Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Zhenlong Gong | -- | 448 | 2024-01-30 15:31:11 | | | |

| 2 | Rita Xu | + 1058 word(s) | 1506 | 2024-01-31 04:10:42 | | | | |

| 3 | Rita Xu | Meta information modification | 1506 | 2024-01-31 04:15:11 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Gong, Z.; Miao, Y.; Lantieri, C. Tire–Pavement Contact Behavior. Encyclopedia. Available online: https://encyclopedia.pub/entry/54538 (accessed on 07 March 2026).

Gong Z, Miao Y, Lantieri C. Tire–Pavement Contact Behavior. Encyclopedia. Available at: https://encyclopedia.pub/entry/54538. Accessed March 07, 2026.

Gong, Zhenlong, Yinghao Miao, Claudio Lantieri. "Tire–Pavement Contact Behavior" Encyclopedia, https://encyclopedia.pub/entry/54538 (accessed March 07, 2026).

Gong, Z., Miao, Y., & Lantieri, C. (2024, January 30). Tire–Pavement Contact Behavior. In Encyclopedia. https://encyclopedia.pub/entry/54538

Gong, Zhenlong, et al. "Tire–Pavement Contact Behavior." Encyclopedia. Web. 30 January, 2024.

Copy Citation

The tire–pavement contact problem is one of the important problems in the field of pavement engineering. Tire–pavement contact behavior is essential to understanding issues such as pavement skid resistance, noise, rolling resistance, and driving safety and comfort.

tire–pavement

contact behavior

pavement engineering

1. Introduction

The tire–pavement contact problem is one of the important problems in the field of pavement engineering [1][2][3]. Tire–pavement contact behavior is essential to understanding issues such as pavement skid resistance [4][5], noise [6], rolling resistance [7], and driving safety and comfort [8][9]. Tire–pavement contact involves tribology [10], acoustics [11], contact mechanics [12][13], tire dynamics, and other multidisciplinary fields [14] and has attracted widespread interest in the field of pavement engineering. The tire–pavement contact process is also the process of pavement skid resistance deterioration [15][16], pavement disease formation [17], and tire performance decline [18]. Therefore, the study of tire–pavement contact behavior is of great significance for improving pavement performance, enhancing pavement life, and enhancing vehicle energy saving and environmental protection [19][20].

Currently, there are two main types of research methods for tire–pavement contact behavior: One is contact experimental research, which analyzes tire–pavement contact characteristics through tests, but these tests are difficult to perform, and only in recent years has there been related research. Some researchers use pressure sensors [21], carbon paper [22], and pressure-sensitive materials [23] to test the pressure distribution. The second type of research method is theoretical research, in which researchers analyze tire–pavement contact behavior through mathematical models. Later, with the development of computer technology, many researchers have studied the interaction between tires and pavements through numerical analysis techniques based on theoretical research [24][25][26]. The finite element analysis method can build tire and pavement models quickly and efficiently and analyze the tire–pavement contact accurately and cost-effectively, but there are differences between simulation and reality [27]. Experimental research can truly reflect the tire–pavement contact behavior, but these tests have problems such as high costs and external environmental influences [1][13]. Although tire–pavement contact behavior and its influence on pavements have been understood to some extent, contact characteristics are still controversial, and the influence law on the pavement is still unclear. Some researchers have carried out numerical simulations and experimental research on the tire–pavement contact behavior, but there is a lack of detailed and complete summary and generalization.

2. Tire–Pavement Contact Characteristics

Tire–pavement contact behavior is understood to help optimize tire design and pavement structure design. This can help improve pavement performance and the overall performance of tires. Researchers have characterized tire–pavement contact behavior through tire–pavement contact characteristics [2][28]. Tire–pavement contact characteristics are mainly geometric characteristics defined according to the contact area and mechanical characteristics defined according to the stress distribution [29][30]. The definition, understanding, and application of tire–pavement contact characteristics vary among researchers because of differences in the study subjects and methods.

2.1. Geometric Characteristics

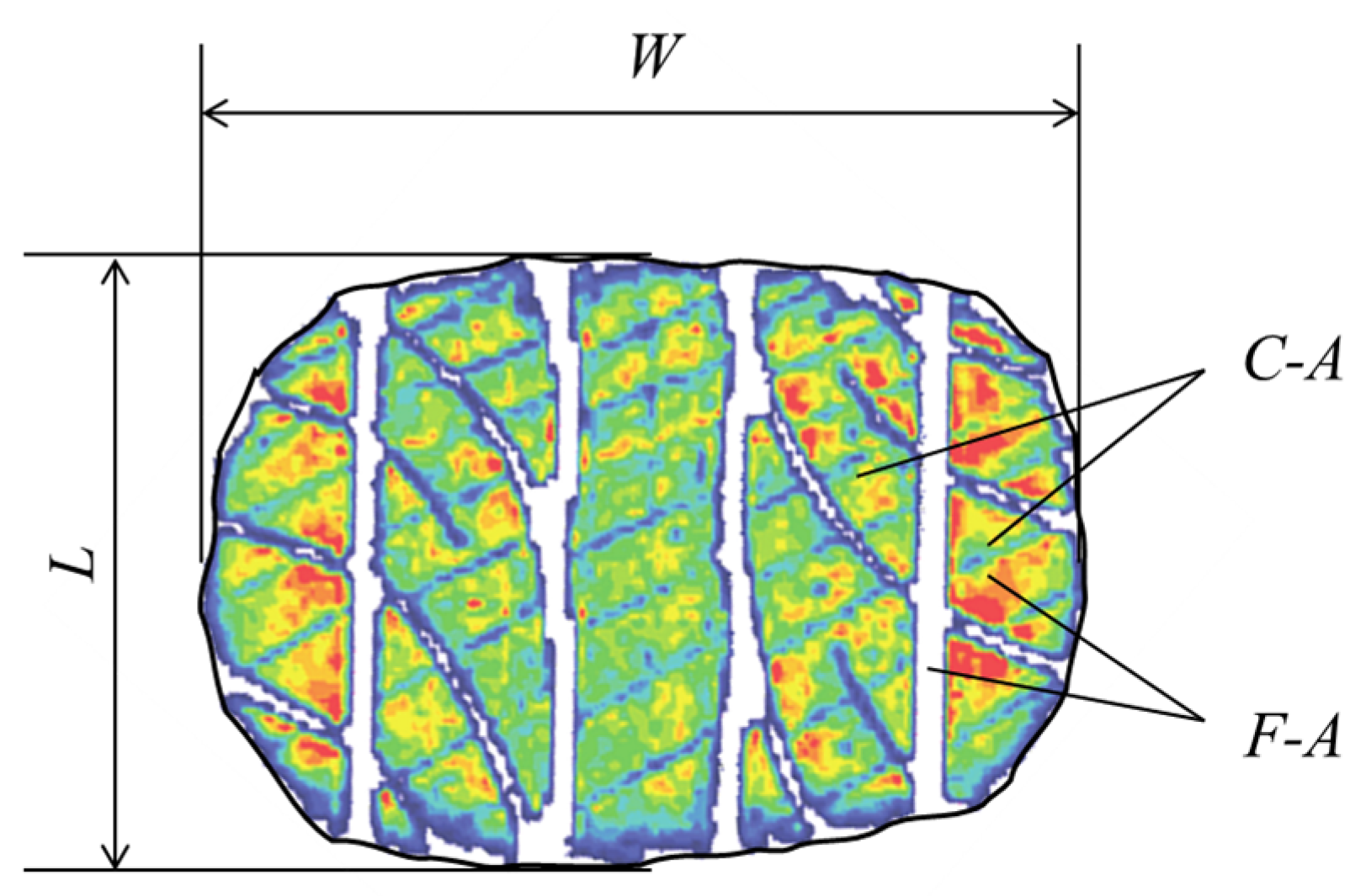

The geometric characteristics of tire–pavement contact mainly refer to the contact area and contact shape. There is no clear definition of contact characteristics in the field of pavement engineering; however, the geometric characteristics of tire–pavement contact are summarized and defined in the field of tires, and “Tire Terms and Their Definitions” (GB/T 6326-2005) [31] define the tread contact length (L), tread contact width (W), coefficient of contact (L/W), contact area (C-A), and footprint area (F-A), as shown in Figure 1.

Figure 1. Geometric characteristics of tire–pavement contact.

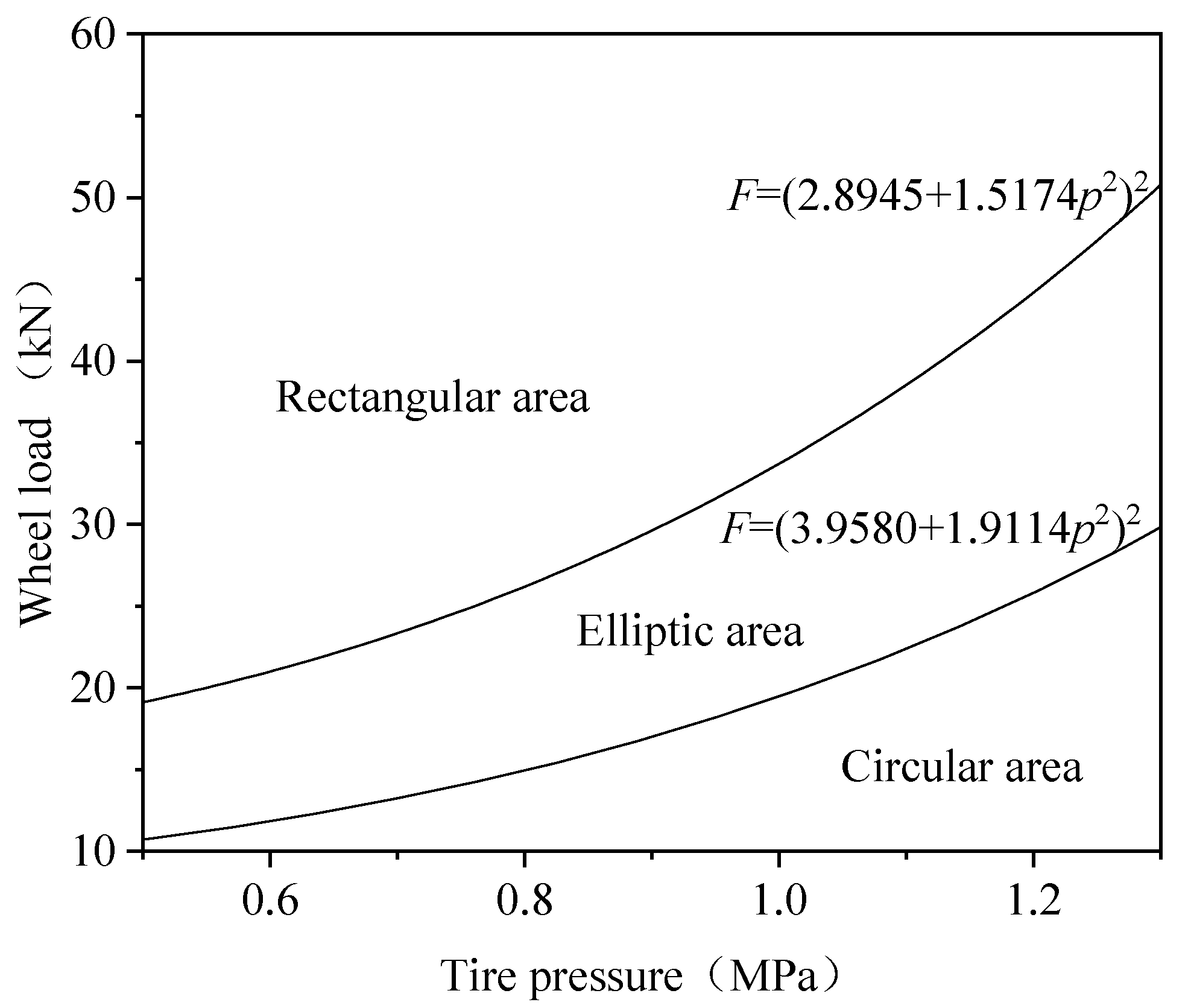

The tire–pavement contact area is usually assumed to be circular or rectangular with uniform pressure distribution. This can simplify mechanical calculations and reflects tire–pavement contact behavior to a certain extent, and is widely used in pavement design [32]. However, measurements and modeling data show that the vertical stress distribution at the tire–pavement interface is not uniform, and the contact area is not regularly circular [29] or rectangular [33][34]. Tire pattern and pavement texture influences are ignored in this assumption, so researchers have conducted extensive research on contact geometric characteristics [35][36]. Pillai et al. [37] used the tire footprint to determine the tire–pavement contact area and obtained two simple predictive equations for tire–pavement contact area based on tire deflection and tire and wheel dimensional parameters found on the tire sidewall, as shown in Equations (1) and (2), with an error between the calculated and measured footprint areas within 15%. Ge and Wang [38] established a tire–pavement contact finite element model using ABAQUS to simulate the tire–pavement contact process and obtain a contact area equation based on tire pressure and wheel load, as shown in Equation (3). A quantitative expression of tire contact characteristics under vehicle load was obtained, as shown in Figure 2.

where A is tire footprint area; r, s, and a are tire radius, wheel diameter, and aspect ratio, respectively; and d is tire deflection.

where δ is tire footprint area, 103 mm; p is tire pressure, Mpa; and F is wheel load, kN.

Figure 2. Distribution map of the tire contact area.

Tielking et al. [39] found that the contact area between the tire and the pavement increases as the wheel load increases, and the effect of a single wheel load on the contact area is lower. Based on experiments, Weissman et al. [40] found that the width of the tire footprint remained essentially constant due to the stiffness constraint of the tire sidewall, and that the wheel load mainly affected the length of the tire footprint. Yu et al. [2] conducted a static tire–pavement contact test using super-low-pressure (LLW) Fujifilm Holdings Corporation (FUJI) pressure film paper. As the mean profile depth (MPD) increases, the actual tire–pavement contact area decreases, and as the tire load increases, the contact area gradually increases. However, when the tire load exceeds 250 N, the tire–pavement contact area does not broadly change and even shows a slight decrease. This is mainly because the contact width becomes larger when the load is too large but the contact length is significantly reduced. In summary, it can be seen that the geometric characteristics of tire–pavement contact are related to the wheel load, pavement texture, tire type, etc. Research has mostly used the footprint method for static tire–pavement contact geometric characteristic analysis, lacking dynamic contact studies, while more direct simplification is used in pavement design.

2.2. Mechanical Characteristics

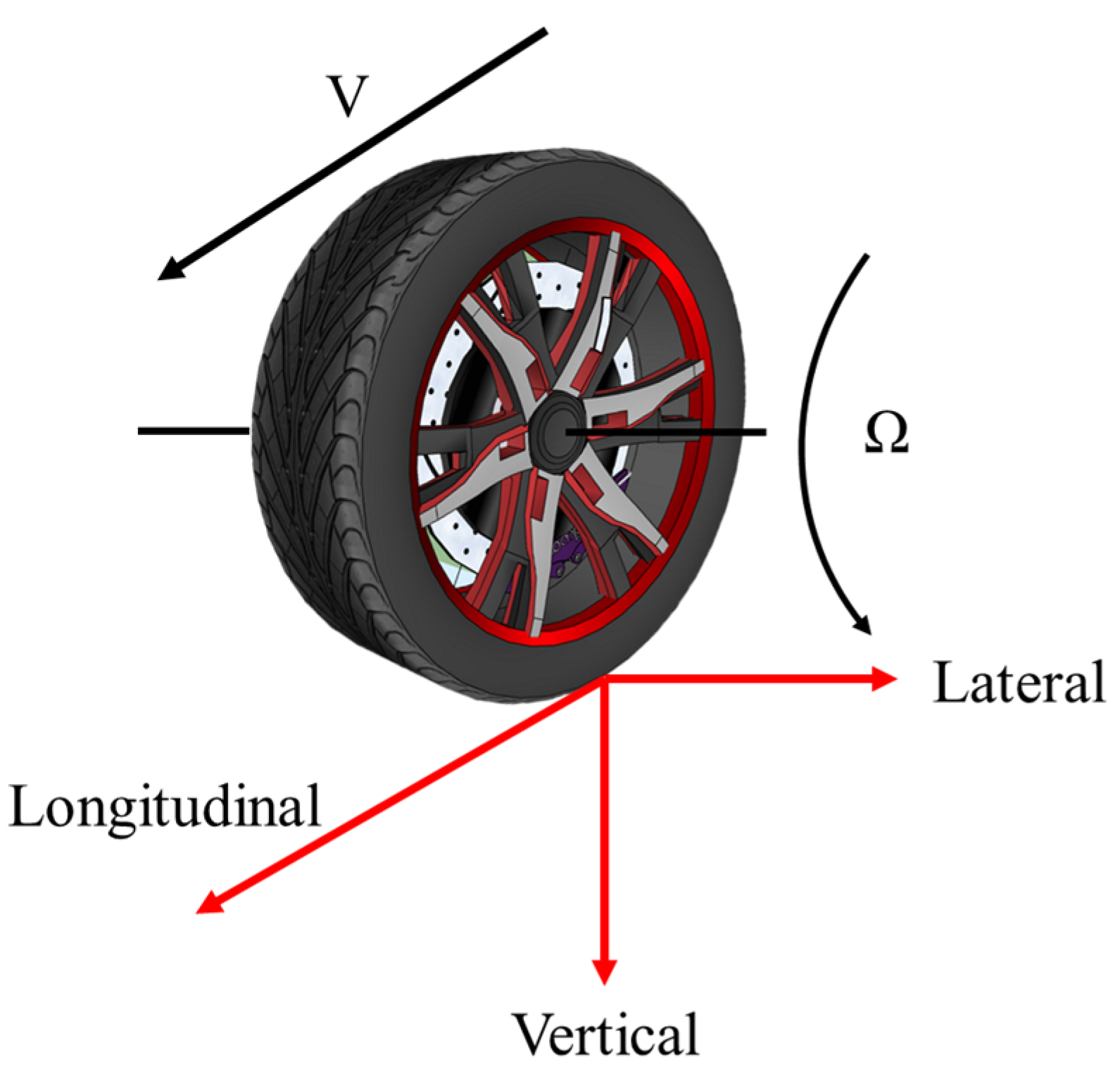

Tire–pavement contact creates stresses and forces. These tire–pavement contact stresses and forces provide the driving force when the vehicle accelerates, the lateral force when it rotates, and the braking force when it decelerates, and it can be seen that the contact behavior is directly related to vehicle performance [41] and pavement performance [42][43]. Therefore, it is significant to conduct contact mechanical characterization studies. When a tire is in contact with pavement, the tire is subjected to a complex load through the complex deformation of the tread and carcass. This complex load is generally described in the study of tire–pavement contact dynamics as the six tire forces, which are vertical force, longitudinal force, lateral force, aligning torque, lateral tilt moment, and rolling resistance moment. Some of these forces are shown in Figure 3. Due to the large deformation of a tire in mutual contact with pavement coupled with the environment and load, these forces are coupled with each other and affect each other [39][44].

Figure 3. Schematic diagram of contact stress.

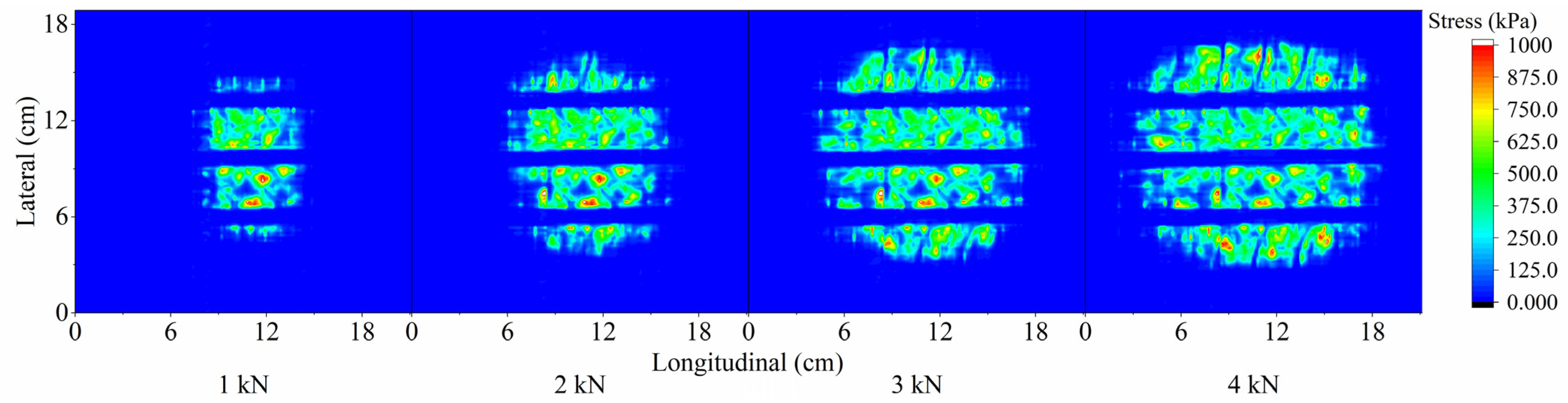

The vertical forces are of most concern in pavement studies. Marshek et al. [45] attempted to test the pressure distribution footprint of diagonal truck tires using pressure-sensitive films, and their results showed that the contact pressure was non-uniformly distributed and that the contact pressure at the tire shoulder was significantly greater than the tire air pressure. Wang et al. [46] analyzed the non-uniformity of vertical contact stresses and found that the non-uniformity of stress distribution decreases with increasing load but increases with increasing inflation pressure. Gong et al. [47] used a high-precision pressure sensor to test the tire–pavement contact pattern and stress under different forces, as shown in Figure 4. It can be seen that with an increase in force, the contact area and the region of stress concentration gradually increase. The distribution of vertical contact stresses is not uniform.

Figure 4. Contact stress distribution images.

For longitudinal forces, Tielking et al. [39] analyzed longitudinal contact stresses and vertical contact stresses as a function of vehicle speed. They found that vehicle speed had almost no effect on the vertical contact stress but had a significant influence on the longitudinal contact stress; the longitudinal stress on the pavement and the tire changed direction twice from the stationary state to the rolling state. Douglas et al. [48] tested the distribution of vertical and longitudinal pressures between the tire and the pavement under different tire pressures and loads. Their test was a full-scale laboratory test and confirmed Tielking’s analysis of the contact stresses. For lateral forces, Hugo et al. [49] found that lateral forces can cause pavement cracking. Research on the aligning torque, lateral tilt moment, and rolling resistance moment has mostly been conducted in the field of vehicle engineering. In summary, it can be seen that the mechanical characteristics of tire–pavement contact are closely related to pavement performance and vehicle performance, and there are certain rules.

References

- Chen, B.; Zhang, X.; Yu, J.; Wang, Y. Impact of contact stress distribution on skid resistance of asphalt pavements. Constr. Build. Mater. 2017, 133, 330–339.

- Yu, M.; Xu, X.; Wu, C.; Li, S.; Li, M.; Chen, H. Research on the prediction model of the friction coefficient of asphalt pavement based on tire-pavement coupling. Adv. Mater. Sci. Eng. 2021, 2021, 6650525.

- Zheng, B.; Chen, J.; Zhao, R.; Tang, J.; Tian, R.; Zhu, S.; Huang, X. Analysis of contact behaviour on patterned tire-asphalt pavement with 3-D FEM contact model. Int. J. Pavement Eng. 2022, 23, 171–186.

- Yu, M.; You, Z.; Wu, G.; Kong, L.; Liu, C.; Gao, J. Measurement and modeling of skid resistance of asphalt pavement: A review. Constr. Build. Mater. 2020, 260, 119878.

- Yun, D.; Hu, L.; Tang, C. Tire–road contact area on asphalt concrete pavement and its relationship with the skid resistance. Materials 2020, 13, 615.

- Li, T.; Burdisso, R.; Sandu, C. Literature review of models on tire-pavement interaction noise. J. Sound Vibr. 2018, 420, 357–445.

- Kawakami, A.; Ishigaki, T.; Shirai, Y.; Terada, M.; Kubo, K. Evaluation method of pavement surface characteristics for rolling resistance. Road Mater. Pavement Des. 2017, 18 (Suppl. 2), 2–11.

- Maia, M.M.A.S.; Dinis-Almeida, M.; Martinho, F.C.G. The influence of the affinity between aggregate and bitumen on the mechanical performance properties of asphalt mixtures. Materials 2021, 14, 6452.

- Yu, L.; Hu, J.; Li, R.; Yang, Q.; Guo, F.; Pei, J. Tire-pavement contact pressure distribution analysis based on ABAQUS simulation. Arab. J. Sci. Eng. 2022, 47, 4119–4132.

- Belghith, S.; Mezlini, S.; BelhadjSalah, H.; Ligier, J. Modeling of contact between rough surfaces using homogenisation technique. Comptes Rendus Mécanique 2010, 338, 48–61.

- Ren, W.; Han, S.; Fwa, T.F.; Zhang, J.; He, Z. A new laboratory test method for tire-pavement noise. Measurement 2019, 145, 137–143.

- Hernandez, J.A.; Al-Qadi, I.L. Tire–pavement interaction modelling: Hyperelastic tire and elastic pavement. Road Mater. Pavement Des. 2016, 18, 1067–1083.

- Oubahdou, Y.; Wallace, E.; Reynaud, P.; Picoux, B.; Dopeux, J.; Petit, C.; Nélias, D. Effect of the tire—Pavement contact at the surface layer when the tire is tilted in bend. Constr. Build. Mater. 2021, 305, 124765.

- Ma, B.; Xu, H. Vehicle unsteady dynamics characteristics based on tire and road features. Adv. Mech. Eng. 2013, 5, 153257.

- Guo, M.; Li, X.; Ran, M.; Zhou, X.; Yan, Y. Analysis of contact stresses and rolling resistance of truck-bus tyres under different working conditions. Sustainability 2020, 12, 10603.

- Rasol, M.; Schmidt, F.; Ientile, S.; Adelaide, L.; Nedjar, B.; Kane, M.; Chevalier, C. Progress and monitoring opportunities of skid resistance in road transport: A critical review and road sensors. Remote Sens. 2021, 13, 3729.

- Vázquez, V.; Terán, F.; Huertas, P.; Paje, S. Surface aging effect on tire/pavement noise medium-term evolution in a medium-size city. Coatings 2018, 8, 206.

- Lorenz, B.; Oh, Y.R.; Nam, S.K.; Jeon, S.H.; Persson, B. Rubber friction on road surfaces: Experiment and theory for low sliding speeds. J. Chem. Phys. 2015, 142, 194701.

- Ueckermann, A.; Wang, D.; Oeser, M.; Steinauer, B. A contribution to non-contact skid resistance measurement. Int. J. Pavement Eng. 2014, 16, 646–659.

- Woodward, D.; Millar, P.; Lantieri, C.; Sangiorgi, C.; Vignali, V. The wear of Stone Mastic Asphalt due to slow speed high stress simulated laboratory trafficking. Constr. Build. Mater. 2016, 110, 270–277.

- Hamlat, S.; Hammoum, F.; Kerzreho, J. Evaluation of the distribution of local pressures and the real contact area between the tyre and the road surface. Int. J. Pavement Eng. 2014, 16, 832–841.

- Wang, W.; Zhao, K.; Li, J.; Luo, R.; Wang, L. Characterization of dynamic response of asphalt pavement in dry and saturated conditions using the full-scale accelerated loading test. Constr. Build. Mater. 2021, 312, 125355.

- Riehm, P.; Unrau, H.; Gauterin, F.; Torbrügge, S.; Wies, B. 3D brush model to predict longitudinal tyre characteristics. Veh. Syst. Dyn. 2019, 57, 17–43.

- Jiang, X.; Zeng, C.; Gao, X.; Liu, Z.; Qiu, Y. 3D FEM analysis of flexible base asphalt pavement structure under non-uniform tyre contact pressure. Int. J. Pavement Eng. 2017, 20, 999–1011.

- Kuraishi, T.; Takizawa, K.; Tezduyar, T.E. Space–time computational analysis of tire aerodynamics with actual geometry, road contact, tire deformation, road roughness and fluid film. Comput. Mech. 2019, 64, 1699–1718.

- Wang, G.; Roque, R. Impact of wide-based tires on the near-surface pavement stress states based on three-dimensional tire-pavement interaction model. Road Mater. Pavement Des. 2011, 12, 639–662.

- Ding, Y. Numerical Simulation of Tire-Pavement Interaction For Noise, Safety, and Rolling Resistance. Doctoral Thesis, Rutgers The State University of New Jersey, School of Graduate Studies, New Brunswick, NJ, USA, 2018.

- Liang, C.; Wang, G.; An, D.; Ma, Y. Tread wear and footprint geometrical characters of truck bus radial tires. Chin. J. Mech. Eng. 2013, 26, 506–511.

- Liu, Q.; Shalaby, A. Simulation of pavement response to tire pressure and shape of contact area. Can. J. Civ. Eng. 2013, 40, 236–242.

- Xie, Y.; Yang, Q. Tyre–pavement contact stress distribution considering tyre types. Road Mater. Pavement Des. 2018, 20, 1899–1911.

- GB/T 6326-2014; Tyre Terms and Definitions. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of the P.R.C: Beijing China, 2014.

- Guo, M.; Zhou, X. Tire-pavement contact stress characteristics and critical slip ratio at multiple working conditions. Adv. Mater. Sci. Eng. 2019, 2019, 5178516.

- Blab, R.; Harvey, J.T. Modeling measured 3D tire contact stresses in a viscoelastic FE pavement model. Int. J. Geomech. 2002, 2, 271–290.

- Prozzi, J.A.; Luo, R. Quantification of the joint effect of wheel load and tire inflation pressure on pavement response. Transp. Res. Rec. 2005, 1919, 134–141.

- Cesbron, J.; Anfosso-Lédée, F.; Yin, H.P.; Duhamel, D.; Le Houédec, D. Influence of Road Texture on Tyre/Road Contact in Static Conditions. Road Mater. Pavement Des. 2011, 9, 689–710.

- Muniandy, R.; Moazami, D.; Hamid, H.; Hassim, S. Characterization of effective tire contact area for various tread patterns. Instrum. Sci. Technol. 2013, 42, 15–26.

- Pillai, P.S.; Fielding-Russell, G.S. Empirical equations for tire footprint area. Rubber Chem. Technol. 1986, 59, 155–159.

- Ge, S.; Wang, B. Analysis and Test Verification on Contact Characteristics of Tire. Mach. Des. Manuf. 2014, 7, 233–235+239.

- Tielking, J.T.; Roberts, F.L. Tire contact pressure and its effect on pavement strain. J. Transp. Eng. 1987, 113, 56–71.

- Weissman, S.L. Influence of tire-pavement contact stress distribution on development of distress mechanisms in pavements. Transp. Res. Rec. 1999, 1655, 161–167.

- Linhui, Z.; Zhiyuan, L.; Hong, C. Vehicle state and friction force estimation using nonlinear observer strategies. In Proceedings of the 27th Chinese Control Conference, Kunming, China, 1 January 2008.

- Hajj, E.Y.; Thushanthan, P.; Sebaaly, P.E.; Siddharthan, R.V. Influence of tire–pavement stress distribution, shape, and braking on performance predictions for asphalt pavement. Transp. Res. Rec. J. Transp. Res. Board 2012, 2306, 73–85.

- Luo, R.; Prozzi, J.A. Effect of measured three-dimensional tire–pavement contact stress on pavement response at asphalt surface. Transp. Res. Rec. J. Transp. Res. Board 2007, 2037, 115–127.

- Yang, S.; Zhang, J.; Lu, Y.; Li, S. Research progress of vehicle-pavement interaction. J. Mech. Eng. 2021, 57, 1–17.

- Marshek, K.M.; Chen, H.H.; Connell, R.B.; Hudson, R.W. Experimental determination of pressure distribution of truck tire-pavement contact. Transp. Res. Rec. 1986, 1070, 9–14.

- Wang, H.; Al-Qadi, I.L.; Stanciulescu, I. Simulation of tyre–pavement interaction for predicting contact stresses at static and various rolling conditions. Int. J. Pavement Eng. 2012, 13, 310–321.

- Gong, Z.; Miao, Y.; Li, W.; Yu, W.; Wang, L. Analysis of tyre-pavement contact behaviour of heavy truck in full-scale test. Int. J. Pavement Eng. 2023, 24, 2235630.

- Douglas, R.A.; Woodward, W.D.H.; Woodside, A.R. Road contact stresses and forces under tires with low inflation pressure. Can. J. Civ. Eng. 2000, 27, 1248–1258.

- Hugo, F.; Kennedy, T.W. Surface cracking of asphalt mixtures in southern africa. In Proceedings of the Association of Asphalt Paving Technologists, St Paul, MN, USA, 7–11 January 1985.

More

Information

Subjects:

Transportation Science & Technology

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.3K

Revisions:

3 times

(View History)

Update Date:

31 Jan 2024

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No