| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Virendra Kumar | + 6715 word(s) | 6715 | 2021-04-26 05:46:27 | | | |

| 2 | Vivi Li | Meta information modification | 6715 | 2021-04-26 07:51:19 | | |

Video Upload Options

The use of natural fibres has rapidly increased due to their high availability, low density, and renewable capability over synthetic fibre. Natural leaf fibres are easy to extract from the plant (retting process is easy), which offers high stiffness, less energy consumption, less health risk, environment friendly, and better insulation property than the synthetic fibre-based composite. Natural leaf fibre composites have low machining wear with low cost and excellent performance in engineering applications, and hence established as superior reinforcing materials compared to other plant fibres.

1. Introduction

The evolution of various efficient natural fibres as reinforcing material made natural fibre polymer composites (NFPC’s) a key attraction for the couple of decades. In the present scenario, scientists and technologists have highlighted natural fibres supremacy over synthetic fibres as reinforcement materials. Synthetic fibres (for e.g. glass fibre and carbon fibre, etc.) were used earlier in polymer composite because of their high mechanical strength in various engineering applications. In view of environmental concern, the synthetic fibre polymer composite materials are not eco-friendly and non-biodegradable. However, when natural fibre is introduced in the field as a replacement for synthetic fibre, many studies have reported that natural fibre-reinforced polymer composite sustainability is high [1][2][3][4][5][6][7][8][9]. Its acceptability to the environment is better due to renewability and biodegradability. Nowadays, researchers are developing the governing acts and general social perception regarding energy, raw material wastage, and pollution towards the environment. The issue can be minimized by using natural fibres. Ancient civilizations were involved in using natural fibres in various forms to meet their requirements. As time passed, the fibre extraction from the plant became significant and easy due to advancement in technology.

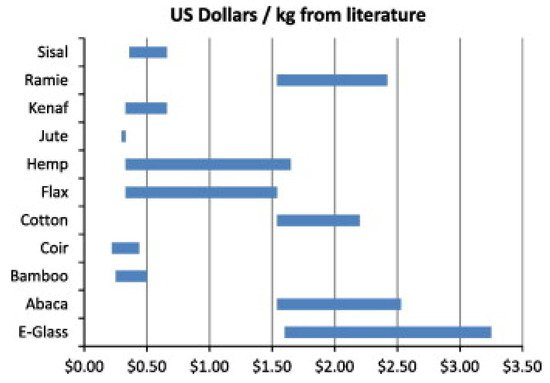

NFPC’s and their utilization have increased tremendously in various engineering applications like automobile, packaging, structural component, aerospace, marine, electronic industry, sports goods, microbial fuel cell, air filter, and housing panels. The NFPC’s showed high strength due to the presence of the cellulosic component. Recently, industries found that natural fibres have great potential in the outdoor insulation, production of nano-whisker and packaging applications [9]. NFPC’s demonstrated several advantages such as high specific strength, wide availability, low density, renewability, high stiffness, a high degree of flexibility, less energy expenditure, low health risk, and low abrasiveness. NFPC’s are biodegradable, inexpensive, and own excellent mechanical performance, which made them a favorite attraction for many industries [10]. NFPC’s also offers disadvantages to some extentas natural fibres are hydrophilic, increased water intake while matrices are hydrophobic (water-resistant) which decreases the adhesion behaviour between fibre and matrices causing a reduction in their physical and mechanical properties [11]. However, various treatment methods of natural fibres increase the fibre/matrix adhesion as reported in literature for enhancing the adhesion in fibre/polymer composite material [12][13]. The cost comparison is an essential factor, since natural fibres have much lower density and strength than glass fibres. Cost per weight comparison between glass and natural fibres is shown in Figure 1 [14]. The figure clearly states that natural fibres, mainly bamboo, sisal, jute, kenaf, are useful to compete with glass fibres. Overall, it was found that lower densities of natural fibres are cheap compared to glass fibres [14].

Figure 1. Cost per kg weight comparison between glass and natural fibres. Reprinted with the permission from Reference [14]. Copyright 2012 Elsevier.

Bio-composites materials have played a promising role in their substituting petrochemical materials with materials having less greenhouse gas emissions [15]. Natural fibre composites usage would provide an alternative to minimize carbon footprint due to the capability of carbon dioxide (CO2) absorption by natural fibre resources [16][17][18].

2. Classification of Natural Leaf Fibers

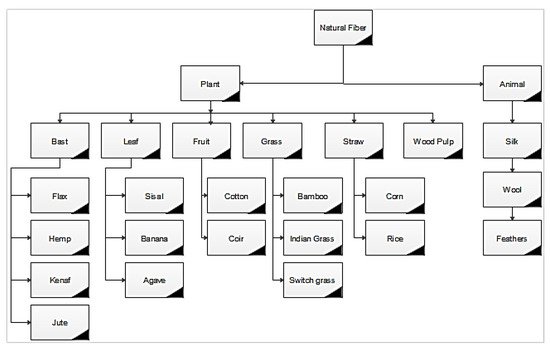

The natural fibre is classified into two forms namely, plant fibre and animal fibre. Natural fibre can be extracted from plants and classified according to their utilization. The fibre is directly extracted from the primary plant, and fibre is produced as a by-product called secondary plant [19]. A broad classification of the natural fibres is shown in Figure 2, as reported by Zini et al. [20]. The primary fibres are jute, hemp, Kenaf, sisal, and secondary fibres are pineapple, oil palm, and coir. The leaf fibers are a group of long, multiple-celled lignocellulosic fibers extracted from plants, generally, organize as leafage. While leaves can be diversified in appearance and function, the leaf that can be used for the production of fiber tends to be short and long, with limited structures that can be mechanically detached with relative comfort. The leaf of different lignocellulosic plants that are generally used as reinforcement for polymer composites material comprises those of sisal, agave, banana, pineapple, abaca, and date palm fiber [21][22][23]. Sisal leaf fiber, also known as agave sisalana, is commonly produced in tropical countries, e.g., Brazil and East Africa. Its life span is about 7–10 years, with 200–250 leaves, and each of them extracts about 1000 bundles of fiber [24]. The sisal plant generally grows up to 2 m; sisal fiber length varies according to climatic condition, i.e., 6–1.5 m. The leaf of the sisal plant is enclosed with three categories of fiber: structural, arch, and xylem [10]. Among three, the structural fiber is the most important type, due to non-split nature at the time of extraction, arch fiber has the ability to hold high mechanical strength and hence use in short fiber application. However, xylem fiber is lost at the time of extraction. Sisal fiber has a dominant fiber due to its strength, endurance, stretch ability, and resistance ability to degradation in saltwater. However, as the temperature increases the mechanical strength, toughness, and modulus is decreases [25]. The overall requirement for sisal lignocellulosic fibre and its commodity somehow decreased in years 1998–2000 and 2010 by a yearly rate of 2.3% in terms of agricultural yarn. Agave fiber belongs to the same family of sisal plant fiber. It is extracted from basal part of agave plant, length of fiber is about 0.5–2.2 m long, thick, flat, and margins outwardly directed spines. It is generally used to make ropes, mats, and twines in rural areas. It generally grows in dry uncovered waste lands mostly above 1300 m. It is generally found in the north and south region of India and its native plant is also found in North America.

Figure 2. Classification of natural fibre. Adapted with the permission from Reference [20]. Copyright 2011 John Wiley and Sons.

Banana is the largest growing aromatic flowering plant. The leaves of the banana plant are arranged spirally and can grow up to 2.0–2.7 m long. They are usually used as eco-friendly biodegradable plates and food containers in most Asian countries. The chemical constituent such as cellulose in banana and sisal lignocellulosic fiber is almost the same, but the structure of the banana fiber is different than sisal fiber, i.e., the spiral angle is 11° in a banana and 20° sisal [26]. Therefore, the mechanical strength of the banana fiber is higher than sisal [27]. Pineapple fiber is extracted from the leaves of the pineapple plant, and it is found generally in Asia and the Philippines. It is mixed with polyester or silk to produced fabric for textiles, mops, curtains, and carpets. The pineapple plant spreads all over the tropical countries as fruit, and thus pineapple fiber is treated as an agricultural by-product. The leaves of the pineapple plant are long, about 1 m, but the crop of the pineapple plant has a short stem. The chemical content present in pineapple fiber is identical to flax fiber, and the structural angle is comparably lower (14°). The mechanical strength of pineapple fiber is similar as compared to jute fibers, but the fiber structure of pineapple has no mesh. Pineapple fibre is highly microscopic, and the fiber strength can reduce by 50% when pineapple fibers are wet [28]. Abaca plant belongs to indigenous banana species generally produced in the countries like the Philippines. The leaf height of the abaca plant is about 3–4 m. Fiber is extracted from the leaf wrap of the abaca plant, also known as “manila hemp” even though it does not belong to bast fiber. It is usually used for ropes and twines. It is chosen as the strongest among all lignocellulosic plant fibers because its mechanical strength is three times more than cotton and two times better more than the sisal fiber. Additionally, it has a superior capability to resist salt water [10]. Date Palm fiber is cultivated from sweet palm fruit-growing trees native to Northern Africa, India, Middle East, India, United States (US), and the Canary Islands. The general palm tree leaf is 3–5 m long. The stem part of the palm tree is wrapped in a single fiber with mesh. Usually, these fibers are mostly used to make baskets and ropes [10].

3. Physical and Mechanical Properties of Natural Fibre Composites

Physical and mechanical properties of natural fibre composite’s (NFC’s) such as tensile, flexural, impact, and water absorption are the most general tested properties. The natural fibre selection for different applications depends on the NFC’s strength [29]. The factors that influence NFC’s mechanical properties are matrix selection, polymer interface strength, dispersion, orientation, manufacturing process, and porosity [30]. The tensile properties are improved by adding fibre to the polymer matrix because they have higher values of strength and stiffness as compared to matrices. When the weight ratio increases near the optimum values (i.e., maximum fibre loading), it increases the load distribution, which is strongly bonded with matrix and resin, thus revealing better tensile strength. Higher fibre loading is required for achieving the high performance for short-reinforced polymer composite [31]. The properties of flexural strength are completely dependent on the bottom and top surfaces of the specimen. The flexural stiffness is a criterion for measuring the deformability of the sample. The material structure’s flexural stiffness depends on two essential properties: elastic modulus (stress per unit strain) and its moment of inertia around the cross-sectional geometry of the material [29]. Fracture toughness is the most important characteristic property of the material. Impact strength is the energy required to cause damage and the failure progress in the composite. The composite toughness relies on natural stress and strain behaviour. Fibres with superior mechanical properties show the highest impact strength. Water absorption behaviour shows the hydrophilicity of the fibre to take maximum water in the presence of holes and voids. Some challenges are still present in leaf fibre-reinforced polymer composite. At first, eco-friendly fibre surface treatment should be developed and implemented. Secondly, natural fibre’s basic characteristics should be identified before it will introduce in polymer, enhancing the quality of fibre matrix adhesion. The current challenge is to make them cost-effective. The efforts to produce economically attractive composite components have resulted in several innovative manufacturing techniques currently being used in the composites industry. Additionally, flammability is one of very important phenomena that often limits the application of composites to a given area. However, very little information is available on their fire performance. Thermal stability of natural fibers, moisture content of the fibers and biodegradation and photo degradation of natural fibers is one big issue in the natural fiber polymer composite.

Different chemical treatments can resolve this problem, like alkali treatment such as NaOH. However, silane treatment plays a crucial role in leaf fibre polymer composite to enhance NFC’s physical and mechanical properties. For example, surface modification helps to improve natural fibre network structure. For example, alkaline treatment (NaOH) creates a disturbance of hydrogen bonds in the fibre, therefore increasing the fibre’s surface roughness. The alkaline treatment eliminates the assured quantity of oil, wax, inorganic salt, and lignin, which covered the fibre outer surface, uncover the short length crystallites, and cellulosic component is depolymerized. On the other hand, silane was used as a coupling agent. Silane coupling agents can decrease the number of non-cellulosic components in the fibre–matrix interface. Additionally, the silane coupling-treated natural fiber polymer composites are thermally stable as compared to other surface modifications. Leaf-extracted fibre has low density, high specific strength, and modulus. Leaf fibre, i.e., Sisal, abaca, pineapple, agave, and banana fibre used in a polymer composite, is useful in a lightweight material potential resource like packaging industry, interior paneling in the automobile industry, and house holding application. Availability and cost of natural leaf fibre much low as compared to other natural fibre. Additionally, the use of eco-friendly chemical treatment can improve the thermal stability of natural leaf fibres-reinforced polymer composite.

3.1. Sisal Fiber Composite

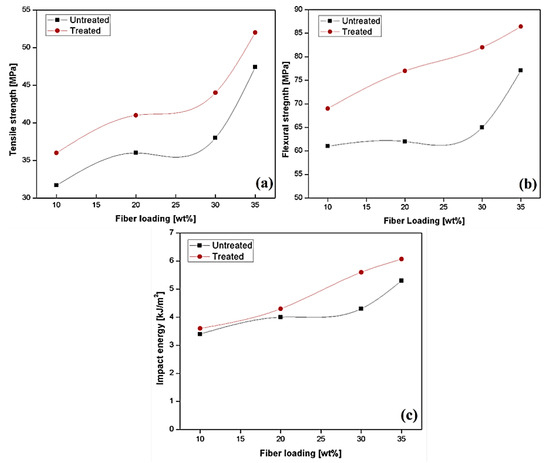

A study on unidirectional Sisal-epoxy composite with alkali treatment of 2% sodium hydroxide (NaOH) was reported by Rong et al. [32]. The tensile property of the composite material was increased as fibre loading increased. However, a further increase of fibre- loading in matrix resulted in a decrease in the tensile strength due to the cavities present between the fiber-matrix contacts. An alkali treatment linearly increased the tensile strength because of better fibre adhesion with the matrix. The surface modification (alkali treatment) made the surface much coarser compared to untreated/epoxy composite. The flexural strength of the unidirectional sisal-reinforced epoxy composite was controlled by resistance to inter-laminar failure. It was reported that the flexural strength increased with alkali treatment. The main reason for the increase in the strength was due to epoxy, which was capable of filling up the apparent flaws resulting in better load sharing [32]. Nimanpure et al. [33] studied the 5 wt. % of alkaline (NaOH)-treated sisal fibrils epoxy composite with fibre loading 10–35 wt. %. The tensile strength of treated (NaOH) sisal composite was higher than untreated sisal composites, and as the fibre loading increased, the tensile strength increased for both treated and untreated composites, as shown in Figure 3. NaOH treatment caused the removal of the hemicellulose and lignin components. Decreasing the hemicellulose content led to the reduction of rigidity and density of the interfibrillar region. Therefore, fibrils were highly capable of reorganizing themselves along with the tensile deformation direction. Reorganization led to an increase in the transfer of load capacity among the fibril, hence increased the higher stress-bearing capacity. Lignin removal caused the elimination of micro-voids; hence the middle lamella of the fibrils was more homogeneous and plastic. Flexural strength and impact energy showed similar trends as tensile property as shown in Figure 3 [33]. The treated composite also showed good interfacial bonding between fiber and matrix.

Figure 3. (a) Tensile (b) Flexural, and (c) Impact strength at fiber loading (10, 20, 30, and 35 wt. %) of untreated and 5 wt. % of alkali (NaOH)-treated sisal-reinforced epoxy composite. Adapted with the permission from Reference [33]. Copyright 2017 John Wiley and Sons.

Mechanical properties of short sisal epoxy composite with varying length 5–20 mm was reported by Maya et al. [34]. The 5 mm sisal-based composite had the least tensile strength due to short epoxy composite underwent cluster formation and not mixed uniformly with the matrix. The tensile strength initially decreased with the dispersion of shorts, but with the increase in the length of sisal fibres, the tensile strength was slightly enhanced, i.e., 32.2 MPa to 45.45 MPa. At the same time, the flexural strength and impact strength was increased with an increase in fibre length. The result indicated that with long length, the interfacial bonding of fibre and matrix was enhanced. The 20 mm length of sisal epoxy composite showed the highest mechanical properties [34]. Yan et al. [35] studied the mechanical properties of sisal lumen-reinforced epoxy composites. The epoxy resin ratio filled in the sisal lumen was adjusted by injecting in an aligned direction at the required pressure. At low injection pressure, the resin amount penetrated more in the sisal lumen and strengthened the sisal. The crack phenomenon of the resin penetrated sisal was hindered, and thus the crack propagation was decreased. Additionally, resistance towards the water uptake was increased due to the lumen space’s occupation by the hydrophobic epoxy resins. Thus, mechanical properties like tensile, flexural, impact strength and water absorption were increased with more lumen filled with the resin [35]. Beetle et al. [36] studied the fracture mechanism for randomly chopped sisal fibre reinforced epoxy composite with different loading, i.e., 15, 25, 30, 35, and 40 wt. %. The result showed that as the loading increased, the fracture toughness properties of sisal/epoxy composite were increased till 30 wt. %, but after 30 wt. %, the fracture toughness was decreased. This showed that 30 wt. % of fibre loading was the optimum value for sisal-epoxy composite. Decreasing the toughness after 30 wt. % revealed the poor interfacial bond between matrix and chopped sisal [36]. The mechanical properties of unidirectional sisal/epoxy composites prepared by resin transfer moulding (RTM) were investigated by Oksman et al. [37]. The studies explained that the tensile strength increased as the fibre loading was increased. The mechanical test results indicated that the mechanical properties of sisal-epoxy composite showed higher modulus (40 GPa) compared to the mechanical sisal test (24 GPa), i.e., absence of matrix. On the other hand, the effective strength of technical composite strength was lower than measured technical strength. This showed that the low strength weight fraction of the mechanical commanded the composite. Additionally, the more uniform sisal distribution in composite improved the fibre matrix adhesion in sisal–epoxy composites [37].

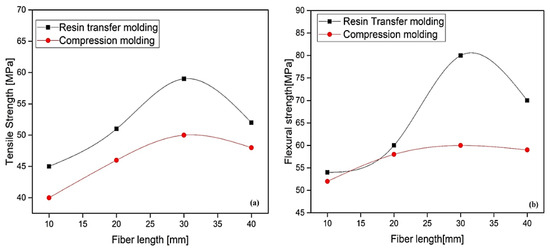

Sreekumar et al. [38] reported the influence of surface modification on the mechanical and water absorption properties of sisal/polyester composites manufactured by resin transfer moulding (RTM). Chopped sisal was treated with different surface modification chemicals, i.e., permanganate, silane, benzoyl chloride, sodium hydroxide (NaOH). The chemical treatments and the physical treatment like heating (100 °C) improved the interfacial bond between fibre and polyester resin. The treatment also indicated that impact properties were decreased as compared to untreated sisal/polyester composite. The study showed that water uptake was also decreased with treatment which supported the higher sisal–polyester interaction. Properties like sorption, diffusion and permeability coefficient decreased after different treatments [38]. Mechanical properties of sisal-reinforced polyester composites fabricated by RTM and compression moulding (CM) were studied and compared. The tensile strength at different lengths for RTM and CM is shown in Figure 4a. Flexural strength at different loading for both RTM and CM is shown in Figure 4b. The mechanical properties like tensile and flexural strength were studied as a function of length (10, 20, 30, and 40 mm) and fibre loading for both fabrication methods, i.e., RTM and CM. The tensile and flexural strength of length 30 mm demonstrated the maximum strength by the RTM technique compared to CM. This maximum tensile strength and flexural strength delivered with 30 mm length at 30 vol. % of fibre loading attributed to CM due to superior interfacial bonding between fiber and matrix [39].

Figure 4. (a) Tensile strength, and (b) Flexural strength at different lengths (10, 20, 30, and 40 mm) at 30 vol. % of sisal/polyester composites. Adapted with the permission from Reference [39]. Copyright 2009 Elsevier.

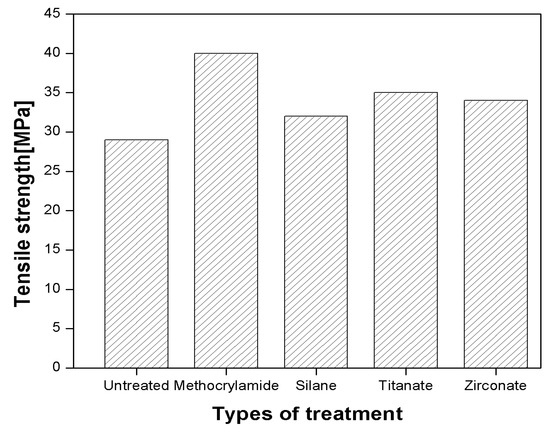

Singh et al. [40] reported the effect of different chemical treatments, i.e., titanate, zirconate, silane, and N-substituted meth-acrylamide, on the mechanical properties of sisal fibre-reinforced polyester composites. An improvement in mechanical properties was observed when sisal fibres were modified with surface treatments. Under dry conditions, i.e., unmodified, a decrease of 30 to 44% in tensile strength and 50 to 70% in flexural strength was reported due to higher hydrophilicity. It was observed that the extent of moisture/water absorption of surface-treated fibres had been reduced significantly by providing hydrophobicity to the surface via long-chain hydrocarbon attachment. The different surface modifications of sisal fibre showed an improvement of 15 to 33% in tensile strength and 21 to 29% in both flexural strength and modulus (silane-treated samples showed an improvement of 62% in flexural properties). This improvement indicated an improved fibre-matrix adhesion due to surface modification. The tensile strength of different treatments is shown in Figure 5 [40].

Figure 5. Influence of different chemical treatment on tensile strength of sisal/polyester composite (50 vol. % of sisal fiber). Reprinted with the permission from Reference [40]. Copyright 2004 John Wiley and Sons.

Sangthong et al. [41] studied the mechanical properties of untreated and treated sisal polyester composite. Sisal surfaces were modified by 6% NaOH, and further, the fibres were coated by ad-micellar polymerization with a poly methyl methacrylate. It was observed that both tensile and flexural properties were increased with increasing fibre loading, up to 30 vol. %, and after that, the tensile properties were slightly decreased at 40 vol. % fibre loading for all types of sisal fibres composite due to poor adhesion of fibre and matrices. Additionally, both impact and hardness properties were increased with increasing the fibre loading and length. Higher amounts of the coating were also found to impart higher impact and hardness properties. After treatment, moisture absorption of the composite was reduced to almost 50% (7.98% to 4.48%). Similarly, as the length increased from 10–40 mm at 30 vol. % loading of fibre, the tensile and flexural strength delivered maximum value at 30 mm length. At high loading, it was more difficult for the resin to penetrate the decreasing spaces between the fibres, thus causing poor wetting, and hence, a reduction in the stress-transfer efficiency between fibre-resin interface. This study exhibited the optimum value of fibre loading is 30 vol. % and 30 mm of length for all sisal-polyester composites [41].

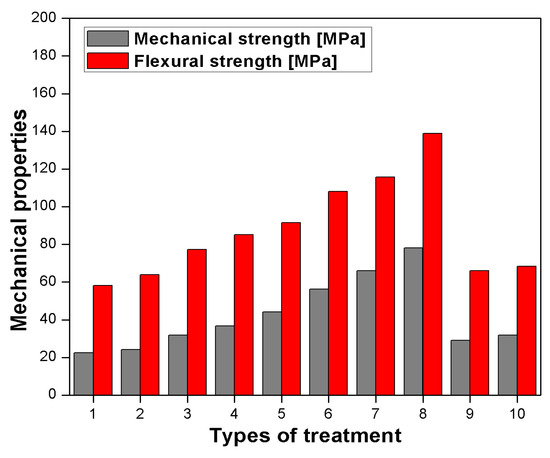

The mechanical properties of sisal-reinforced polyester composites with different concentration of alkali treatment (aqueous NaOH) was reported by Khanam et al. [42]. It was evident from Figure 6 [42], that the tensile and flexural strength linearly increased with NaOH concentration. The tensile and flexural strength of sisal/polyester composite were found maximum at boiled 18% aqueous NaOH solution treatment. At boiled 18% aqueous NaOH solution, all the natural and artificial impurities were removed, creating a rough surface. The rough surface led to a better/matrix adhesion, which increased sisal/polyester composite’s mechanical properties. Influence of surface modification on mechanical properties untreated and treated sisal fibre composites. The impact of different treatments (5, 10 and 18% aqueous NaOH boiled and treated, acetic acid-treated, and methanol treated) of sisal fibre on the tensile and flexural strength of sisal fibre composites was enhanced at 18% NaOH boiled sisal fibres due to roughness of fibre after treatment and adhesion between fibre and matrix were improved. This is because alkali treatment can remove natural and artificial impurities and produce a rough surface topography. This topography offers better fibre matrix interface adhesion and an increase in the mechanical properties of the composites. There is a lot of betterment in strength and modulus with 18% NaOH boiled sisal fibres, which again shows, at high temperature, a rougher surface might have taken place. This rough surface increases the interface bonding between the fibre and the matrix.

Figure 6. Mechanical properties of (1: Neat polyester; and different concentration of chemical treatment 2: untreated Sisal fibre; 3: 5% NaOH-treated; 4: 5% NaOH boiled; 5: 5% NaOH-treated; 6: 10% NaOH boiled; 7: 18% NaOH-treated; 8: 18% NaOH boiled; 9: 20% acetic acid-treated 10: methanol-treated) sisal/polyester composite.

3.2. Abaca Fibre Composite

Liu et al. [43] studied the effect of chemical treatments on transverse tensile properties of unidirectional abaca/epoxy composite. The transverse tensile test was performed to analyze the linkages in a unidirectional abaca-epoxy composite. It was revealed that the transverse tensile behaviour of unidirectional composite purely depended on the bond between fibre and matrix. The chemical composition of lignin and hemicellulose showed a reducing effect on transverse tensile behaviour. Salinization and light mercerization (1.0 wt. % NaOH solution for 5 min) played a key role in enhancing the/epoxy interfacial strength, while a heavy surface modification, i.e., 5.0 wt. % NaOH solution for 30 min decreased the fiber-matrix adhesion, and led to resin interface modification and affected the lumen size, which weakened the interfacial bonding between fibre and matrix [43].

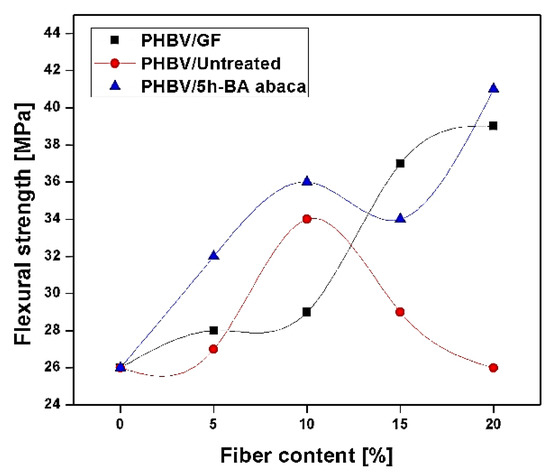

The influence of alkali treatment on abaca-reinforced composites was reported by Cai et al. [44]. The abaca fibres were immersed for 2 h with an aqueous solution of NaOH having a different concentration of 5, 10, and 15 wt. % for better penetration of NaOH solutions into the bundles. The untreated abaca showed a tensile strength of 717 MPa and Young’s modulus of 18.6 GPa. The abaca fibres treated with 5% of NaOH solution showed an increment in tensile strength by ~8% and in tensile modulus by 36% in comparison to untreated abaca fibres. Above 5% NaOH treatment, i.e., 10% and 15% of abaca, the mechanical strength was found to deteriorate due to excess elimination of binding material (cellulose and hemicellulose) due to interactions of highly concentrated alkali environment. The 10 and 15% NaOH-treated abaca fibres-reinforced epoxy composites maintained their tensile strength of 682 ± 83 MPa and 670 ± 26 MPa, respectively, but their Young modulus was decreased by 34% and 49%, respectively. Abaca bundles treated in 5 wt. % NaOH showed high cellulose crystallinity and minimal fibrillation and exhibited tremendous interfacial adhesion with epoxy resin. Results indicated that the low concentration of alkali treatments (5%) was beneficial in improving the surface properties and its performance of abaca fibres for leading composites applications [44]. Shibata et al. [45] studied flexural strength of untreated abaca fiber, and butyric anhydride (BA)-treated abaca fiber-reinforced with biodegradable polyester, i.e., poly (3-hydroxybutyrate-co-3-hydroxyvarelate) (PHBV) composite, and compared with PHBV-reinforced with GF, i.e., PHBV-GF composites. The abaca fiber was treated with butyric anhydride (BA) for 5 h and reinforced with PHBV biodegradable polyester, represented as PHBV/5h-BA abaca in Figure 7. The result showed that PHBV/5h-BA abaca-treated composite showed maximum flexural strength as compared to untreated PHBV/abaca composite (PHBV/untreated). On the other hand, when fiber loading increases, i.e., 5–20 wt. %, the flexural strength at 20 wt. % of PHBV-treated abaca showed the highest flexural strength (41 MPa) as compared to PHBV-untreated abaca fiber and PHBV-GF composite. This showed that the interfacial adhesion between fiber and matrix became superior due to treatment, as shown in Figure 7 [45].

Figure 7. Flexural strength of biodegradable polyester composite-reinforced with glass fiber (PHBV/GF) composite, PHBV/untreated abaca composite, and PHBV/5h-BA abaca composite at different fiber loading (5–20 wt. %). Adapted with the permission from Reference [45]. Copyright 2002 John Wiley and Sons.

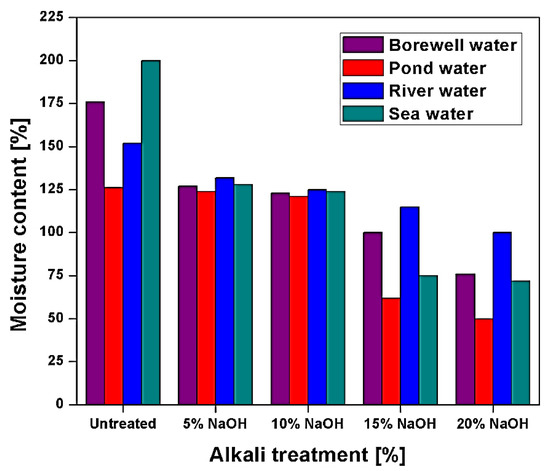

Punyamurthy et al. [46] investigate the water absorption behaviour of untreated and alkali-treated abaca fibre with different water resources. Moisture absorption studies are done with four different water sources, i.e., seawater, pond water, river water, and borewell water. Alkali treatment of abaca fibre is done by 5–20% of NaOH. Result suggests that as the concentration of treatment increases, the water absorption of abaca fibre is decreased, as shown in Figure 8 [46]. Pond water showed the least water absorption as the concentration of the alkali treatment is increasing; this is due to excessive removal of lignin and hemicellulose content which reduces the hydrophilicity of the abaca fibre [46].

Figure 8. Water absorption tendency of untreated and alkali (NaOH)-treated single abaca fibre from different water sources [46].

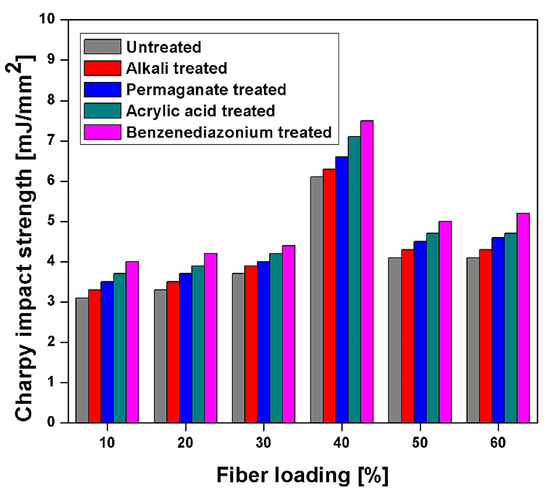

Punyamurthy et al. [47] studied the Charpy impact strength of different surface modification techniques for abaca-reinforced epoxy composite. It is treated with different chemical treatments, i.e., Alkali (6% NaOH), Acrylic acid (1%), Permanganate treatment (0.5% KMnO4), and benzene-diazonium chloride solution for better surface modification. The study is done with different loading 10, 20, 30, 40, 50, and 60 wt. %. Further, 40 wt. % loading of all the different treatments shows maximum impact strength as shown in Figure 9 [47]. This is because at 40% loading, composite showed better distribution in the matrix, low fractures, and better transfer of load from fibre to the matrix. After 40% of loading, impact strength decreased due to poor bond and less transfer of load from the matrix to fibres. Untreated composites showed poor mechanical properties due to easy pullout from the interfacial between the fibre and matrix. Simultaneously, alkali treatment removes non-cellulosic components and more hydroxyl (-OH) groups in the surface to improve fibre-matrix adhesion. KMnO4 treatment deliver better interlink at the interface by accomplishing rough surface to improve the fiber-matrix bond. Similarly, acrylic acid improves stress transfer capability to the fibres and matrix to enhance the impact strength.

Figure 9. Influence of chemical treatment on impact strengths at different fiber loading (10–60 wt.%) of abaca-reinforced epoxy composite.

Paglicawan et al. [48] investigated the mechanical properties of plasma and alkali-treated abaca/epoxy polymer composite. The abaca fibre is put between the electrode plate in which plasma polymerization takes place. Acrylic acid was used as a monomer for surface modification by plasma polymerization. On the other hand, hybrid treatment of 2% NaOH (alkali-treated) was used for abaca fibre at a different times for plasma treatment. The tensile strength of the composites treated with plasma was better for those with hybrid treatment and no treatment due to better adhesion. The composite’s water absorption is shown to reduce with increase plasma disclosure time and reduced with combined treatment of NaOH and plasma [48]. Chemical treatment of waste abaca-reinforced fly ash is investigated by Malenab et al. [49]. Alkali pre-treatment of 6% NaOH is introduced to remove impurities result create a rough surface. NaOH-treated abaca is then treated with aluminum sulphate Al2(SO4)3. Chemical treatment of waste abaca enhances the structure and chemical composition, and high tensile strength is achieved by removing non-cellulosic components like pectic, wax, hemicellulose, and lignin. Geopolymer itself is coated in the composite to become a barrier to the pre-treated composite’s thermal degradation. The aluminum sulphate treatment indicates that it deposits the Al(OH)3 and roughens the surface for better fibre-matrix adhesion to protect the fibre from the harsh environment [49].

Ahmed et al. [50] reported the effect of silane-modified and vinyl ester on the mechanical properties of abaca composites. A vinyl ester with 1 wt. % of Hexamethyldisiloxane (HMDS) silane modification with dispersion time of 120 min showed 10% more tensile strength than untreated vinyl ester composite due to the homogeneity of the dispersion of resin components after stirring for an appropriate time. On the other hand, at 2 wt. % of HMDS silane modification-vinyl ester abaca fibre, the tensile strength increases about 18% because vinyl ester is adsorbed to the hydroxyl (-OH) groups of natural abaca fibres by hydrogen bonds on the surfaces and improve adhesion between fibre and matrix. Similarly, 2 wt. % of HMDS-vinyl ester composite showed higher flexural strength. Water absorption is at least at 3 wt. % of HMDS-vinyl ester composite due to the removal of non-cellulosic components and decreases the composite’s hydrophilicity [50].

Liu et al. [51] studied alkali (NaOH)-treated abaca-reinforced friction composites. The chopped abaca of 10 mm length and treated with 3 wt. % of alkali treatment and then soaked with 1 wt. % of sulphuric acid (H2SO4) solution. The tensile strength of treated abaca is increased by 5.19%, and elastic modulus is enhanced by 2.61% MPa. The result illustrates that the stiffness and brittleness of the abaca composite improved after alkali treatment. The impact strength of specimens is improved initially and then decreased with the increase of abaca fiber loading. At 3 wt. % of abaca fibre shows maximum impact strength because of better interfacial bonding between matrix and fibre due to chemical treatment [51]. Batara et al. [52] studied the influence of chemical treatment of alkaline and permanganate treatment on abaca’s mechanical properties. The mechanical properties illustrate the combination and individual of both the chemical treatment. It is treated with 10% of NaOH with different concentrations of permanganate treatment, it is also exposed individually for permanganate for a respective time. The result indicates that the tensile strength exposed to 0.125% potassium permanganate for 3 min showed maximum tensile strength. This is due to treated fibers having fewer hemicellulose and lignin as compared to the untreated, as treatment is known to eliminate the lignin and hemicellulose component. Those treated directly with KMnO4 exhibited the cleanest surface which enhances the mechanical property [52].

3.3. Pineapple Fibre Composite

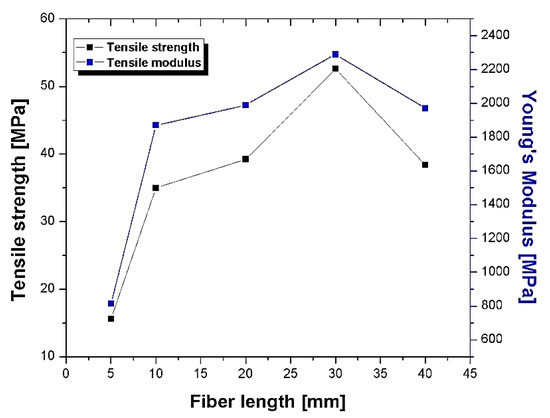

The influence of different chemical treatments (alkali, silane A-172) on fibre length and loading on mechanical properties of different chemical-treated pineapple-reinforced polyester composites was reported by Devi et al. [53]. The chopped ones with different lengths 5–40 mm were studied, and results indicate that after the length is increased from 5 mm to 30 mm, it shows a decreasing trend. At 30 mm long fibre, the tensile, flexural, and impact strength is the maximum due to entanglements that occur above an optimum size. Similarly, as fibre loading increases, the tensile and flexural strength is increased at 30 wt. %. This showed that 30 mm and 30 wt. % is the optimum value of pineapple polyester composite in this investigation, as shown in Figure 10 [53]. At different nature of treatment silane, A-172-treated showed superior mechanical properties as compared to alkali, and other silane-graded-treated composites.

Figure 10. Tensile properties of chopped pineapple leaf fiber (PALF) with different fibre lengths (5–40 mm) at 30 wt. % of PALF reinforced with polyester composite. Adapted with the permission from Reference [53]. Copyright 1998 John Wiley and Sons.

Mishra et al. [54] reported mechanical properties of different surface modifications on pineapple leaf fibre (PALF) polyester composite. Detergent washed (ethanol and benzene) alkali-treated (5%, NaOH), grafted acrylonitrile (AN), and cyanoethylated PALF polyester composites were fabricated and compared. The tensile strength of the alkali-treated pineapple polyester composite showed a maximum value of 44.77 MPa because alkali treatment removes the impurities from the surface of the material and enhances the fibre-matrix adhesion as compared to other surface modifications. Additionally, the grafted AN modification at 10 wt. % concentration the flexural strength is maximum due to wettability and better fiber-matrix adhesion. However, a further increase in grafting tends to decrease in flexural strength by 20% drastically due to significant breakage and delamination [54]. Water absorption and mechanical properties of the pineapple-reinforced polyester composite are reported by Devi et al. [55]. PALF polyester composite showed a 123% increment in the water absorption capacity as loading increased from 30 wt. % to 40%, due to the presence of hydroxyl groups which enhance the absorption of water in composite by developing hydrogen bond. Tensile strength of the composite increases with an increase in fibre loading. At 40 wt. % of loading, maximum tensile strength of 63.3 MPa is shown because of the better interface between fibre and matrix [55].

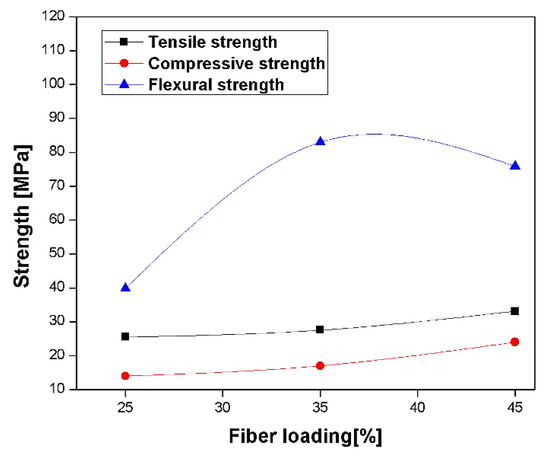

Mechanical and morphology study of PALF reinforced in unsaturated isophthalic polyester composite was reported by Senthil Kumar et al. [56]. Figure 11, showed that the tensile and compressive strength is increased as the fibre loading increases from 25% to 45 wt. %. The improved strength of composites with high fibre loading is due to the improved interfacial adhesion. At the same time, flexural strength is maximum at 35 wt. % of loading. The decrement of flexural strength at 45 wt. % loading, due to undistributed applied stress transfer between the fibre and matrix at higher interaction within the matrix and poor dispersion. In Figure 12a–c [56], the morphology study of the composite in the flexural fracture test is presented. The properties showed a strength of 25 wt. % composite is low, adhesion between fibre and the matrix is improved. On the other hand, it was bending and the poor dispersion of shorts fibre which did not allow the appropriate load transfer. Further, 45 wt. % loading shows the more significant contact between the fibres due to the reduction of the matrix, which can resist the shearing movement across the fibres, and it manages part of the decrement in flexural strength [56]. Impact strength of 3 mm chopped PALF polyester composite with chemical treatment, i.e., sodium hydroxide (NaOH) and potassium hydroxide (KOH) with loading 25%, 35%, and 45 wt. % was observed by Senthil Kumar [57]. The impact strength at 25 wt. % loading composites with NaOH-treated has maximum impact strength (70 J/m) due to better interfacial bonding between the fibre and matrix and removal of soluble oily contents from the fibre as compared to untreated and KOH-treated [57].

Figure 11. Tensile, Compressive, and Flexural strength of pineapple-reinforced polyester composite at different fiber loading (25, 35, and 45 wt. %). Adapted with permission from Reference [56]. Copyright 2019, with permission from Elsevier.

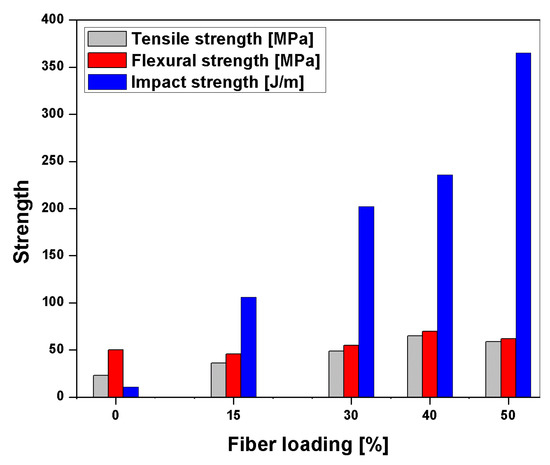

Krishnasamy et al. [58] studied the calcium hydro-oxide (Ca(OH)2)-treated PALF/polyester composite. The chopped 3 mm PALF is treated with 7% of calcium hydro-oxide at different loading, i.e., 25%, 35%, and 45 wt. %. From this investigation, the damping properties are improved due to effectiveness in the load distribution from fibre to the matrix. While maximum impact strength (59.27 J/m) was obtained for 35 wt. %-loaded composite with treated fibres for strong interface bonding. The result showed that PALF is suitable for applications requiring vibration damping and impact resistance [58]. Devi et al. [59] studied PALF reinforced in polyester composite’s mechanical properties with different loading at 30 mm length with 600 aspect ratio (length to diameter). The loading of PALF, i.e., 0, 15, 30, 40, and 50 wt. %, the tensile and flexural strength increases linearly from 0–40 wt. %. Moreover, 40 wt. % of PALF showed maximum tensile and flexural strength due to better adhesion of fibre/matrix. After 40 wt. %, a decreasing effect was shown due to poor dispersion, while impact strength showed an increasing effect as the content was increased. The impact properties of composites increase with the fibre microfibrillar angle when it reaches a maximum value at 15°–20°. In this investigation, the microfibrillar angle is 16°, so the PALF-polyester composite showed superior impact strength, as shown in Figure 13 [59].

Figure 13. Mechanical properties at different fiber loading (0–50 wt. %) of pineapple leaf fiber-reinforced polyester composite. Adapted with the permission from Reference [59]. Copyright 2011 John Wiley and Sons.

The performance of surface treatment on a single PALFepoxy composite was studied by Payae et al. [60]. The PALF is treated with 5% of NaOH for surface modification. Epoxy resin in toluene (1 wt. %) was coated in PALF. The untreated showed the least interfacial shear strength (26.68 MPa) due to poor interlocking, while the alkaline treated showed higher strength (52.39 MPa) compared to the untreated due to increment in surface roughness and area, and thus build up the interaction between pineapple fibre and epoxy. On the other hand, epoxy-coated composite showed a relatively higher interfacial shear strength of fibre about 66.46 MPa; this is due to better load sharing and high-stress reinforcement in the single PALF reinforced-epoxy composite. Similarly, tensile strength showed a similar pattern as interfacial shear stress due to improved stress transfer efficiency at the interface of the matrix in the alkali-treated composite as compared to epoxy-coated composite, as shown in Table 1.

Table 1. Tensile strength of untreated, alkali (NaOH)-treated, and single pineapple leaf fibres (PALF) epoxy composite [60].

| PALF | Young’s Modulus (MPa) |

Tensile Strength (MPa) |

Strain to Failure (%) |

|---|---|---|---|

| Untreated | 12.58 | 532.74 | 4.83 |

| Alkali treated | 15.72 | 635.44 | 4.38 |

| Epoxy-coated PALF | 14.33 | 534.88 | 3.86 |

Lopattananon et al. [61] reported the interfacial adhesion and mechanical properties by surface modification of PALFreinforced in epoxy composites. The PALF is treated with 5% NaOH, 1% di-glycidyl ether of bisphenol A (DGEBA), and 5% NaOH with 1% DGEBA. The flexural strength of 5% NaOH and 5% NaOH with 1% DGEBA showed maximum strength of about 156 and 155 MPa, respectively. Flexural strength is efficient due to fiber-matrix adhesion and more efficient stress transfer. Impact strength of 5% NaOH with 1% DGEBA-treated had superior strength, which means the better combined synergetic effect of NaOH/DGEBA with combined adhesion and fibre toughness. On the other hand, interfacial shear strength of NaOH/DGEBA surface modification showed maximum strength, which suggests that the grafting site of a hydroxyl group (-OH) of lignocellulosic is more efficient as compared to other treatments. Longitudinal tensile strength of natural rubber (NR) composites were at a different percentage of NaOH-treated PALF. The PALF treated with different concentrations of alkali, i.e., 0, 1, 2, 3, 5, and 7%, showed maximum tensile strength as 10.02 MPa treated with 5% NaOH. This indicates that at 5%-treated, PALF showed the effective surface area available for bonding with the matrix and chemical constituents like lignin and hemicellulose from a multicellular as compared to untreated and other percentages of treatment [62]. Mechanical properties of the jute–pineapple–glass in different resin, i.e., epoxy and polyester composite, are studied by Reddy et al. [63]. Volume fraction of hybrid is varied from 0.18, 0.24, 0.30, 0.36 and 0.42% respectively. Epoxy resin composite showed higher strength as compared to polyester resin due to better stress transfer in epoxy matrix resin. At 0.42% of volume fraction of both polyester and epoxy composite, maximum tensile, flexural, and impact strength is shown, but epoxy-fabricated composite showed higher strength as compared to polyester composite. Other thermoset resins like phenol-formaldehyde (PF) and vinyl ester also play a key role in the performance of the natural composite’s mechanical properties. Mangal et al. [64] reported the thermal conductivity of pineapple leaf fibre/phenol formaldehyde composite with different weight fractions of PALF, i.e., 15, 20, 30, 40, and 50%. PALF/PF composites thermal conductivity showed a decreasing trend with increasing PALF fibre content varying from 15 to 50 wt. %. Phenol formaldehyde composite could not improve thermal conductivity because PF is not provided a conductive path to the heat energy to the PALF/PF composite material [64]. Pre-treatment of PALF/vinyl ester composite on tensile properties of the composite is studied by Mohamed et al. [65]. Sodium hypochlorite (NaOCl) solution is used to improve PALF composite to enhance the mechanical properties. Tensile strength and modulus with bleaching effect of NaOCl help to improve about 123% and 35% respectively. This study also suggests that an increase in bleaching reduces the strength due to excessive removal of a cellulosic component. However, fine PALF strands are higher as compared to untreated PALF bundles in terms of tensile strength by 155.3% and modulus by 134.3%, due to better adhesion [65]. PALF fabricated with vinyl ester resin with different loading was investigated by Mohamad et al. [66]. In this investigation, liquid compression moulding (LCM) is used to enhance PALF-reinforced vinyl ester composite properties, mostly water absorption. Cost-efficient pretreatment using a dilute aqueous sodium hypochlorite solution (NaOCl) is used to treat PALF, resulting in enhanced mechanical properties and reduced water absorption. So, using PALF bleached with a higher concentration aqueous NaOCl solution did not improved composite thermal stability because it does not provide a conducive way for heat energy to reach the PALF/PF composite material. This study indicates that aqueous NaOCl may be beneficial in producing vinyl ester composites with improved thermal stability [66]. In conclusion, pineapple leaf surface modification with the different matrix can be cost-effective and add value to composite materials.

References

- Cheung, H.-Y.; Ho, M.-P.; Lau, K.-T.; Cardona, F.; Hui, D. Natural fibre-reinforced composites for bioengineering and environmental engineering applications. Compos. Part B Eng. 2009, 40, 655–663.

- Holbery, J.; Houston, D. Natural-fiber-reinforced polymer composites in automotive applications. JOM 2006, 58, 80–86.

- Sanjay, M.R.; Arpitha, G.R.; Naik, L.L.; Gopalakrishna, K.; Yogesha, B. Applications of Natural Fibers and Its Composites: An Overview. Nat. Resour. 2016, 7, 108–114.

- Mohammed, L.; Ansari, M.N.M.; Pua, G.; Jawaid, M.; Islam, M.S. A Review on Natural Fiber Reinforced Polymer Composite and Its Applications. Int. J. Polym. Sci. 2015, 2015, 1–15.

- Duan, L.; Yu, W. Review of recent research in nano cellulose preparation and application from jute fibers. In Proceedings of the 2016 3rd International Conference on Materials Engineering, Manufacturing Technology and Control, Taiyuan, China, 27–28 February 2016.

- Burgueño, R.; Quagliata, M.J.; Mehta, G.M.; Mohanty, A.K.; Misra, M.; Drzal, L.T. Sustainable Cellular Biocomposites from Natural Fibers and Unsaturated Polyester Resin for Housing Panel Applications. J. Polym. Environ. 2005, 13, 139–149.

- Lescher, P.; Jayaraman, K.; Bhattacharyya, D. Characterization of water-free thermoplastic starch blends for manufacturing processes. Mater. Sci. Eng. A 2012, 532, 178–189.

- Le Phuong, H.A.; Ayob, N.A.I.; Blanford, C.F.; Rawi, N.F.M.; Szekely, G. Nonwoven Membrane Supports from Renewable Resources: Bamboo Fiber Reinforced Poly(Lactic Acid) Composites. ACS Sustain. Chem. Eng. 2019, 7, 11885–11893.

- Zhang, S.; Tanioka, A.; Okamoto, M.; Haraoka, Y.; Hayashi, N.; Matsumoto, H. High-Quality Nanofibrous Nonwoven Air Filters: Additive Effect of Water-Jet Nanofibrillated Celluloses on Their Performance. ACS Appl. Polym. Mater. 2020, 2, 2830–2838.

- Fuqua, M.A.; Huo, S.; Ulven, C.A. Natural Fiber Reinforced Composites. Polym. Rev. 2012, 52, 259–320.

- Prasad, L.; Singh, G.; Yadav, A.; Kumar, V.; Kumar, A. Properties of functionally gradient composites reinforced with waste natural fillers. Acta Period. Technol. 2019, 50, 250–259.

- Begum, K.; Islam, M.A. Treatment of Shear Stress versus Shear Rate Data for Natural Fiber Reinforced Polymer Composites: A Discussion. J. Sci. Res. 2019, 11, 89–100.

- Prasad, L.; Kumar, S.; Patel, R.V.; Yadav, A.; Kumar, V.; Winczek, J. Physical and Mechanical Behaviour of Sugarcane Bagasse Fibre-Reinforced Epoxy Bio-Composites. Materials 2020, 13, 5387.

- Dittenber, D.B.; GangaRao, H.V. Critical review of recent publications on use of natural composites in infrastructure. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1419–1429.

- Patel, M.; Narayan, R.; Mohanty, A.K.; Misra, M.; Drzal, L.T. How Sustainable Are Biopolymers and Biobased Products? The Hope, the Doubts, and the Reality. In Natural Fibers, Biopolymers, and Biocomposites; CRC Press: Boca Raton, FL, USA, 2005.

- Hanana, F.E.; Rodrigue, D. Rotational Molding of Polymer Composites Reinforced with Natural Fibers. Plast. Eng. 2015, 71, 28–31.

- Santulli, C.; Sarasini, F.; Puglia, D.; Kenny, J.M. 8 Injection moulding of plant fibre composites. In Advanced Composite Materials: Properties and Applications; De Gruyter Open Access: Warsaw, Poland, 2017; pp. 420–439.

- Chaitanya, S.; Singh, I. Processing of PLA / Sisal Fiber Biocomposites Using Direct and Extrusion-Injection Molding. Mater. Manuf. Process. 2017, 32, 468–474.

- Kamath, S.S.; Sampathkumar, D.; Bennehalli, B. A review on natural areca fibre reinforced polymer composite materials. Ciência Tecnol. Mater. 2017, 29, 106–128.

- Zini, E.; Scandola, M. Green composites: An overview. Polym. Compos. 2011, 32, 1905–1915.

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596.

- Prasad, L.; Singh, V.; Patel, R.V.; Yadav, A.; Kumar, V.; Winczek, J. Physical and Mechanical Properties of Rambans (Agave) Fiber Reinforced with Polyester Composite Materials. J. Nat. Fibers 2021, 1–15.

- Prasad, L.; Kumain, A.; Patel, R.V.; Yadav, A.; Winczek, J. Physical and Mechanical Behavior of Hemp and Nettle Fiber-Reinforced Polyester Resin-based Hybrid Composites. J. Nat. Fibers 2020, 1–16.

- Li, Y.; Mai, Y.-W.; Ye, L. Sisal fibre and its composites: A review of recent developments. Compos. Sci. Technol. 2000, 60, 2037–2055.

- Chand, N.; Hashmi, S.A.R. Mechanical properties of sisal fibre at elevated temperatures. J. Mater. Sci. 1993, 28, 6724–6728.

- Idicula, M.; Joseph, K.; Thomas, S. Mechanical Performance of Short Banana/Sisal Hybrid Fiber Reinforced Polyester Composites. J. Reinf. Plast. Compos. 2010, 29, 12–29.

- Idicula, M.; Neelakantan, N.R.; Oommen, Z.; Joseph, K.; Thomas, S. A study of the mechanical properties of randomly oriented short banana and sisal hybrid fiber reinforced polyester composites. J. Appl. Polym. Sci. 2005, 96, 1699–1709.

- Shih, Y.-F.; Cai, J.-X.; Kuan, C.-S.; Hsieh, C.-F. Plant fibers and wasted fiber/epoxy green composites. Compos. Part B Eng. 2012, 43, 2817–2821.

- Mohanty, A.; Misra, M.; Drzal, L. Sustainable Bio-composites from Renewable Resources: Opportunities and Challenges in the Green Materials World. Renew. Energy 2018, 396–409.

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112.

- Ku, H.; Wang, H.; Pattarachaiyakoop, N.; Trada, M. A review on the tensile properties of natural fiber reinforced polymer composites. Compos. Part B Eng. 2011, 42, 856–873.

- Rong, M.Z.; Zhang, M.Q.; Liu, Y.; Yang, G.C.; Zeng, H.M. The effect of fiber treatment on the mechanical properties of unidirectional sisal-reinforced epoxy composites. Compos. Sci. Technol. 2001, 61, 1437–1447.

- Nimanpure, S.; Hashmi, S.; Kumar, R.; Nigrawal, A.; Bhargaw, H.; Naik, A. Sisal fibril epoxy composite-a high strength electrical insulating material. Polym. Compos. 2017, 39, E2175–E2184.

- Maya, M.; George, S.C.; Jose, T.; Sreekala, M.; Thomas, S. Mechanical Properties of Short Sisal Fibre Reinforced Phenol Formaldehyde Eco-Friendly Composites. Polym. Renew. Resour. 2017, 8, 27–42.

- Li, Y.; Ma, H.; Shen, Y.; Li, Q.; Zheng, Z. Effects of resin inside fiber lumen on the mechanical properties of sisal fiber reinforced composites. Compos. Sci. Technol. 2015, 108, 32–40.

- Betelie, A.A.; Megera, Y.T.; Redda, D.T.; Sinclair, A. Experimental investigation of fracture toughness for treated sisal epoxy composite. AIMS Mater. Sci. 2018, 5, 93–104.

- Oksman, K.; Skrifvars, M.; Selin, J.-F. Natural fibres as reinforcement in polylactic acid (PLA) composites. Compos. Sci. Technol. 2003, 63, 1317–1324.

- Sreekumar, P.; Thomas, S.P.; Saiter, J.M.; Joseph, K.; Unnikrishnan, G.; Thomas, S. Effect of fiber surface modification on the mechanical and water absorption characteristics of sisal/polyester composites fabricated by resin transfer molding. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1777–1784.

- Sreekumar, P.; Joseph, K.; Unnikrishnan, G.; Thomas, S. A comparative study on mechanical properties of sisal-leaf fibre-reinforced polyester composites prepared by resin transfer and compression moulding techniques. Compos. Sci. Technol. 2007, 67, 453–461.

- Singh, B.; Gupta, M.; Verma, A. Influence of fiber surface treatment on the properties of sisal-polyester composites. Polym. Compos. 1996, 17, 910–918.

- Sangthong, S.; Pongprayoon, T.; Yanumet, N. Mechanical property improvement of unsaturated polyester composite reinforced with admicellar-treated sisal fibers. Compos. Part A Appl. Sci. Manuf. 2009, 40, 687–694.

- Khanam, P.N.; Khalil, H.P.S.A.; Reddy, G.R.; Naidu, S.V. Tensile, Flexural and Chemical Resistance Properties of Sisal Fibre Reinforced Polymer Composites: Effect of Fibre Surface Treatment. J. Polym. Environ. 2011, 19, 115–119.

- Liu, K.; Zhang, X.; Takagi, H.; Yang, Z.; Wang, D. Effect of chemical treatments on transverse thermal conductivity of unidirectional abaca fiber/epoxy composite. Compos. Part A Appl. Sci. Manuf. 2014, 66, 227–236.

- Cai, M.; Takagi, H.; Nakagaito, A.N.; Li, Y.; Waterhouse, G.I. Effect of alkali treatment on interfacial bonding in abaca fiber-reinforced composites. Compos. Part A Appl. Sci. Manuf. 2016, 90, 589–597.

- Shibata, M.; Takachiyo, K.-I.; Ozawa, K.; Yosomiya, R.; Takeishi, H. Biodegradable polyester composites reinforced with short abaca fiber. J. Appl. Polym. Sci. 2002, 85, 129–138.

- Punyamurthy, R.; Sampathkumar, D.; Srinivasa, C.V.; Bennehalli, B. Effect of alkali treatment on water absorption of single cellulosic abaca fiber. BioResources 2012, 7, 3515–3524.

- Punyamurthy, R.; Sampathkumar, D.; Bennehalli, B.; Srinivasa, C.V. Abaca fiber reinforced epoxy composites: Evaluation of impact strength. Int. J. Sci. Basic Appl. 2014, 18, 305–317.

- Paglicawan, M.A.; Basilia, B.A.; Kim, B.S. Water Uptake and Tensile Properties of Plasma Treated Abaca Fiber Reinforced Epoxy Composite. Compos. Res. 2013, 26, 165–169.

- Malenab, R.A.J.; Ngo, J.P.S.; Promentilla, M.A.B. Chemical Treatment of Waste Abaca for Natural Fiber-Reinforced Geopolymer composite. Materials 2017, 10, 579.

- Ahmed, S.N.; Prabhakar, M.N.; Siddaramaiah; Song, J.I. Influence of silane-modified Vinyl ester on the properties of Abaca fiber reinforced composites. Adv. Polym. Technol. 2017, 37, 1970–1978.

- Liu, Y.; Ma, Y.; Yu, J.; Zhuang, J.; Wu, S.; Tong, J. Development and characterization of alkali treated abaca fiber reinforced friction composites. Compos. Interfaces 2018, 26, 67–82.

- Batara, A.G.N.; Llanos, P.S.P.; De Yro, P.A.N.; Sanglay, G.C.D.; Magdaluyo, E.R. Surface modification of abaca fibers by permanganate and alkaline treatment via factorial design. AIP Conf. Proc. 2019, 2083, 030007.

- Devi, L.U.; Bhagawan, S.S.; Thomas, S. Mechanical properties of pineapple leaf fiber-reinforced polyester composites. J. Appl. Polym. Sci. 1997, 64, 1739–1748.

- Mishra, S.; Misra, M.; Tripathy, S.S.; Nayak, S.K.; Mohanty, A.K. Potentiality of Pineapple Leaf Fibre as Reinforcement in PALF-Polyester Composite: Surface Modification and Mechanical Performance. J. Reinf. Plast. Compos. 2001, 20, 321–334.

- Devi, L.U.; Joseph, K.; Nair, K.C.M.; Thomas, S. Ageing studies of pineapple leaf fiber-reinforced polyester composites. J. Appl. Polym. Sci. 2004, 94, 503–510.

- Senthilkumar, K.; Saba, N.; Chandrasekar, M.; Jawaid, M.; Rajini, N.; Alothman, O.Y.; Siengchin, S. Evaluation of mechanical and free vibration properties of the pineapple leaf fibre reinforced polyester composites. Constr. Build. Mater. 2019, 195, 423–431.

- Senthilkumar, K.; Rajini, N.; Saba, N.; Chandrasekar, M.; Jawaid, M.; Siengchin, S. Effect of Alkali Treatment on Mechanical and Morphological Properties of Pineapple Leaf Fibre/Polyester Composites. J. Polym. Environ. 2019, 27, 1191–1201.

- Krishnasamy, S.; Muthukumar, C.; Nagarajan, R.; Thiagamani, S.M.K.; Saba, N.; Jawaid, M.; Siengchin, S.; Ayrilmis, N. Effect of fibre loading and Ca(OH)2 treatment on thermal, mechanical, and physical properties of pineapple leaf fibre/polyester reinforced composites. Mater. Res. Express 2019, 6, 085545.

- Devi, L.U.; Bhagawan, S.; Thomas, S. Dynamic mechanical properties of pineapple leaf fiber polyester composites. Polym. Compos. 2011, 32, 1741–1750.

- Payae, Y.; Lopattananon, N. Adhesion of pineapple-leaf fiber to epoxy matrix: The role of surface treatments. Songklanakarin J. Sci. & Technol. 2009, 31, 189–194.

- Lopattananon, N.; Payae, Y.; Seadan, M. Influence of fiber modification on interfacial adhesion and mechanical properties of pineapple leaf fiber-epoxy composites. J. Appl. Polym. Sci. 2008, 110, 433–443.

- Lopattananon, N.; Panawarangkul, K.; Sahakaro, K.; Ellis, B. Performance of pineapple leaf fiber–natural rubber composites: The effect of fiber surface treatments. J. Appl. Polym. Sci. 2006, 102, 1974–1984.

- Reddy, M.I.; Varma, U.P.; Kumar, I.A.; Manikanth, V.; Raju, P.K. Comparative Evaluation on Mechanical Properties of Jute, Pineapple leaf fiber and Glass fiber Reinforced Composites with Polyester and Epoxy Resin Matrices. Mater. Today Proc. 2018, 5, 5649–5654.

- Mangal, R.; Saxena, N.; Sreekala, M.; Thomas, S.; Singh, K. Thermal properties of pineapple leaf fiber reinforced composites. Mater. Sci. Eng. A 2003, 339, 281–285.

- Mohamed, A.R.; Sapuan, S.M.; Shahjahan, M.; Khalina, A.; Sapuan, M.S. Effects of Simple Abrasive Combing and Pretreatments on the Properties of Pineapple Leaf Fibers (Palf) and Palf-Vinyl Ester Composite Adhesion. Polym. Technol. Eng. 2010, 49, 972–978.

- Mohamed, A.R.; Sapuan, S.M.; Khalina, A.; Sapuan, M.S. Mechanical and thermal properties of josapine pineapple leaf fiber (PALF) and PALF-reinforced vinyl ester composites. Fibers Polym. 2014, 15, 1035–1041.