| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Petros Gkotsis | -- | 4571 | 2023-12-05 12:21:56 | | | |

| 2 | Jason Zhu | Meta information modification | 4571 | 2023-12-06 02:57:26 | | | | |

| 3 | Jason Zhu | + 23 word(s) | 4594 | 2023-12-29 06:35:41 | | |

Video Upload Options

Carbon dioxide (CO2), which results from fossil fuel combustion and industrial processes, accounts for a substantial part of the total anthropogenic greenhouse gases (GHGs). As a result, several carbon capture, utilization and storage (CCUS) technologies have been developed during the last decade. Chemical absorption, adsorption, cryogenic separation and membrane separation are the most widely used post-combustion CO2 capture technologies.

1. CO2 capture with Membrane Technologies

1.1. Basic Principles and Mechanism of Membrane Gas Separation

where Ji is the flux across the membrane of species i (mol/m2/s); Qi is the membrane permeability for species i (mol·m/m2/s/Pa); δ is the effective membrane thickness (m); Pr and Pp are the feed/retentate high pressure and the permeate low pressure (Pa), respectively; and xi and yi are the high-pressure and low-pressure gas-phase mole fractions (mol/mol), respectively. The permeability is equal to the product of gas solubility and diffusivity in the membrane. The ratio of permeability to membrane thickness in Equation (1) is defined as the gas permeance: q ≡ 𝑄𝑖𝛿

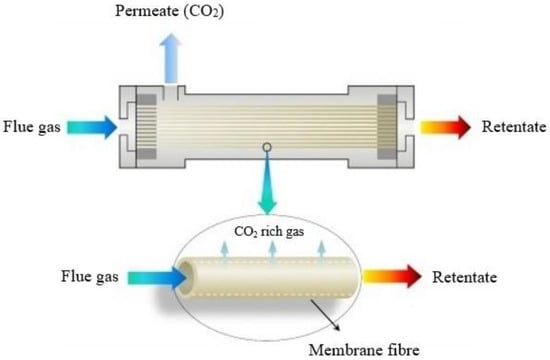

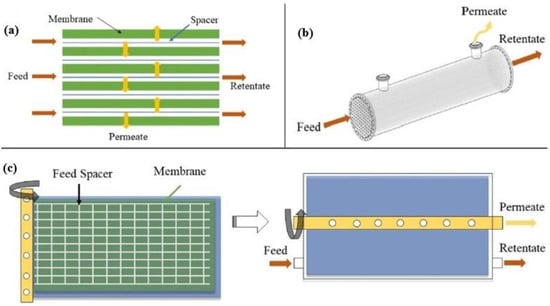

1.2. Membrane Configurations and Process Engineering

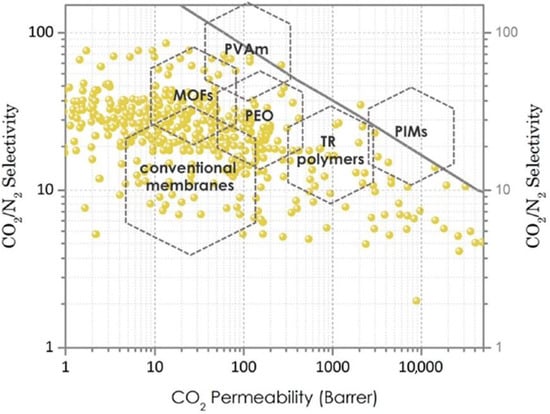

1.3. Membrane Materials

2. State of the Art in CO2 Capture with the Use of Membrane Technologies

- (i)

-

Inorganic materials, e.g., zeolites.

- (ii)

-

Carbon-based materials, e.g., carbon nanotubes and carbon molecular sieves (CMSs).

- (iii)

-

Organic-based materials, such as (a) porous organic frameworks (POFs), which include covalent organic frameworks (COFs), porous aromatic frameworks (PAFs), covalent organic polymers (COPs) and porous organic polymers (POPs), and (b) microporous polymers, which include polymers of intrinsic microporosity (PIM) and thermally rearranged (TR) polymers.

- (iv)

-

Hybrid materials, which are also known as metal–organic frameworks (MOFs).

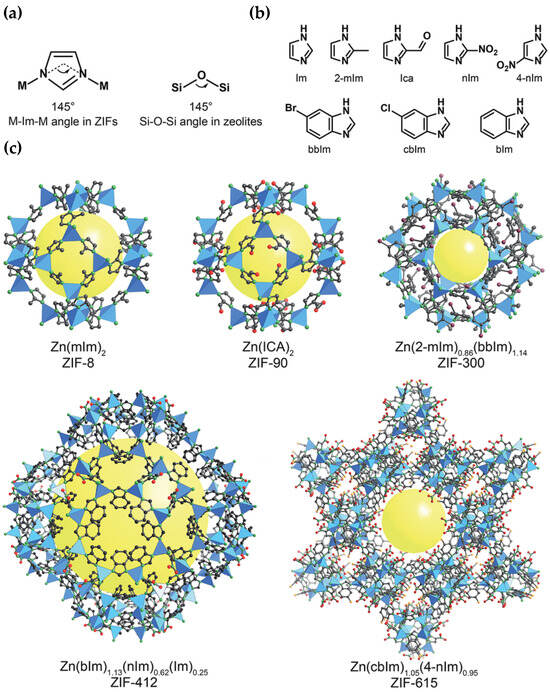

2.1. Metal–Organic Framework (MOF) Membraness

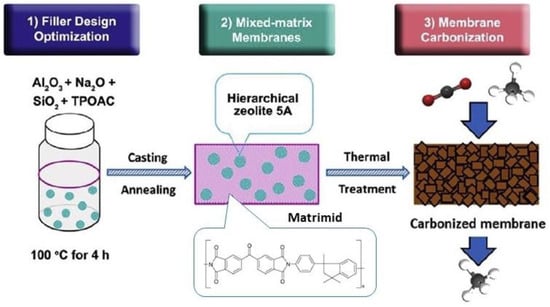

2.2. Carbon Molecular Sieve (CMS) Membranes

2.3. Nanocomposite Membranes

2.4. Ionic Liquid (IL)-Based Membranes

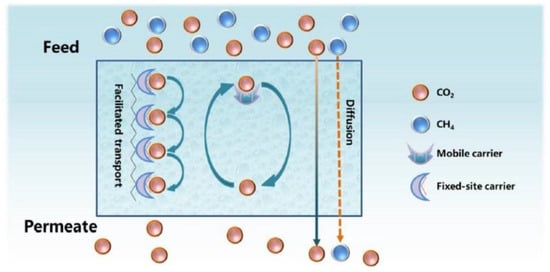

2.5. Facilitated Transport Membranes (FTMs)

3. Commercially Applied Membrane Modules for Industrial CO2 Capture

References

- Gkotsis, P.K.; Zouboulis, A.I. The use of bio-carriers and zeolite in a lab-scale MBR for membrane fouling mitigation. Glob. Nest J. 2018, 21, 58–63.

- Kim, S.; Scholes, C.A.; Heath, D.E.; Kentish, S.E. Gas-liquid membrane contactors for carbon dioxide separation: A review. Chem. Eng. J. 2021, 41, 128468.

- Ji, G.; Zhao, M. Membrane Separation Technology in Carbon Capture. In Recent Advances in Carbon Capture and Storage; Yun, Y., Ed.; InTech: Rijeka, Croatia, 2017.

- Da Conceicao, M.; Nemetz, L.; Rivero, J.; Hornbostel, K.; Lipscomb, G. Gas Separation Membrane Module Modeling: A Comprehensive Review. Membranes 2023, 13, 639.

- Rafiq, S.; Deng, L.; Hägg, M.B. Role of Facilitated Transport Membranes and Composite Membranes for Efficient CO2 Capture—A Review. ChemBioEng Rev. 2016, 3, 68–85.

- Tong, Z.; Sekizkardes, A.K. Recent Developments in High-Performance Membranes for CO2 Separation. Membranes 2021, 11, 156.

- Castro-Dominguez, B.; Leelachaikul, P.; Messaoud, S.B.; Takagaki, A.; Sugawara, T.; Kikuchi, R.; Oyama, S.T. The optimal point within the Robeson upper boundary. Chem. Eng. Res. Des. 2015, 97, 109–119.

- Rivero, J.R.; Nemetz, L.R.; Da Conceicao, M.M.; Lipscomb, G.; Hornbostel, K. Modeling gas separation in flat sheet membrane modules: Impact of flow channel size variation. Carbon Capture Sci. Technol. 2023, 6, 100093.

- Wu, H.; Li, Q.; Guo, B.; Sheng, M.; Wang, D.; Mao, S.; Ye, N.; Qiao, Z.; Kang, G.; Cao, Y.; et al. Industrial-scale spiral-wound facilitated transport membrane modules for post-combustion CO2 capture: Development, investigation and optimization. J. Membr. Sci. 2023, 670, 121368.

- Ahmed, S.F.; Mofijur, M.; Tarannum, K.; Chowdhury, A.T.; Rafa, N.; Nuzhat, S.; Kumar, P.S.; Vo, D.-V.N.; Lichtfouse, E.; Mahlia, T.M.I. Biogas upgrading, economy and utilization: A review. Environ. Chem. Lett. 2021, 19, 4137–4164.

- Hidalgo, D.; Sanz-Bedate, S.; Martín-Marroquín, J.M.; Castro, J.; Antolín, G. Selective separation of CH4 and CO2 using membrane contactors. Renew. Energy 2020, 150, 935–942.

- Xu, J.; Wu, H.; Wang, Z.; Qiao, Z.; Zhao, S.; Wang, J. Recent advances on the membrane processes for CO2 separation. Chin. J. Chem. Eng. 2018, 26, 2280–2291.

- He, X. A review of material development in the field of carbon capture and the application of membrane-based processes in power plants and energy-intensive industries. Energy Sustain. Soc. 2018, 8, 34.

- Zhu, B.; He, S.; Yang, Y.; Li, S.; Lau, C.H.; Liu, S.; Shao, L. Boosting membrane carbon capture via multifaceted polyphenol-mediated soldering. Nat. Commun. 2023, 14, 1697.

- Chen, G.; Chen, C.; Guo, Y.; Chu, Z.; Pan, Y.; Liu, G.; Liu, G.; Han, Y.; Jin, W.; Xu, N. Solid-solvent processing of ultrathin, highly loaded mixed-matrix membrane for gas separation. Science 2023, 381, 1350–1356.

- Chen, M.; Hu, G.; Shen, T.; Zhang, H.; Sun, J.Z.; Tang, B.Z. Applications of Polyacetylene Derivatives in Gas and Liquid Separation. Molecules 2023, 28, 2748.

- Vostiňáková, M.; Lupínková, S.; Ryšánek, P.; Stejskal, J.; Kolská, Z. Polyaniline/aramid composite for carbon dioxide capture. Polym. Int. 2023, 72, 552–557.

- Quian, H.; Zheng, J.; Zhang, S. Preparation of microporous polyamide networks for carbon dioxide capture and nanofiltration. Polymer 2013, 54, 557–564.

- Jankowski, A.; Grabiec, E.; Nocoń-Szmajda, K.; Marcinkowski, A.; Janeczek, H.; Wolińska-Grabczyk, A. Polyimide-Based Membrane Materials for CO2 Separation: A Comparison of Segmented and Aromatic (Co)polyimides. Membranes 2021, 11, 274.

- Naim, R.; Ismail, A.F.; Matsuura, T.; Rudaini, I.A.; Abdullah, S. Polyetherimide hollow fiber membranes for CO2 absorption and stripping in membrane contactor application. RSC Adv. 2018, 8, 3556.

- Hauenstein, O.; Rahman, M.M.; Elsayed, M.; Krause-Rehberg, R.; Agarwal, S.; Abetz, V.; Greiner, A. Biobased Polycarbonate as a Gas Separation Membrane and “Breathing Glass” for Energy Saving Applications. Adv. Mater. Technol. 2017, 2, 1700026.

- Sridhar, S.; Smitha, B.; Ramakrishna, M.; Aminabhavi, T.M. Modified poly(phenylene oxide) membranes for the separation of carbon dioxide from methane. J. Membr. Sci. 2006, 280, 202–209.

- Zhu, B.; Jiang, X.; He, S.; Yang, X.; Long, J.; Zhang, Y.; Shao, L. Rational design of poly(ethylene oxide) based membranes for sustainable CO2 capture. J. Mater. Chem. A. 2020, 8, 24233–24252.

- Suhail, F.; Batool, M.; Anjum, T.; Shah, A.T.; Tabassum, S.; Khan, A.L.; AlMohamadi, H.; Najam, M.; Gilani, M.A. Enhanced CO2 separation performance of polysulfone membranes via incorporation of pyrazole modified MCM-41 mesoporous silica as a nano-filler. Fuel 2023, 350, 128840.

- Akbarzadeh, E.; Shockravi, A.; Vatanpour, V. High performance compatible thiazole-based polymeric blend cellulose acetate membrane as selective CO2 absorbent and molecular sieve. Carbohydr. Polym. 2021, 252, 117215.

- Singh, P.; Shah, S.; Rai, S.K. Post-combustion carbon capture by polymeric membrane: A review. Mater. Today Proc. 2022, 62, 318–324.

- Chen, G.; Wang, T.; Zhang, G.; Li, G.; Jin, W. Membrane materials targeting carbon capture and utilization. Adv. Membr. 2022, 2, 100025.

- Koros, W.J.; Zhang, C. Materials for next-generation molecularly selective synthetic membranes. Nat. Mater. 2017, 16, 289–297.

- Golmakani, A.; Nabavi, S.A.; Wadi, B.; Manovic, V. Advances, challenges, and perspectives of biogas cleaning, upgrading, and utilisation. Fuel 2022, 317, 123085.

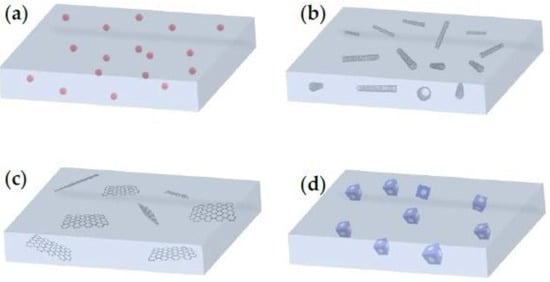

- Luo, W.; Li, F.; Li, H.; Zhang, Z.; Zhang, X.; Liang, Y.; Huang, G. From 0D to 3D nanomaterial-based composite membranes for CO2 capture: Recent advances and perspectives. J. Environ. Chem. Eng. 2023, 11, 110657.

- Chen, D.; Wang, K.; Yuan, Z.; Lin, Z.; Zhang, M.; Li, Y.; Tang, J.; Liang, Z.; Li, Y.; Chen, L.; et al. Boosting membranes for CO2 capture toward industrial decarbonization. Carbon Capture Sci. Technol. 2023, 7, 100117.

- Asghar, U.; Rafiq, S.; Anwar, A.; Iqbal, T.; Ahmed, A.; Jamil, F.; Khurram, M.S.; Akbar, M.M.; Farooq, A.; Shah, N.S.; et al. Review on the progress in emission control strategies for the abatement of CO2, SOx and NOx from fuel combustion. J. Environ. Chem. Eng. 2021, 9, 106064.

- Basile, A.; Gugliuzza, A.; Iulianelli, A.; Morrone, P. Membrane technology for carbon dioxide (CO2) capture in power plants. In Advanced Membrane Science and Technology for Sustainable Energy and Environmental Applications; Woodhead Publishing Limited; Elsevier: Sawston, UK, 2021; pp. 113–159.

- Shah, Y.T. CO2 Capture, Utilization and Sequestration Strategies; CRC Press: Boca Raton, FL, USA, 2020.

- Wu, H.; Li, X.; Li, Y.; Wang, S.; Guo, R.; Jiang, Z.; Wu, C.; Xin, Q.; Lu, X. Facilitated transport mixed matrix membranes incorporated with amine functionalized MCM-41 for enhanced gas separation properties. J. Membr. Sci. 2014, 465, 78–90.

- Prasetya, N.; Himma, N.F.; Sutrisna, P.D.; Wenten, I.G.; Ladewig, B.P. A review on emerging organic-containing microporous material membranes for carbon capture and separation. Chem. Eng. J. 2020, 391, 123575.

- Shan, M.; Liu, X.; Wang, X.; Yarulina, I.; Seoane, B.; Karteijin, F.; Gascon, J. Facile manufacture of porous organic framework membranes for precombustion CO2 capture. Sci. Adv. 2018, 4, 1698.

- Zhao, M.; Guo, J.; Xin, Q.; Zhang, Y.; Li, X.; Ding, X.; Zhang, L.; Zhao, L.; Ye, H.; Li, H.; et al. Novel aminated F-Ce nanosheet mixed matrix membranes with controllable channels for CO2 capture. Sep. Purif. Technol. 2023, 324, 124512.

- Liu, M.; Xie, K.; Nothling, M.D.; Gurr, P.A.; Tan, S.S.L.; Fu, Q.; Webley, P.A.; Qiao, G. Ultrathin Metal-Organic Framework Nanosheets as A Gutter Layer for Flexible Composite Gas Separation Membranes. ACS Nano 2018, 12, 11591–11599.

- Liu, M.; Nothling, M.D.; Webley, P.A.; Jin, J.; Fu, Q.; Qiao, G.G. High-throughput CO2 capture using PIM-1@MOF based thin film composite membranes. Chem. Eng. J. 2020, 396, 125328.

- Yao, B.; Wang, Y.; Fang, Z.; Hu, Y.; Ye, Z.; Peng, X. Electrodepositing MOFs into laminated graphene oxide membrane for CO2 capture. Microporous Mesoporous Mater. 2023, 361, 112758.

- Wang, J.; Li, L.; Li, X.; Zhang, J. Constructing double-faced CO2-capture domains by sandwich-like fillers in membranes for efficient CO2 separation. Chem. Eng. Sci. 2024, 283, 119374.

- Demir, H.; Aksu, G.O.; Gulbalkan, H.C.; Keskin, S. MOF Membranes for CO2 Capture: Past, Present and Future. Carbon Capture Sci. Technol. 2022, 2, 100026.

- Rungtaweevoranit, B.; Diercks, C.S.; Kalmutzki, M.J.; Yaghi, O.M. Spiers Memorial Lecture: Progress and prospects of reticular chemistry. Faraday Discuss. 2017, 201, 9–45.

- Gutierrez-Ortega, A.; Montes-Morán, M.A.; Parra, J.P.; Sempere, J.; Nomen, R.; Gonzalez-Olmos, R. Comparative study of binderless zeolites and carbon molecular sieves as adsorbents for CO2 capture processes. J. CO2 Util. 2022, 61, 102012.

- Sanyal, O.; Hays, S.S.; León, N.E.; Guta, Y.A.; Itta, A.K.; Lively, R.P.; Koros, W.J. A Self-Consistent Model for Sorption and Transport in Polyimide-Derived Carbon Molecular Sieve Gas Separation Membranes. Angew. Chem. 2020, 132, 20525–20891.

- Wang, Y.; Wang, K.; Zhang, X.; Li, J. Co@NC@ZIF-8-hybridized carbon molecular sieve membranes for highly efficient gas separation. J. Membr. Sci. 2023, 682, 121781.

- Cheng, L.-H.; Fu, Y.-J.; Liao, K.-S.; Chen, J.-T.; Hu, C.-C.; Hung, W.-S.; Lee, K.-R.; Lai, J.-Y. A high-permeance supported carbon molecular sieve membrane fabricated by plasma-enhanced chemical vapor deposition followed by carbonization for CO2 capture. J. Membr. Sci. 2014, 460, 1–8.

- Dasgupta, S.; Rajasekaran, M.; Roy, P.K.; Thakkar, F.M.; Pathak, A.D.; Ayappa, K.G.; Maiti, P.K. Influence of chain length on structural properties of carbon molecular sieving membranes and their effects on CO2, CH4 and N2 adsorption: A molecular simulation study. J. Membr. Sci. 2022, 664, 121044.

- Zhang, Y.; Sun, M.; Li, L.; Xu, R.; Pan, Y.; Wang, T. Carbon molecular sieve/ZSM-5 mixed matrix membranes with enhanced gas separation performance and the performance recovery of the aging membranes. J. Membr. Sci. 2023, 660, 120869.

- Li, W.; Goh, K.; Chuah, C.Y.; Bae, T.-H. Mixed-matrix carbon molecular sieve membranes using hierarchical zeolite: A simple approach towards high CO2 permeability enhancements. J. Membr. Sci. 2019, 588, 117220.

- Yang, G.; Xie, Z.; Cran, M.; Wu, C.; Gray, S. Dimensional Nanofillers in Mixed Matrix Membranes for Pervaporation Separations: A Review. Membranes 2020, 10, 193.

- Dai, Y.; Niu, Z.; Fang, T.; Wang, Y.; Zhong, S.; Mu, P.; Li, J. 1D-2D intercalated network CMC@g-C3N4/IL membrane with high permeability and selectivity for the CO2 capture. J. Membr. Sci. 2023, 686, 122019.

- Maleh, M.S.; Kiani, S.; Raisi, K. Study on the advantageous effect of nano-clay and polyurethane on structure and CO2 separation performance of polyethersulfone based ternary mixed matrix membranes. Chem. Eng. Res. Des. 2022, 179, 27–40.

- Mahboubi, R.; Joudaki, E.; Behbahani, R.M.; Azizi, N. Enhancing CO2/(light gases) separation performance of Pebax-based mixed-matrix membranes by ionic liquid. Mater. Today Commun. 2023, 36, 106542.

- Mulk, W.U.; Ali, S.A.; Shah, S.N.; Shah, M.U.H.; Zhang, Q.-J.; Younas, M.; Fatehizadeh, A.; Sheikh, M.; Rezakazemi, M. Breaking boundaries in CO2 capture: Ionic liquid-based membrane separation for post-combustion applications. J. CO2 Util. 2023, 75, 102555.

- Sanni, S.E.; Vershima, D.A.; Okoro, E.E.; Oni, B.A. Technological advancements in the use of ionic liquid-membrane systems for CO2 capture from biogas/flue gas—A review. Heliyon 2022, 8, 12233.

- Nabais, A.R.; Ahmed, S.; Younis, M.; Zhou, J.-X.; Pereira, J.R.; Freitas, F.; Mecerreyes, D.; Crespo, J.G.; Huang, M.H.; Neves, L.A.; et al. Mixed matrix membranes based on ionic liquids and porous organic polymers for selective CO2 separation. J. Membr. Sci. 2022, 660, 120841.

- Ahmad, N.N.R.; Leo, C.P.; Mohammad, A.W.; Ahmad, A.L. Interfacial sealing and functionalization of polysulfone/SAPO-34 mixed matrix membrane using acetate-based ionic liquid in post-impregnation for CO2 capture. Sep. Purif. Technol. 2018, 197, 439–448.

- Ahmad, N.N.R.; Leo, C.P.; Mohammad, A.W. Enhancement on the CO2 separation performance of mixed matrix membrane using ionic liquid. Mater. Lett. 2021, 304, 130736.

- Guo, H.; Wei, J.; Ma, Y.; Deng, J.; Yi, S.; Wang, B.; Deng, L.; Jiang, X.; Dai, Z. Facilitated transport membranes for CO2/CH4 separation—State of the art. Adv. Membr. 2022, 2, 100040.

- Zheng, W.; Tian, Z.; Wang, Z.; Peng, D.; Zhang, Y.; Wang, J.; Zhang, Y. Dual-function biomimetic carrier based facilitated transport mixed matrix membranes with high stability for efficient CO2/N2 separation. Sep. Purif. Technol. 2022, 285, 120371.

- Kilner, J.A.; Skinner, S.J.; Irvine, S.J.C.; Edwards, P.P. Chapter 7.3.2—Facilitated transport membranes. In Functional Materials for Sustainable Energy Applications; Woodhead Publishing Limited; Elsevier: Sawston, UK, 2012.

- He, X. Polyvinylamine-Based Facilitated Transport Membranes for Post-Combustion CO2 Capture: Challenges and Perspectives from Materials to Processes. Engineering 2021, 7, 124–131.

- Janakiram, S.; Yu, X.; Ansaloni, L.; Dai, Z.; Deng, L. Manipulation of fibril surfaces in nanocellulose-based facilitated transport membranes for enhanced CO2 capture. ACS Appl. Mater. Interfaces 2019, 11, 33302–33313.

- Janakiram, S.; Santinelli, F.; Costi, R.; Lindbråthen, A.; Nardelli, G.M.; Milkowski, K.; Ansaloni, L.; Deng, L. Field trial of hollow fiber modules of hybrid facilitated transport membranes for flue gas CO2 capture in cement industry. Chem. Eng. J. 2021, 413, 127405.

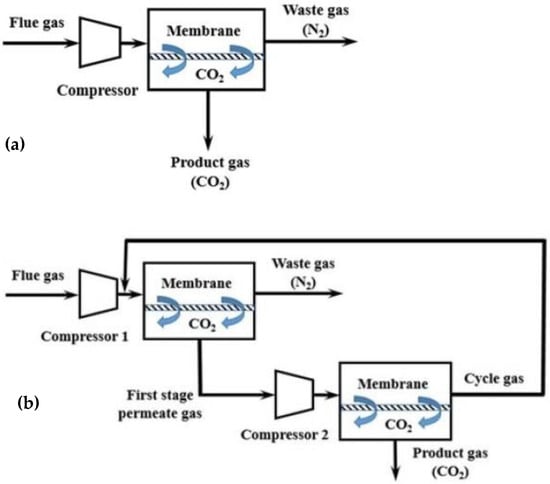

- Janakiram, S.; Lindbråthen, A.; Ansaloni, L.; Peters, T.; Deng, L. Two-stage membrane cascades for post-combustion CO2 capture using facilitated transport membranes: Importance on sequence of membrane types. Int. J. Greenh. Gas Control. 2022, 119, 103698.

- He, X.; Chen, D.; Liang, Z.; Yang, F. Insight and Comparison of Energy-efficient Membrane Processes for CO2 Capture from Flue Gases in Power Plant and Energy-intensive Industry. Carbon Capture Sci. Technol. 2022, 2, 100020.

- Kniep, J.; Richard, B.; Casillas, C.; Chan, K.; Huang, I.; Merkel, T.; Nguyen, V.; Sun, Z.; Wang, X. Small Pilot Test Results from a Polaris Membrane 1 MWe CO2 Capture System. In Proceedings of the 14th Greenhouse Gas Control Technologies Conference, Melbourne, Australia, 21–26 October 2018. (GHGT-14).

- Baker, R.; Freeman, B.; Casillas, C.; Chan, K.; Hofmann, T.; Huang, I.; Kniep, J.; Merkerl, T.; Nguyen, V.; Sun, Z.; et al. CO2 Capture from Power Plant Flue Gas with the MTR PolarCap™ Process: Update on Field Demonstration Tests; Membrane Technology and Research (MTR), Report: Houston, TX, USA, 2019.

- Merkerl, T.; Kniep, J. Scale-up and Testing of Advanced Polaris Membrane CO2 Capture Technology (DE-FE0031591). Membrane Technology and Research (MTR), Report: Newark, CA, USA, 2018.

- Hou, R.; Fong, C.; Freeman, B.D.; Hill, M.R.; Xie, Z. Current status and advances in membrane technology for carbon capture. Sep. Purif. Technol. 2022, 300, 121863.

- Cui, Q.; Wang, B.; Zhao, X.; Zhang, G.; He, Z.; Long, Y.; Sun, Y.; Ku, A.Y. Post-combustion slipstream CO2-capture test facility at Jiangyou Power Plant, Sichuan, China: Performance of a membrane separation module under dynamic power-plant operations. Clean Ener. 2021, 5, 742–755.

- Pohlmann, J.; Bram, M.; Wilkner, K.; Brinkmann, T. Pilot scale separation of CO2 from power plant flue gases by membrane technology. Int. J. Greenh. Gas Control. 2016, 53, 56–64.

- Brinkmann, T.; Lillepärg, J.; Notzke, H.; Pohlmann, J.; Shishatskiy, S.; Wind, J.; Wolff, T. Development of CO2 selective poly(ethylene oxide)-based membranes: From laboratory to pilot plant scale. Engineering 2017, 3, 485–493.

- Schuldt, K.; Pohlmann, J.; Shishatskiy, S.; Brinkmann, T. Applicability of polyactive™ thin film composite membranes for CO2 separation from C2H4 containing multicomponent gas mixtures at pressures up to 30 bar. Membranes 2018, 8, 27.

- Kárászová, M.; Zach, B.; Petrusová, Z.; Červenka, V.; Bobák, M.; Šyc, M.; Izák, P. Post-combustion carbon capture by membrane separation, Review. Sep. Purif. Technol. 2020, 238, 116448.

- Scholes, C.A.; Qader, A.; Stevens, G.W.; Kentish, S.E. Membrane pilot plant trials of CO2 separation from flue gas. Greenh. Gases Sci. Technol. 2015, 5, 229–237.