Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Hai Zhu | -- | 1702 | 2024-03-12 04:11:03 | | | |

| 2 | Catherine Yang | Meta information modification | 1702 | 2024-03-12 04:25:14 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Zhu, H.; Chen, J.; Lin, Y.; Guo, J.; Gao, X.; Chen, Y.; Ge, Y.; Wang, W. In-Line Inspection (ILI) Techniques for Subsea Pipelines. Encyclopedia. Available online: https://encyclopedia.pub/entry/56140 (accessed on 07 February 2026).

Zhu H, Chen J, Lin Y, Guo J, Gao X, Chen Y, et al. In-Line Inspection (ILI) Techniques for Subsea Pipelines. Encyclopedia. Available at: https://encyclopedia.pub/entry/56140. Accessed February 07, 2026.

Zhu, Hai, Jiawang Chen, Yuan Lin, Jin Guo, Xu Gao, Yuanjie Chen, Yongqiang Ge, Wei Wang. "In-Line Inspection (ILI) Techniques for Subsea Pipelines" Encyclopedia, https://encyclopedia.pub/entry/56140 (accessed February 07, 2026).

Zhu, H., Chen, J., Lin, Y., Guo, J., Gao, X., Chen, Y., Ge, Y., & Wang, W. (2024, March 12). In-Line Inspection (ILI) Techniques for Subsea Pipelines. In Encyclopedia. https://encyclopedia.pub/entry/56140

Zhu, Hai, et al. "In-Line Inspection (ILI) Techniques for Subsea Pipelines." Encyclopedia. Web. 12 March, 2024.

Copy Citation

Offshore oil and gas resources play a crucial role in supplementing the energy needs of human society. The crisscrossing subsea pipeline network, which serves as vital infrastructure for the storage and transportation of offshore oil and gas, requires regular inspection and maintenance to ensure safe operation and prevent ecological pollution. In-line inspection (ILI) techniques have been widely used in the detection and inspection of potential hazards within the pipeline network.

subsea pipelines

in-line inspection (ILI)

non-destructive testing (NDT)

pipeline inspection gauge (PIG)

1. Introduction

The ocean, teeming with an array of resources such as oil and gas reserves, mineral deposits, diverse biological entities, and vital water reserves, is often hailed as the “blue frontier” [1][2][3][4][5]. Subsea energy minerals within the oceanic strata, due to their immense economic value, have been extensively exploited [6][7]. Taking offshore oil and gas resources as an example, with the rapid development of ocean engineering technology [8][9][10], the cost and difficulty of production have been decreasing year by year [11][12]. In addition, the geopolitical influence and the increasing cost of onshore oil and gas extraction have made offshore energy an important growth area for energy supply [13][14][15][16]. Consequently, there is an urgent societal and economic demand for rapid, voluminous, economical, and reliable oil and gas storage and transportation [17].

Subsea pipelines offer a definitive solution [18][19][20][21]. Originating in the Gulf of Mexico in the United States, the world’s first subsea pipeline was constructed there in 1951, spanning a total length of 16 kilometers. As depicted in Figure 1, subsequent to this milestone, the global construction of subsea pipelines expanded comprehensively, encompassing regions such as North America, Latin America, Australasia, East Asia, Southeast Asia, Africa, the Mediterranean, and the Middle East [22]. This has led to the formation of a vast and interconnected network of undersea pipelines. Compared to maritime shipping, subsea pipelines have saved substantial costs in cross-sea oil product transportation, achieving notable economic and scale benefits [23]. Taking China as an example, pipelines, which constitute 5% of the total length of subsea oil and gas pipelines, handle 25% of the total throughput of petroleum and natural gas [24].

Figure 1. Laying of subsea pipelines (left) and a crisscrossing subsea pipeline network (right).

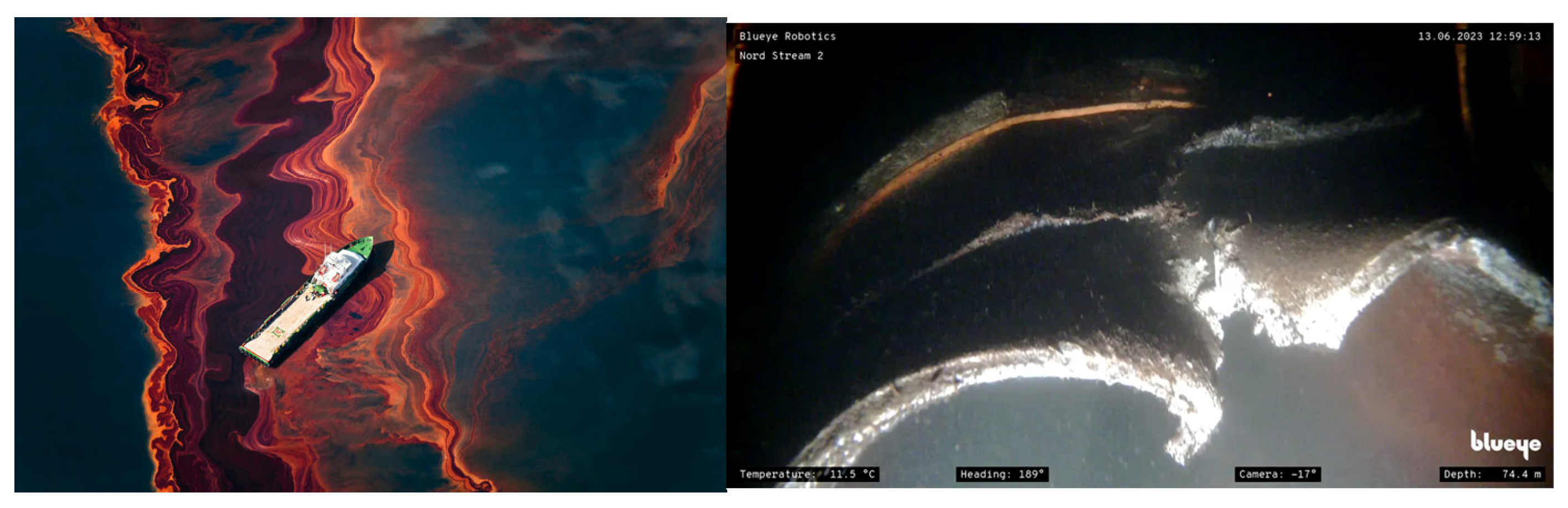

However, corresponding to this, the maintenance cost of subsea pipelines is also extremely high [25]. Subsea pipelines may suffer from deformation defects under various damaging factors (such as corrosion, alternating sea currents, geological deformation, and human activities) [26][27][28]. Severe interplay among these factors can exacerbate each other and may even lead to pipeline rupture, causing major safety accidents, and inestimable damage to the global environment and regional economies [29][30]. As shown in Figure 2, the oil spill from the 2010 Gulf of Mexico oil drilling platform was considered the worst marine oil spill in American history, causing massive ecological devastation [31] and sparking subsequent studies on the aftermath of this event by numerous scholars [32][33][34][35]. In 2022, explosions occurred in the primary pipelines transporting natural gas from Russia to Europe, the Nord Stream 1 and Nord Stream 2, severely affecting the energy supply in Europe, exacerbating the European energy crisis, and impacting regional politics [36]. As the lifeline of offshore oil and gas engineering [37], maintaining the integrity of pipelines becomes an area of increasing relevance [38]

Figure 2. Oil spill in the Gulf of Mexico (left) and damaged section of the Nord Stream pipeline (right).

The length of submarine pipelines is generally measured in kilometers, and the length of some longer submarine pipelines can reach tens of kilometers, making it quite difficult to inspect for damage. For submarine pipelines that have already leaked, remote sensing, the negative pressure wave method, the subsonic wave method, and the Transient Test-Based Techniques (TTBTs) can be used for leak detection and localization [39][40]. Taking negative pressure waves and TTBTs as examples, data quality, a dynamic slope in anomaly detection, and false alarms caused by normal working condition changes are the three primary technological challenges associated with the negative pressure wave [41]. Furthermore, achieving an accurate estimation of the time difference between the arrival of leakage-induced negative pressure wave signals at the sensor’s two sides is key in precisely locating the leakage point. In this regard, a leakage location algorithm based on difference cross-correlation delay estimation has been established [42]. TTBTs can offer the capability to detect not only leaks but also various defects, such as partial blockages, wall deterioration, and even branching features. Moreover, TTBTs have proven their effectiveness not only in controlled laboratory environments but also under real-world conditions in operational pipe systems [43][44][45]. For pipelines that have not yet leaked, their daily maintenance relies on monitoring the operating parameters of the pipeline system (such as the pressure, temperature, flow rate, density, and pH value at the inlet and outlet), checking fluid composition data, inspecting cleaning data, and inspecting corrosion monitoring data [46]. For suspected deformation points, in-line inspection (ILI) is accepted as the optimum approach, detecting and qualifying flaws as well as revealing the growth rate information of active flaws [47][48].

The typical underwater pipeline inspection process includes pigging, flushing, mechanical cleaning, internal inspection, and issuing an inspection report. The narrow sense of pipeline internal inspection specifically refers to the measurement and evaluation of parameters such as pipeline deformation defects, metal loss, cracks, welds, and structural dimensions. This is the scope of the discussion in this article.

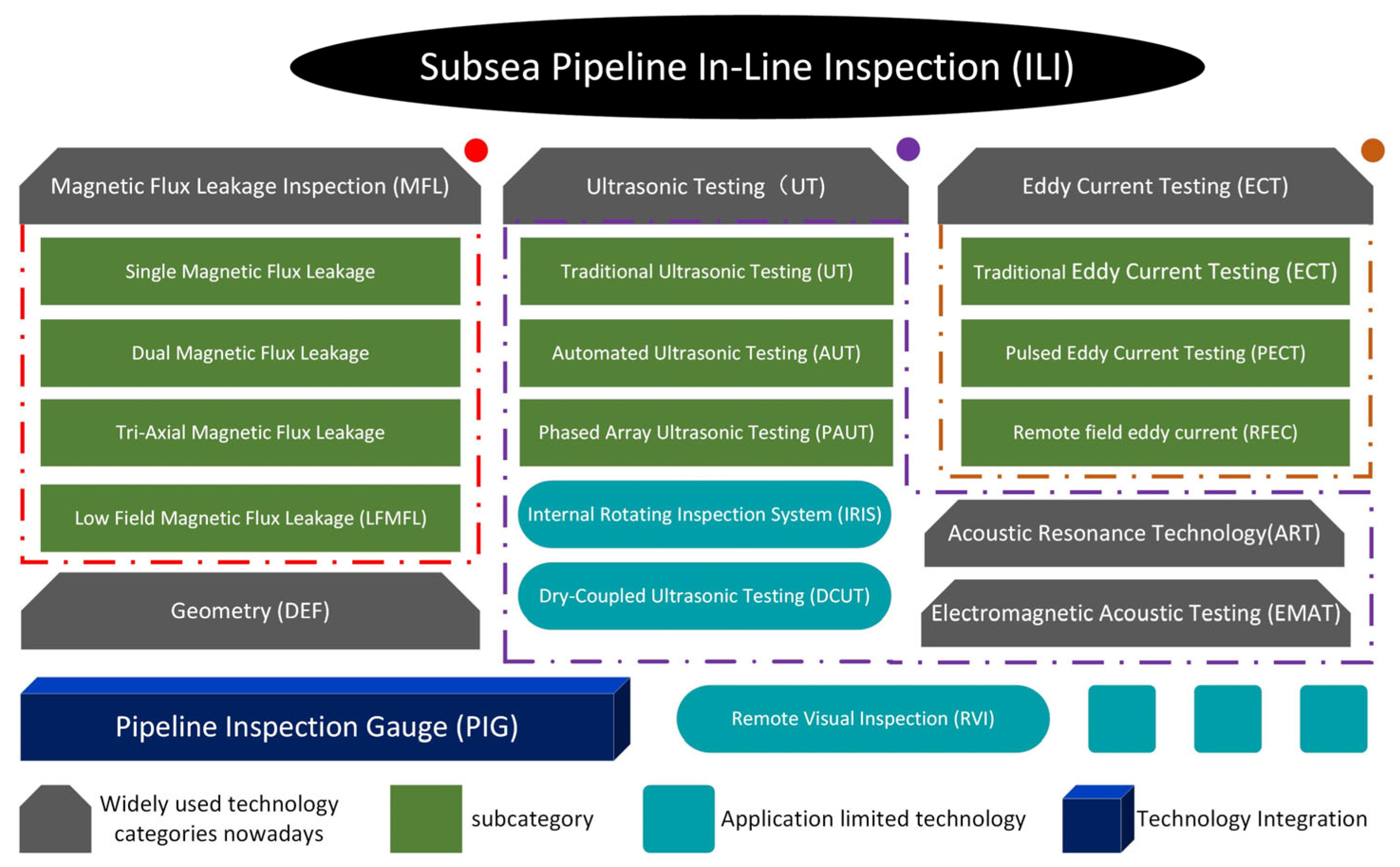

Figure 3 depicts the classification of ILI methodologies, including geometry deformation mapping (DEF) and NDT methods. These NDT techniques cover a wide array of technologies, typically including Magnetic Flux Leakage (MFL), Ultrasonic Testing (UT), Eddy Current Testing (ECT), Electromagnetic Acoustic Testing (EMAT), and Acoustic Resonance Technology (ART).

Figure 3. Classification of internal inspection techniques for submarine pipelines.

The solitary application of each technology can lead to partial insights into pipeline health due to their individual constraints. However, integrating these NDT methods within a single Pipeline Inspection Gauge (PIG) framework allows for a comprehensive, multi-faceted analysis. Such an integrated approach enables the cross-verification of data, enhancing detection accuracy and reliability. This consensus for a united inspection system has evolved from the necessity to ensure maximal coverage and diagnostic precision, facilitating preemptive maintenance strategies and reducing the risk of pipeline failures.

2. Possible New Technologies

The applicability and innovation of technologies in the field of subsea pipeline inspection are vital. Although certain technologies may not initially be suitable for the complexity and harsh conditions of the subsea environment, future research and enhancements could render them viable. Here is an extended discussion on two original technologies that, with redesign and optimization, could potentially be adapted for subsea pipeline inspection tasks.

2.1. Internal Rotating Inspection System (IRIS)

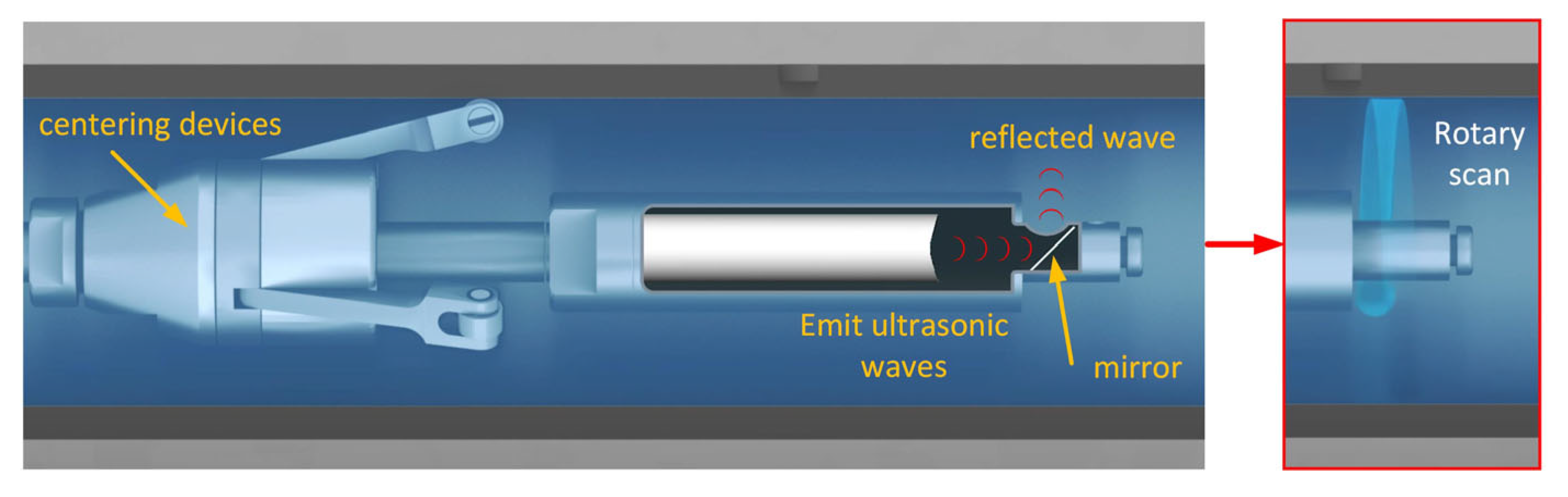

IRIS is a distinct variation of UT, functioning on the principle illustrated in Figure 4. IRIS relies on a transducer that generates ultrasonic pulses parallel to the axis of the pipe being tested. The ultrasonic waves are then directed perpendicularly into the pipe wall by a reflector. The rotation of the reflector is driven by a small turbine, which is powered by the medium within the pipe. Similar to conventional ultrasonic testing, a portion of the ultrasonic waves is reflected by the inner wall, while the remainder is reflected by the outer wall. As the velocity of ultrasonic waves in the pipe material is known, the thickness of the wall can be assessed by calculating the difference in flight time between the echoes.

Figure 4. The principle of IRIS ILI.

As shown in Figure 5, a key to the quality of IRIS inspection is ensuring that the reflector is centered within the pipe, as eccentricity or wobble can produce distorted scan images. The Olympus, located in Tokyo, Japan, its ILI tool, embracing IRIS technology, epitomizes an advanced ultrasonic inspection method, markedly efficacious for exhaustive scrutiny within the petrochemical industry and for evaluations of balance-of-plant tubing. This refined modality is adept at gauging wall thickness variations, discerning material degradation, and ascertaining flaw orientations in tubes with internal diameters from 0.5 to 3 inches. It is meticulously engineered to conduct thorough inspections of tube and shell heat exchangers, air-cooled heat exchangers, and boiler tubes, delivering superior accuracy in the detection and characterization of potential defects, thereby bolstering the safety and reliability of these critical components.

Figure 5. Olympus’ IRIS ILI tool.

IRIS can detect corrosion, pitting, and wall loss and is most commonly used for tube inspection in boilers, heat exchangers, air coolers, and feed water heaters. It is particularly versatile as it is suitable for both ferrous and non-ferrous materials, and IRIS can be used on a wide range of tube diameters and wall thicknesses. Companies producing inspection equipment based on IRIS technology include Eddyfi Technologies in Quebec City, QC, Canada; APPLUS in Barcelona, Spain; and Olympus in Tokyo, Japan, among others. However, while IRIS is commonly used for inspecting heat-exchanger tubing, there are no instances of its use for subsea pipeline inspection to date.

2.2. Dry-Coupled Ultrasonic Testing (DCUT)

DCUT offers a cost-effective and environmentally friendly solution for the inspection of a wide array of materials, both metallic and non-metallic, negating the requirement for liquid couplants. Capable of accommodating high voltages, DCUT utilizes diverse transducer types such as flexible, contact, wheel, and remote UT transducers, as illustrated in Figure 6. This breakthrough in non-destructive evaluation harnesses cutting-edge high-voltage piezoelectric transducers that proficiently propagate ultrasound through a rubber medium, bypassing the necessity for conventional liquid couplants. This pioneering method mitigates issues related to liquid couplants, such as the risk of environmental harm, potential damage to components, and ancillary expenses. Additionally, DCUT extends the versatility of ultrasonic examinations to a more comprehensive range of material forms and geometries.

Figure 6. Types of dry-coupled UT transducers.

The advent of flexible, thin-profile transducers through DCUT enables the swift and precise detection of flaws and the measurement of material thickness, even on intricate configurations. This is further complemented by the incorporation of wheel probes and remote contact sensors, which facilitate extensive scanning and access to otherwise unreachable areas. When combined with high-power UT instruments, DCUT transducers streamline the inspection workflow, excising the logistical and financial burdens associated with couplant usage. As a result, DCUT not only enhances the efficiency of inspection practices but also offers a more sustainable, cost-effective, and adaptable option for industrial inspection demands, thereby expanding the capabilities of ultrasonic testing without compromising on accuracy or dependability. However, despite its benefits, DCUT’s application within the natural gas pipeline sector remains limited and has not yet met the foundational requirements for in situ use on underwater pipelines.

References

- Tong, X.; Zhang, G.; Wang, Z.; Wen, Z.; Tian, Z.; Wang, H.; Ma, F.; Wu, Y. Distribution and Potential of Global Oil and Gas Resources. Pet. Explor. Dev. 2018, 45, 779–789.

- Rosenberg, A.A.; Bolster, W.J.; Alexander, K.E.; Leavenworth, W.B.; Cooper, A.B.; McKenzie, M.G. The History of Ocean Resources: Modeling Cod Biomass Using Historical Records. Front. Ecol. Environ. 2005, 3, 78–84.

- Kim, G.; Lee, M.E.; Lee, K.S.; Park, J.-S.; Jeong, W.M.; Kang, S.K.; Soh, J.-G.; Kim, H. An Overview of Ocean Renewable Energy Resources in Korea. Renew. Sustain. Energy Rev. 2012, 16, 2278–2288.

- Zheng, C.W.; Li, C.Y.; Pan, J.; Liu, M.Y.; Xia, L.L. An Overview of Global Ocean Wind Energy Resource Evaluations. Renew. Sustain. Energy Rev. 2016, 53, 1240–1251.

- Chong, Z.R.; Yang, S.H.B.; Babu, P.; Linga, P.; Li, X.-S. Review of Natural Gas Hydrates as an Energy Resource: Prospects and Challenges. Appl. Energy 2016, 162, 1633–1652.

- Xu, Z.; Hu, T.; Pang, X.-Q.; Wang, E.-Z.; Liu, X.-H.; Wu, Z.-Y.; Chen, D.; Li, C.-R.; Zhang, X.-W.; Wang, T. Research Progress and Challenges of Natural Gas Hydrate Resource Evaluation in the South China Sea. Pet. Sci. 2022, 19, 13–25.

- Peach, J.; Starbuck, C.M. Oil and Gas Production and Economic Growth in New Mexico. J. Econ. Issues 2011, 45, 511–526.

- Wang, H.; Chen, J.; Cao, C.; Ge, Y.; Fang, J.; Zhou, P.; Lin, P. Capturing Amphipods in the Mariana Trench with a Novel Pressure Retaining Sampler. Deep Sea Res. Part I Oceanogr. Res. Pap. 2022, 184, 103772.

- Abimbola, M.; Khan, F.; Khakzad, N. Dynamic Safety Risk Analysis of Offshore Drilling. J. Loss Prev. Process Ind. 2014, 30, 74–85.

- Randolph, M.F.; Gaudin, C.; Gourvenec, S.M.; White, D.J.; Boylan, N.; Cassidy, M.J. Recent Advances in Offshore Geotechnics for Deep Water Oil and Gas Developments. Ocean Eng. 2011, 38, 818–834.

- Hansen, P.; de Luna Pedrosa Filho, E.; Ribeiro, C.C. Location and Sizing of Offshore Platforms for Oil Exploration. Eur. J. Oper. Res. 1992, 58, 202–214.

- Suslick, S.B.; Furtado, R. Quantifying the Value of Technological, Environmental and Financial Gain in Decision Models for Offshore Oil Exploration. J. Pet. Sci. Eng. 2001, 32, 115–125.

- Sällh, D.; Wachtmeister, H.; Tang, X.; Höök, M. Offshore Oil: Investigating Production Parameters of Fields of Varying Size, Location and Water Depth. Fuel 2015, 139, 430–440.

- Sorrell, S.; Speirs, J.; Bentley, R.; Miller, R.; Thompson, E. Shaping the Global Oil Peak: A Review of the Evidence on Field Sizes, Reserve Growth, Decline Rates and Depletion Rates. Energy 2012, 37, 709–724.

- Hu, W.; Bao, J.; Hu, B. Trend and Progress in Global Oil and Gas Exploration. Pet. Explor. Dev. 2013, 40, 439–443.

- Managi, S.; Opaluch, J.J.; Jin, D.; Grigalunas, T.A. Technological Change and Depletion in Offshore Oil and Gas. J. Environ. Econ. Manag. 2004, 47, 388–409.

- Zhang, H.; Zhang, S.; Wang, Y.; Liu, Y.; Yang, Y.; Zhou, T.; Bian, H. Subsea pipeline leak inspection by autonomous underwater vehicle. Appl. Ocean Res. 2021, 107, 102321.

- Fyrileiv, O.; Aamlid, O.; Venås, A.; Collberg, L. Deepwater Pipelines—Status, Challenges and Future Trends. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2013, 227, 381–395.

- Shafiee, M.; Ayudiani, P.S. Development of a Risk-Based Integrity Model for Offshore Energy Infrastructures—Application to Oil and Gas Pipelines. Int. J. Process Syst. Eng. 2015, 3, 211–231.

- Seo, J.K.; Cui, Y.; Mohd, M.H.; Ha, Y.C.; Kim, B.J.; Paik, J.K. A Risk-Based Inspection Planning Method for Corroded Subsea Pipelines. Ocean Eng. 2015, 109, 539–552.

- Ouyang, Y.; Wang, C.; Wu, Y.; Zhang, J.; Lin, Z.; Cai, L. Trend of the Environmental Supervision on Submarine Pipeline Installation. Environ. Sci. Pollut. Res. 2018, 25, 28829–28833.

- Fang, H.; Duan, M. Submarine Pipelines and Pipeline Cable Engineering. In Offshore Operation Facilities; Fang, H., Duan, M., Eds.; Gulf Professional Publishing: Boston, MA, USA, 2014; pp. e1–e181. ISBN 978-0-12-396977-4.

- Kahnamouei, J.T.; Moallem, M. A comprehensive review of in-pipe robots. Ocean Eng. 2023, 277, 114260.

- Chen, R.; Lei, Z. Progress and outlook of submarine pipeline engineering technologies in China. Oil Gas Storage Transp. 2022, 41, 667–672.

- Mahdi, E.; Eltai, E. Development of cost-effective composite repair system for oil/gas pipelines. Compos. Struct. 2018, 202, 802–806.

- Andersen, T.; Misund, A. Pipeline Reliability: An Investigation of Pipeline Failure Characteristics and Analysis of Pipeline Failure Rates for Submarine and Cross-Country Pipelines. J. Pet. Technol. 1983, 35, 709–717.

- Tian, Y.; Chai, W.; Borgi, S.E.; Zhang, C.; Sun, L.; Xiao, Z.; Fu, D. Assessment of Submarine Pipeline Damages Subjected to Falling Object Impact Considering the Effect of Seabed. Mar. Struct. 2021, 78, 102963.

- Fan, N.; Jiang, J.; Nian, T.; Dong, Y.; Guo, L.; Fu, C.; Tian, Z.; Guo, X. Impact Action of Submarine Slides on Pipelines: A Review of the State-of-the-Art since 2008. Ocean Eng. 2023, 286, 115532.

- Adumene, S.; Khan, F.; Adedigba, S.; Mamudu, A.; Rosli, M.I. Offshore Oil and Gas Development in Remote Harsh Environments: Engineering Challenges and Research Opportunities. Saf. Extrem. Environ. 2023, 5, 17–33.

- Taleghani, N.D.; Tyagi, M. Impacts of Major Offshore Oil Spill Incidents on Petroleum Industry and Regional Economy. J. Energy Resour. Technol. 2017, 139, 022913.

- Crone, T.J.; Tolstoy, M. Magnitude of the 2010 Gulf of Mexico Oil Leak. Science 2010, 330, 634.

- Dubinsky, E.A.; Conrad, M.E.; Chakraborty, R.; Bill, M.; Borglin, S.E.; Hollibaugh, J.T.; Mason, O.U.; Piceno, Y.M.; Reid, F.C.; Stringfellow, W.T.; et al. Succession of Hydrocarbon-Degrading Bacteria in the Aftermath of the Deepwater Horizon Oil Spill in the Gulf of Mexico. Environ. Sci. Technol. 2013, 47, 10860–10867.

- McCrea-Strub, A.; Kleisner, K.; Sumaila, U.R.; Swartz, W.; Watson, R.; Zeller, D.; Pauly, D. Potential Impact of the Deepwater Horizon Oil Spill on Commercial Fisheries in the Gulf of Mexico. Fisheries 2011, 36, 332–336.

- Campagna, C.; Short, F.T.; Polidoro, B.A.; McManus, R.; Collette, B.B.; Pilcher, N.J.; Sadovy de Mitcheson, Y.; Stuart, S.N.; Carpenter, K.E. Gulf of Mexico Oil Blowout Increases Risks to Globally Threatened Species. BioScience 2011, 61, 393–397.

- White, H.K.; Hsing, P.-Y.; Cho, W.; Shank, T.M.; Cordes, E.E.; Quattrini, A.M.; Nelson, R.K.; Camilli, R.; Demopoulos, A.W.J.; German, C.R.; et al. Impact of the Deepwater Horizon Oil Spill on a Deep-Water Coral Community in the Gulf of Mexico. Proc. Natl. Acad. Sci. USA 2012, 109, 20303–20308.

- Soldi, G.; Gaglione, D.; Raponi, S.; Forti, N.; d’Afflisio, E.; Kowalski, P.; Millefiori, L.M.; Zissis, D.; Braca, P.; Willett, P.; et al. Monitoring of Critical Undersea Infrastructures: The Nord Stream and Other Recent Case Studies. IEEE Aerosp. Electron. Syst. Mag. 2023, 38, 4–24.

- Du, F.; Li, C.; Wang, W. Development of Subsea Pipeline Buckling, Corrosion and Leakage Monitoring. J. Mar. Sci. Eng. 2023, 11, 188.

- Wang, H.; Yajima, A.; Liang, R.Y.; Castaneda, H. A Bayesian Model Framework for Calibrating Ultrasonic In-Line Inspection Data and Estimating Actual External Corrosion Depth in Buried Pipeline Utilizing a Clustering Technique. Struct. Saf. 2015, 54, 19–31.

- Che, T.-C.; Duan, H.-F.; Lee, P.J. Transient wave-based methods for anomaly detection in fluid pipes: A review. Mech. Syst. Signal Process. 2021, 160, 107874.

- Xu, X.; Karney, B. An Overview of Transient Fault Detection Techniques. In Modeling and Monitoring of Pipelines and Networks: Advanced Tools for Automatic Monitoring and Supervision of Pipelines; Applied Condition Monitoring; Verde, C., Torres, L., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 13–37. ISBN 978-3-319-55944-5.

- Tian, C.H.; Yan, J.C.; Huang, J.; Wang, Y.; Kim, D.-S.; Yi, T. Negative pressure wave based pipeline Leak Detection: Challenges and algorithms. In Proceedings of the 2012 IEEE International Conference on Service Operations and Logistics, and Informatics, Suzhou, China, 8–10 July 2012; pp. 372–376.

- Zhao, L.; Wang, J.; Hou, M.; Li, Z. Negative Pressure Wave Leakage Location Algorithm Based on Difference Cross-Correlation Delay Estimation. IOP Conf. Ser. Mater. Sci. Eng. 2019, 612, 042047.

- Brunone, B. Transient Test-Based Technique for Leak Detection in Outfall Pipes. J. Water Resour. Plan. Manag. 1999, 125, 302–306.

- Meniconi, S.; Capponi, C.; Frisinghelli, M.; Brunone, B. Leak Detection in a Real Transmission Main Through Transient Tests: Deeds and Misdeeds. Water Resour. Res. 2021, 57, e2020WR027838.

- Meniconi, S.; Brunone, B.; Frisinghelli, M. On the Role of Minor Branches, Energy Dissipation, and Small Defects in the Transient Response of Transmission Mains. Water 2018, 10, 187.

- Adegboye, M.A.; Fung, W.-K.; Karnik, A. Recent Advances in Pipeline Monitoring and Oil Leakage Detection Technologies: Principles and Approaches. Sensors 2019, 19, 2548.

- Brockhaus, S.; Ginten, M.; Klein, S.; Teckert, M.; Stawicki, O.; Oevermann, D.; Meyer, S.; Storey, D. In-Line Inspection (ILI) Methods for Detecting Corrosion in Underground Pipelines. In Underground Pipeline Corrosion; Orazem, M.E., Ed.; Woodhead Publishing: Sawston, UK, 2014; pp. 255–285. ISBN 978-0-85709-509-1.

- Ma, Q.; Tian, G.; Zeng, Y.; Li, R.; Song, H.; Wang, Z.; Gao, B.; Zeng, K. Pipeline In-Line Inspection Method, Instrumentation and Data Management. Sensors 2021, 21, 3862.

More

Information

Subjects:

Engineering, Ocean

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.1K

Revisions:

2 times

(View History)

Update Date:

12 Mar 2024

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No