| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Hareer Fatima Ahmed | -- | 1892 | 2024-02-15 09:22:25 | | | |

| 2 | Lindsay Dong | Meta information modification | 1892 | 2024-02-18 01:48:39 | | |

Video Upload Options

The dynamics of supply chain networks have changed due to increasing complexities. Global expansions and knowledge transfer in supply chain networks bring efficiency and effectiveness to companies. However, the probability of supply chain complexity has also been seen increasing. The barriers to sustainable supply chain networks need to be tackled in an effective manner as they impact business operations. Therefore, it is essential to eliminate and reduce the supply chain complexities, as it will facilitate the process of knowledge transfer and increase the implementation of sustainable practises in supply chain networks.

1. Introduction

2. Impact of Supply Chain Complexity on Knowledge Transfer

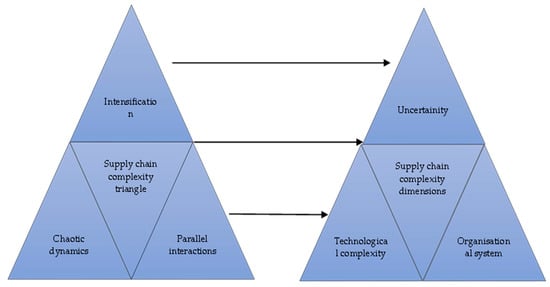

In previous studies on complex supply chain networks [5][6][7], researchers and industry professionals have examined the supply chain networks with regards to the associated complexities. Nevertheless, the growing focus on supply chain complexity reflects the growing developments in the field of supply chain management. More researchers are looking at systems and networks rather than just dyadic partnerships to better reflect on the complex structure of global supply chain networks [8][9].

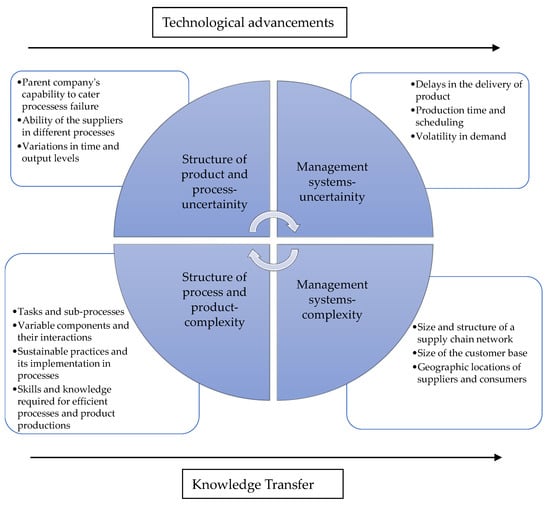

According to Sabahi and Parast, supply chains are systems made up of several entities and processes with various risk perceptions and vulnerabilities [10]. The problem of supply chain complexity has received widespread recognition in both academic research and practice. The complexity of the supply chain raises several ambiguities, difficulties, and sensitive issues for supply chain management [11]. Iftikhar et al. highlight that supply chains are becoming more disruptive, and if the complexity is not successfully handled, it might have negative effects on organisations [12]. Supply chain collaborations and internal activities contribute both externally and internally to the complexity of supply chain networks [13]. Marriotti argues that managerial decisions are also compromised due to the intricacies of supply chain systems, a challenge further exacerbated by the elevated complexity of goods, processes, and collaborations [14]. While complex linkages and interactions between entities are presented by global supply chains, higher operating expenses, lower customer satisfaction, delayed deliveries, a lack of knowledge transfer, and integration among supply chain partners are some of the essential negative effects of supply chain complexity [15]. A rising proportion of customers in industrialised regions view sustainability initiatives as more of an obligation than an added value, and this trend is particularly prevalent where growing populations are placing greater strain on the environment.

2.1. Contingency Theory

2.2. Complex Adaptive System

2.3. Natural Accident Theory

2.4. Systems Theory

References

- Weber, Y.; Tarba, S.Y. Strategic agility: A state of the art introduction to the special section on strategic agility. Calif. Manag. Rev. 2014, 56, 5–12.

- Del Giudice, M.; Maggioni, V. Managerial practices and operative directions of knowledge management within inter-firm networks: A global view. J. Knowl. Manag. 2014, 18, 841–846.

- Lee, M.C. Knowledge management and innovation management: Best practices in knowledge sharing and knowledge value chain. Int. J. Innov. Learn. 2016, 19, 206–226.

- Hussain, G.; Nazir, M.S.; Rashid, M.A.; Sattar, M.A. From supply chain resilience to supply chain disruption orientation: The moderating role of supply chain complexity. J. Enterp. Inf. Manag. 2023, 36, 70–90.

- Hobday, M. Product complexity, innovation and industrial organisation. Res. Policy 1998, 26, 689–710.

- Closs, D.J.; Jacobs, M.A.; Swink, M.; Webb, G.S. Toward a theory of competencies for the management of product complexity: Six case studies. J. Oper. Manag. 2008, 26, 590–610.

- Closs, D.J.; Nyaga, G.N.; Voss, M.D. The differential impact of product complexity, inventory level, and configuration capacity on unit and order fill rate performance. J. Oper. Manag. 2010, 28, 47–57.

- Choi, T.Y.; Wu, Z. Triads in supply networks: Theorizing buyer–supplier–supplier relationships. J. Supply Chain Manag. 2009, 45, 8–25.

- Hearnshaw, E.J.; Wilson, M.M. A complex network approach to supply chain network theory. Int. J. Oper. Prod. Manag. 2013, 33, 442–469.

- Sabahi, S.; Parast, M.M. Firm innovation and supply chain resilience: A dynamic capability perspective. Int. J. Logist. Res. Appl. 2020, 23, 254–269.

- Jermsittiparsert, K.; Srisawat, S. Complexities in a flexible supply chain and the role of knowledge transfer. Humanit. Soc. Sci. Rev. 2019, 7, 531–538.

- Iftikhar, A.; Purvis, L.; Giannoccaro, I.; Wang, Y. The impact of supply chain complexities on supply chain resilience: The mediating effect of big data analytics. Prod. Plan. Control. 2022, 34, 1562–1582.

- Chand, P.; Kumar, A.; Thakkar, J.; Ghosh, K.K. Direct and mediation effect of supply chain complexity drivers on supply chain performance: An empirical evidence of organizational complexity theory. Int. J. Oper. Prod. Manag. 2022, 42, 797–825.

- Mariotti, J.L. The Complexity Crisis: Why too Many Products, Markets, and Customers are Crippling Your Company—And What to Do about It; Simon and Schuster: New York, NY, USA, 2007.

- Lee, G. Supply Chain Complexity and Supply Chain Resilience: A Literature Review; EasyChair Preprint: Atlanta, GA, USA, 2023.

- Wilding, R. The supply chain complexity triangle: Uncertainty generation in the supply chain. Int. J. Phys. Distrib. Logist. Manag. 1998, 28, 599–616.

- Milgate, M. Supply chain complexity and delivery performance: An international exploratory study. Supply Chain Manag. Int. J. 2001, 6, 106–118.

- Christopher, M.; Lee, H. Mitigating supply chain risk through improved confidence. Int. J. Phys. Distrib. Logist. Manag. 2004, 34, 388–396.

- Soni, U.; Jain, V.; Kumar, S. Measuring supply chain resilience using a deterministic modeling approach. Comput. Ind. Eng. 2014, 74, 11–25.

- Soni, U.; Jain, V. Minimizing the vulnerabilities of supply chain: A new framework for enhancing the resilience. In Proceedings of the 2011 IEEE International Conference on Industrial Engineering and Engineering Management, Singapore, 6–9 December 2011; IEEE: Piscataway, NJ, USA, 2011; pp. 933–939.

- Papa, A.; Chierici, R.; Ballestra, L.V.; Meissner, D.; Orhan, M.A. Harvesting reflective knowledge exchange for inbound open innovation in complex collaborative networks: An empirical verification in Europe. J. Knowl. Manag. 2021, 25, 669–692.

- Philip, J. An application of the dynamic knowledge creation model in big data. Technol. Soc. 2018, 54, 120–127.

- Paulin, D.; Suneson, K. Knowledge transfer, knowledge sharing and knowledge barriers–three blurry terms in KM. Lead. Issues Knowl. Manag. 2015, 2, 73.

- Ketokivi, M. Elaborating the contingency theory of organizations: The case of manufacturing flexibility strategies. Prod. Oper. Manag. 2006, 15, 215–228.

- Brandon-Jones, E.; Squire, B.; Van Rossenberg, Y.G. The impact of supply base complexity on disruptions and performance: The moderating effects of slack and visibility. Int. J. Prod. Res. 2015, 53, 6903–6918.

- Brandon-Jones, A.; Knoppen, D. The role of strategic purchasing in dynamic capability development and deployment: A contingency perspective. Int. J. Oper. Prod. Manag. 2018, 38, 446–473.

- Day, J.M. Fostering emergent resilience: The complex adaptive supply network of disaster relief. Int. J. Prod. Res. 2014, 52, 1970–1988.

- Pathak, S.D.; Day, J.M.; Nair, A.; Sawaya, W.J.; Kristal, M.M. Complexity and adaptivity in supply networks: Building supply network theory using a complex adaptive systems perspective. Decis. Sci. 2007, 38, 547–580.

- Anderson, P. Perspective: Complexity theory and organization science. Organ. Sci. 1999, 10, 216–232.

- Kim, Y.; Chen, Y.S.; Linderman, K. Supply network disruption and resilience: A network structural perspective. J. Oper. Manag. 2015, 33, 43–59.

- Speier, C.; Whipple, J.M.; Closs, D.J.; Voss, M.D. Global supply chain design considerations: Mitigating product safety and security risks. J. Oper. Manag. 2011, 29, 721–736.

- Perrow, C. The limits of safety: The enhancement of a theory of accidents. J. Contingencies Crisis Manag. 1994, 2, 212–220.

- Marley, K.A.; Ward, P.T.; Hill, J.A. Mitigating supply chain disruptions–a normal accident perspective. Supply Chain Manag. Int. J. 2014, 19, 142–152.

- Janvier-James, A.M. A new introduction to supply chains and supply chain management: Definitions and theories perspective. Int. Bus. Res. 2012, 5, 194–207.

- Lai, C.H.; Huili Lin, S. Systems theory. In the International Encyclopedia of Organizational Communication; John Wiley & Sons: Hoboken, NJ, USA, 2017; pp. 1–18.

- Farsi, M.; Hosseinian-Far, A.; Daneshkhah, A.; Sedighi, T. Mathematical and computational modelling frameworks for integrated sustainability assessment (ISA). In Engineering for Cloud Computing and Big Data Analytics; Springer: Cham, Switzerland, 2017; pp. 3–27.

- Serdarasan, S. A review of supply chain complexity drivers. Comput. Ind. Eng. 2013, 66, 533–540.

- Dittfeld, H.; Scholten, K.; Van Donk, D. Burden or blessing in disguise: Interactions in supply chain complexity. Int. J. Oper. Prod. Manag. 2018, 38, 314–332.

- Chen, M.; Liu, H.; Wei, S.; Gu, J. Top managers’ managerial ties, supply chain integration, and firm performance in China: A social capital perspective. Ind. Mark. Manag. 2018, 74, 205–214.

- de Leeuw, S.; Grotenhuis, R.; van Goor, A.R. Assessing complexity of supply chains: Evidence from wholesalers. Int. J. Oper. Prod. Manag. 2013, 33, 960–980.

- Lorentz, H.; Töyli, J.; Solakivi, T.; Hälinen, H.M.; Ojala, L. Effects of geographic dispersion on intra-firm supply chain performance. Supply Chain Manag. Int. J. 2012, 17, 611–626.

- Vachon, S.; Klassen, R.D. An exploratory investigation of the effects of supply chain complexity on delivery performance. IEEE Trans. Eng. Manag. 2002, 49, 218–230.

- Xiao, T.; Qi, X. Price competition, cost and demand disruptions and coordination of a supply chain with one manufacturer and two competing retailers. Omega 2008, 36, 741–753.

- Kanda, A.; Deshmukh, S.G. Supply chain coordination: Perspectives, empirical studies and research directions. Int. J. Prod. Econ. 2008, 115, 316–335.

- Shou, Y.; Kang, M.; Park, Y.W. Product complexity, variety and supply chain integration. In Supply Chain Integration for Sustainable Advantages; Springer: Singapore, 2022; pp. 31–48.

- Yin, W.; Ran, W. Utilizing blockchain technology to manage the dark and bright sides of supply network complexity to enhance supply chain sustainability. Complexity 2022, 2022, 7734580.