Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

The tire–pavement contact problem is one of the important problems in the field of pavement engineering. Tire–pavement contact behavior is essential to understanding issues such as pavement skid resistance, noise, rolling resistance, and driving safety and comfort.

- tire–pavement

- contact behavior

- pavement engineering

1. Introduction

The tire–pavement contact problem is one of the important problems in the field of pavement engineering [1,2,3]. Tire–pavement contact behavior is essential to understanding issues such as pavement skid resistance [4,5], noise [6], rolling resistance [7], and driving safety and comfort [8,9]. Tire–pavement contact involves tribology [10], acoustics [11], contact mechanics [12,13], tire dynamics, and other multidisciplinary fields [14] and has attracted widespread interest in the field of pavement engineering. The tire–pavement contact process is also the process of pavement skid resistance deterioration [15,16], pavement disease formation [17], and tire performance decline [18]. Therefore, the study of tire–pavement contact behavior is of great significance for improving pavement performance, enhancing pavement life, and enhancing vehicle energy saving and environmental protection [19,20].

Currently, there are two main types of research methods for tire–pavement contact behavior: One is contact experimental research, which analyzes tire–pavement contact characteristics through tests, but these tests are difficult to perform, and only in recent years has there been related research. Some researchers use pressure sensors [21], carbon paper [22], and pressure-sensitive materials [23] to test the pressure distribution. The second type of research method is theoretical research, in which researchers analyze tire–pavement contact behavior through mathematical models. Later, with the development of computer technology, many researchers have studied the interaction between tires and pavements through numerical analysis techniques based on theoretical research [24,25,26]. The finite element analysis method can build tire and pavement models quickly and efficiently and analyze the tire–pavement contact accurately and cost-effectively, but there are differences between simulation and reality [27]. Experimental research can truly reflect the tire–pavement contact behavior, but these tests have problems such as high costs and external environmental influences [1,13]. Although tire–pavement contact behavior and its influence on pavements have been understood to some extent, contact characteristics are still controversial, and the influence law on the pavement is still unclear. Some researchers have carried out numerical simulations and experimental research on the tire–pavement contact behavior, but there is a lack of detailed and complete summary and generalization.

2. Tire–Pavement Contact Characteristics

Tire–pavement contact behavior is understood to help optimize tire design and pavement structure design. This can help improve pavement performance and the overall performance of tires. Researchers have characterized tire–pavement contact behavior through tire–pavement contact characteristics [2,28]. Tire–pavement contact characteristics are mainly geometric characteristics defined according to the contact area and mechanical characteristics defined according to the stress distribution [29,30]. The definition, understanding, and application of tire–pavement contact characteristics vary among researchers because of differences in the study subjects and methods.

2.1. Geometric Characteristics

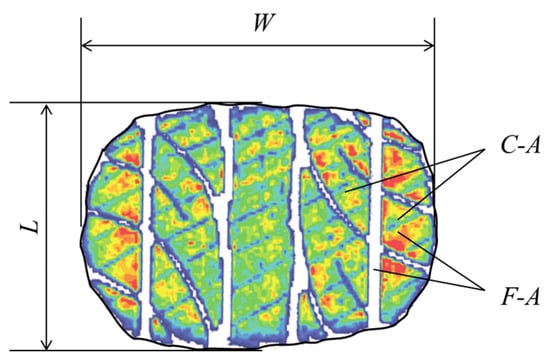

The geometric characteristics of tire–pavement contact mainly refer to the contact area and contact shape. There is no clear definition of contact characteristics in the field of pavement engineering; however, the geometric characteristics of tire–pavement contact are summarized and defined in the field of tires, and “Tire Terms and Their Definitions” (GB/T 6326-2005) [31] define the tread contact length (L), tread contact width (W), coefficient of contact (L/W), contact area (C-A), and footprint area (F-A), as shown in Figure 1.

Figure 1. Geometric characteristics of tire–pavement contact.

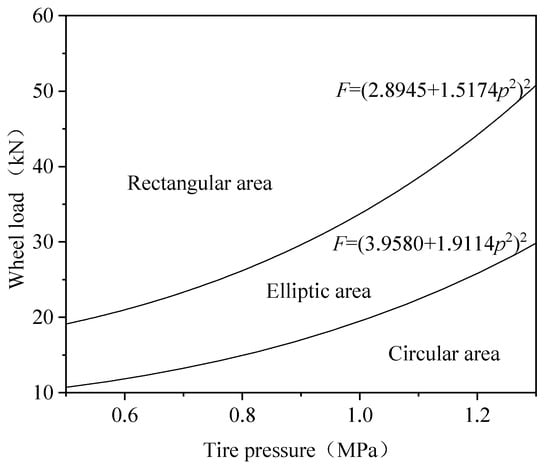

The tire–pavement contact area is usually assumed to be circular or rectangular with uniform pressure distribution. This can simplify mechanical calculations and reflects tire–pavement contact behavior to a certain extent, and is widely used in pavement design [32]. However, measurements and modeling data show that the vertical stress distribution at the tire–pavement interface is not uniform, and the contact area is not regularly circular [29] or rectangular [33,34]. Tire pattern and pavement texture influences are ignored in this assumption, so researchers have conducted extensive research on contact geometric characteristics [35,36]. Pillai et al. [37] used the tire footprint to determine the tire–pavement contact area and obtained two simple predictive equations for tire–pavement contact area based on tire deflection and tire and wheel dimensional parameters found on the tire sidewall, as shown in Equations (1) and (2), with an error between the calculated and measured footprint areas within 15%. Ge and Wang [38] established a tire–pavement contact finite element model using ABAQUS to simulate the tire–pavement contact process and obtain a contact area equation based on tire pressure and wheel load, as shown in Equation (3). A quantitative expression of tire contact characteristics under vehicle load was obtained, as shown in Figure 2.

where A is tire footprint area; r, s, and a are tire radius, wheel diameter, and aspect ratio, respectively; and d is tire deflection.

where δ is tire footprint area, 103 mm; p is tire pressure, Mpa; and F is wheel load, kN.

Figure 2. Distribution map of the tire contact area.

Tielking et al. [39] found that the contact area between the tire and the pavement increases as the wheel load increases, and the effect of a single wheel load on the contact area is lower. Based on experiments, Weissman et al. [40] found that the width of the tire footprint remained essentially constant due to the stiffness constraint of the tire sidewall, and that the wheel load mainly affected the length of the tire footprint. Yu et al. [2] conducted a static tire–pavement contact test using super-low-pressure (LLW) Fujifilm Holdings Corporation (FUJI) pressure film paper. As the mean profile depth (MPD) increases, the actual tire–pavement contact area decreases, and as the tire load increases, the contact area gradually increases. However, when the tire load exceeds 250 N, the tire–pavement contact area does not broadly change and even shows a slight decrease. This is mainly because the contact width becomes larger when the load is too large but the contact length is significantly reduced. In summary, it can be seen that the geometric characteristics of tire–pavement contact are related to the wheel load, pavement texture, tire type, etc. Research has mostly used the footprint method for static tire–pavement contact geometric characteristic analysis, lacking dynamic contact studies, while more direct simplification is used in pavement design.

2.2. Mechanical Characteristics

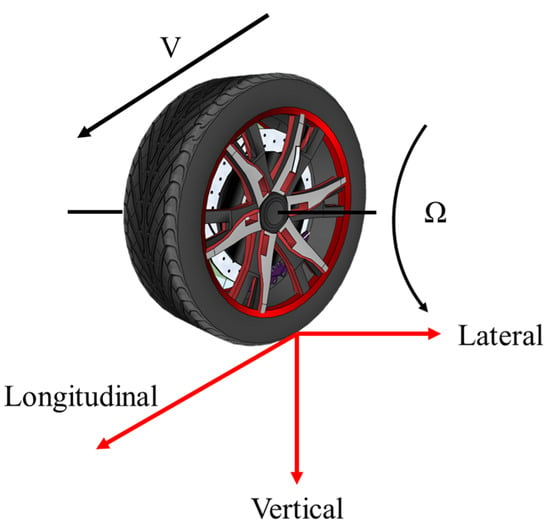

Tire–pavement contact creates stresses and forces. These tire–pavement contact stresses and forces provide the driving force when the vehicle accelerates, the lateral force when it rotates, and the braking force when it decelerates, and it can be seen that the contact behavior is directly related to vehicle performance [41] and pavement performance [42,43]. Therefore, it is significant to conduct contact mechanical characterization studies. When a tire is in contact with pavement, the tire is subjected to a complex load through the complex deformation of the tread and carcass. This complex load is generally described in the study of tire–pavement contact dynamics as the six tire forces, which are vertical force, longitudinal force, lateral force, aligning torque, lateral tilt moment, and rolling resistance moment. Some of these forces are shown in Figure 3. Due to the large deformation of a tire in mutual contact with pavement coupled with the environment and load, these forces are coupled with each other and affect each other [39,44].

Figure 3. Schematic diagram of contact stress.

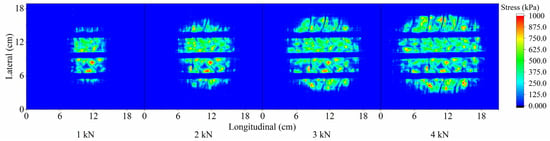

The vertical forces are of most concern in pavement studies. Marshek et al. [45] attempted to test the pressure distribution footprint of diagonal truck tires using pressure-sensitive films, and their results showed that the contact pressure was non-uniformly distributed and that the contact pressure at the tire shoulder was significantly greater than the tire air pressure. Wang et al. [46] analyzed the non-uniformity of vertical contact stresses and found that the non-uniformity of stress distribution decreases with increasing load but increases with increasing inflation pressure. Gong et al. [47] used a high-precision pressure sensor to test the tire–pavement contact pattern and stress under different forces, as shown in Figure 4. It can be seen that with an increase in force, the contact area and the region of stress concentration gradually increase. The distribution of vertical contact stresses is not uniform.

Figure 4. Contact stress distribution images.

For longitudinal forces, Tielking et al. [39] analyzed longitudinal contact stresses and vertical contact stresses as a function of vehicle speed. They found that vehicle speed had almost no effect on the vertical contact stress but had a significant influence on the longitudinal contact stress; the longitudinal stress on the pavement and the tire changed direction twice from the stationary state to the rolling state. Douglas et al. [48] tested the distribution of vertical and longitudinal pressures between the tire and the pavement under different tire pressures and loads. Their test was a full-scale laboratory test and confirmed Tielking’s analysis of the contact stresses. For lateral forces, Hugo et al. [49] found that lateral forces can cause pavement cracking. Research on the aligning torque, lateral tilt moment, and rolling resistance moment has mostly been conducted in the field of vehicle engineering. In summary, it can be seen that the mechanical characteristics of tire–pavement contact are closely related to pavement performance and vehicle performance, and there are certain rules.

This entry is adapted from the peer-reviewed paper 10.3390/coatings14020157

This entry is offline, you can click here to edit this entry!