Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Elena Ferretti | -- | 863 | 2023-12-14 12:23:15 | | | |

| 2 | Rita Xu | Meta information modification | 863 | 2023-12-18 02:58:52 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Ferretti, E. Masonry Walls with Stainless Steel Straps. Encyclopedia. Available online: https://encyclopedia.pub/entry/52759 (accessed on 07 February 2026).

Ferretti E. Masonry Walls with Stainless Steel Straps. Encyclopedia. Available at: https://encyclopedia.pub/entry/52759. Accessed February 07, 2026.

Ferretti, Elena. "Masonry Walls with Stainless Steel Straps" Encyclopedia, https://encyclopedia.pub/entry/52759 (accessed February 07, 2026).

Ferretti, E. (2023, December 14). Masonry Walls with Stainless Steel Straps. In Encyclopedia. https://encyclopedia.pub/entry/52759

Ferretti, Elena. "Masonry Walls with Stainless Steel Straps." Encyclopedia. Web. 14 December, 2023.

Copy Citation

Among all the active confinement techniques, the use of pre-tensioned stainless steel straps has recently gained much attention. The flexibility of the stainless steel straps allows us to bend and pass them through the thickness of the masonry, thus creating a three-dimensional strengthening system between the two opposite facings.

masonry walls

CAM® system

shear behavior

reinforcement arrangement

1. General Information on the CAM® System

Among the various techniques of active reinforcement, this work focuses on the CAM® system (active confinement of masonry: CAM is the Italian acronym for active stitching of masonry) [1][2][3][4][5]. This system is an evolution of the strengthening method with post-tensioned horizontal and vertical tie rods [6][7][8][9][10][11][12]. The evolution consists of the strengthening elements of the CAM® system [13], which are stainless steel straps instead of metal bars. The stainless steel straps pass through the thickness of the masonry thanks to openings made in the masonry by core drilling.

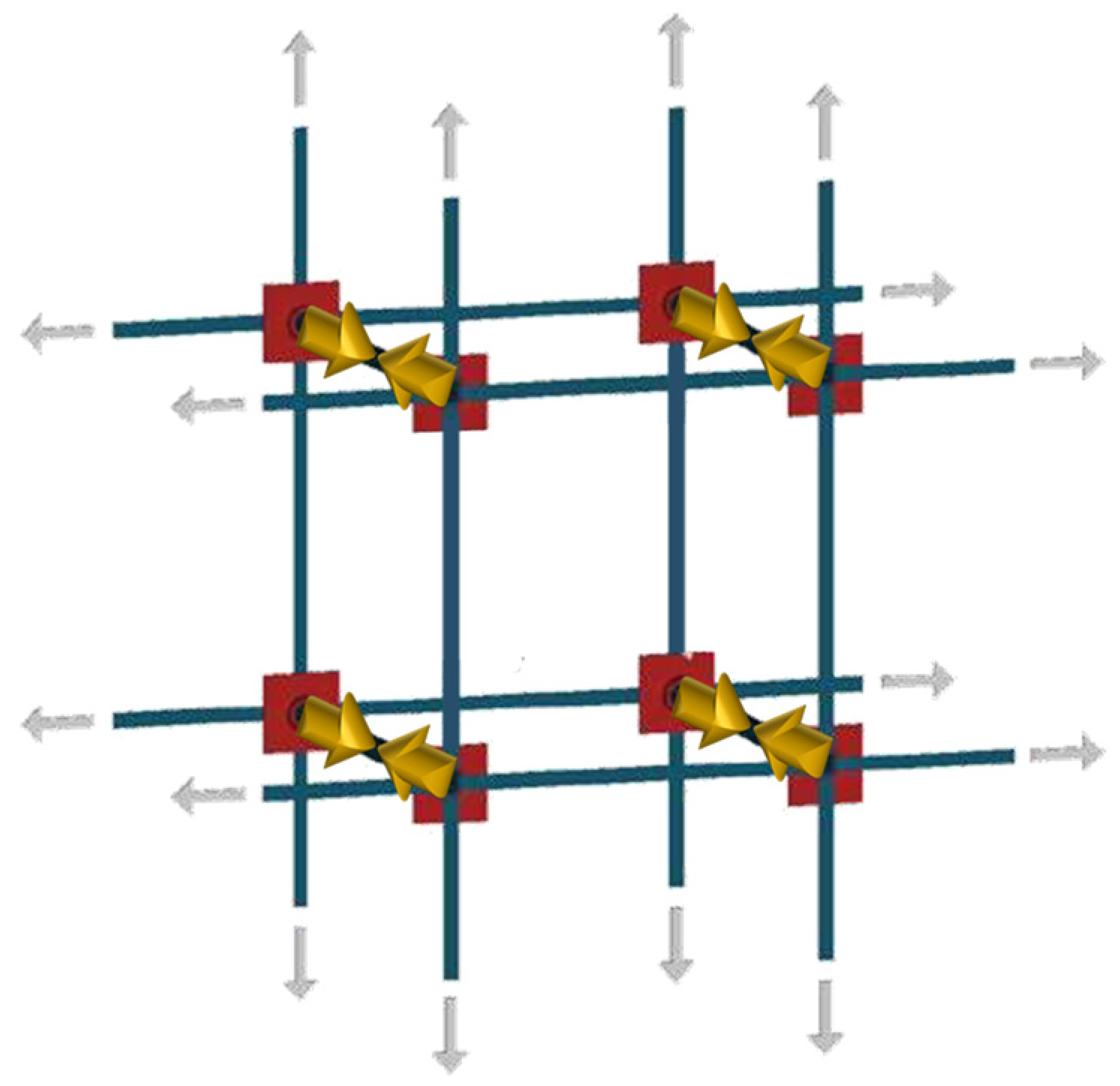

When four stainless steel straps share the perforations and the loops have horizontal and vertical directions, the CAM® system replicates the reinforcement scheme with horizontal and vertical ties. In this case, known as a rectangular arrangement, the perforations divide the masonry wall into volume units in the shape of right parallelepipeds (Figure 1). Some theoretical analyses [14][15] revealed that the CAM® system adds confinement forces only in the transverse direction (Figure 1), except for volume units located near the free ends of the masonry wall. Recently, the numerical results of a FEM simulation [16] also confirmed that the confinement provided by the CAM® system to the wall is not isotropic.

Figure 1. Stress transfer mechanism from the three-dimensional net of stainless steel loops placed in tension to the volume units of the masonry wall.

2. The Idea behind the Experimental Program

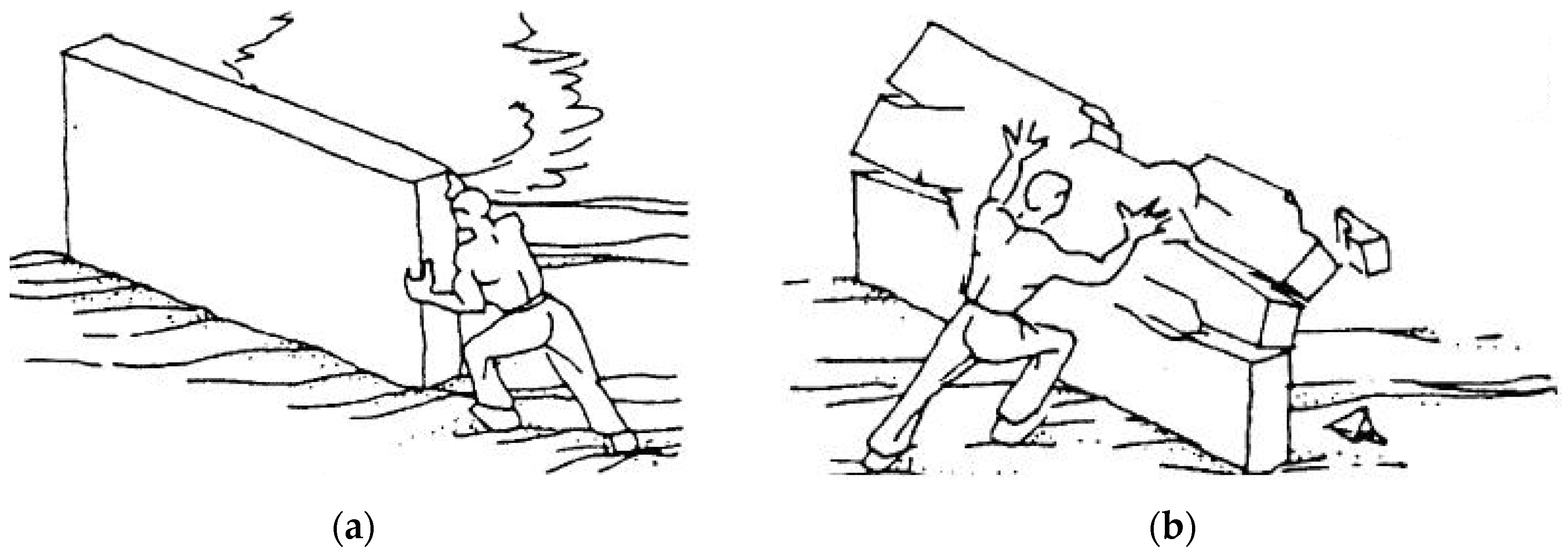

Seismic events impose two types of dominant loads on structures—the in-plane shear load (Figure 2a) and the out-of-plane bending load (Figure 2b)—which causes two types of dominant failure modes in URM structures [17][18]: the in-plane shear mechanisms and the out-of-plane bending mechanisms. The CAM® system with a rectangular arrangement (Figure 1) is suitable for increasing the out-of-plane strength of masonry walls when used in conjunction with other strengthening systems [15][19][20]. In the plane of the wall, however, the rectangular arrangement does not bring any increase in strength or stiffness. Both in-depth experimental tests [21] and recent numerical analyses [22], in fact, have shown that the rectangular arrangement of the stainless steel straps leads to an almost negligible increase in the strength of the shear-loaded masonry panels while providing a significant increase in ductility. The use of steel grids on both faces of the masonry wall, conversely, increases both the shear strength and the ductility, but the ultimate displacement achieved with the steel grids is lower than that achieved with the CAM® system [22].

Figure 2. How a seismic event loads a wall (being oscillatory in nature, the seismic action acts, in an alternating manner, both in the direction of the load schematized as the action of a man on the wall, and in the opposite direction): (a) in the plane of the wall (shear loading in the midplane); (b) along the direction perpendicular to the plane of the wall (out-of-plane loading).

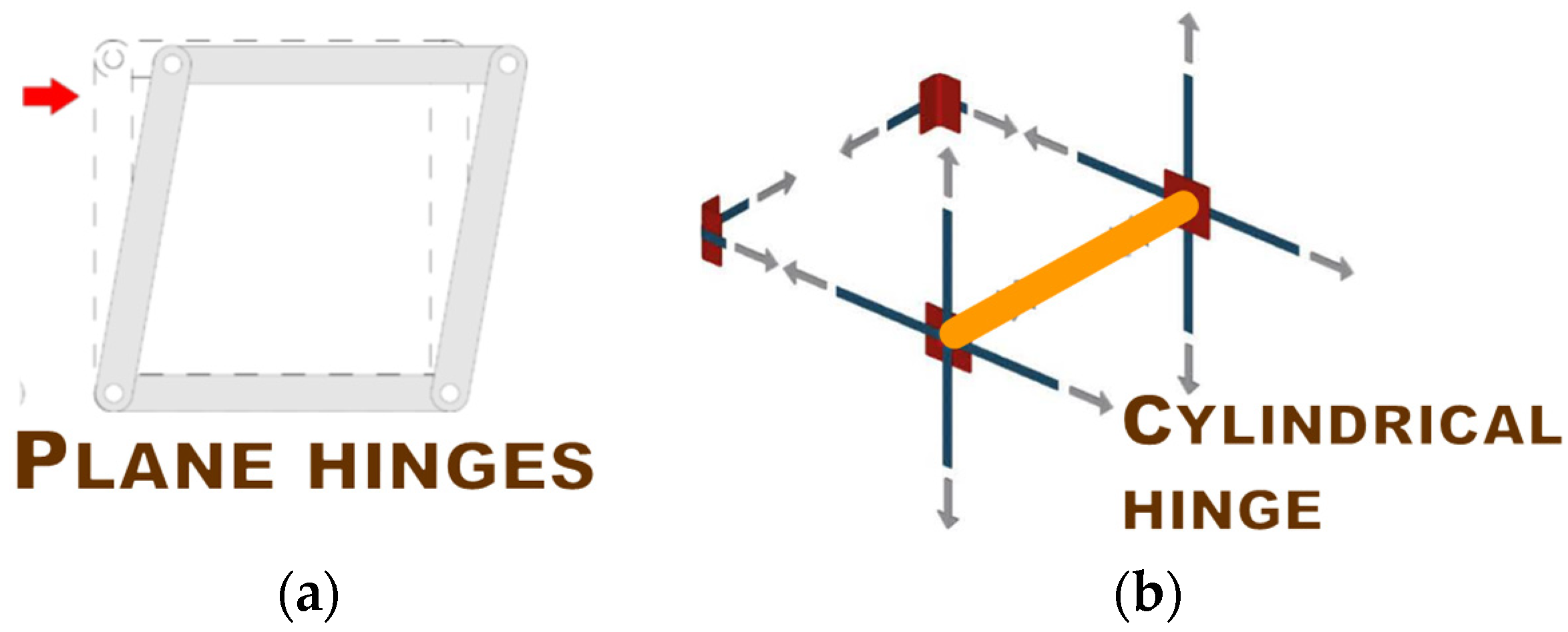

The lack of increase in shear strength with the CAM® system depends on the arrangement of the perforations, which makes the strengthening system labile to horizontal loads [15]. On the two wall facings, in fact, the straps of the rectangular arrangement form unbraced rectangular frame structures with hinged nodes. Under the action of horizontal forces, these nodes sway laterally exactly like the nodes of the simplified mechanical model in Figure 3a. Therefore, the perforations for the common passage of the straps are cylindrical hinges (Figure 3b), around which the loops connecting the two wall facings can rotate freely.

Figure 3. Lability of the CAM® system with a rectangular arrangement: (a) in the wall plane, according to the simplified mechanical model of an unbraced rectangular frame structure with hinged nodes and load oriented as the red arrow; (b) in the wall thickness, as represented by the orange element of the axonometric view (without the masonry blocks, to better appreciate the three-dimensional arrangement of the straps).

The in-plane lability of the strengthening system with a rectangular arrangement makes the CAM® system useless under horizontal loads. In order to allow the CAM® system with a rectangular arrangement to also improve the in-plane behavior of masonry walls subjected to seismic loads, it is therefore mandatory to eliminate its in-plane lability.

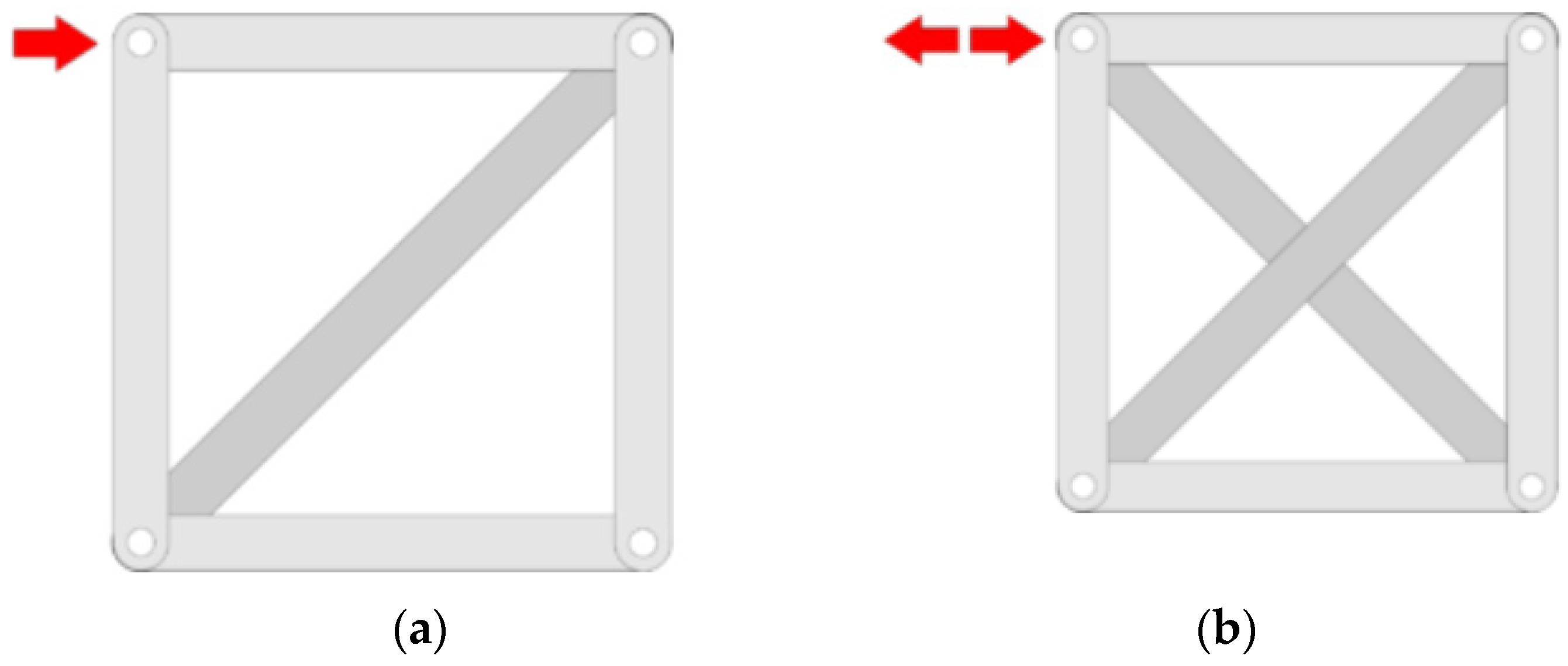

In rectangular frame structures, it is customary to cancel the horizontal displacement of the hinged nodes by bracing the structures along one or both diagonals, as shown in the simplified mechanical models of Figure 4a and Figure 4b, respectively. However, bracing is not the only possible solution to remedy the lability of the rectangular arrangement in the CAM® system: a 45° rotation of the straps makes the rectangular arrangement effective even in the plane of masonry walls.

Figure 4. Bracing of a rectangle made of hinged strips: (a) by adding a strip along a diagonal, which will prevent the rectangle from collapsing in the direction of the red arrow but not in the opposite direction; (b) by adding strips along both diagonals, which will prevent the rectangle from collapsing in either direction.

References

- Dolce, M.; Nigro, D.; Ponzo, F.C.; Marnetto, R. The CAM system for the retrofit of masonry structures. In Proceedings of the 7th International Seminar on Seismic Isolation, Passive Energy Dissipation and Active Control of Vibrations of Structures, Assisi, Italy, 2–5 October 2001.

- Dolce, M.; Ponzo, F.C.; Di Croce, M.; Moroni, C.; Giordano, F.; Nigro, D.; Marnetto, R. Experimental assessment of the CAM and DIS-CAM systems for the seismic upgrading of monumental masonry buildings. In Proceedings of the PROHITECH 2009 1st International Conference on Protection of Historical Constructions, Rome, Italy, 21–24 June 2009; CRC Press/Balkema: Leiden, The Netherlands, 2009; pp. 1021–1028.

- Dolce, M.; Ponzo, F.C.; Goretti, A.; Moroni, C.; Giordano, F.; De Canio, G.; Marnetto, R. 3d dynamic tests on 2/3 scale masonry buildings retrofitted with different systems. In Proceedings of the 14th World Conference on Earthquake Engineering, Beijing, China, 12–17 October 2008.

- Marnetto, R.; Vari, A.; Marnetto, L.; Leonori, M. Conservare l’Edilizia in Muratura: Il Sistema CAM—Cuciture Attive dei Manufatti ; Edizioni PREprogetti: Rome, Italy, 2014.

- Marnetto, R.; Vari, A. Linee Guida—Cuciture Attive per la Muratura: Procedura Generale per la Progettazione, Modellazione, Calcolo e Verifica di Edifici in Muratura Rinforzati con il Sistema di Cucitura attiva CAM; EDIL CAM Sistemi S.r.l.: Roma, Italy, 2015.

- Al-Manaseer, A.A.; Neis, V.V. Load tests on post-tensioned masonry wall panels. ACI Struct. J. 1987, 84, 467–472.

- Ganz, H.R.; Shaw, G. Stressing masonry’s future. Civ. Eng. 1997, 67, 42–45.

- Rosenboom, O.A.; Kowalsky, M.J. Reversed in-plane cyclic behavior of post-tensioned clay brick masonry walls. J. Struct. Eng. ASCE 2004, 130, 787–798.

- Bean Popehn, J.R.; Schultz, A.E.; Lu, M.; Stolarski, H.K.; Ojard, N.J. Influence of transverse loading on the stability of slender unreinforced masonry walls. Eng. Struct. 2008, 30, 2830–2839.

- Sperbeck, S. Seismic Risk Assessment of Masonry Walls and Risk Reduction by Means of Prestressing. Ph.D. Thesis, Technical University of Braunschweig, University of Florence, Florence, Italy, 2009.

- Preciado, A. Seismic Vulnerability Reduction of Historical Masonry Towers by External Prestressing Devices. Ph.D. Thesis, Technical University of Braunschweig (Germany), University of Florence, Florence, Italy, 2011.

- Ismail, N.; Schultz, A.E.; Ingham, J.M. Out-of-Plane Seismic Performance of Unreinforced Masonry Walls Retrofitted using Post-Tensioning. In Proceedings of the 15th International Brick and Block Masonry Conference, Florianópolis, Brazil, 3–6 June 2012.

- Ordinanza del Presidente del Consiglio dei Ministri 20 Marzo 2003 n.3274. Primi Elementi in Materia di Criteri Generali per la Classificazione Sismica del Territorio Nazionale e Normative Tecniche per le Costruzioni in Zona Sismica, G.U. n. 105 - S.o. n. 72, 8 May 2003. Available online: https://www.gazzettaufficiale.it/eli/id/2003/05/08/03A04408/sg (accessed on 1 December 2023).

- Ferretti, E.; Pascale, G. Some of the Latest Active Strengthening Techniques for Masonry Buildings: A Critical Analysis. Materials 2019, 12, 1151.

- Ferretti, E.; Pascale, G. Combined Strengthening Techniques to Improve the Out-of-Plane Performance of Masonry Walls. Materials 2019, 12, 1171.

- Di Re, P.; Greco, M.; Lofrano, E.; Paolone, A. Finite element modeling of masonry elements reinforced with the CAM system. Structures 2022, 44, 740–754.

- Kalali, A.; Kabir, M.Z. Experimental response of double-wythe masonry panels strengthened with glass fiber reinforced polymers subjected to diagonal compression tests. Eng. Struct. 2012, 39, 24–37.

- Mustafaraj, E.; Yardim, Y. Retrofitting damaged unreinforced masonry using external shear strengthening techniques. J. Build. Eng. 2019, 26, 100913.

- Ferretti, E. Recent advances in the Straps/Strips technique for out-of-plane strengthening of load-bearing masonry walls. Procedia Struct. Integr. 2020, 25, 33–46.

- Ferretti, E. Wire Ropes and CFRP Strips to Provide Masonry Walls with Out-Of-Plane Strengthening. Materials 2019, 12, 2712.

- Spinella, N.; Colajanni, P.; Recupero, A. Experimental in situ behaviour of unreinforced masonry elements retrofitted by pretensioned stainless steel ribbons. Constr. Build. Mater. 2014, 73, 740–753.

- Zizi, M.; Vari, A.; Colajanni, P.; De Matteis, G. Steel based retrofitting interventions for existing masonry walls: A comparative numerical investigation. ce/papers Proc. Civ. Eng. 2021, 4, 2442–2450.

More

Information

Subjects:

Engineering, Civil

Contributor

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

583

Revisions:

2 times

(View History)

Update Date:

18 Dec 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No