| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Amine el Mahdi Safhi | -- | 782 | 2024-11-22 07:36:01 | | | |

| 2 | Vicky Zhou | Meta information modification | 782 | 2024-11-22 07:44:01 | | |

Video Upload Options

Non-destructive testing (NDT) is essential for evaluating the integrity and safety of structures without causing damage. The integration of artificial intelligence (AI) into traditional NDT methods can revolutionize the field by automating data analysis, enhancing defect detection accuracy, enabling predictive maintenance, and facilitating data-driven decision-making. This entry provides a comprehensive overview of AI-enhanced NDT, detailing AI models and their applications in techniques like ultrasonic testing and ground-penetrating radar. Case studies demonstrate that AI can improve defect detection accuracy and reduce inspection times. Challenges related to data quality, ethical considerations, and regulatory standards were discussed as well. By summarizing established knowledge and highlighting advancements, this entry serves as a valuable reference for engineers and researchers, contributing to the development of safer and more efficient infrastructure management practices.

-

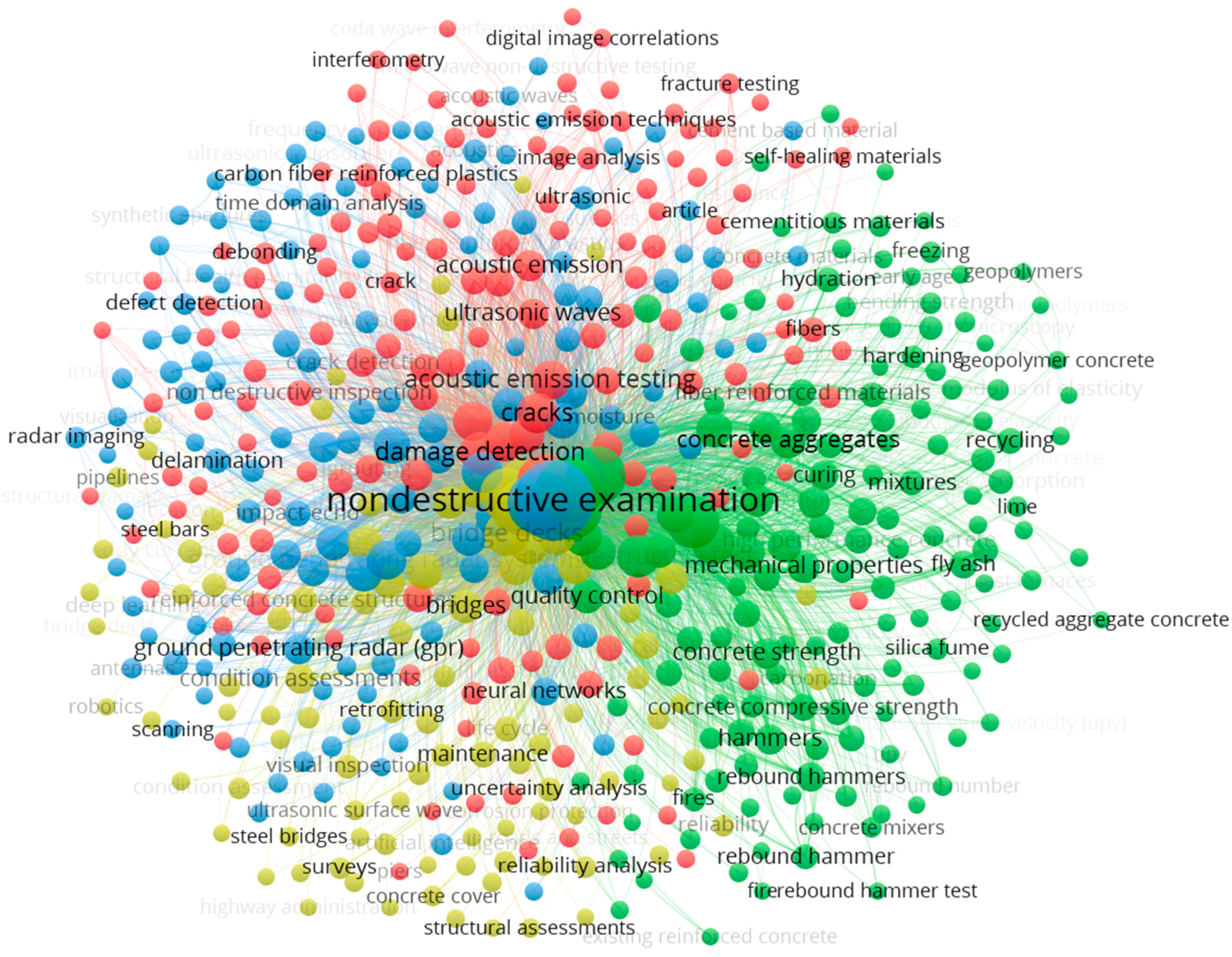

Red cluster (159 items): Material properties. This group focuses on fracture testing, self-healing materials, digital image correlations, and interferometry. These represent more specialized and emerging techniques in the NDT domain.

-

Green cluster (150 items): Mechanical properties. This section focuses on concrete-related testing methods, aggregate analysis, compressive strength, and mechanical properties. The presence of terms like geopolymer concrete, recycled aggregate, and curing mixtures suggests a focus on sustainable and advanced concrete technologies.

-

Blue cluster (133 items): Acoustic NDT methods. This cluster focuses on methods like acoustic emission, ultrasonic waves, defect detection, radar imaging, and damage detection. These are common techniques used to identify internal flaws in materials.

-

Yellow cluster (100 items): Structure quality. This section appears to emphasize infrastructure assessment and condition monitoring, including ground-penetrating radar (GPR), retrofitting, quality control, and maintenance.

References

- Ottosen, L.M.; Kunther, W.; Ingeman-Nielsen, T.; Karatosun, S. Non-Destructive Testing for Documenting Properties of Structural Concrete for Reuse in New Buildings: A Review. Materials 2024, 17, 3814.

- Azimi, M.; Eslamlou, A.D.; Pekcan, G. Data-Driven Structural Health Monitoring and Damage Detection through Deep Learning: State-of-the-Art Review. Sensors 2020, 20, 2778.

- Taheri, H.; Gonzalez Bocanegra, M.; Taheri, M. Artificial Intelligence, Machine Learning and Smart Technologies for Nondestructive Evaluation. Sensors 2022, 22, 4055.

- Sarkar, K.; Shiuly, A.; Dhal, K.G. Revolutionizing Concrete Analysis: An in-Depth Survey of AI-Powered Insights with Image-Centric Approaches on Comprehensive Quality Control, Advanced Crack Detection and Concrete Property Exploration. Constr. Build. Mater. 2024, 411, 134212.

- Zhang, C.; Yan, Q.; Zhang, Y.; Liao, X.; Xu, G.; He, Z. Nondestructive Detection of Fiber Content in Steel Fiber Reinforced Concrete through Percussion Method Coordinated with a Hybrid Deep Learning Network. J. Build. Eng. 2024, 86, 108857.

- Alavi, S.A.; Noel, M.; Moradi, F.; Layssi, H. Development of a Machine Learning Model for On-Site Evaluation of Concrete Compressive Strength by SonReb. J. Build. Eng. 2024, 82, 108328.

- Safhi, A.e.M.; Mejjad, N.; El FadilI, H.; Bortali, M. Dredged Materials in Morocco: Current Practices, Policies, and Roadmap for Sustainable Management. Case Stud. Constr. Mater. 2024, 20, e03045.

- Safhi, A.e.M.; Dabiri, H.; Soliman, A.; Khayat, K.H. Prediction of Self-Consolidating Concrete Properties Using XGBoost Machine Learning Algorithm: Part 1–Workability. Constr. Build. Mater. 2023, 408, 133560.

- Benaicha, M. AI-Driven Prediction of Compressive Strength in Self-Compacting Concrete: Enhancing Sustainability through Ultrasonic Measurements. Sustainability 2024, 16, 6644.