| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Rosanna Mallamaci | + 1249 word(s) | 1249 | 2021-03-22 07:59:20 | | | |

| 2 | Lily Guo | Meta information modification | 1249 | 2021-03-25 01:47:24 | | |

Video Upload Options

Extra-virgin olive oil (EVOO) contains many bioactive compounds with multiple biological activities that make it one of the most important functional foods. Both the constituents of the lipid fraction and that of the unsaponifiable fraction show a clear action in reducing oxidative stress by acting on various body components, at concentrations established by the European Food Safety Authority’s claims. In addition to the main product obtained by the mechanical pressing of the fruit, i.e., the EVOO, the residual by-products of the process also contain significant amounts of antioxidant molecules, thus potentially making the Olea europea L. an excellent example of the circular economy. In fact, the olive mill wastewaters, the leaves, the pomace, and the pits discharged from the EVOO production process are partially recycled in the nutraceutical and cosmeceutical fields also because of their antioxidant effect.

1. Introduction

Olive oil is the main product obtained from olives, fruits that come from the Olea europaea L. evergreen trees [1]. Olive oil is a characteristic element of the Mediterranean Diet (MD) because of the health-beneficial effects deriving from its chemical composition [2][3][4] as well as its appreciable taste and usefulness in flavoring a large variety of foods. In particular, the constituents of both lipidic and unsaponifiable fractions in extra-virgin olive oils (EVOOs) have been demonstrated to be able to reduce oxidative stress by acting on various biomolecules in the body, as also stated by the European Food Safety Authority (EFSA) [5].

During the production process of EVOOs, olive milling yields a mixture of olive paste and water. Subsequent malaxation of the olive paste allows for the separation of three phases: (i) the olive oil, (ii) a solid residue, and (iii) the olive mill wastewater (OMW). The last two components are produced in large quantities, and they are considered an agro-industrial waste whose disposal represents an important environmental problem as the plant material is usually subjected to microbial deterioration [6][7].

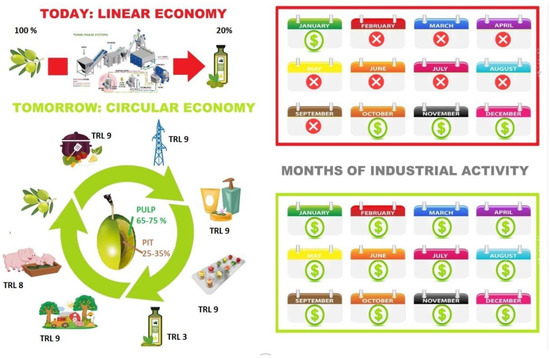

Currently, in the linear economy, agricultural by-products are mainly used as combustion feedstock for biofuels (Figure 1) [8][9].

Figure 1. From linear to the circular economy in the olive oil sector.

The most important biomasses are residues from wood working (wood shavings and sawdust) or forestry activities, wastes from farms and agro-business, the organic fraction of municipal solid wastes, and plants deliberately grown for energetic purposes. Similarly, pruning wastes from olive trees are also used as biomass. However, in coherence with the “circular economy” principle, it is important to valorize these waste products containing high levels of secondary metabolites, thus accelerating the implementation of the “Transforming our world: the 2030 Agenda for Sustainable Development” [10][11].

Nevertheless, the transition from linear to the circular economy requires a cultural and structural change: a deep revision and innovation of production, distribution, and consumption models [12]. Furthermore, from a circular economy perspective, the added value of materials and energy must be maintained for as long as possible over multiple productions and use cycles, representing a new opportunity also for seasonal sectors, such as the EVOOs manufacturing industry.

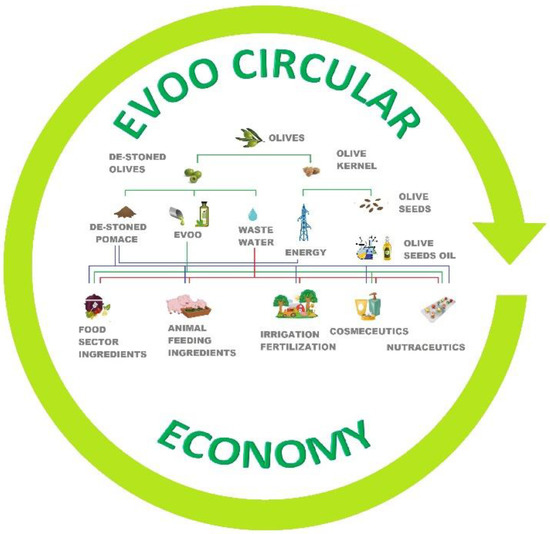

Olive mill waste, olive pomace (exhausted pulp, kernel, and seeds), and vegetative water are significant by-products of the olive oil-producing countries in the Mediterranean basin, with a high environmental impact if not properly treated. In addition, these wastes are rich in high-value compounds, which can be either used directly after extraction or exploited as ingredients with different applications, e.g., as food supplements, nutraceuticals, cosmeceuticals, and animal feed.

The transition from linear to the circular economy, largely desired from stakeholders in the olive oil sector, requires a multidisciplinary approach that exploits know-how harmonically from different fields (Figure 2).

Figure 2. Extra virgin olive oil’s (EVOO’s) circular economy: overview of an integrated olive tree exploitation.

This transition would also bring an additional value, represented by the possibility that each oil mill can integrate new processes with the pre-existing ones, with the resulting economic advantages, guaranteeing both product diversification and fair income for all stakeholders, who are currently threatened by the increasing oil price trend and the emerging Xylella pandemic.

In this review, we focused our attention on the secondary metabolites contained in waste materials derived from the olive oil production process and their ability to reduce oxidative stress, both in vitro and in vivo. Particular attention has been paid to their potential exploitation in the circular economy by obtaining new high-value ingredients for health-related products (nutraceuticals, pharmaceuticals, and cosmeceuticals).

2. Olea europea L.: Overview on Its Chemical Compounds

The most represented chemical classes in Olea europea L. tree are mainly classified as nonpolar compounds (present in the lipophilic oil fraction, such as squalene, tocopherols, sterols, and triterpenic compounds) and polar phenolic compounds [13].

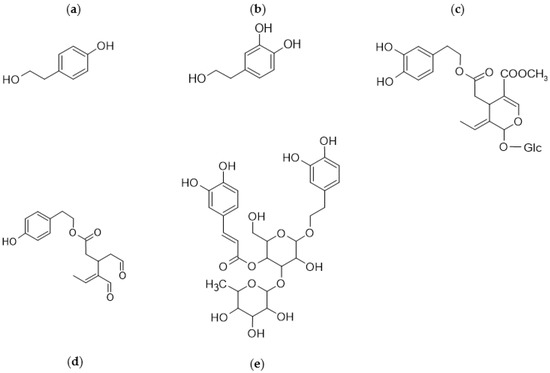

Among the polyphenolic compounds, the most abundant and studied in olives are tyrosol (TY), hydroxytyrosol (HT), oleuropein (OL), oleocanthal, and verbascoside (Figure 3).

Figure 3. Most abundant polyphenols in olives: (a) tyrosol; (b) hydroxytyrosol; (c) oleuropein; (d) oleocanthal; (e) verbascoside.

The secondary metabolites from Olea europea L. have high biological value, and they are present in different concentrations in the various parts of the olive plant (Table 1); as such, many of them are present in the derived EVOOs, but they can also be found in the waste products from the production process.

Table 1. Distribution of the main classes of metabolites in the different parts of the plant Olea europea L. [13][14][15][16][17][18][19][20][21].

| Seed Oil | Virgin Olive Oil | Skin | Pulp | Wood | Leaves |

|---|---|---|---|---|---|

| Phenolic acid/aldehydes | Phenolic acid/aldehydes | Phenolic acid/aldehydes | Phenolic acid/aldehydes | Phenolic acid/aldehydes | Phenolic acid/aldehydes |

| Tocopherols | Tocopherols | Tocopherols | |||

| Sterols | Sterols | Organic acid and coumarins | Organic acid and coumarins | Organic acid and coumarins | Organic acid and coumarins |

| Flavonoids | Simple phenols and derivatives | Simple phenols and derivatives | Simple phenols and derivatives | ||

| Lignans | Secoiridoids and derivatives | Secoiridoids and derivatives | Secoiridoids and derivatives | ||

| Fatty acids and derivatives | Flavonoids | Flavonoids | |||

| Pentacyclic triterpenes |

Tocopherols |

For this reason, all the materials involved in olive oil manufacturing represent a precious reservoir that could supply extracts reusable for health purposes. The most studied secondary metabolites are the polyphenols (or biophenols, as they are often referred to in EVOOs) that represent a group of molecules with one or more phenolic rings [14]. These compounds can be defined as nutraceuticals for their biological/pharmacological actions [15], mostly derived from their antioxidant properties, that play a protective role against oxidative stress [16] and extend the shelf-life of olive oil [17].

The antioxidant activity is mainly due to five classes of polyphenols identified as simple phenols, phenolic acids, secoiridoids, flavonoids, and lignans [18]. Among these, OL represents the principal biophenol in the olive leaf [19], followed by other constituents such as verbascoside, luteolin-7-O-glucoside, apigenin-7-O-glucoside, and TY [20]. Their antioxidant activity is even higher than that of antioxidants, such as vitamins E and C [21].

For this reason, all the materials involved in olive oil manufacturing represent a precious reservoir that could supply extracts reusable for health purposes. The most studied secondary metabolites are the polyphenols (or biophenols, as they are often referred to in EVOOs) that represent a group of molecules with one or more phenolic rings [14]. These compounds can be defined as nutraceuticals for their biological/pharmacological actions [15], mostly derived from their antioxidant properties, that play a protective role against oxidative stress [16] and extend the shelf-life of olive oil [17].

The antioxidant activity is mainly due to five classes of polyphenols identified as simple phenols, phenolic acids, secoiridoids, flavonoids, and lignans [18]. Among these, OL represents the principal biophenol in the olive leaf [19], followed by other constituents such as verbascoside, luteolin-7-O-glucoside, apigenin-7-O-glucoside, and TY [20]. Their antioxidant activity is even higher than that of antioxidants, such as vitamins E and C [21].

References

- Huang, C.L.; Sumpio, E.B.J. Olive Oil, the Mediterranean Diet, and Cardiovascular Health. Am. Coll. Surg. 2008, 207, 407–416.

- Boskou, D.; Blekas, G.; Tsimidou, M. History and characteristics of the olive tree. In Olive Oil Chemistry and Technology; Boskou, D., Ed.; AOCS Press: Champaign IL, USA, 1996.

- Cicerale, S.; Lucas, L.J.; Keast, R.S.J. Antimicrobial, antioxidant and anti-inflammatory phenolic activities in extra virgin olive oil. Curr. Opin. Biotechnol. 2012, 23, 129–135.

- Marcelino, G.; Hiane, P.A.; Freitas, K.C.; Santana, L.F.; Pott, A.; Donadon, J.R.; Guimarães, R.C.A. Effects of olive oil and its minor components on cardiovascular diseases, inflammation, and gut microbiota. Nutrients 2019, 11, 1826.

- Roselli, L.; Clodoveo, M.L.; Corbo, F.; De Gennaro, B. Are health claims a useful tool to segment the category of extra-virgin olive oil? Threats and opportunities for the Italian olive oil supply chain. Trends Food Sci. Tech. 2017, 68, 176–181.

- Hanifi, S.; El Hadrami, I. Olive mill wastewaters: Diversity of the fatal product in olive oil industry and its valorisation as agronomical amendment of poor soils: A review. J. Agron. 2009, 8, 1–13.

- Jarboui, R.; Sellami, F.; Kharroubi, A.; Gharsallah, N.; Ammar, E. Olive mill wastewater stabilization in open-air ponds: Impact on clay-sandy soil. Bioresour. Technol. 2008, 99, 7699–7708.

- Chandra, R.; Takeuchi, H.; Hasegawa, T. Methane production from lignocellulosic agricultural crop wastes: A review in context to second generation of biofuel production. Renew. Sustain. Energy Rev. 2012, 16, 1462–1476.

- Demirbas, M.F.; Balat, M.; Balat, H. Biowastes-to-biofuels. Energy Convers. Manag. 2011, 52, 1815–1828.

- Romani, A.; Pinelli, P.; Ieri, F.; Bernini, R. Sustainability, innovation, and green chemistry in the production and valorization of phenolic extracts from Olea europaea L. Sustainability 2016, 8, 1002.

- Robert, K.W.; Parris, T.M.; Leiserowitz, A.A. What is sustainable development? Goals, indicators, values, and practice. Environ. Sci. Policy 2005, 47, 8–21.

- De Jesus, A.; Antunes, P.; Santos, R.; Mendonça, S. Eco-innovation in the transition to a circular economy: An analytical literature review. J. Cleaner Prod. 2018, 172, 2999–3018.

- Boskou, D. Olive fruit, table olives, and olive oil bioactive constituents. In Olive and olive oil bioactive constituents, 1st ed.; Boskou, D., Ed.; AOCS Press: Champaign IL, USA, 2015; pp. 1–30.

- Vermerris, W.; Nicholson, R. Phenolic Compounds Biochemistry, 1st ed.; Springer: Dordrecht, The Netherlands, 2006; pp. 1–276.

- Tresserra-Rimbau, A.; Lamuela-Raventos, R.M.; Moreno, J.J. Polyphenols, food and pharma. Current knowledge and directions for future research. Biochem. Pharmacol. 2018, 156, 186–195.

- Gambacorta, G.; Faccia, M.; Previtali, M.A.; Pati, S.; La Notte, E.; Baiano, A. Effects of olive maturation and stoning on quality indices and antioxidant concentration of extra virgin oils (cv. Coratina) during storage. J. Food Sci. 2010, 75, 229–235.

- Cinquanta, L.; Esti, M.; Notte, E. Evaluation of phenolic compounds in virgin olive oil during storage. J. Am. Oil Chem. Soc. 1997, 74, 1259–1264.

- Leouifoudi, I.; Harnafi, H.; Zyad, A. Olive mill waste extracts: Polyphenols content, antioxidant, and antimicrobial activities. Adv. Pharmacol. Sci. 2015, 2015, 1–11.

- Omar, S.H. Oleuropein in olive and its pharmacological effects. Sci. Pharm. 2010, 78, 133–154.

- Bianco, A.; Uccella, N. Biophenolic components of olives. Food Res. Int. 2000, 33, 475–485.

- Benavente-Garcıa, O.; Castillo, J.; Lorente, J.; Ortuño, A.D.R.J.; Del Rio, J.A. Antioxidant activity of phenolics extracted from Olea europaea L. leaves. Food Chem. 2000, 68, 457–462.