| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Chongdu Cho | + 1990 word(s) | 1990 | 2021-03-31 05:00:00 | | | |

| 2 | Chongdu Cho | Meta information modification | 1990 | 2021-04-07 05:01:00 | | | | |

| 3 | Chongdu Cho | Meta information modification | 1990 | 2021-04-07 06:16:05 | | | | |

| 4 | Bruce Ren | -21 word(s) | 1969 | 2021-04-07 06:26:44 | | |

Video Upload Options

Fiber-reinforced composite structures are used in different applications due to their excellent strength to weight ratio. Due to cost and tool handling issues in conventional manufacturing processes, like resin transfer molding (RTM) and autoclave, vacuum-assisted resin transfer molding (VARTM) is the best choice among industries. VARTM is highly productive and cheap. However, the VARTM process produces complex, lightweight, and bulky structures, suitable for mass and cost-effective production, but the presence of voids and fiber misalignment in the final processed composite influences its strength. Voids are the primary defects, and they cannot be eliminated completely, so a design without considering void defects will entail unreliability. Many conventional failure theories were used for composite design but did not consider the effect of voids defects, thus creating misleading failure characteristics.

1. Introduction

Composite materials have significant properties like their high strength to weight ratio [1][2][3]. They are used in many industries for different complex structures, such as aircraft, automobiles, marine, and sports. Polymer matrix composites (CFRP and GFRP) are widely used composite materials [4][5][6]. Different manufacturing processes are used to fabricate composite parts like hand layup, autoclave, out-of-autoclave (OoA), and additive manufacturing (AM) [7][8][9]. The autoclave is a highly labor-dependent, time-consuming, and costly process not suitable for mass production. Additive manufacturing is also a well-known fabrication technique based on adding material. Now, this process is also improved at a significant level for better quality. However, for large and bulky products, this will be costly, time-consuming, and can affect shape quality. Postprocessing is another issue in this process [10][11]. Out-of-autoclave processes are less costly and based on oven/mold [12][13]. Liquid composite molding (LCM) is an appropriate OoA technique that can produce complex shapes with high quality and quantity. Resin transfer molding (RTM) specifically is mostly accepted among industries, having numerous advantages to manufacture complex aero-engines and automotive parts [14]. The matched metal tooling process in the RTM is costly, and for manufacturing large and bulky structures such as boat hulls, tool design is complicated. Vacuum-assisted resin transfer molding (VARTM) was developed to modify the traditional RTM process to diminish the cost and design difficulties linked with bulky metal tools. Due to the cheap and mass-productive advantage of the VARTM process, it is developing day by day.

Initially, the VARTM cycle’s advancement was introduced by Williams, Summerscales, and Gove in their noteworthy review of resin injection under flexible tooling (RIFT) [15]. In 1950, The VARTM process was presented, and furthermore, vacuum infusion process (VIP) or resin infusion under flexible tooling (RIFT) were investigated. Later, different groups worked for a variant of VARTM like Lotus Car Ltd. Then, in 1980 and 1985, Gotch extended and replaced one half of the mold with a silicone vacuum rubber bag, incorporating vacuum pressure to draw the resin from a resin supply into the dry preform [16]. In 1990, Seemann patented the Seemann composite resin infusion molding process (SCRIMP) as a variant of the VARTM process, which is widely used for manufacturing large composite structures [17]. Fast remotely actuated channeling (FASTRAC) is another developed variant of the VARTM process to reduce waste [18]. Some other studies were also recommended to spread external compaction pressure. such as the inflatable bladder, permanent magnets, or pressurized air to reduce process-induced voids and increase fiber volume fraction [19][20][21]. Despite that, due to the restriction of estimating clamping powers, these recommended variations of VARTM are limited to small and medium-size composite parts. Other variants, such as double bag vacuum infusion (DBVI), vacuum-assisted process (VAP), and controlled atmospheric pressure resin infusion (CAPRI), were also developed and patented to enhance repeatability of the process and to minimize void contents and the intrinsic thickness gradient [22][23][24].

However, because of the mass and cost-effective production environment, the VARTM manufactured products contain voids and micro-voids as ordinary deformities which influence the composites’ applications [25][26][27]. The production of voids and flaw-free composites will be costly and not feasible, so it is necessary to consider the effects of voids defects and their progression, even in the design cycle’s beginning phases. Different experimental or analytical studies have proven that these defects are responsible for initiating and evolving damage actions and then certainly affect the critical state of final failure [28][29].

It is an important topic to determine failure state and components’ effectiveness due to growth in the advanced application of composite structural materials in current years. When the final processed composites present flaws, then it is necessary to incorporate manufacturing defects in failure theories. There are many failure criteria for composites which have been developed without consideration of voids. These are summarized in Section 3. Researchers have started to work and estimate the strength of composites with manufacturing defects. Many studies have shown that voids diminish the transverse tensile and compressive strength of laminate at the application level and decrease the trustworthiness of manufactured composites. Composite defects should be taken into consideration because they influence many functionalities of composite products. Air voids are the most common influenceable flaws, significantly affecting the application and eligibility of composite structures [30]. Experimental studies showed that voids and microcracks are the common known defects in textile composite materials caused by the manufacturing process [31].

Void-free manufacturing is impossible, but to work safely at the application level, reliable design is necessary [25][27][32]. That’s why today’s performances under defects are studied, and different approaches are coming into the picture to make it feasible [33]. The suitable failure theory could be incorporated into the performance evaluation process when the defect information is gained from previous material characterization and manufacturing processes.

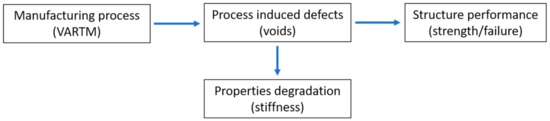

Figure 1 shows the manufacturing process and its defect and effects of defect on manufactured components. This review presents the VARTM process (polymer matrix composites) as cost-effective, failure theories with and without considering voids, the need to consider voids, and suggested failure theories to consider defects (voids). Some suitable failure theories have been discussed comprehensively, which are capable for composites in voids scenario and safe the design from misleading. Every suggested criterion has its advantage for a designed application. A strain-based criterion was suggested for a primary or initial check of failure. Discrete damage mechanics is suitable as it considers voids as a crack or void density and its evolution function. Fracture mechanics (virtual crack closure technique (VCCT)) was suggested for delamination, which is the case of void growth, and a micro-mechanics study was discussed for the estimation of failure at the micro level due to voids and their effect on macro-failure. These theories were suggested to consider the effect of voids in composite failure design, and these are also well established in the finite element method (FEM) to save time and costs for predesign. Based on this review for failure theories, one can obtain the importance of manufacturing conditions in the design strategy, and in the future, further enhanced and accurate criteria can be established considering manufacturing effects like voids among others.

Figure 1. Process and effect of defects (voids).

2. VARTM Process

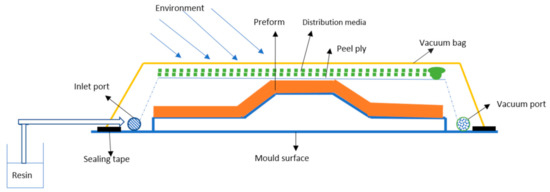

The vacuum-assisted resin transfer molding (VARTM) process has been developed to use effectively during the past two decades. This closed-mold technique can produce high performance and various types of composites, especially fiber reinforced polymer structures, at low cost [34]. The method involves primarily putting the fibers or cloth fabrics in a preform in the desired configuration. Often, these fabrics are held together by a binder and pre-pressed to the mold shape. A top (second) matching mold tool is clamped over the first and vacuum-sealed used as a deformable vacuum bag. Then, the pressurized resin is injected into the cavity by the aid of vacuum [35].

Afterward, the laminate is healed, and both injection and cure can occur at either ambient or elevated temperature. In this process, it is possible to use any fibers, and the stitched materials work well since the gaps allow for the rapid transport of resin [36]. This is a flawless process using low-cost composite materials without prepregs and autoclaves compared with the conventional composite fabrication process used in the aeronautical field. The resin cup is typically open to the atmosphere, creating a pressure differential between the inlet and exit, causing the resin to be drawn into the layup [37]. Figure 2 shows a typical VARTM process setup.

Figure 2. VARTM process setup layout.

Broadly, the VARTM technique can be separated into three processing steps, including material and tool preparation, viz. pre-infusion, infusion, and post-infusion [38]. Each process steps influence the final material quality, mostly the fiber volume fraction and void content distribution. Table 1 shows three-step process completion with the reason for voids inclusion in each process step.

Table 1. Steps for process completion of VARTM with voids’ reason at a certain step.

| Process | Pre-Infusion | Infusion | Post-Infusion |

| • Mold preparation • Material placement (fiber reinforcement) • Maintain flow distribution medium, injection port, vent port, vacuum bag against the sealing tap • Debulking process (optional) |

• apply the vacuum inside the bagged preform assembly • Fill the resin into the resin reservoir. Keep the vacuum port on |

• Close the injection port • After curing resin, turn off the vacuum then demold the composite part |

|

| Defects (Voids) reason | • Moisture in resin • Resin mixing and degassing and bag integrity • Leak rate |

• Resin flow, pressure, flow timing, and thickness management | • Injection and vacuum off timing, • demolding conditions |

There are different names to describe this process, viz. vacuum-assisted resin infusion molding (VARIM), vacuum-assisted resin infusion (VARI), and vacuum bag resin transfer molding (VBRTM). Further, many other developments have been in the VARTM process, such as Seeman composites resin infusion molding process (SCRIMP), vacuum-assisted process (VAP), and controlled atmospheric pressure resin infusion (CAPRI).

2.1. Advantage

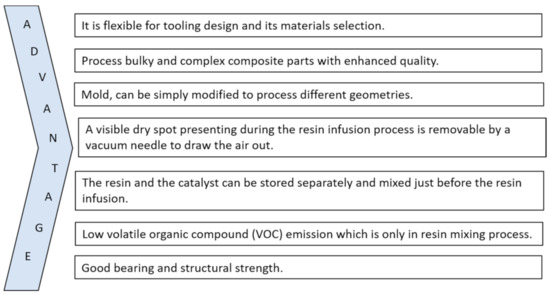

The VARTM procedure was formerly produced to fabricate superior and huge composite parts, such as infrastructure and transport structures [38][39]. This process is cheap and established for mass production, and the basic principle is to develop the pressure difference between the vacuum and environment pressure to get the desired necessities. The points of advantages in the VARTM process are summarized below in Figure 3.

Figure 3. Advantages of VARTM.

The main benefit of VARTM is that it lies in the low injection pressures (approx. 1 atm). At the time of manufacturing, less movement is required for reinforcement, which has been achieved by this little pressure to get better quality products [40]. Due to the advantage and improved understanding of process physics, VARTM is employed in various railroads, naval, aerospace, and automobile parts with many variations of VARTM, and more complex composite parts with higher quality, strength, and lower cast can be produced [34][38]. Although there are advantages of VARTM process and it is used widely, for accurate design, its primary defects’ (voids) effect should be known and considered alongside the formation of voids, as summarized below.

2.2. Defects in VARTM Processed Composites

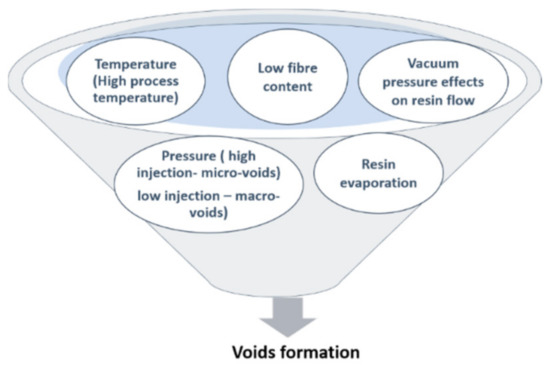

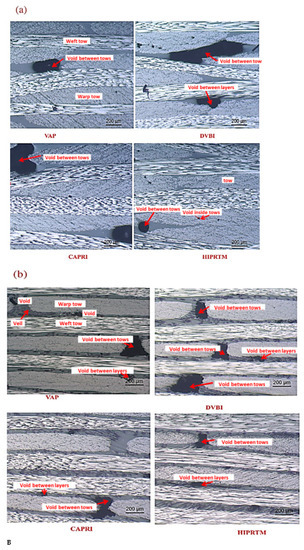

Over the VARTM process’s advantages, there are different types of defects, like fiber misalignment and voids, whereby defect-free manufacturing is impossible. In mass production, voids formation is the primary defect. Many factors like resin-flow pressure variation or temperature changes initiate voids formation in this process [41][42]. Figure 4 shows void formation factors in the VARTM manufacturing process. In the VARTM process, void content is a significant issue in mass production and a cost-effective environment [26]. It reduces strength and the modulus which creates an early failure of composites in a loading environment [25][27]. This is why taking care of voids in failure theories remains very important to safe instead of misleading design. Figure 5A shows the voids scenario’s schematic in the VARTM processes to demonstrate a high void content in the process. Figure 5B illustrates actual images of voids in different VARTM processes for woven (a) and non-crimp (b) reinforcement from experiments [14]. This figure indicates that the voids’ conditions are higher in the mass production process (VARTM). This is why it is necessary to consider the manufacturing details (voids effect) in failure design conditions.

Figure 4. Voids formation factors.

Figure 5. (A) Voids demonstration (Schematic), (B) (a) Voids in different VARTM processes for woven reinforcement, (b) voids in different VARTM for non-crimp reinforcement adapted from [14], with permission from Elsevier, 2021.

References

- David Müzel, S.; Bonhin, E.P.; Guimarães, N.M.; Guidi, E.S. Application of the Finite Element Method in the Analysis of Composite Materials: A Review. Polymers 2020, 12, 818.

- Hussain, N.N.; Regalla, S.P.; Rao, Y.V.D.; Dirgantara, T.; Gunawan, L.; Jusuf, A. Drop-weight impact testing for the study of energy absorption in automobile crash boxes made of composite material. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2020.

- Dhimole, V.K.; Chen, Y.; Cho, C. Modeling and Two—Step Homogenization of Aperiodic Heterogenous 3D Four—Directional Braided Composites. J. Compos. Sci. 2020, 4, 179.

- Hong, B.; Xian, G.; Li, H. Comparative study of the durability behaviors of epoxy- and polyurethane-based CFRP plates subjected to the combined effects of sustained bending and water/seawater immersion. Polymers 2017, 9, 603.

- Bazli, M.; Ashrafi, H.; Jafari, A.; Zhao, X.L.; Singh Raman, R.K.; Bai, Y. Effect of fibers configuration and thickness on tensile behavior of GFRP laminates exposed to harsh environment. Polymers 2019, 11, 1401.

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-reinforced polymer composites: Manufacturing, properties, and applications. Polymers 2019, 11, 1667.

- Schubel, P.J. Cost modelling in polymer composite applications: Case study—Analysis of existing and automated manufacturing processes for a large wind turbine blade. Compos. Part B Eng. 2012, 43, 953–960.

- McIlhagger, A.; Archer, E.; McIlhagger, R. 3-Manufacturing processes for composite materials and components for aerospace applications. In Soutis CBT-PC in the AI, 2nd ed.; Irving, P., Ed.; Woodhead Publishing: Sawston, UK, 2020; pp. 59–81.

- Saleh Alghamdi, S.; John, S.; Roy Choudhury, N.; Dutta, N.K. Additive Manufacturing of Polymer Materials: Progress, Promise and Challenges. Polymers 2021, 13, 753.

- Fidan, I.; Imeri, A.; Gupta, A.; Hasanov, S.; Nasirov, A.; Elliott, A.; Alifui-Segbaya, F.; Nanami, N. The trends and challenges of fiber reinforced additive manufacturing. Int. J. Adv. Manuf. Technol. 2019, 102, 1801–1818.

- Mantelli, A.; Romani, A.; Suriano, R.; Diani, M.; Colledani, M.; Sarlin, E.; Turri, S.; Levi, M. UV-Assisted 3D Printing of Polymer Composites from Thermally and Mechanically Recycled Carbon Fibers. Polymers 2021, 13, 726.

- Sunilpete, M.A.; Cadambi, R.M. Development of Cost Effective Out-of-Autoclave Technology—Vacuum Infusion Process with Tailored Fibre Volume Fraction. Mater. Today Proc. 2020, 21, 1293–1297.

- Taylor, T.; Zhang, J.; Yanagimoto, J. Evaluation of a concept out-of-autoclave process for manufacturing carbon fibre reinforced polymer automotive parts. Procedia CIRP 2019, 86, 162–166.

- Bodaghi, M.; Costa, R.; Gomes, R.; Silva, J.; Correia, N.; Silva, F. Experimental comparative study of the variants of high-temperature vacuum-assisted resin transfer moulding. Compos. Part A Appl. Sci. Manuf. 2020, 129, 105708.

- Williams, C.; Summerscales, J.; Grove, S. Resin infusion under flexible tooling (RIFT): A review. Compos. Part A Appl. Sci. Manuf. 1996, 27, 517–524.

- Summerscales, J.; Searle, T.J. Low-pressure (vacuum infusion) techniques for moulding large composite structures. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2005, 219, 45–58.

- Sun, X.; Li, S.; Lee, L.J. Mold filling analysis in vacuum-assisted resin transfer molding. part I: SCRIMP based on a high-permeable medium. Polym. Compos. 1998, 19, 807–817.

- Allende, M.; Mohan, R.V.; Walsh, S.M. Experimental and numerical analysis of flow behavior in the FASTRAC liquid composite manufacturing process. Polym. Compos. 2004, 25, 384–396.

- Anderson, J.P.; Kelly, A.J.; Altan, M.C. Fabrication of Composite Laminates by Vacuum-Assisted Resin Transfer Molding Augmented with an Inflatable Bladder. In Proceedings of the 28th Annual Technical Conference American Society for Composites, State College, PA, USA, 9–11 September 2013; pp. 1283–1294.

- Amirkhosravi, M.; Pishvar, M.; Altan, M.C. Void reduction in VARTM composites by compaction of dry fiber preforms with stationary and moving magnets. J. Compos. Mater. 2019, 53, 769–782.

- Yalcinkaya, M.A.; Sozer, E.M.; Altan, M.C. Fabrication of high quality composite laminates by pressurized and heated-VARTM. Compos. Part A Appl. Sci. Manuf. 2017, 102, 336–346.

- van Oosterom, S.; Allen, T.; Battley, M.; Bickerton, S. An objective comparison of common vacuum assisted resin infusion processes. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105528.

- Aruniit, A.; Herranen, H.; Miller, K. Comparative study of the VARTM, VAP and MTI vacuum infusion processes. Key Eng. Mater. 2016, 674, 71–76.

- Song, Y.S.; Youn, J.R. Numerical Investigation on Flow through Porous Media in the Post-infusion Process. Polym. Compos. 2008, 30, 1125–1131.

- Kuentzer, N.; Simacek, P.; Advani, S.G.; Walsh, S. Correlation of void distribution to VARTM manufacturing techniques. Compos. Part A Appl. Sci. Manuf. 2007, 38, 802–813.

- Kedari, V.R.; Farah, B.I.; Hsiao, K.T. Effects of vacuum pressure, inlet pressure, and mold temperature on the void content, volume fraction of polyester/e-glass fiber composites manufactured with VARTM process. J. Compos. Mater. 2011, 45, 2727–2742.

- Mehdikhani, M.; Gorbatikh, L.; Verpoest, I.; Lomov, S.V. Voids in fiber-reinforced polymer composites: A review on their formation, characteristics, and effects on mechanical performance. J. Compos. Mater. 2019, 53, 1579–1669.

- Mishnaevsky, L. Fiber Reinforced Composites: Numerical Analysis of Damage Initiation and Growth. In Computational Mesomechanics of Composites; John Wiley & Sons: Hoboken, NJ, USA, 2007; pp. 215–237.

- Cantwell, W.J.; Morton, J. The significance of damage and defects and their detection in composite materials: A review. J. Strain. Anal. Eng. Des. 1992, 27, 29–42.

- Nikopour, H. A virtual frame work for predication of effect of voids on transverse elasticity of a unidirectionally reinforced composite. Comput. Mater. Sci. 2013, 79, 25–30.

- Xu, J.; Lu, X.; Zhu, X. Effect of Random Void Defects on the Mechanical Behavior of C/C Braided Composites. Adv. Eng. Mater. 2018, 20, 1–14.

- Parnas, R.S.; Walsh, S.M. Vacuum-assisted resin transfer molding model. Polym. Compos. 2005, 26, 477–485.

- Yang, B.J.; Ha, S.K.; Pyo, S.H.; Lee, H.K. Mechanical characteristics and strengthening effectiveness of random-chopped FRP composites containing air voids. Compos. Part B Eng. 2014, 62, 159–166.

- Sevkat, E.; Brahimi, M. The bearing strength of pin loaded woven composites manufactured by Vacuum Assisted Resin Transfer Moulding and hand lay-up techniques. Procedia Eng. 2011, 10, 153–158.

- Bolick, R. Composite Fabrication via the VARTM Process; A&T State University: Greensboro, NC, USA, 2000.

- Wu, D.; Larsson, R.; Rouhi, M.S. Modeling and experimental validation of the VARTM process for thin-walled preforms. Polymers 2019, 11, 2003.

- Federal Aviation Administration. Overview of Vacuum-Assisted Resin Transfer Molding Processing; U.S. Department of Transportation: New Jesrey, WA, USA, 2013.

- Heider, D.; Gillespie, J.W. VARTM Variability and Substantiation Information; University of Delware Center for Composite Materials: Newark, DE, USA, 2008.

- Uddin, N.; Vaidya, U.; Shohel, M.; Serrano-Perez, J.C. Cost-effective bridge girder strengthening using vacuum-assisted resin transfer molding (VARTM). Adv. Compos. Mater. 2004, 13, 255–281.

- Chang, C.Y. Modeling and evaluation of the filling process of vacuum-assisted compression resin transfer molding. J. Polym. Eng. 2013, 33, 211–219.

- Dong, C. Effects of Process-Induced Voids on the Properties of Fibre Reinforced Composites. J. Mater. Sci. Technol. 2016, 32, 597–604.

- Liu, X.; Chen, F. A review of void formation and its effects on the mechanical performance of carbon fiber reinforced plastic. Eng. Trans. 2016, 64, 33–51.