| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Muhammad Wasim | + 954 word(s) | 954 | 2020-04-24 10:33:09 | | | |

| 2 | Camila Xu | Meta information modification | 954 | 2020-04-26 11:16:43 | | | | |

| 3 | Camila Xu | Meta information modification | 954 | 2020-04-26 11:40:39 | | | | |

| 4 | Bruce Ren | + 2 word(s) | 956 | 2020-07-23 09:33:13 | | | | |

| 5 | Camila Xu | -7 word(s) | 949 | 2020-11-01 07:57:35 | | |

Video Upload Options

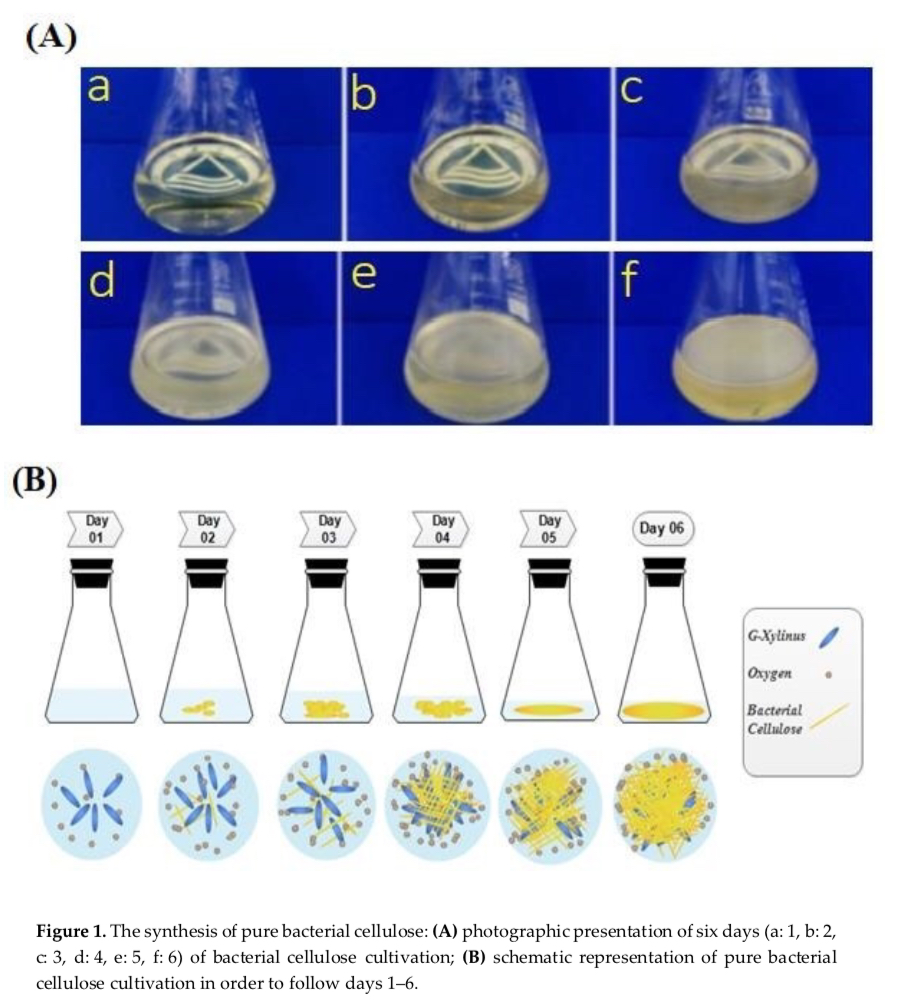

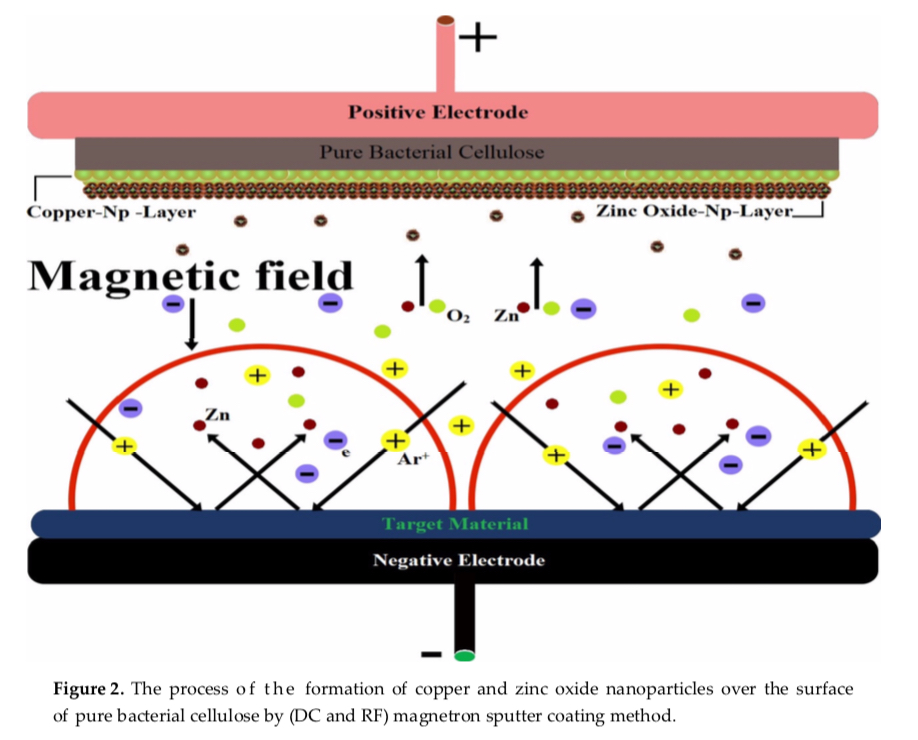

The surface of bacterial cellulose was successively modified by copper and zinc oxide nanoparticles using direct current (DC) magnetron sputtering and radio frequency (RF) reactive sputter coating techniques. The target materials, copper and zinc, were 99.99% pure and used in the presence of argon (Ar) gas, while zinc nanoparticles were sputtered in the presence of oxygen gas to make zinc oxide nanoparticles. The as-prepared bacterial cellulose/copper/zinc oxide nanocomposite has good ultraviolet resistance, anti-static and antibacterial characteristics. The surface morphology and chemical compositionof the nanocomposite were examined by X-ray photoelectron spectroscopy (XPS), X-ray diffraction (XRD) and energy-dispersive X-ray spectroscopic (EDS) techniques. The prepared bacterial cellulose/copper/zinc oxide nanocomposite illustrates excellent ultraviolet resistance (T.UVA%; 0.16 ± 0.02, T.UVB%; 0.07 ± 0.01, ultraviolet protection factor (UPF); 1850.33 ± 2.12), antistatic behavior (S.H.P; 51.50 ± 4.10, I.E. V; 349.33 ± 6.02) and antibacterial behavior (Escherichia coli; 98.45%, Staphylococcus aureus; 98.11%). Our nanocomposite prepared by sputter coating method could be a promising and effective candidate for ultraviolet resistance, antistatic and antibacterial in term of functional, technical, medical and in many daily life applications.

1. Introduction

In the modern age, metallic semiconductor nanocomposites are studied extensively due to their high potential for applicability in daily life [1][2][3][4][5]. Such types of nanocomposites are enriched with mechanical, physical and chemical characteristics, which enhance their applications in sensitive sensors, pharmaceutical, medical, optical, electronic gadgets and devices. Copper and zinc oxide nanoparticles are used abundantly for the formation of nanocomposites with polymers and cellulosic materials; copper has excellent electrical, optical and chemical properties, whereas zinc oxide possesses high binding energy, performs efficient photocatalysis, and has excellent thermal properties. These types of metals and metals oxide are eco-friendly, on top of being low cost with non-toxic behavior and easily available commercially [6][7][8][9][10][11][12][13][14].

Copper nanoparticles have good antibacterial and thermal characteristics; in addition, their metallic ions can restrict the activities of proteins clusters and improve the surface of the film. Additionally, because of their biodegradability and high stability, they are suitable to be used with cellulosic materials [15]. In industrial applications, a requirement of many cost-effective instruments is to control microwaves, thereby absorbing harmful radiation. Copper has gained extensive attention toward its use as a conductive material due to its low resistance characteristic in such applications. Cellulosic materials such as bacterial cellulose (BC) do not show any type of bactericidal property [16]. In order to acquire the bactericidal characteristic from bacterial cellulose, many scientists have worked on bacterial cellulose, that work encompassing several types of metals and metal oxide nanoparticles, among which Cu, CuO and ZnO conclusively exist [17][18]. Additionally, Zinc oxide has distinguished properties and has been considered for serval applications in terms of piezoelectric gadgets, semiconductors and sensors, and for antimicrobial functions [19][20]. Nowadays, researchers have more interest in using zinc oxide in the composition of nanoparticles with different approaches to regulate its structure and scope. Preparation of a nanocomposite with suitable base materials and zinc oxide nanoparticles could advance multifunctional materials, which exhibit a wide range of UV-resistance and antibacterial applications [21][22].

Human beings, as well as other living organisms, are affected by ultraviolet radiation in this universe. A decrease in environmental pollution has gained more attention, but there still needs to be a type of composite which can resist ultraviolet radiation to save the lives of all creatures [23][24]. The main cause of skin cancer is ultraviolet radiation, which is a medium of free radicals. Moreover, it is a cause of environmental degradation; and damages various pigments and materials and degrades their physical characteristics [25]. The deposition of zinc oxide nanoparticles on substrates is an excellent opportunity not only for antimicrobial characteristics but for ultraviolet radiation protection too [26]. The application of zinc oxide with other materials provides long term stability against ultraviolet radiation and improves the absorption capacity of its base material [27][28]. Besides, zinc oxide nanoparticles’ restriction capacity against ultraviolet radiations depends upon the morphological structure and size of nanoparticles [29]. Zinc oxide is a common element in many sunscreens, which converts ultraviolet radiation to infrared, yet infrared could be dangerous depending on the exposure [30].

2. Applications

The application of a zinc oxide nanocomposite has been studied extensively in terms of optical, electrical, optoelectronic and photochemical characteristics. The high energy surface area of zinc oxide nanocomposites presents excellent characteristics in the applications of sensing devices, color creation and antimicrobial materials [31][32][33][34].

The fabrication of metallic and metallic oxide nanoparticles on polymers and cellulosic materials has been reported with several methods and techniques, among which are hydrothermal, sol–gel, chemical deposition, photoreduction and laser deposition methods, according to applications [35][36][37][38][39]. Meanwhile, high temperatures, high pressures, costly machines, harmful elements and high process times are those factors which limit the material applications. Thus, to avoid these types of problems, a unique and fast method for the formation of a nanocomposite material is a magnetron sputter coating, which can be economically and commercially fit. The method of reactive sputter coating of ZnO nanoparticles improves the UV radiation absorbency [40]. The features of this method describe its characteristics in terms of smooth deposition of nanoparticles; high crystalline formation; preparation of conductive materials; and optical and magnetic film preparation [41][42][43].

Bacterial cellulose is a three-dimensional nanofibrils structure prepared by Acetobacter xylinum [44]. It possesses outstanding characteristics—biocompatibility, high porosity, crystallinity (63–71%), good tensile strength and increased water holding capacity [45]. Additionally, in recent years BC has gained more attention due to its excellent mechanical and physical properties as a novel substrate for porous aerogel nanocomposites [46][47][48]. The pellicles of bacterial cellulose play a major role in the medical field in terms of wound dressing, because of the protection from infection they grant, and their being suitable for drug delivery. The recent development of BC for burned wound dressing is Albeit BC, which works efficiently against bacterial infections [49].

References

- Deliang Chen; Qianqian Chen; Lianfang Ge; Li Yin; Bingbing Fan; Hailong Wang; Hongxia Lu; Hongliang Xu; Rui Zhang; Guosheng Shao; Synthesis and Ag-loading-density-dependent photocatalytic activity of Ag@TiO2 hybrid nanocrystals. Applied Surface Science 2013, 284, 921-929, 10.1016/j.apsusc.2013.08.051.

- Yogendra Kumar Mishra; Satyabrata Mohapatra; Rahul Singhal; D.K. Avasthi; D. C. Agarwal; SatishChandra Ogale; Au–ZnO: A tunable localized surface plasmonic nanocomposite. Applied Physics Letters 2008, 92, 043107, 10.1063/1.2838302.

- Nasser A.M. Barakat; Salem Al-Deyab; Hak Yong Kim; Synthesis and study of the photoluminescence and optical characteristics of Cd/CdO nanorods prepared by the electrospinning process. Materials Letters 2012, 66, 225-228, 10.1016/j.matlet.2011.08.074.

- D. Geetha; S. Kavitha; P.S. Ramesh; A novel bio-degradable polymer stabilized Ag/TiO2 nanocomposites and their catalytic activity on reduction of methylene blue under natural sun light. Ecotoxicology and Environmental Safety 2015, 121, 126-134, 10.1016/j.ecoenv.2015.04.042.

- Der-Shing Lee; Yu-Wen Chen; Nano Ag/TiO2 catalyst prepared by chemical deposition and its photocatalytic activity. Journal of the Taiwan Institute of Chemical Engineers 2014, 45, 705-712, 10.1016/j.jtice.2013.07.007.

- Pavel Bazant; Ivo Kuritka; Lukas Munster; Lukas Kalina; Microwave solvothermal decoration of the cellulose surface by nanostructured hybrid Ag/ZnO particles: a joint XPS, XRD and SEM study. Cellulose 2015, 22, 1275-1293, 10.1007/s10570-015-0561-y.

- Fazhe Sun; Xueliang Qiao; Fatang Tan; Wei Wang; Xiaolin Qiu; One-step microwave synthesis of Ag/ZnO nanocomposites with enhanced photocatalytic performance. Journal of Materials Science 2012, 47, 7262-7268, 10.1007/s10853-012-6676-8.

- You-Cun Chen; Jinnan Cheng; Jun Cheng; Si Cheng; l-Arginine assisted preparation of Ag/ZnO nanocomposites with enhanced photocatalytic performance. Journal of Materials Science: Materials in Electronics 2015, 26, 2775-2781, 10.1007/s10854-015-2758-0.

- V. Gunasekar; V. Ponnusami; Plasmonic photocatalysis and kinetics of reactive dye degradation in aqueous solution using enzymatically synthesized Ag/ZnO. Journal of Sol-Gel Science and Technology 2014, 74, 84-93, 10.1007/s10971-014-3580-5.

- Laura Tamayo; Manuel Azócar; Marcelo Kogan; Ana Riveros; M.A. Páez; Copper-polymer nanocomposites: An excellent and cost-effective biocide for use on antibacterial surfaces. Materials Science and Engineering: C 2016, 69, 1391-1409, 10.1016/j.msec.2016.08.041.

- Nathaniel C. Cady; Jason L. Behnke; Aaron D. Strickland; Copper-Based Nanostructured Coatings on Natural Cellulose: Nanocomposites Exhibiting Rapid and Efficient Inhibition of a Multi-Drug Resistant Wound Pathogen, A. baumannii, and Mammalian Cell Biocompatibility In Vitro. Advanced Functional Materials 2011, 21, 2506-2514, 10.1002/adfm.201100123.

- Yang Yang; Quanbo Huang; Gregory Francis Payne; Shaolong Sun; Xiaohui Wang; A highly conductive, pliable and foldable Cu/cellulose paper electrode enabled by controlled deposition of copper nanoparticles. Nanoscale 2019, 11, 725-732, 10.1039/c8nr07123c.

- M. Kishanji; G. Mamatha; K. Obi Reddy; A. Varada Rajulu; K. Madhukar; In situ generation of silver nanoparticles in cellulose matrix using Azadirachta indica leaf extract as a reducing agent. International Journal of Polymer Analysis and Characterization 2017, 22, 734-740, 10.1080/1023666X.2017.1369612.

- Joseph Christopher Hannon; Joseph P. Kerry; Malco Cruz-Romero; Shafrina Azlin-Hasim; Michael A. Morris; Enda Cummins; Assessment of the migration potential of nanosilver from nanoparticle-coated low-density polyethylene food packaging into food simulants. Food Additives & Contaminants: Part A 2015, 33, 1-12, 10.1080/19440049.2015.1114184.

- Lakshmanan Muthulakshmi; Anumakonda Varada Rajalu; Gobi Saravanan Kaliaraj; Suchart Siengchin; Jyotishkumar Parameswaranpillai; Ramiah Saraswathi; Preparation of cellulose/copper nanoparticles bionanocomposite films using a bioflocculant polymer as reducing agent for antibacterial and anticorrosion applications. Composites Part B: Engineering 2019, 175, , 10.1016/j.compositesb.2019.107177.

- Hanif Ullah; Fazli Wahid; Hélder A. Santos; Taous Khan; Advances in biomedical and pharmaceutical applications of functional bacterial cellulose-based nanocomposites. Carbohydrate Polymers 2016, 150, 330-352, 10.1016/j.carbpol.2016.05.029.

- M.L. Foresti; A. Vázquez; Bruno Boury; Applications of bacterial cellulose as precursor of carbon and composites with metal oxide, metal sulfide and metal nanoparticles: A review of recent advances. Carbohydrate Polymers 2017, 157, 447-467, 10.1016/j.carbpol.2016.09.008.

- Amin Yoosefi Booshehri; Rong Wang; Rong Xu; Simple method of deposition of CuO nanoparticles on a cellulose paper and its antibacterial activity. Chemical Engineering Journal 2015, 262, 999-1008, 10.1016/j.cej.2014.09.096.

- Jingbo Mu; Changlu Shao; Zengcai Guo; Zhenyi Zhang; Mingyi Zhang; Peng Zhang; Bin Chen; Yichun Liu; High Photocatalytic Activity of ZnO−Carbon Nanofiber Heteroarchitectures. ACS Applied Materials & Interfaces 2011, 3, 590-596, 10.1021/am101171a.

- Jinshu Wang; Dongfeng Xue; Progress of Science and Technology of ZnO as Advanced Material. Science of Advanced Materials 2011, 3, 127-149, 10.1166/sam.2011.1144.

- Sheng Xu; Zhong Lin Wang; One-dimensional ZnO nanostructures: Solution growth and functional properties. Nano Research 2011, 4, 1013-1098, 10.1007/s12274-011-0160-7.

- R. Pandimurugan; S. Thambidurai; UV protection and antibacterial properties of seaweed capped ZnO nanoparticles coated cotton fabrics. International Journal of Biological Macromolecules 2017, 105, 788-795, 10.1016/j.ijbiomac.2017.07.097.

- Kyung Lee; Seung-Sin Lee; Fabrication and Evaluation of Electrospun TiO 2 Nanocomposite Fibers for the Development of UV-protective Textile Materials. Journal of the Korean Society of Clothing and Textiles 2010, 34, 1767-1778, 10.5850/jksct.2010.34.11.1767.

- Kenneth Bielinski; Nolan Bielinski; UV radiation transmittance: regular clothing versus sun-protective clothing.. Cutis 2014, 94, , null.

- Pilar Garcia Parejo; Marcos Zayat; David Levy; Highly efficient UV-absorbing thin-film coatings for protection of organic materials against photodegradation. J. Mater. Chem. 2006, 16, 2165, 10.1039/b601577h.

- M. Sasani Ghamsari; Sanaz Alamdari; Wooje Han; Hyung-Ho Park; Impact of nanostructured thin ZnO film in ultraviolet protection. International Journal of Nanomedicine 2016, 12, 207-216, 10.2147/IJN.S118637.

- Mauricio E. Calvo; José R. Castro Smirnov; Hernán Míguez; Novel approaches to flexible visible transparent hybrid films for ultraviolet protection. Journal of Polymer Science Part B: Polymer Physics 2012, 50, 945-956, 10.1002/polb.23087.

- Roshidah Rusdi; Azilah Abd Rahman; Nor Sabirin Mohamed; Norashikin Kamarudin; Norlida Kamarulzaman; Preparation and band gap energies of ZnO nanotubes, nanorods and spherical nanostructures. Powder Technology 2011, 210, 18-22, 10.1016/j.powtec.2011.02.005.

- Yun-Ju Lee; Douglas S. Ruby; David W. Peters; Bonnie B. McKenzie; Julia W. P. Hsu; ZnO Nanostructures as Efficient Antireflection Layers in Solar Cells. Nano Letters 2008, 8, 1501-1505, 10.1021/nl080659j.

- Silva; Rasiah Ladchumananandasivam; José Heriberto O. Nascimento; Fernando R. Oliveira; António P. Souto; Helena P. Felgueiras; Andrea Zille; Multifunctional Chitosan/Gold Nanoparticles Coatings for Biomedical Textiles. Nanomaterials 2019, 9, 1064, 10.3390/nano9081064.

- David R. Bauer; John L. Gerlock; Deborah F. Mielewski; Michelline C. Paputa Peck; Roscoe O. Carter; Photodegradation and photostabilization of urethane crosslinked coatings. Industrial & Engineering Chemistry Research 1991, 30, 2482-2487, 10.1021/ie00059a019.

- Burçin Acar Çakır; Leyla Budama; Önder Topel; Numan Hoda; Synthesis of ZnO nanoparticles using PS-b-PAA reverse micelle cores for UV protective, self-cleaning and antibacterial textile applications. Colloids and Surfaces A: Physicochemical and Engineering Aspects 2012, 414, 132-139, 10.1016/j.colsurfa.2012.08.015.

- Y. B. Han; J. B. Han; S. Ding; D. J. Chen; Q. Q. Wang; Optical nonlinearity of ZnO microcrystallite enhanced by interfacial state.. Optics Express 2005, 13, 9211-9216, 10.1364/opex.13.009211.

- Qing-Xia Niu; Yu-Jie Liu; Da-Jie Song; Ying-Jie Gao; Cun-Li Dai; Hong-Wei Yang; Research of anti-ultraviolet nano-film structure based on the FDTD method. Optik 2016, 127, 539-543, 10.1016/j.ijleo.2015.10.042.

- Y.F. Wang; J.H. Yao; G. Jia; H. Lei; Optical Prosperities of Ag-ZnO Composition Nanofilm Synthesized by Chemical Bath Deposition. Acta Physica Polonica A 2011, 119, 451-454, 10.12693/aphyspola.119.451.

- Giuseppina Iervolino; Ian Zammit; Vincenzo Vaiano; Luigi Rizzo; Limitations and Prospects for Wastewater Treatment by UV and Visible-Light-Active Heterogeneous Photocatalysis: A Critical Review. Topics in Current Chemistry 2019, 378, 7, 10.1007/s41061-019-0272-1.

- J. Wang; X.M. Fan; Z.W. Zhou; K. Tian; Preparation of Ag nanoparticles coated tetrapod-like ZnO whisker photocatalysts using photoreduction. Materials Science and Engineering: B 2011, 176, 978-983, 10.1016/j.mseb.2011.05.027.

- Weiwei Lu; Shuyan Gao; Jianji Wang; One-Pot Synthesis of Ag/ZnO Self-Assembled 3D Hollow Microspheres with Enhanced Photocatalytic Performance. The Journal of Physical Chemistry C 2008, 112, 16792-16800, 10.1021/jp803654k.

- Kyoungwon Kim; Deuk-Hee Lee; Sang Yeol Lee; Gun-Eik Jang; Jin-Sang Kim; Effect of Ag/Al co-doping method on optically p-type ZnO nanowires synthesized by hot-walled pulsed laser deposition. Nanoscale Research Letters 2012, 7, 273-273, 10.1186/1556-276X-7-273.

- Qufu Wei; Qiuxiang Xu; Yibing Cai; Weidong Gao; Congzhi Bo; Characterization of polymer nanofibers coated by reactive sputtering of zinc. Journal of Materials Processing Technology 2009, 209, 2028-2032, 10.1016/j.jmatprotec.2008.04.068.

- Ravindra G. Waykar; Amit Pawbake; Rupali R. Kulkarni; Ashok A. Jadhavar; Adinath Funde; Vaishali S. Waman; Habib M. Pathan; Sandesh Jadkar; Influence of RF power on structural, morphology, electrical, composition and optical properties of Al-doped ZnO films deposited by RF magnetron sputtering. Journal of Materials Science: Materials in Electronics 2015, 27, 1134-1143, 10.1007/s10854-015-3862-x.

- Shikhgasan Ramazanov; M. K. Kurbanov; G. K. Safaraliev; B. A. Bilalov; N. I. Kargin; A. S. Gusev; Structural properties of the epitaxial (SiC)1 − x (AlN) x solid solution films fabricated by magnetron sputtering of SiC-Al composite targets. Technical Physics Letters 2014, 40, 300-302, 10.1134/s1063785014040099.

- H. T. Li; T. Wang; Q. Wang; Composition and residual stress analysis of Ti-Si/(Ti-Si)xN film on Mg–Al alloy substrate prepared by magnetron sputtering. Materials Research Innovations 2015, 19, S5-1268, 10.1179/1432891714z.0000000001291.

- Shiyan Chen; Bihui Zhou; Weili Hu; Wen Zhang; Na Yin; Huaping Wang; Polyol mediated synthesis of ZnO nanoparticles templated by bacterial cellulose. Carbohydrate Polymers 2013, 92, 1953-1959, 10.1016/j.carbpol.2012.11.059.

- Dieter Klemm; Dieter Schumann; Ulrike Udhardt; Silvia Marsch; Bacterial synthesized cellulose — artificial blood vessels for microsurgery. Progress in Polymer Science 2001, 26, 1561-1603, 10.1016/s0079-6700(01)00021-1.

- Zhiyong Yan; Shiyan Chen; Huaping Wang; Biao Wang; Jianming Jiang; Biosynthesis of bacterial cellulose/multi-walled carbon nanotubes in agitated culture. Carbohydrate Polymers 2008, 74, 659-665, 10.1016/j.carbpol.2008.04.028.

- Lixia Wen; Yongjun Ma; B. Dai; Yong Zhou; Jinsong Liu; Chonghua Pei; Preparation and dielectric properties of SiC nanowires self-sacrificially templated by carbonated bacterial cellulose. Materials Research Bulletin 2013, 48, 687-690, 10.1016/j.materresbull.2012.11.025.

- Hou-Yong Yu; Guo-Yin Chen; Yi-Bo Wang; Juming Yao; A facile one-pot route for preparing cellulose nanocrystal/zinc oxide nanohybrids with high antibacterial and photocatalytic activity. Cellulose 2014, 22, 261-273, 10.1007/s10570-014-0491-0.

- Jian Wu; Yudong Zheng; Wenhui Song; Jiabin Luan; Xiaoxiao Wen; Zhigu Wu; Xiaohua Chen; Qi Wang; Shaolin Guo; In situ synthesis of silver-nanoparticles/bacterial cellulose composites for slow-released antimicrobial wound dressing. Carbohydrate Polymers 2014, 102, 762-771, 10.1016/j.carbpol.2013.10.093.