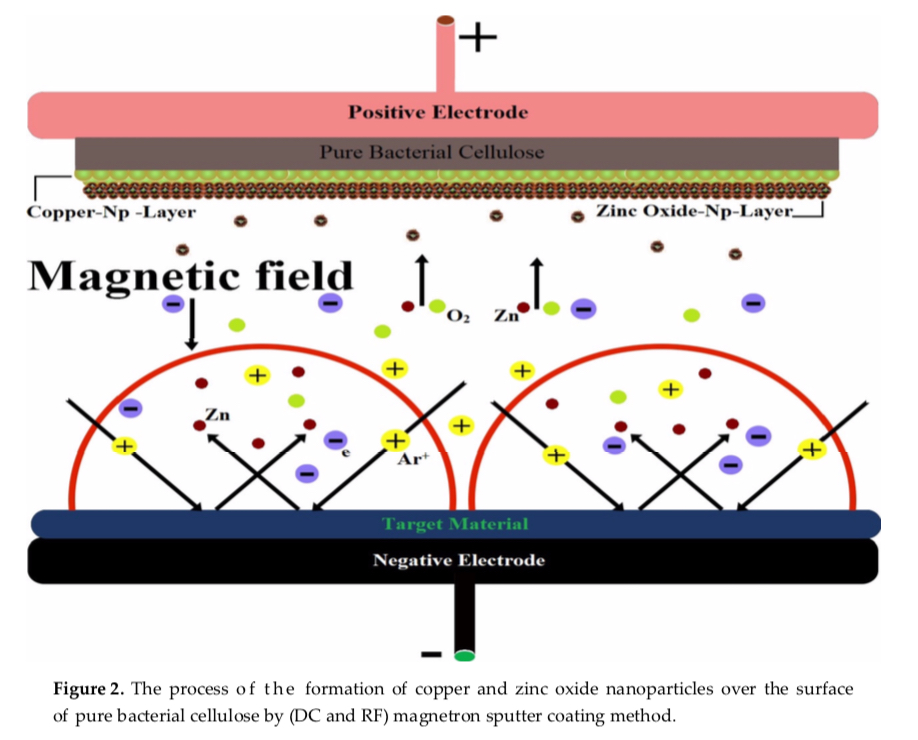

TIn our study, the surface of bacterial cellulose was successively modified by copper and zinc oxide nanoparticles using direct current (DC) magnetron sputtering and radio frequency (RF) reactive sputter coating techniques. The target materials, copper and zinc, were 99.99% pure and used in the presence of argon (Ar) gas, while zinc nanoparticles were sputtered in the presence of oxygen gas to make zinc oxide nanoparticles. The as-prepared bacterial cellulose/copper/zinc oxide nanocomposite has good ultraviolet resistance, anti-static and antibacterial characteristics. The surface morphology and chemical compositionof the nanocomposite were examined by X-ray photoelectron spectroscopy (XPS), X-ray diffraction (XRD) and energy-dispersive X-ray spectroscopic (EDS) techniques. The prepared bacterial cellulose/copper/zinc oxide nanocomposite illustrates excellent ultraviolet resistance (T.UVA%; 0.16 ± 0.02, T.UVB%; 0.07 ± 0.01, ultraviolet protection factor (UPF); 1850.33 ± 2.12), antistatic behavior (S.H.P; 51.50 ± 4.10, I.E. V; 349.33 ± 6.02) and antibacterial behavior (Escherichia coli; 98.45%, Staphylococcus aureus; 98.11%). Our nanocomposite prepared by sputter coating method could be a promising and effective candidate for ultraviolet resistance, antistatic and antibacterial in term of functional, technical, medical and in many daily life applications.

- Bacterial cellulose,

- Sputter coating,

- Copper

- Zinc oxide

- UV-Resistance

- Anti-Static

- Antibacterial

1. Introduction

In the modern age, metallic semiconductor nanocomposites are studied extensively due to their high potential for applicability in daily life [1][2][3][4][5]. Such types of nanocomposites are enriched with mechanical, physical and chemical characteristics, which enhance their applications in sensitive sensors, pharmaceutical, medical, optical, electronic gadgets and devices. Copper and zinc oxide nanoparticles are used abundantly for the formation of nanocomposites with polymers and cellulosic materials; copper has excellent electrical, optical and chemical properties, whereas zinc oxide possesses high binding energy, performs efficient photocatalysis, and has excellent thermal properties. These types of metals and metals oxide are eco-friendly, on top of being low cost with non-toxic behavior and easily available commercially [6][7][8][9][10][11][12][13][14].

Copper nanoparticles have good antibacterial and thermal characteristics; in addition, their metallic ions can restrict the activities of proteins clusters and improve the surface of the film. Additionally, because of their biodegradability and high stability, they are suitable to be used with cellulosic materials [15]. In industrial applications, a requirement of many cost-effective instruments is to control microwaves, thereby absorbing harmful radiation. Copper has gained extensive attention toward its use as a conductive material due to its low resistance characteristic in such applications. Cellulosic materials such as bacterial cellulose (BC) do not show any type of bactericidal property [16]. In order to acquire the bactericidal characteristic from bacterial cellulose, many scientists have worked on bacterial cellulose, that work encompassing several types of metals and metal oxide nanoparticles, among which Cu, CuO and ZnO conclusively exist [17][18]. Additionally, Zinc oxide has distinguished properties and has been considered for serval applications in terms of piezoelectric gadgets, semiconductors and sensors, and for antimicrobial functions [19][20]. Nowadays, researchers have more interest in using zinc oxide in the composition of nanoparticles with different approaches to regulate its structure and scope. Preparation of a nanocomposite with suitable base materials and zinc oxide nanoparticles could advance multifunctional materials, which exhibit a wide range of UV-resistance and antibacterial applications [21][22].

Human beings, as well as other living organisms, are affected by ultraviolet radiation in this universe. A decrease in environmental pollution has gained more attention, but there still needs to be a type of composite which can resist ultraviolet radiation to save the lives of all creatures [23][24]. The main cause of skin cancer is ultraviolet radiation, which is a medium of free radicals. Moreover, it is a cause of environmental degradation; and damages various pigments and materials and degrades their physical characteristics [25]. The deposition of zinc oxide nanoparticles on substrates is an excellent opportunity not only for antimicrobial characteristics but for ultraviolet radiation protection too [26]. The application of zinc oxide with other materials provides long term stability against ultraviolet radiation and improves the absorption capacity of its base material [27][28]. Besides, zinc oxide nanoparticles’ restriction capacity against ultraviolet radiations depends upon the morphological structure and size of nanoparticles [29]. Zinc oxide is a common element in many sunscreens, which converts ultraviolet radiation to infrared, yet infrared could be dangerous depending on the exposure [30].

2. Applications

The application of a zinc oxide nanocomposite has been studied extensively in terms of optical, electrical, optoelectronic and photochemical characteristics. The high energy surface area of zinc oxide nanocomposites presents excellent characteristics in the applications of sensing devices, color creation and antimicrobial materials [31][32][33][34].

The fabrication of metallic and metallic oxide nanoparticles on polymers and cellulosic materials has been reported with several methods and techniques, among which are hydrothermal, sol–gel, chemical deposition, photoreduction and laser deposition methods, according to applications [35][36][37][38][39]. Meanwhile, high temperatures, high pressures, costly machines, harmful elements and high process times are those factors which limit the material applications. Thus, to avoid these types of problems, a unique and fast method for the formation of a nanocomposite material is a magnetron sputter coating, which can be economically and commercially fit. The method of reactive sputter coating of ZnO nanoparticles improves the UV radiation absorbency [40]. The features of this method describe its characteristics in terms of smooth deposition of nanoparticles; high crystalline formation; preparation of conductive materials; and optical and magnetic film preparation [41][42][43].

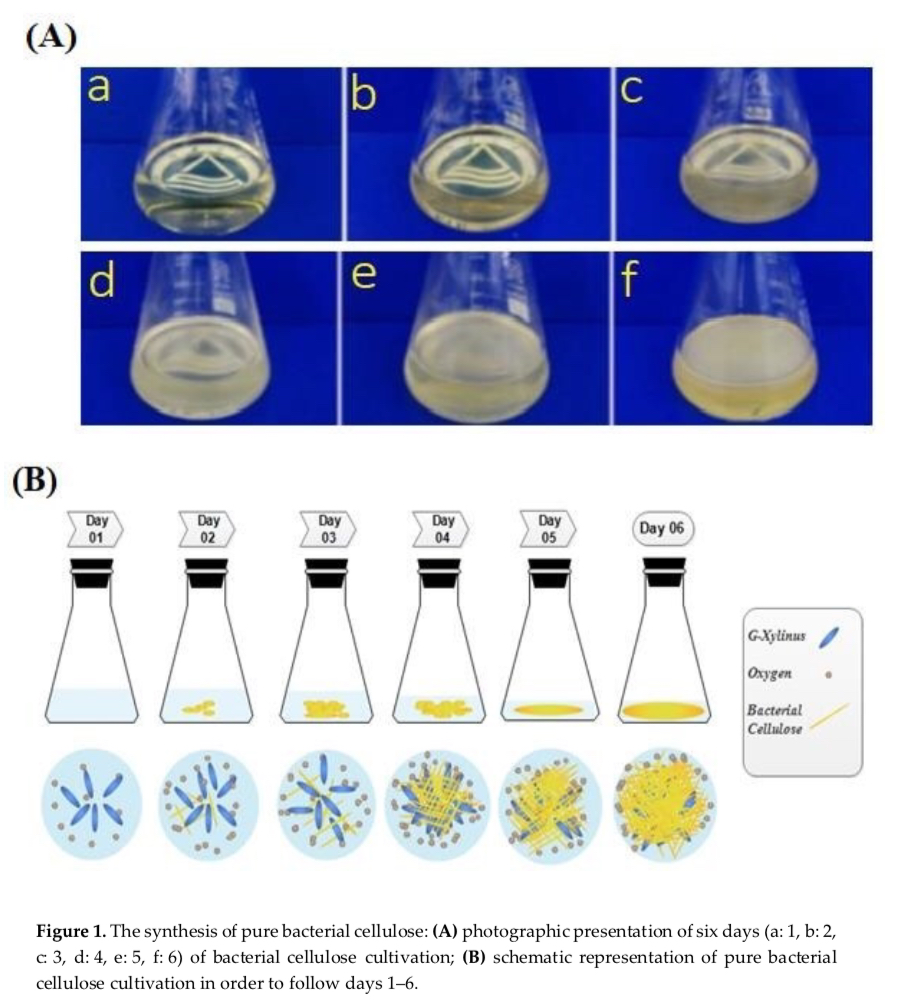

Bacterial cellulose is a three-dimensional nanofibrils structure prepared by

Acetobacter xylinum [44]. It possesses outstanding characteristics—biocompatibility, high porosity, crystallinity (63–71%), good tensile strength and increased water holding capacity [45]. Additionally, in recent years BC has gained more attention due to its excellent mechanical and physical properties as a novel substrate for porous aerogel nanocomposites [46][47][48]. The pellicles of bacterial cellulose play a major role in the medical field in terms of wound dressing, because of the protection from infection they grant, and their being suitable for drug delivery. The recent development of BC for burned wound dressing is Albeit BC, which works efficiently against bacterial infections [49].