradle to cradle design. On top of mechanical properties, the capability of cellulose-based polymer as bio-filler and hydrogel matrix will be a key to developing sustainable additive manufacturing

3.1 Fused Deposition Modeling Filament

Cellulose particles in micro/nano size can be incorporated in 3D printing filaments to increase the mechanical properties of the printed products. This is due to the properties of cellulose, especially nanocellulose that possesses high surface area, high mechanical properties, and shear-thinning properties, thus making cellulose suitable for many applications. Table 2 reviews the typical reinforcement of cellulosic materials in commercial thermoplastic filaments for the FDM printing technique.

Table 2. Recent findings on the cellulose composited in thermoplastic filament for FDM extrusion.

|

Polymer/ Cellulose Composition (wt%) |

Extrusion Technique |

FDM Printer |

Nozzle Temp. (°C) |

Nozzle Diameter (mm) |

Improvements. |

Ref. |

|

73.5% PLA, 24.5% PHB, 1% CNC, 1% dicumyl peroxide

|

Twin-screw |

WASP Delta 2040 Turbo 2 |

200 |

0.4 |

Mechanical properties and thermal stability |

[18] |

|

93% PLA, 7% Hydroxypropyl methylcellulose

|

Single-screw |

Ender-3S |

200 |

0.4 |

Thermal properties and contact angle |

[19] |

|

70% PLA, 25% recycled PLA, 5% MCC, 0.5 phr epoxy-based chain extender

|

Twin-screw |

LulzBot TAZ 6 |

200 |

0.5 |

Tensile strength, modulus and Izod impact strength |

[20]

|

|

95% ABS, 5% CNC/Silica nanohybdrids |

Twin-screw |

S1 Architect 3D |

235 |

0.3 |

Reduced warping, tensile strength, and layer adhesion |

[21]] |

|

90% Polycaprolactone, (PCL), 10% MCC

|

Single-screw |

Prusa i3 |

210 |

0.4 |

Mechanical strength and cell proliferation |

[22] |

3.2 Vat Photopolymerization

Apart from FDM, VP has also been extensively improved through the development of liquid photopolymer resin due to the accuracy of the printed product, even though the method is comparatively longer than the extrusion technique. Research on the incorporation of fillers in resin is increasing in recent years, and one of the main approaches is cellulose-based fillers. The purpose of the incorporation is to improve the mechanical properties and thermal stability of the printed product. The compilation of the recent activity on the addition of cellulose-based polymer in photopolymeric resins is simplified in Table 3.

Table 3. The compatibility of cellulose-based biopolymer as a filler in photopolymeric resins.

|

Cellulose Composition |

3D Printer |

Printing Parameter |

Solidification Method |

Potential Application |

Ref. |

|

Polyurethane aryclate, CNF-rGO, CNF-PEG |

Wanhao Duplicator D7 Plus |

UV light of wavelength 405 nm |

UV curing |

Bio based resin |

[23] |

|

Polymethyl methacrylate (PMMA), CNC-Silver Nanoparticles (CNC-AgNPs) |

Envision TEC |

Layer thickness 100 μm, 4.4 s exposure time, UV intensity 2500 μm/cm2 |

UV curing |

Dental restoration material |

[24] |

|

CNC, methacrylate resin |

Form 1+ |

N/A |

Photocuring and heating |

Electronic, engineering and tissue engineering |

[25] |

|

Ethyl cellulose macromonomerm resin-based monomer |

Creality, LD 001, |

N/A |

Photocuring |

Flexible electronic materials |

[26] |

|

CNC, PEGDA, 1,3-diglycerolate diacrylate (DiGlyDA) |

DLP 3D printer |

Layer thickness 100 μm, 4.0 s exposure time, UV intensity 18 mW/cm2 |

UV curing |

Biomedical application |

[27] |

3.3 Liquid Deposition Modeling

As cellulose solution has the shear-thinning property, the solution can be readily used for ME printing technique, which is usually known as direct ink writing for liquid deposition modeling (LDM). The product printed with liquid cellulose should retain the shape after printing; thus, viscosity is essential, which is directly related to the concentration of cellulose and the shear rate applied. High mechanical strength of the printed part is vital to maintain the printed shape; therefore, increasing the concentration of cellulose can improve strength and reduce shrinkage, which consequently reduces the accuracy and smoothness of the printed part. Table 4 reviews the studies done on liquid deposition of cellulose-based materials using various printing techniques and materials.

Table 4. Review of cellulose matrix as 3D printing hydrogel using LDM technique.

|

Cellulose Composition |

3D Printer |

Printing Parameter |

Solidification Method |

Potential Application |

Ref. |

|

Dialdehyde CNC, gelatin |

Bio-Architect |

Nozzle 0.21 mm, Extrusion pressure 100–250 kPa, Print speed 10–40 mm/s

|

Crosslinking with Ca2+ |

Tissue engineering |

[28] |

|

CNF, Alginate |

Regemat3D Designer |

Nozzle 0.58 mm, Flow speed 3.0 mm/s

|

Crosslinking with CaCl2 |

Tissue engineering |

[29] |

|

Bacterial CNF, silk fibroin (SF)/gelatin composite |

3D Bioplotter |

Nozzle 0.41 mm, Extrusion pressure 1–2 bar, Print speed 3.0

|

Crosslinking with genipin |

Biomedical applications |

[30] |

|

CNF, |

3D bioprinter, RegenHU, Switzerland |

Nozzle 0.42 mm, print speed 40 mm/s, layer height 0.4 mm

|

Crosslinking with H2O2 |

Clothes, packaging, health care products, furniture |

[31] |

|

CNF, CMC |

Bioscaffolder 3.1 |

Nozzle 0.25 mm, Extrusion pressure 260 kPa, print speed 15 mm/s

|

Crosslinking with dehyrothermal treatment (DHT) |

Bone tissue engineering |

[32] |

4. Cellulose-Based Polymers in 3D Printing Technology

The merging of 3D printing technology and cellulose-based smart materials will be able to fabricate 4D-printed cellulose-based materials that can change shape over external stimuli. Many types of cellulose that are responsive to various stimuli reviewed in the previous section are suitable for the production of 4D cellulose materials. As cellulose possesses many useful properties such as biocompatibility, biodegradability, high mechanical properties, and thermal stability, the material will be a driving factor for the fabrication of cellulose-based 4D materials for applications in tissue engineering and medical applications. Table 5 reviews the studies done on 4D-printed cellulose-based materials using LDM technique.

Table 5. Review of 4D printed cellulose based materials using LDM technique.

|

Cellulose Composition |

3D Printer |

Printing Parameter |

Solidification Method |

Stimulus |

Potential Application |

Ref. |

|

CNF, clay, N-isopropylacrylamide

|

ABG 10000, Aerotech |

Nozzle 0.15–1.5 mm |

UV Curing |

Water |

Tissue engineering and soft robotics applications |

[33] |

|

CMC, cellulose fibers, HEC, clay |

Prusa MK2 |

Nozzle 0.8 mm, layer height 0.6 mm |

Crosslinked with citric acid |

Water |

Tissue engineering applications |

[34]

|

|

|

|

|

|

|

|

|

|

HEC, MFC, citric acid/hydrochloric acid, lignin |

Modified TEVO Tarantula i3 |

Nozzle 0.55–4 mm |

Crosslinking using citric acid/hydrochloric acid |

Water |

Biomedical application |

[35]

|

|

MFC, PVA |

3D Bioplotter, EnvisionTEC |

Extrusion pressure 5.0 bar, print speed xy 400 mm/min, print speed Z 350 mm/min, layer thickness 0.67 mm |

Crosslink using glyoxal solution |

Heat and Water |

Tissue engineering applications |

[36] |

|

N-isopropylacrylamide, CMC, sodium alginate, acrylamide |

Custom built printer |

Extrusion flow rate 1.0 μL/s, print speed 1.0 mm/s |

Irradiation with UV light, then soaked in water |

Heat |

Environmental monitoring and medical applications |

[37] |

5. Summary, Conclusions, and Future Trends

AM is a growing industry, and continuous research is being done to improve the technology and materials available. The development of materials with composites enables the fabrication of products with better mechanical properties, which can be fine-tuned according to the demand. AM enables the fabrication of customized products according to customer’s design requirement and offers design flexibilities. AM plays a vital role in reducing the burden of traditional manufacturing processes in the fabrication of prototypes and testing the properties of the printed products.

Currently, more sustainable materials are preferred; as most of the AM materials are made from non-renewable resources, naturally-derived materials are adapted, and new studies are being done to improve interfacial adhesion and voidance for the application in various fields. Some applications such as wound healing or drug delivery cannot adapt AM until natural polymers are adopted as they are biocompatible. The proof of concept and in vivo studies are being continuously done in order to use natural-based materials for AM so that the applications can be broadened, where the materials will be the future trend of material development.

Cellulose, which is mainly derived from lignocellulosic biomass, possesses various useful properties; hence, more studies should be done to incorporate cellulose in AM. The potential of cellulose materials in AM is yet to be fully tapped, even though major developments can be seen in recent years with studies being conducted for various applications. Surface grafting of cellulose can nullify the hydrophilicity of cellulose, and hence voidance and interfacial adhesion can be improved. Further research should be carried out continuously to improve the mechanical properties so that AM-fabricated products will have better mechanical properties than traditionally-manufactured products. The increment of cellulose percentage in 3D printing filaments is also essential to improve the biodegradability of filaments and reduce the burden on petroleum resources, as well as to protect the environment as petroleum-based materials emit unpleasant odors.

Liquid deposition modeling of cellulose materials should also be further studied as the rheological properties of cellulose and cellulose derivatives favor the extrusion process. A high concentration of cellulose should be incorporated due to its high mechanical properties, and the structure of the printed part can be maintained after printing. Studies have shown that in vivo 3D-printed BC was able to cure diabetic wounds within four months, and many more studies should be done to present further proof. Cellulose materials can be synthesized with the desired properties according to the needs of applications and incorporated in AM for various types of applications with the developing technology.

4D printing of bio-based materials is a newer technology compared to other AM-based technologies. Cellulose-based 4D printing materials are majorly developed based on water and heat stimuli. Further studies should be done on other stimulus-responsive cellulose-based materials for 4D printing, as vast cellulose smart materials are available and developed continuously. The development of cellulose-based 4D printing will contribute majorly in tissue engineering and drug delivery application, which can also change the prospect of the healthcare industry in the treatment of patients by using AM technologies.

References

- Wadley,D. The City of Grace: An Urban Manifesto; Springer Nature Singapore Pte Ltd.: Gateway East, Singapore, 2020; pp. 1-12.

- Ha Thi Hoang Nguyen; PengXu Qi; Mayra Rostagno; Amr Feteha; Stephen A. Miller; The quest for high glass transition temperature bioplastics. J. Mater. Chem. A 2018, 6, 9298-9331, 10.1039/c8ta00377g.

- Neufeld, L.; Stassen, F.; Sheppard, R.; Gilman, T.. The New Plastics Economy: Rethinking the Future of Plastics; World Economic Forum: Cologne, Switzerland, 2016; pp. 13.

- Mohd Fahmi Awalludin; Othman Sulaiman; Rokiah Hashim; Wan Noor Aidawati Wan Nadhari; An overview of the oil palm industry in Malaysia and its waste utilization through thermochemical conversion, specifically via liquefaction. Renewable and Sustainable Energy Reviews 2015, 50, 1469-1484, 10.1016/j.rser.2015.05.085.

- Hernán Charreau; Ema Cavallo; María Laura Foresti; Patents involving nanocellulose: Analysis of their evolution since 2010. Carbohydrate Polymers 2020, 237, 116039, 10.1016/j.carbpol.2020.116039.

- Shweta Mishra; Prashant S. Kharkar; Anil M. Pethe; Biomass and waste materials as potential sources of nanocrystalline cellulose: Comparative review of preparation methods (2016 – Till date). Carbohydrate Polymers 2019, 207, 418-427, 10.1016/j.carbpol.2018.12.004.

- Pedram Parandoush; Ng Lin; A review on additive manufacturing of polymer-fiber composites. Composite Structures 2017, 182, 36-53, 10.1016/j.compstruct.2017.08.088.

- Zhangwei Chen; Ziyong Li; Junjie Li; Chengbo Liu; Changshi Lao; Yuelong Fu; Changyong Liu; Yang Li; P. Wang; Yi He; et al.He YiFu Yuelong 3D printing of ceramics: A review. Journal of the European Ceramic Society 2019, 39, 661-687, 10.1016/j.jeurceramsoc.2018.11.013.

- Claas Willem Visser; Ralph Pohl; Chao Sun; Gert-Willem Römer; Bert Huis In ‘T Veld; Detlef Lohse; 3D Printing: Toward 3D Printing of Pure Metals by Laser-Induced Forward Transfer (Adv. Mater. 27/2015). Advanced Materials 2015, 27, 4103-4103, 10.1002/adma.201570183.

- Jain, A.; Mathur, T.; Pandian, N.K.R.; Selahi, A. . Organ-on-a-chip and 3D printing as preclinical models for medical research and practice; Elsevier Ltd: Duxford, UK, 2020, 2020; pp. 83-95.

- Additive Manufacturing Technologies: An Overview . 3Dhubs. Retrieved 2020-9-1

- John Ryan C. Dizon; Alejandro H. Espera Jr.; Qiyi Chen; Rigoberto C. Advincula; Mechanical characterization of 3D-printed polymers. Additive Manufacturing 2018, 20, 44-67, 10.1016/j.addma.2017.12.002.

- Nanya Li; Yingguang Li; Shuting Liu; Rapid prototyping of continuous carbon fiber reinforced polylactic acid composites by 3D printing. Journal of Materials Processing Technology 2016, 238, 218-225, 10.1016/j.jmatprotec.2016.07.025.

- Mohammad Heidari-Rarani; M. Rafiee-Afarani; A.M. Zahedi; Mechanical characterization of FDM 3D printing of continuous carbon fiber reinforced PLA composites. Composites Part B: Engineering 2019, 175, 107147, 10.1016/j.compositesb.2019.107147.

- K Prashantha; Frederic Roger; Multifunctional properties of 3D printed poly(lactic acid)/graphene nanocomposites by fused deposition modeling. Journal of Macromolecular Science, Part A 2016, 54, 24-29, 10.1080/10601325.2017.1250311.

- Chin-San Wu; Chi-Hui Tsou; Fabrication, characterization, and application of biocomposites from poly(lactic acid) with renewable rice husk as reinforcement. Journal of Polymer Research 2019, 26, 44, 10.1007/s10965-019-1710-z.

- Zhaobing Liu; Qian Lei; Shuaiqi Xing; Mechanical characteristics of wood, ceramic, metal and carbon fiber-based PLA composites fabricated by FDM. Journal of Materials Research and Technology 2019, 8, 3741-3751, 10.1016/j.jmrt.2019.06.034.

- Adriana N. Frone; Dan Batalu; Ioana Chiulan; Madalina Oprea; Augusta Raluca Gabor; Augusta Raluca Gabor; Valentin Raditoiu; Roxana Trusca; Denis Mihaela Panaitescu; Morpho-Structural, Thermal and Mechanical Properties of PLA/PHB/Cellulose Biodegradable Nanocomposites Obtained by Compression Molding, Extrusion, and 3D Printing. Nanomaterials 2019, 10, 51, 10.3390/nano10010051.

- Guang‐Peng Jiang; Ting Yang; Jie Xu; Dongliang Tao; Chunhua Luo; Chang Wang; Qiujing Dong; Yongzhong Wang; Investigation into hydroxypropyl-methylcellulose-reinforced polylactide composites for fused deposition modelling. Industrial Crops and Products 2020, 146, 112174, 10.1016/j.indcrop.2020.112174.

- Cisneros-López, E.O.; Pal, A.K.; Rodriguez, A.U.; Wu, F.; Misra, M.; Mielewski, D.F.; Kiziltas, A.; Mohanty, A.K.; Recycled poly(lactic acid). Mater. Today Sustain 2020, 8, 1-12.

- Bai Huang; Hui He; Shuna Meng; Yunchao Jia; Optimizing 3D printing performance of acrylonitrile‐butadiene‐styrene composites with cellulose nanocrystals/silica nanohybrids. Polymer International 2019, 68, 1351-1360, 10.1002/pi.5824.

- María Elena Alemán-Domínguez; Elena Giusto; Zaida Ortega; Maryam Tamaddon; Antonio Nizardo Benítez; Chaozong Liu; Three-dimensional printed polycaprolactone-microcrystalline cellulose scaffolds. Journal of Biomedical Materials Research Part B: Applied Biomaterials 2018, 107, 521-528, 10.1002/jbm.b.34142.

- Denesh Mohan; Mohd Sajab; Hatika Kaco; Saiful Bahari Bakarudin; An’Amt Mohamed Noor; 3D Printing of UV-Curable Polyurethane Incorporated with Surface-Grafted Nanocellulose. Nanomaterials 2019, 9, 1726, 10.3390/nano9121726.

- Shenggui Chen; Junzhong Yang; Yong-Guang Jia; Bingheng Lu; Li Ren; A Study of 3D-Printable Reinforced Composite Resin: PMMA Modified with Silver Nanoparticles Loaded Cellulose Nanocrystal. Materials 2018, 11, 2444, 10.3390/ma11122444.

- Zhaozhe Yang; Guomin Wu; Siqun Wang; Min Xu; Xinhao Feng; Dynamic postpolymerization of 3D-printed photopolymer nanocomposites: Effect of cellulose nanocrystal and postcure temperature. Journal of Polymer Science Part B: Polymer Physics 2018, 56, 935-946, 10.1002/polb.24610.

- Chuanwei Lu; Chunpeng Wang; Juan Yu; Jifu Wang; Fuxiang Chu; Two‐Step 3 D‐Printing Approach toward Sustainable, Repairable, Fluorescent Shape‐Memory Thermosets Derived from Cellulose and Rosin. ChemSusChem 2020, 13, 854-854, 10.1002/cssc.202000324.

- Vincent Chi-Fung Li; Xiao Kuang; Arie Mulyadi; Craig M. Hamel; Yulin Deng; H. Jerry Qi; 3D printed cellulose nanocrystal composites through digital light processing. Cellulose 2019, 26, 3973-3985, 10.1007/s10570-019-02353-9.

- Yani Jiang; Jiping Zhou; Zhe Yang; Dongfang Liu; Xiaodong Xv; Guoqi Zhao; Hongcan Shi; Qi Zhang; Dialdehyde cellulose nanocrystal/gelatin hydrogel optimized for 3D printing applications. Journal of Materials Science 2018, 53, 11883-11900, 10.1007/s10853-018-2407-0.

- Ellinor B. Heggset; Berit L. Strand; Kristin W. Sundby; Sébastien Simon; Gary Chinga-Carrasco; Kristin Syverud; Viscoelastic properties of nanocellulose based inks for 3D printing and mechanical properties of CNF/alginate biocomposite gels. Cellulose 2018, 26, 581-595, 10.1007/s10570-018-2142-3.

- Li Huang; Xiaoyu Du; Suna Fan; Gesheng Yang; Huili Shao; Dejian Li; Chengbo Cao; Yufang Zhu; Meifang Zhu; Yaopeng Zhang; et al. Bacterial cellulose nanofibers promote stress and fidelity of 3D-printed silk based hydrogel scaffold with hierarchical pores.. Carbohydrate Polymers 2019, 221, 146-156, 10.1016/j.carbpol.2019.05.080.

- Kajsa Markstedt; Alfredo Escalante; Guillermo Toríz; Paul Gatenholm; Biomimetic Inks Based on Cellulose Nanofibrils and Cross-Linkable Xylans for 3D Printing. ACS Applied Materials & Interfaces 2017, 9, 40878-40886, 10.1021/acsami.7b13400.

- Tamilselvan Mohan; Andreja Dobaj Štiglic; Marco Beaumont; Johannes Konnerth; Fazilet Gürer; Damjan Makuc; Uroš Maver; Lidija Gradišnik; Janez Plavec; Rupert Kargl; et al.Karin Stana Kleinschek Generic Method for Designing Self-Standing and Dual Porous 3D Bioscaffolds from Cellulosic Nanomaterials for Tissue Engineering Applications. ACS Applied Bio Materials 2020, 3, 1197-1209, 10.1021/acsabm.9b01099.

- A. Sydney Gladman; Elisabetta A. Matsumoto; Ralph G. Nuzzo; L. Mahadevan; Jennifer A. Lewis; Biomimetic 4D printing. Nature Materials 2016, 15, 413-418, 10.1038/nmat4544.

- Manu C. Mulakkal; R. S. Trask; Valeska P. Ting; Annela Seddon; Responsive cellulose-hydrogel composite ink for 4D printing. Materials & Design 2018, 160, 108-118, 10.1016/j.matdes.2018.09.009.

- P. A. G. S. Giachini; S. S. Gupta; Wendong Wang; Dylan Wood; Muhammad Yunusa; E. Baharlou; Metin Sitti; Achim Menges; Additive manufacturing of cellulose-based materials with continuous, multidirectional stiffness gradients.. Science Advances 2020, 6, eaay0929, 10.1126/sciadv.aay0929.

- Benjamin Stolz; Rolf Mülhaupt; Cellular, Mineralized, and Programmable Cellulose Composites Fabricated by 3D Printing of Aqueous Pastes Derived from Paper Wastes and Microfibrillated Cellulose. Macromolecular Materials and Engineering 2020, 305, 1900740, 10.1002/mame.201900740.

- Takuya Uchida; Hiroaki Onoe; 4D Printing of Multi-Hydrogels Using Direct Ink Writing in a Supporting Viscous Liquid. Micromachines 2019, 10, 433, 10.3390/mi10070433.