Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Zhenlong Gong and Version 3 by Rita Xu.

The tire–pavement contact problem is one of the important problems in the field of pavement engineering. Tire–pavement contact behavior is essential to understanding issues such as pavement skid resistance, noise, rolling resistance, and driving safety and comfort.轮胎与路面接触问题是路面工程领域的重要问题之一。轮胎与路面的接触行为对于了解路面防滑性、噪音、滚动阻力以及驾驶安全性和舒适性等问题至关重要。

- tire–pavement

- contact behavior

- pavement engineering

1. Introduction引言

The tire–pavement contact problem is one of the important problems in the field of pavement engineering [1][2][3]. Tire–pavement contact behavior is essential to understanding issues such as pavement skid resistance [4][5]轮胎-路面接触涉及摩擦学[10]、声学[11]、接触力学[12, noise [6]13]、轮胎动力学和其他多学科领域[14],在路面工程领域引起了广泛的兴趣。轮胎与路面接触过程也是路面防滑性恶化[15, rolling resistance [7], and driving safety and comfort [8][9]. Tire–pavement contact involves tribology [10], acoustics [11], contact mechanics [12][13], tire dynamics, and other multidisciplinary fields [14] and has attracted widespread interest in the field of pavement engineering. The tire–pavement contact process is also the process of pavement skid resistance deterioration [15][16], pavement disease formation [17], and tire performance decline [18]. Therefore, the study of tire–pavement contact behavior is of great significance for improving pavement performance, enhancing pavement life, and enhancing vehicle energy saving and environmental protection [19][20].16]、路面病害形成[17]和轮胎性能下降[18]的过程。因此,研究轮胎与路面的接触行为对于改善路面性能、延长路面寿命、增强车辆节能环保具有重要意义[19\u201220]。此外,只有清楚地了解轮胎与路面的相互作用,才能获得真实的接触应力和路面荷载分布数据。只有这样,我们才能设计出更经济、更耐用的路面,并进行摩擦分析。

Currently, there are two main types of research methods for tire–pavement contact behavior: One is contact experimental research, which analyzes tire–pavement contact characteristics through tests, but these tests are difficult to perform, and only in recent years has there been related research. Some researchers use pressure sensors [21], carbon paper [22], and pressure-sensitive materials [23] to test the pressure distribution. The second type of research method is theoretical research, in which researchers analyze tire–pavement contact behavior through mathematical models. Later, with the development of computer technology, many researchers have studied the interaction between tires and pavements through numerical analysis techniques based on theoretical research [24][25][26]. The finite element analysis method can build tire and pavement models quickly and efficiently and analyze the tire–pavement contact accurately and cost-effectively, but there are differences between simulation and reality [27]. Experimental research can truly reflect the tire–pavement contact behavior, but these tests have problems such as high costs and external environmental influences [1][13]. Although tire–pavement contact behavior and its influence on pavements have been understood to some extent, contact characteristics are still controversial, and the influence law on the pavement is still unclear. Some researchers have carried out numerical simulations and experimental research on the tire–pavement contact behavior, but there is a lack of detailed and complete summary and generalization.目前,轮胎与路面接触行为的研究方法主要有两种:一种是接触实验研究,通过试验分析轮胎与路面接触特性,但这些试验难以进行,直到最近几年才有相关研究。一些研究人员使用压力传感器[21]、复写纸[22]和压敏材料[23]来测试压力分布。第二种研究方法是理论研究,研究人员通过数学模型分析轮胎与路面的接触行为。后来,随着计算机技术的发展,许多研究者通过基于理论研究的数值分析技术研究了轮胎与路面之间的相互作用[24,25,26]。有限元分析方法可以快速高效地建立轮胎和路面模型,并准确、经济地分析轮胎与路面的接触,但仿真和现实之间存在差异[27]。实验研究可以真实反映轮胎与路面的接触行为,但这些试验存在成本高、外部环境影响等问题[1,13]。虽然轮胎与路面的接触行为及其对路面的影响已经得到了一定程度的了解,但接触特性仍存在争议,对路面的影响规律仍不明确。一些研究人员对轮胎与路面接触行为进行了数值模拟和实验研究,但缺乏详细和完整的总结和概括。

2. Tire–Pavement Contact Characteristics轮胎-路面接触特性

Tire–pavement contact behavior is 据了解,轮胎与路面的接触行为有助于优化轮胎设计和路面结构设计。这有助于提高路面性能和轮胎的整体性能。研究人员通过轮胎-路面接触特性表征了轮胎-路面接触行为[2,28]。轮胎-路面接触特性主要是根据接触面积定义的几何特性和根据应力分布定义的机械特性[29\understood to help optimize tire design and pavement structure design. This can help improve pavement performance and the overall performance of tires. Researchers have characterized tire–pavement contact behavior through tire–pavement contact characteristics [2][28]. Tire–pavement contact characteristics are mainly geometric characteristics defined according to the contact area and mechanical characteristics defined according to the stress distribution [29][30]. The definition, understanding, and application of tire–pavement contact characteristics vary among researchers because of differences in the study subjects and methods.201230]。由于研究对象和方法的差异,轮胎-路面接触特性的定义、理解和应用因研究对象而异。2.1. Geometric Characteristics几何特性

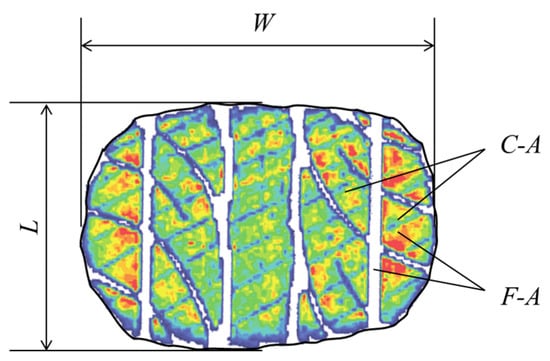

The geometric characteristics of tire–pavement contact mainly refer to the contact area and contact shape. There is no clear definition of contact characteristics in the field of pavement engineering轮胎-路面接触的几何特性主要是指接触面积和接触形状。在路面工程领域,接触特性没有明确的定义; however, the geometric characteristics of tire–pavement contact are summarized and defined in the field of tires, and “Tire Terms and Their Definitions” (但是,轮胎与路面接触的几何特性在轮胎领域进行了总结和定义,《轮胎术语及其定义》(GB/T 6326-2005) [31] define the tread contact length ()[31]定义了胎面接触长度(L)、胎面接触宽度(W)、接触系数(L), tread contact width (/W), coefficient of contact (L/W), contact area ()、接触面积(C-A), and footprint area ()和占地面积(F-A), as shown in Figure ),如图1.所示。

Figure图 1. Geometric characteristics of tire–pavement contact.轮胎与路面接触的几何特性。

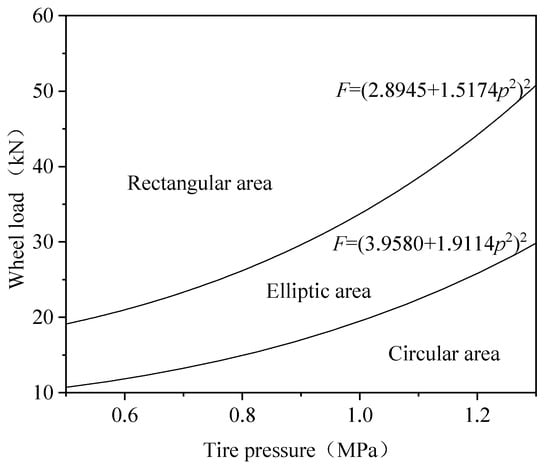

Figure 2. Distribution map of the tire contact area.

2.2. Mechanical Characteristics

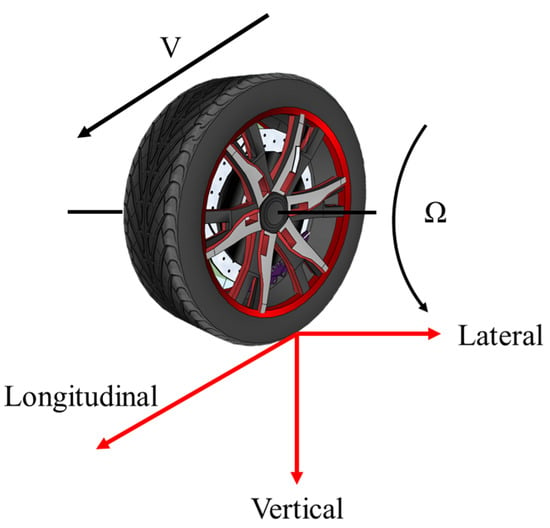

Tire–pavement contact creates stresses and forces. These tire–pavement contact stresses and forces provide the driving force when the vehicle accelerates, the lateral force when it rotates, and the braking force when it decelerates, and it can be seen that the contact behavior is directly related to vehicle performance [41] and pavement performance [42][43][42,43]. Therefore, it is significant to conduct contact mechanical characterization studies. When a tire is in contact with pavement, the tire is subjected to a complex load through the complex deformation of the tread and carcass. This complex load is generally described in the study of tire–pavement contact dynamics as the six tire forces, which are vertical force, longitudinal force, lateral force, aligning torque, lateral tilt moment, and rolling resistance moment. Some of these forces are shown in Figure 3. Due to the large deformation of a tire in mutual contact with pavement coupled with the environment and load, these forces are coupled with each other and affect each other [39][44][39,44].

Figure 图3. Schematic diagram of contact stress.接触应力示意图。

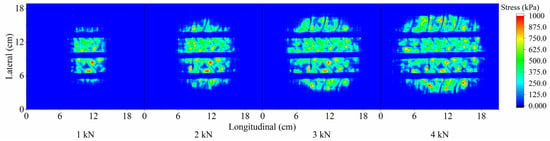

Figure 图4. Contact stress distribution images.接触应力分布图像。