| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Ali Zolfagharian | + 934 word(s) | 934 | 2020-05-06 13:27:11 | | | |

| 2 | Catherine Yang | + 7 word(s) | 941 | 2020-05-12 05:12:47 | | | | |

| 3 | Catherine Yang | + 3 word(s) | 944 | 2020-10-28 09:41:25 | | |

Video Upload Options

Building on the recent progress of four-dimensional (4D) printing to produce dynamic structures, this study aimed to bring this technology to the next level by introducing control-based 4D printing to develop adaptive 4D-printed systems with highly versatile multi-disciplinary applications, including medicine, in the form of assisted soft robots, smart textiles as wearable electronics and other industries such as agriculture and microfluidics. This study introduced and analyzed adaptive 4D-printed systems with an advanced manufacturing approach for developing stimuli-responsive constructs that organically adapted to environmental dynamic situations and uncertainties as nature does. The adaptive 4D-printed systems incorporated synergic integration of three-dimensional (3D)-printed sensors into 4D-printing and control units, which could be assembled and programmed to transform their shapes based on the assigned tasks and environmental stimuli. This paper demonstrates the adaptivity of these systems via a combination of proprioceptive sensory feedback, modeling and controllers, as well as the challenges and future opportunities they present.

1. Introduction

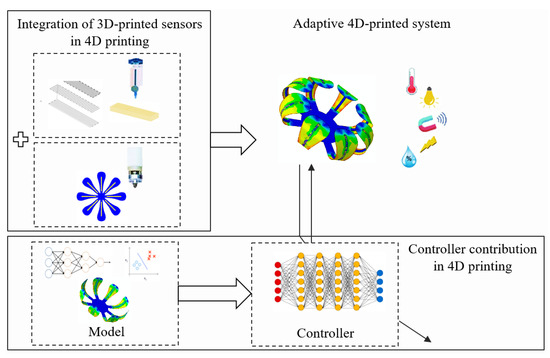

The synergic integration of the main components to develop adaptive 4D-printed systems are explained in this section (Figure 1). In addition to the incorporation of 3D-printed sensors and 4D printing, controller units are required to command the necessary input to the 4D-printed system based on the acquired information. The 4D-printed systems developed so far are mainly reliant on the morphology of soft materials rather than the sophisticated control methods. However, considering the potential exposure to a wide range of dynamic environments, 4D-printed systems demand more robust controllers, particularly in highly sensitive tasks.

Figure 1. Adaptive 4D-printed systems composition.

A closed-loop controller for the 4D-printed soft robots was recently introduced in order to improve the performance of the soft robots [1]. The active control of 4D prints was achieved by combining the 3D-printed shape-memory polymer composites with a controller that regulated power input to the composite in order to manipulate the material’s heating behavior, considering the variations in resistance caused by the changes in strain or temperature [2]. However, the dynamic modeling of such systems was not simply due to their non-linear behavior, infinite degrees of freedom, hyperelasticity, heterogeneous materials properties and hysteresis [3]. In other words, predicting the motion of the actuators based on the input-stimuli could not readily be calculated via the inverse kinematics equations used in the rigid bodies such as the Cosserat rod theory [4] beam theory [5] and constant curvature model [6] methods, because of the computational expenses and steady-state assumptions [7]. Therefore, machine-learning methods could be an appropriate choice to realize adaptive 4D-printed systems [8].

2. Adaptive 4D-Printed Systems

To equip the 4D-printed systems with adaptive controllability required for real-world dynamic variations, ML algorithms are suitable solutions due to recent advancements in nonlinear systems modeling [9][10][11]. The finite element model (FEM) is employed to train the ML algorithm to effectively calculate volumetric properties such as spatially heterogeneous mechanical strengths, variable stiffness, and the targeted anisotropy during the 4D-printing process. Further, the control algorithms will be developed and incorporated into the 4D-printing platform to compute the precise actuation signal to adapt to the uncertain and dynamic environments [12][13][14][15]. However, closed-loop controllers are preferred here to make the most of the integrated 3D-printed sensors in handling uncertainties for wide frequency bandwidths [11][16][17][18][19]. Indeed, in order to increase the efficiency of control strategies in terms of time and computational costs, model-based ML [20] in conjunction with self-learning controllers [21][22] are preferred compared to the model-free controllers to deal with the complexity involved in diverse scenarios [23][18][24][25][26]. A forward dynamics model using recurrent or convolutional neural networks could be employed to implement a model-based feedback controller for an adaptive 4D-printed system [27]. Then, a policy-based reinforcement-learning feedback controller can be used to learn the nonlinear model of a 4D-printed soft robot through experiments and simulation data to compensate for the uncertainties. The self-learning algorithms play a significant role in adaptive 4D-printed systems to optimize the controller commands based on the information acquired from the interaction with the environment via the 3D-printed sensors [28][29][30][31][32].

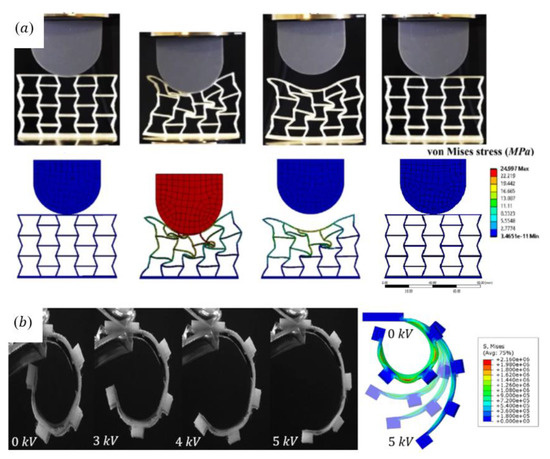

Model-based ML algorithms, however, require a large pool of data containing different scenarios of environmental changes to be trained to represent the 4D-printed system model with time-variable properties and multi-dimensional control states [33][34]. The training process could be repetitious and expensive if it merely relies on experimental tests, therefore, the FEM (Figure 2) can be used in the offline loop for constructing a comprehensive and reliable model exploring the various possible scenarios [33][34][35][36][37][38][39].

Recent advancements in control-based 4D printing with integrating the sensors, ML models trained by FEM results, and controlling the entire 4D-printed systems are gathered in Table 1. To the best of the knowledge of the authors, there has yet to be an entirely adaptive 4D-printed system, as defined in this paper. However, there are some promising studies in integrated 3D-printed sensors in 4D printing [42][43][44][45][46][47][48], the application of the FEM [49] and ML-based controllers in 4D-printed systems [50][23][25]. These relevant research results support the possibility of realizing the proposed adaptive 4D-printed systems.

Table 1. Studies toward adaptive 4D-printed systems.

Additionally, there have been several studies on the design and fabrication of 4D-printed compliant mechanisms promoting controlled self-management and self-actuation without needing sensors [50][52][55][56][57][58]. Further investigations on equipping such mechanisms with controllers to provide more flexibility and adaptability are envisaged, allowing for their wider ranges of autonomous operations. It is interesting to note that, there have been only a few studies on the use of the FEM to design and optimize controllers in 4D-printed systems. This will certainly increase the robustness and repeatability of 4D-printed systems in diverse applications with variable unstructured environments.

References

- Zolfagharian, A.; Kaynak, A.; Kouzani, A.; Closed-loop 4D-printed soft robots. Mater. Des. 2019, 188, 108411.

- I.T. Garces; Cagri Ayranci; Active control of 4D prints: Towards 4D printed reliable actuators and sensors. Sensors and Actuators A: Physical 2020, 301, 111717, 10.1016/j.sna.2019.111717.

- Della Santina, C.; Katzschmann, R.K.; Biechi, A.; Rus, D. Dynamic control of soft robots interacting with the environment. In Proceedings of the 2018 IEEE International Conference on Soft Robotics (RoboSoft), Monterey, CA, USA, 23–26 April 2018; pp. 46–53.

- D. Trivedi; A. Lotfi; C.D. Rahn; Geometrically Exact Models for Soft Robotic Manipulators. IEEE Transactions on Robotics 2008, 24, 773-780, 10.1109/TRO.2008.924923.

- I.A. Gravagne; C.D. Rahn; I.D. Walker; Large deflection dynamics and control for planar continuum robots. IEEE/ASME Transactions on Mechatronics 2003, 8, 299-307, 10.1109/tmech.2003.812829.

- B.A. Jones; I.D. Walker; Kinematics for multisection continuum robots. IEEE Transactions on Robotics 2006, 22, 43-55, 10.1109/TRO.2005.861458.

- Alireza Ramezani; Soon-Jo Chung; Seth Hutchinson; A biomimetic robotic platform to study flight specializations of bats. Science Robotics 2017, 2, eaal2505, 10.1126/scirobotics.aal2505.

- A. V. Prituja; Hritwick Banerjee; Hongliang Ren; Electromagnetically Enhanced Soft and Flexible Bend Sensor: A Quantitative Analysis With Different Cores. IEEE Sensors Journal 2018, 18, 3580-3589, 10.1109/jsen.2018.2817211.

- Phillip Hyatt; David Wingate; Marc D. Killpack; Model-Based Control of Soft Actuators Using Learned Non-linear Discrete-Time Models. Frontiers in Robotics and AI 2019, 6, , 10.3389/frobt.2019.00022.

- Craig M Hamel; Devin J Roach; Kevin N Long; Frederic Demoly; Martin L Dunn; H. Jerry Qi; Jerry Qi; Machine-learning based design of active composite structures for 4D printing. Smart Materials and Structures 2019, 28, 065005, 10.1088/1361-665x/ab1439.

- Thomas George Thuruthel; Egidio Falotico; Mariangela Manti; Cecilia Laschi; Stable Open Loop Control of Soft Robotic Manipulators. IEEE Robotics and Automation Letters 2018, 3, 1292-1298, 10.1109/lra.2018.2797241.

- Andrew D. Marchese; Russ Tedrake; Daniela Rus; Dynamics and trajectory optimization for a soft spatial fluidic elastomer manipulator. The International Journal of Robotics Research 2015, 35, 1000-1019, 10.1177/0278364915587926.

- Charles M. Best; Morgan T. Gillespie; Phillip Hyatt; Levi Rupert; Vallan Sherrod; Marc D. Killpack; A New Soft Robot Control Method: Using Model Predictive Control for a Pneumatically Actuated Humanoid. IEEE Robotics & Automation Magazine 2016, 23, 75-84, 10.1109/MRA.2016.2580591.

- Ali Zolfagharian; Abbas Z. Kouzani; Malith Maheepala; Sui Yang Khoo; Akif Kaynak; Bending control of a 3D printed polyelectrolyte soft actuator with uncertain model. Sensors and Actuators A: Physical 2019, 288, 134-143, 10.1016/j.sna.2019.01.027.

- Ali Zolfagharian; Akif Kaynak; Sui Yang Khoo; Jun Zhang; Saeid Nahavandi; Abbas Kouzani; Control-Oriented Modelling of a 3D-Printed Soft Actuator.. Materials 2018, 12, 71, 10.3390/ma12010071.

- Thomas George Thuruthel; Egidio Falotico; Federico Renda; Cecilia Laschi; Learning dynamic models for open loop predictive control of soft robotic manipulators. Bioinspiration & Biomimetics 2017, 12, 066003, 10.1088/1748-3190/aa839f.

- Thomas George Thuruthel; Egidio Falotico; Federico Renda; Cecilia Laschi; Model-Based Reinforcement Learning for Closed-Loop Dynamic Control of Soft Robotic Manipulators. IEEE Transactions on Robotics 2018, 35, 124-134, 10.1109/tro.2018.2878318.

- Thomas George Thuruthel; Yasmin Ansari; Egidio Falotico; Cecilia Laschi; Control Strategies for Soft Robotic Manipulators: A Survey. Soft Robotics 2018, 5, 149-163, 10.1089/soro.2017.0007.

- Cosimo Della Santina; Matteo Bianchi; Giorgio Grioli; Franco Angelini; Manuel Giuseppe Catalano; Manolo Garabini; Antonio Bicchi; Controlling Soft Robots: Balancing Feedback and Feedforward Elements. IEEE Robotics & Automation Magazine 2017, 24, 75-83, 10.1109/mra.2016.2636360.

- Spielberg, S.; Gopaluni, R.; Loewen, P. Deep reinforcement learning approaches for process control. In Proceedings of the 2017 6th International Symposium on Advanced Control of Industrial Processes (AdCONIP), Taipei, Taiwan, 28–31 May 2017; pp. 201–206

- I Arel; D C Rose; T P Karnowski; Deep Machine Learning - A New Frontier in Artificial Intelligence Research [Research Frontier]. IEEE Computational Intelligence Magazine 2010, 5, 13-18, 10.1109/MCI.2010.938364.

- Raz Birman; Yoram Segal; Ofer Hadar; Overview of Research in the field of Video Compression using Deep Neural Networks. Multimedia Tools and Applications 2020, 79, 11699-11722, 10.1007/s11042-019-08572-3.

- Khaled Elgeneidy; Gerhard Neumann; Michael Jackson; Niels Lohse; Directly Printable Flexible Strain Sensors for Bending and Contact Feedback of Soft Actuators. Frontiers in Robotics and AI 2018, 5, ., 10.3389/frobt.2018.00002.

- Peng Qi; Chuang Liu; Ahmad Ataka; Hak-Keung Lam; Kaspar Althoefer; Kinematic Control of Continuum Manipulators Using a Fuzzy-Model-Based Approach. IEEE Transactions on Industrial Electronics 2016, 63, 5022-5035, 10.1109/tie.2016.2554078.

- Khaled Elgeneidy; Niels Lohse; Michael Jackson; Bending angle prediction and control of soft pneumatic actuators with embedded flex sensors – A data-driven approach. Mechatronics 2018, 50, 234-247, 10.1016/j.mechatronics.2017.10.005.

- C. Larson; B. Peele; S. Li; S. Robinson; Massimo Totaro; Lucia Beccai; Barbara Mazzolai; Robert F. Shepherd; Highly stretchable electroluminescent skin for optical signaling and tactile sensing. Science 2016, 351, 1071-1074, 10.1126/science.aac5082.

- Thomas George Thuruthel; Benjamin Shih; Cecilia Laschi; Michael T. Tolley; Soft robot perception using embedded soft sensors and recurrent neural networks. Science Robotics 2019, 4, eaav1488, 10.1126/scirobotics.aav1488.

- Zhou Xian; Between Knowledge and Politics: Reflections on Reading Ming Dong Gu’s Sinologism: An Alternative to Orientalism and Postcolonialism. Philosophy East and West 2015, 65, 1273-1279, 10.1353/pew.2015.0094.

- Rafael Garcia; Alexandru Telea; Bruno Castro Da Silva; Jim Torresen; João Luiz Dihl Comba; A task-and-technique centered survey on visual analytics for deep learning model engineering. Computers & Graphics 2018, 77, 30-49, 10.1016/j.cag.2018.09.018.

- Jens Kober; J. Andrew Bagnell; Jan Peters; Reinforcement learning in robotics: A survey. The International Journal of Robotics Research 2013, 32, 1238-1274, 10.1177/0278364913495721.

- Javier López-Martínez; José Luis Blanco-Claraco; D. García-Vallejo; A.G. Giménez-Fernández; Design and analysis of a flexible linkage for robot safe operation in collaborative scenarios. Mechanism and Machine Theory 2015, 92, 1-16, 10.1016/j.mechmachtheory.2015.04.018.

- Ivan Koryakovskiy; Manuel Kudruss; Robert Babuska; Wouter Caarls; Christian Kirches; Katja Mombaur; Johannes P. Schlöder; Heike Vallery; Benchmarking model-free and model-based optimal control. Robotics and Autonomous Systems 2017, 92, 81-90, 10.1016/j.robot.2017.02.006.

- Jingwei Zhang; Jost Tobias Springenberg; Joschka Boedecker; Wolfram Burgard; Deep reinforcement learning with successor features for navigation across similar environments. 2017 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS) 2017, null, 2371-2378, 10.1109/iros.2017.8206049.

- Lei Tai; Giuseppe Paolo; Ming Liu; Virtual-to-real Deep Reinforcement Learning: Continuous Control of Mobile Robots for Mapless Navigation. null 2017, null, , null.

- Sara Nasiri; Mohammad Reza Khosravani; Kerstin Weinberg; Fracture mechanics and mechanical fault detection by artificial intelligence methods: A review. Engineering Failure Analysis 2017, 81, 270-293, 10.1016/j.engfailanal.2017.07.011.

- Ali Zolfagharian; Abbas Z. Kouzani; Amir Ali Amiri Moghadam; Sui Yang Khoo; Saeid Nahavandi; Akif Kaynak; Rigid elements dynamics modeling of a 3D printed soft actuator. Smart Materials and Structures 2018, 28, 025003, 10.1088/1361-665x/aae41a.

- Frederick Largilliere; Valerian Verona; Eulalie Coevoet; Mario Sanz-Lopez; Jeremie Dequidt; Christian Duriez; Largilliere F.; Verona V.; Coevoet E.; Sanz-Lopez M.; Dequidt J.; Duriez C.; Real-time control of soft-robots using asynchronous finite element modeling. 2015 IEEE International Conference on Robotics and Automation (ICRA) 2015, null, 2550-2555, 10.1109/icra.2015.7139541.

- Tzeng, E.; Hoffman, J.; Zhang, N.; Saenko, K.; Darrell, T. Deep domain confusion: Maximizing for domain invariance. arXiv 2014, arXiv:1412.3474.

- Ali Zolfagharian; Abbas Z. Kouzani; Sui Yang Khoo; Bijan Nasri-Nasrabadi; Akif Kaynak; Development and analysis of a 3D printed hydrogel soft actuator. Sensors and Actuators A: Physical 2017, 265, 94-101, 10.1016/j.sna.2017.08.038.

- M. Bodaghi; A. Serjouei; A. Zolfagharian; M. Fotouhi; H. Rahman; D. Durand; R. Hafizur; Reversible energy absorbing meta-sandwiches by FDM 4D printing. International Journal of Mechanical Sciences 2020, 173, 105451, 10.1016/j.ijmecsci.2020.105451.

- Fanghao Zhou; Mingqi Zhang; Xunuo Cao; Zhen Zhang; Xiangping Chen; Youhua Xiao; Yiming Liang; Tuck-Whye Wong; Tiefeng Li; Zhongbin Xu; et al. Fabrication and modeling of dielectric elastomer soft actuator with 3D printed thermoplastic frame. Sensors and Actuators A: Physical 2019, 292, 112-120, 10.1016/j.sna.2019.02.017.

- Ryan L. Truby; Michael Wehner; Abigail K. Grosskopf; Daniel M. Vogt; Sebastien G. M. Uzel; Robert J. Wood; Jennifer A. Lewis; Soft Somatosensitive Actuators via Embedded 3D Printing. Advanced Materials 2018, 30, 1706383, 10.1002/adma.201706383.

- Pedro Alhais Lopes; Hugo Paisana; Aníbal T. De Almeida; Carmel Majidi; Mahmoud Tavakoli; Hydroprinted Electronics: Ultrathin Stretchable Ag–In–Ga E-Skin for Bioelectronics and Human–Machine Interaction. ACS Applied Materials & Interfaces 2018, 10, 38760-38768, 10.1021/acsami.8b13257.

- Wang, G.; Cheng, T.; Do, Y.; Yang, H.; Tao, Y.; Gu, J.; An, B.; Yao, L. Printed Paper Actuator: A Low-cost Reversible Actuation and Sensing Method for Shape Changing Interfaces. In Proceedings of the 2018 CHI Conference on Human Factors in Computing Systems, Montreal, QC, Canada, 21–26 April 2018; pp. 1–12.

- Jongsung Park; Ji-Kwan Kim; Su A. Park; Dong-Weon Lee; Biodegradable polymer material based smart stent: Wireless pressure sensor and 3D printed stent. Microelectronic Engineering 2019, 206, 1-5, 10.1016/j.mee.2018.12.007.

- Zhouyue Lei; Quankang Wang; Peiyi Wu; A multifunctional skin-like sensor based on a 3D printed thermo-responsive hydrogel. Materials Horizons 2017, 4, 694-700, 10.1039/C7MH00262A.

- Yoshida, K.; Takishima, Y.; Hara, Y.; Kawakami, M.; Furukawa, H. 3D printing for gel robotics. In Nano-, Bio-, Info-Tech Sensors, and 3D Systems II; International Society for Optics and Photonics: Bellingham, WA, USA, 2018; p. 1059717.

- Neubauer, J.; Stalbaum, T.; Kim, K.J. IPMC Embedded in a Pneumatic Soft Robotic Actuator: Preliminary Experiments in Actuation and SensingBehaviors. In Proceedings of the 2018 15th International Conference on Ubiquitous Robots (UR), Honolulu, HI, USA, 26–30 June 2018; pp. 80–82.

- Jikai Liu; Andrew T. Gaynor; Shikui Chen; Zhan Kang; Krishnan Suresh; Aikihiro Takezawa; Lei Li; Junji Kato; Jinyuan Tang; Charlie C. L. Wang; et al.Lin ChengXuan LiangAlbert C. To Current and future trends in topology optimization for additive manufacturing. Structural Optimization 2018, 57, 2457-2483, 10.1007/s00158-018-1994-3.

- Thuruthel, T.G.; Abidi, S.H.; Cianchetti, M.; Laschi, C.; Falotico, E.; A bistable soft gripper with mechanically embedded sensing and actuation for fast closed-loop grasping. arXiv 2019,, arXiv:1902.04896, ..

- Rob B. N. Scharff; Rens M. Doornbusch; Eugeni L. Doubrovski; Jun Wu; Jo M. P. Geraedts; Charlie C. L. Wang; Zjenja Doubrovski; Color-Based Proprioception of Soft Actuators Interacting With Objects. IEEE/ASME Transactions on Mechatronics 2019, 24, 1964-1973, 10.1109/tmech.2019.2929818.

- Xiaozhi Zhang; Guangwei Wang; Qingsong Xu; Design, Analysis and Testing of a New Compliant Compound Constant-Force Mechanism. Actuators 2018, 7, 65, 10.3390/act7040065.

- Hoon Yeub Jeong; Eunseo Lee; Sangho Ha; Namhun Kim; Young Chul Jun; Multistable Thermal Actuators Via Multimaterial 4D Printing. Advanced Materials Technologies 2018, 4, 1800495, 10.1002/admt.201800495.

- Anand K. Mishra; Thomas J. Wallin; Wenyang Pan; Patricia A. Xu; Kaiyang Wang; Emmanuel P. Giannelis; Barbara Mazzolai; Robert F. Shepherd; Autonomic perspiration in 3D-printed hydrogel actuators. Science Robotics 2020, 5, eaaz3918, 10.1126/scirobotics.aaz3918.

- Majid Taghavi; Tim Helps; Boxiong Huang; Jonathan Rossiter; 3D-Printed Ready-To-Use Variable-Stiffness Structures. IEEE Robotics and Automation Letters 2018, 3, 2402-2407, 10.1109/lra.2018.2812917.

- Yuan-Fang Zhang; Ningbin Zhang; Hardik Hingorani; Ningyuan Ding; Ng Wang; Chao Yuan; Biao Zhang; Guoying Gu; Qi Ge; Fast‐Response, Stiffness‐Tunable Soft Actuator by Hybrid Multimaterial 3D Printing. Advanced Functional Materials 2019, 29, 1806698, 10.1002/adfm.201806698.

- Yang Yang; Yingtian Li; Yonghua Chen; Principles and methods for stiffness modulation in soft robot design and development. Bio-Design and Manufacturing 2018, 1, 14-25, 10.1007/s42242-018-0001-6.

- Gang Zheng; Yuan Zhou; Mingda Ju; Robust control of a silicone soft robot using neural networks.. ISA Transactions 2019, ., ., 10.1016/j.isatra.2019.12.004.