| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Fahed Martini | + 1834 word(s) | 1834 | 2021-09-07 08:32:59 | | | |

| 2 | Fahed Martini | -181 word(s) | 1653 | 2021-09-23 23:30:26 | | | | |

| 3 | Amina Yu | Meta information modification | 1653 | 2021-09-24 04:25:32 | | |

Video Upload Options

In this entry, a comprehensive review of wind turbine icing modelling is presented. The commonly applied approaches and the recent advances have been reported based on a systematic and concise literature review. The paper presents a panorama of the current modelling and simulation studies dealing with different aspects of ice accretion on wind turbines.

1. Introduction

Wind Turbine Icing is the phenomenon of ice build-up mainly on wind turbine blades. It is a common problem in Nordic countries, which has severe consequences on the operation and the life cycle of wind turbines. When wind turbine blades are subjected to supercooled water droplets under specific meteorological conditions, ice starts to build forward in different forms, types, and severities. The deposition of ice on the blades may affect the turbine’s structural integrity, causing much damage to the turbines and the surrounding areas. Safety hazards have been reported, such as the throwing of large chunks of ice may threaten the safety of the public, employees, and nearby roads and facilities [1]. Various types of icing consequences have been stated by the cited sources [2][3][4][5][6]. However, it is the shape rather than the mass or dimensions of ice that significantly impact wind energy production [1]. The accumulation of ice on the leading edge of blade section airfoils, even in small quantities, results in significant consequences on power production of the wind turbine due to the degradation of the aerodynamics performance associated with the iced airfoil deformation [1].

Research into wind turbine icing is a developing discipline with limited available resources for investigations [7]. Given that the phenomenon of ice accumulation is physically complex, the optimization of wind turbines operating under icing conditions depends essentially on experiments. However, experimental tests and wind farm observations being relatively costly and having many operational difficulties; numerical simulation has increasing importance as a means of compliance. By reproducing the ice accretion progression on wind turbines blades, a numerical simulation approach makes it possible to conveniently provide information on the aerodynamic and energy production losses, energy required for de-icing for different wind turbine configurations and weather conditions [8][9]. As computational cost drops, the use of computational fluid dynamics (CFD) for wind turbine design and analysis is becoming increasingly widespread. It results in a better understanding of the phenomenon and its consequences on wind turbines [10]. Thanks to the development of advanced icing simulation tools for aeronautics, the bibliographic study showed increasing interest in modelling and simulation research adapting these tools for wind turbine icing simulation during the last decade. The most commonly used icing simulation tools are LEWICE, developed by NASA and ANSYS FENSAP-ICE, developed by NTI Inc. The latter is often used recently in the literature for wind turbine icing due to its availability and integration with Ansys FLUENT and CFX. Based on what has been mentioned above, it is appropriate to review wind turbine icing modelling and provide engineers, analysts, or similar professionals in computational wind energy with icing simulation tools primarily validated with the operational conditions of wind turbines.

2. Computational Models for Ice Accretion

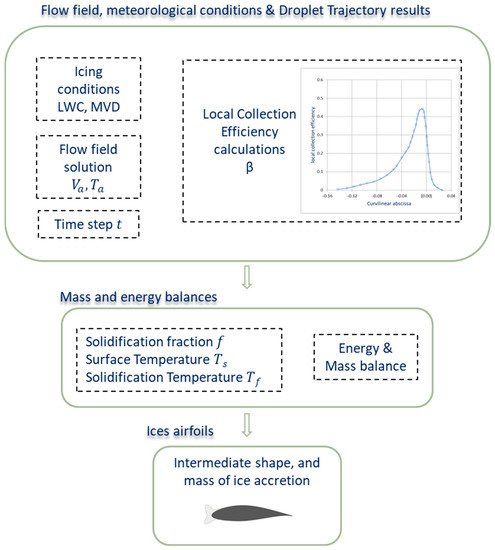

Typically, the computational procedure for ice accretion is a time-step iterative process. It requires considering four consecutive modules of calculation: flow field aerodynamic calculations, particle trajectory calculations, thermodynamic analysis and ice geometry generation. All the modelling techniques used in these modules depend on partial differential equations that require numerical solutions. This section outlines the approaches adopted when modelling ice accretion on wind turbine blades’ airfoils.

In the aerodynamic module, the commonly used turbulence models, such as the SPALART-ALLMARAS, k-ε and k-ω SST have been discussed in addition to surface roughness modelling. For the multiphase modelling of droplet trajectories, the Lagrangian and Eulerian approaches were discussed. Finally, the model of Messinger was concerned with the thermodynamic modelling of ice accretion.

3. Research Survey on Modelling and Simulation of Ice Accretion on Wind Turbines

This section analyzes the different modelling approaches by evaluating their suitability and adequacy for wind turbine icing simulation to identify the most adapted techniques and methodologies. The survey addressed research on modelling the surface roughness, droplets trajectory and the electro-thermal icing protection systems.

For IPS modelling, a module for heat transfer is conjugated in the calculations. This includes the heat transfer coefficient calculations using a boundary layer calculation considering the roughness of the wall due to the presence of ice. Some commercial codes are equipped with this additional module to conduct simulations on the hot air or electro-thermal icing protection systems to estimate the energy consumption required for anti- or de-icing once the ice accretion is estimated. For example, LEWICE integrates a thermal anti-icing model to calculate the thermal energy needed to prevent ice formation, available for two anti-icing modes of prevention: evaporative and running-wet conditions [11]. FENSAP-ICE also has a particular module (CHT3D) that incorporates heat flux distributions in icing calculations to estimate the required total heat load for the hot air or electro-thermal IPS for the two modes of prevention: evaporative and running-wet conditions [12].

Performance degradation due to Icing and heat flux simulation for different anti-icing scenarios is presented in a study on wind turbine blades using FENSAP-ICE [13][14]. This showed the total power required for every considered surface coverage and power distribution for four icing cases. It is worth noting that for initial de-icing computations, the surface roughness should be considered in calculations as it is already determined during ice accretion. However, for anti-icing simulation, uncontaminated surfaces can be considered (with no roughness) since they are expected to remain free of ice [12].

Modelling of the electro-thermal Icing Protection Systems for wind turbines presents many challenges. They are presented and discussed, along with the mathematical models used in IPS modelling, in a published study by Fakorede, 2018 [15] on heat and mass transfer modelling during the anti/de-icing process for wind turbine blades. The thermodynamic models used to calculate de/anti-icing systems are also presented in a study by Fortin and Perron [16] on an airfoil NACA 63-415. The paper also includes a description of atmospheric icing, icing parameters and the different types of ice accretion, in addition to a review of the thermodynamic models used in ice accretion calculations for wind turbines and the numerical methods used for water droplet trajectory calculations and aerodynamic performance degradation [16]. The various published studies on wind turbine icing simulation were mainly up to quite recently on ice growth simulation. Of those, few studies integrate the modelling of electro-thermal IPS in their calculations [17]. In the last decade, ice accretion research has intensified on several techniques for ice prevention solutions. Comparisons between mitigation techniques, their executive design, verification and certification, advantages and disadvantages were systematically discussed in several studies [1][5][9][18][19][20][21] and Chapter 5, pp. 251–324 in [1]. A significant report by the Technical Research Centre of Finland (VTT) published in 2018 analyzed the performance and the maturity of wind turbines equipped with Ice Protection Systems for various icing climates. The report discussed IPS maturity from the viewpoint of availability and heating durations deviation analysis [22].

4. Conclusions

In this paper, a comprehensive review of wind turbine icing modelling is presented. The commonly applied approaches and the recent advances have been reported based on a systematic and concise literature review. The paper presents a panorama of the current modelling and simulation studies dealing with different aspects of ice accretion on wind turbines. The review of numerous CFD-based published studies on wind turbine icing during the last decade leads to the following considerations:

The most common approach uses Computational Fluid Dynamics (CFD). It treats multi-physics aspects including aerothermodynamics, thermodynamics, multiphase flows, heat and mass transfer and optimization theories. Several papers combine the CFD flow and icing simulations with the Blade Element Momentum Theory to generate the power curves for iced-up wind turbines. Some of these attempts were implemented using in-flight icing codes. In contrast, others were special-purpose codes, while most of them were merely methodologies developed using commercial computer-aided engineering software.

As previously mentioned, experimental studies require specialized measuring elements and a special design to analyze the effect of ice on wind turbines. This process is costly and, in some cases, not very accurate. Therefore, little information is available to validate the models proposed in recent years adequately. Thus, the authors generally validated with other numerical studies, other software, experimental data available for specific airfoils (NACA 0012 and S809, mainly), or carried out experimental studies.

Most of the research on wind turbine icing modelling was derived from the aeronautical industry, which has come a long way in this area. Following this progress in aeronautics, intensifying the modelling research on wind turbine icing, for example, by categorizing the wind turbine iced airfoils, could boost our comprehension of this phenomenon towards practical solutions. Following examples from aeronautics, while considering the particularities of wind turbine icing, was our guideline to make this study a unique reference for researchers in this domain. The aim is to suggest appropriate methods, references, and tools to conduct reliable icing modelling for wind turbines. This study can contribute to advancing the research on this phenomenon, common and frequent in Nordic countries, and to adapting wind turbines and optimizing their operation under icing conditions.

References

- Battisti, L. Wind Turbines in Cold Climates: Icing Impacts and Mitigation Systems; Springer: Berlin/Heidelberg, Germany, 2015.

- Mayer, C.; Ilinca, A.; Fortin, G.; Perron, J. Wind tunnel study of the electro-thermal de-icing of wind turbine blades. Int. J. Offshore Polar Eng. 2007, 17. ISOPE–07–17–3–182.

- Battisti, L. Wind Turbines in Cold Climates, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2015; p. 341.

- Lehtomäki, V. Wind Energy in Cold Climates Available Technologies-Report, in Task 19, Tech. Rep., IEA 2018. 2018. Available online: https://community.ieawind.org/HigherLogic/System/DownloadDocumentFile.ashx?DocumentFileKey=6697b7bd-b175-12b0-ecbf-2558c35d309bforceDialog=0 (accessed on 20 March 2021).

- Parent, O.; Ilinca, A. Anti-icing and de-icing techniques for wind turbines: Critical review. Cold Reg. Sci. Technol. 2010, 65, 88–96.

- Fortin, G. Simulation de L’accrétion de Glace sur un Obstacle Bidimensionnel par la Méthode des Bissectrices et par la Modélisation des Ruisselets et des Gouttes de Surface; Université du Québec à Chicoutimi: Chicoutimi, QC, Canada, 2003.

- Fortin, G. Thermodynamique de la Glace Atmosphérique; University Course; Université du Québec à Chicoutimi: Chicoutimi, QC, Canada, 2009.

- Fernando, V. Simulation Numérique de L’accrétion de Glace sur une Pale D’éolienne. Ph.D. Thesis, École Polytechnique de Montréal, Montréal, QC, Canada, 2013.

- Fakorede, O.; Feger, Z.; Ibrahim, H.; Ilinca, A.; Perron, J.; Masson, C. Ice protection systems for wind turbines in cold climate: Characteristics, comparisons and analysis. Renew. Sustain. Energy Rev. 2016, 65, 662–675.

- Sagol, E. Three Dimensional Numerical Predicton of Icing Related Power and Energy Losses on a Wind Turbine. Ph.D. Thesis, École Polytechnique de Montréal, Montréal, QC, Canada, 2014.

- Pallarol, J.; Wu, Z. On Ice Accretion for Wind Turbines and Influence of Some Parameters. Engineering 2014, 1, 129–159.

- ANSYS FENSAP-ICE User Manual, R1. 2020. Available online: https://ansyshelp.ansys.com/account/secured?returnurl=/Views/Secured/corp/v202/en/fensap_manual/fensap_manual.html (accessed on 19 August 2021).

- Reid, T.; Baruzzi, G.; Ozcer, I.; Switchenko, D.; Habashi, W. FENSAP-ICE Simulation of Icing on Wind Turbine Blades, Part 1: Performance Degradation. In Proceedings of the 51st AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Grapevine, TX, USA, 7–10 January 2013.

- Reid, T.; Baruzzi, G.; Ozcer, I.; Switchenko, D.; Habashi, W. FENSAP-ICE Simulation of Icing on Wind Turbine Blades, Part 2: Ice Protection System Design. In Proceedings of the 51st AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Grapevine, TX, USA, 7–10 January 2013.

- Fakorede, C.O. Modélisation du Transfert Thermique et du Transfert de Masse Lors du Processus D’accrétion de Glace et de Dégivrage des Ples D’éoliennes. Ph.D. Thesis, Université du Québec à Chicoutimi, Chicoutimi, QC, Canada, 2018.

- Fortin, G.; Perron, J. Wind turbine icing and de-Icing. In Proceedings of the 47th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 5–8 January 2009; p. 274.

- Davis, N. Icing Impacts on Wind Energy Production; DTU Wind Energy: Copenhagen, Denmark, 2014; 156p.

- Wei, K.; Yang, Y.; Zuo, H.; Zhong, D. A review on ice detection technology and ice elimination technology for wind turbine. Wind Energy 2019, 23, 433–457.

- Madi, E.; Pope, K.; Huang, W.; Iqbal, T. A review of integrating ice detection and mitigation for wind turbine blades. Renew. Sustain. Energy Rev. 2019, 103, 269–281.

- Sunden, B.; Wu, Z. On Icing and Icing Mitigation of Wind Turbine Blades in Cold Climate. J. Energy Resour. Technol. 2015, 137, 051203.

- Habibi, H.; Cheng, L.; Zheng, H.; Kappatos, V.; Selcuk, C.; Gan, T.-H. A dual de-icing system for wind turbine blades combining high-power ultrasonic guided waves and low-frequency forced vibrations. Renew. Energy 2015, 83, 859–870.

- Lehtomäki, V.; Karlsson, T.; Rissanen, S. Wind Turbine Ice Protection System Benchmark Analysis; VTT Technology No. 341; VTT Technical Research Centre of Finland: Espoo, Finland, 2018.