Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Manikant Tripathi | -- | 3124 | 2023-11-20 13:12:36 | | | |

| 2 | Peter Tang | Meta information modification | 3124 | 2023-11-21 02:13:50 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Tripathi, M.; Singh, S.; Pathak, S.; Kasaudhan, J.; Mishra, A.; Bala, S.; Garg, D.; Singh, R.; Singh, P.; Singh, P.K.; et al. Approaches for Dyes Remediation. Encyclopedia. Available online: https://encyclopedia.pub/entry/51805 (accessed on 07 February 2026).

Tripathi M, Singh S, Pathak S, Kasaudhan J, Mishra A, Bala S, et al. Approaches for Dyes Remediation. Encyclopedia. Available at: https://encyclopedia.pub/entry/51805. Accessed February 07, 2026.

Tripathi, Manikant, Sakshi Singh, Sukriti Pathak, Jahnvi Kasaudhan, Aditi Mishra, Saroj Bala, Diksha Garg, Ranjan Singh, Pankaj Singh, Pradeep Kumar Singh, et al. "Approaches for Dyes Remediation" Encyclopedia, https://encyclopedia.pub/entry/51805 (accessed February 07, 2026).

Tripathi, M., Singh, S., Pathak, S., Kasaudhan, J., Mishra, A., Bala, S., Garg, D., Singh, R., Singh, P., Singh, P.K., Shukla, A.K., & Pathak, N. (2023, November 20). Approaches for Dyes Remediation. In Encyclopedia. https://encyclopedia.pub/entry/51805

Tripathi, Manikant, et al. "Approaches for Dyes Remediation." Encyclopedia. Web. 20 November, 2023.

Copy Citation

Different types of dyes emanating from textile wastewater have adverse effects on the aquatic environment. Various methods including physical, chemical, and biological strategies are applied in order to reduce the amount of dye pollution in the environment. The development of economical, ecologically acceptable, and efficient strategies for treating dye-containing wastewater is necessary. It has been shown that microbial communities have significant potential for the remediation of hazardous dyes in an environmentally friendly manner.

bioremediation

dye degradation

environmental pollutants

genetic engineering

microbial fuel cells

nanotechnology

textile wastewater treatment

1. Introduction

Industrial wastewater is very harmful for our environment and causes various adverse impacts on the ecosystem. Most wastewater is generated from the textile, cosmetics, printing, paper, and rubber industries [1]. The textile industry generates huge amounts of highly toxic chemicals that are released at various stages of processing [2]. In addition, it is well documented that textile dyes, without proper treatment, pose serious eco-toxicological threats to living forms [3][4].

Textile dye-containing wastewater is also one of the major sources of water pollution, and it affects the environment by disturbing aquatic life, inhibiting the photosynthesis process in aquatic plants, and affects human health by causing breathing difficulties, irregular heartbeats, skin rashes, dizziness, and cancer [3][5][6]. Different types of dyes are used in the textile industry. Most of the common dyes applied in the textile industry are called azo dyes [7][8].

Since ancient times, mankind has known about and utilized dyes [9]. In many manufacturing sectors, including the paper industry and many more, a number of techniques are effective in removing dyes [10][11][12]. It has been found that the dyes used in the textile industry have high toxicity and a potential carcinogenic nature [6][13]. The textile industry is responsible for a broad range of impacts on the environment [14]. Textile dyes can cause diseases ranging from dermatitis to central nervous system disorders [15]. Consequently, treating toxic wastewater containing different types of textile dyes is a very compelling issue currently [16][17][18]. Accommodating a single or multiple azo groups, azo dyes constitute 60–70% of known dye structures [19][20][21].

The treatment of dye-containing wastewater occurs through various methods like physical, chemical, biological, and recent advanced technologies such as using nanotechnology, microbial biosorbents, microbial films, genetic engineering, plant–microbe-mediated techniques, and others [5][12]. In recent studies, researchers have reported the use of chemical-based methods for the remediation of pollutants from wastewater [22][23][24]. Metal-based organic frameworks are also used as sensitive and selective sensors for detecting hazardous pollutants [25]. However, physical and chemical methods are not cost-effective [3].

Microbial processes using algae, bacteria, yeast, and fungi are low-cost and can be successfully utilized for dye remediation. Microorganisms are capable of breaking down the azo bonds present in dye molecules through their enzymatic activity [3][26]. Advanced treatment strategies using microorganisms can make the remediation process more effective, while appropriate environmental conditions should also be ensured for effective bioremediation [27].

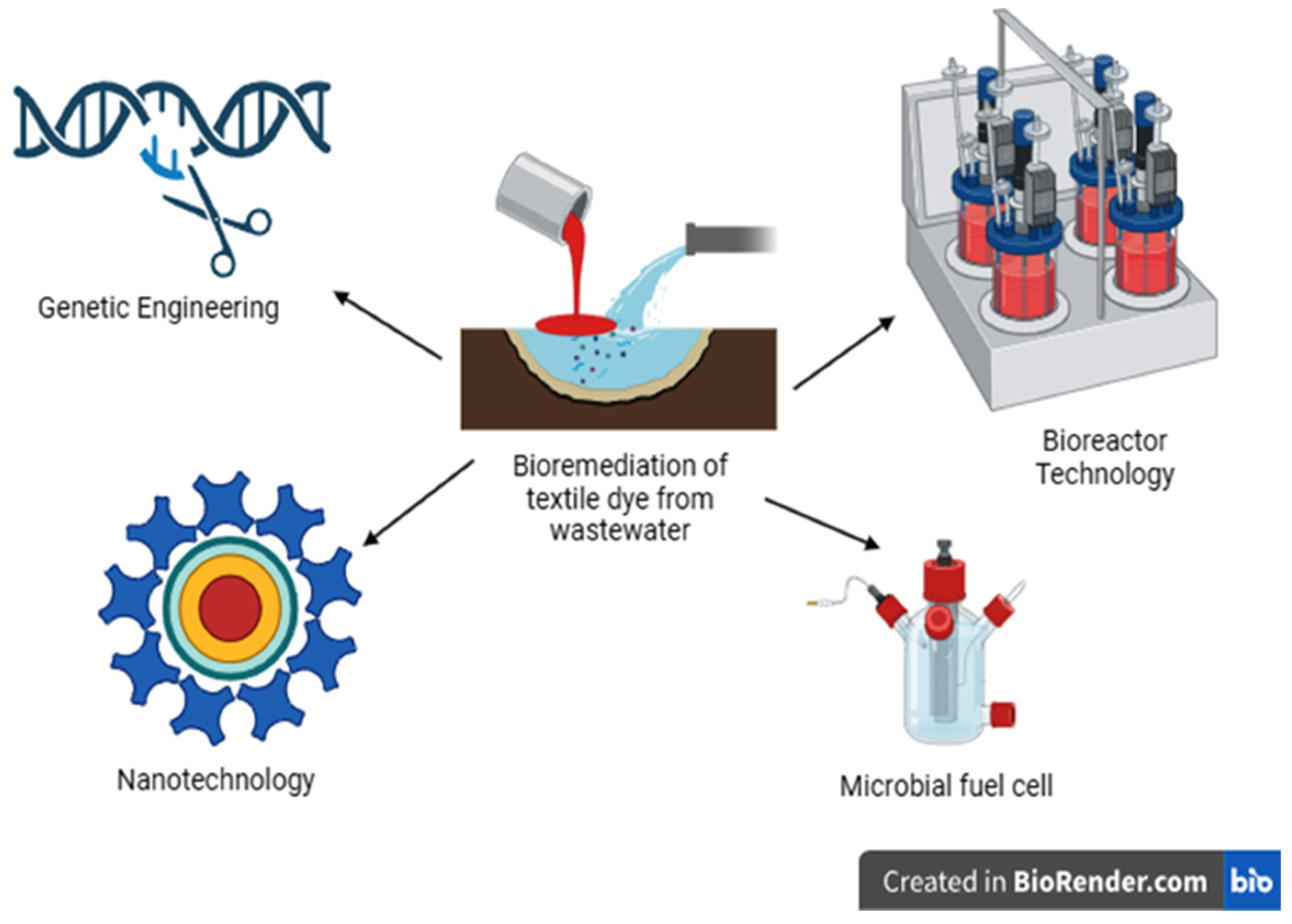

Pollutants such as dyes from the textile industry are present in wastewater. Various techniques, such as physical, chemical, and biological methods, are used for the decontamination of dyes in aquatic environments. The physical and chemical procedures used to treat textile wastewater are inadequate and not always environmentally feasible. A safe method to detoxify dyes from wastewater is bioremediation technology using microorganisms or plants. Nowadays, advanced technologies such as bioremediation, including nanotechnology, bioreactors, microbial fuel cells, genetic engineering, and others, are being applied in the treatment of dye pollution in the environment (Figure 1).

Figure 1. Recent possible strategies for dyes remediation from aquatic environment.

2. Physical and Chemical Approaches

Adsorption, ion exchange, and membrane filtration are a few of the physical methods used in the remediation of environmental pollutants.

2.1. Adsorption

Adsorption is used for the management of industrial wastewater. Adsorption is a surface-based phenomenon in which the solid surface of the adsorbent attracts charged ions or molecules, which then adsorb onto the surface. Several types of forces are responsible for dye molecule adsorption, including hydrophobic, electrostatic interaction, hydrogen bonding, and van der Waals forces [28]. The adsorption process removes dyes from contaminated wastewater, and there is a possibility of upcycling the adsorbent for reuse in treatment [29]. The phenomenon of adsorption is dependent on the adsorbent, which contains pore-like structures that are required for the quick and systematic adsorption of dye molecules from wastewater [30][31]. Most adsorbents, such as silica gel, alumina, zeolite, and activated carbon, are commonly used for the removal of toxic dyes from contaminated wastewater [32]. Other mechanisms like complexation and ion exchange are applied in the remediation of dyes [33][34][35]. In their study, Briao et al. [36] found that ZSM-5 zeolite adsorbent is used in the treatment of dye-containing wastewater, such as basic fuchsin, crystal violet, and methylene blue, with a degradation percentage of 81.2%, 75.3%, and 86.6%, respectively. In another study, Madan et al. [37] reported 90% Congo red decolorization by ZnO, used as an adsorbent, while Harza et al. [38] reported Congo red dye remediation with the help of fly ash generated from a local powerplant. Several researchers have also reported different types of organic adsorbents and their composites for dye remediation from aqueous solutions, and some of the most interesting adsorbents are conducting polymers in their different forms, including powders and aerogels, as well as biopolymers [39][40][41].

2.2. Ion-Exchange Method

In the ion-exchange method, effective separation is accomplished by creating a complex bond between resin, which is a bed reactor, and a solute. Akpomie and Conardie [29] and Ahmad et al. [42] found that the process of dye removal in ion exchange mainly depends on strong interactions between charged molecules in the dye and the functional group of the resin. The cation exchangers and anion exchangers are used as resins to separate solutes with different surface charges [43]. Many researchers reported that dyes like acid orange 10 are removed by an anion-exchanger resin named Amberlite IRA-400, and the percentage of dye removed was 96.8% [44]. Another dye, acid black, was remediated at a rate of 100% by an anion exchanger that was synthesized using cellulose [45]. Disperse violet 28 dye is generally removed by cation-exchanger resin, and the dye removal percentage is 91.7 [46].

2.3. Membrane Filtration

Membrane filtration is one of the most important physical methods for textile dye removal from wastewater [47][48]. In this method, due to the small pore size of the membrane, molecules larger than the filter pores become trapped. Microfiltration is a membrane-based phenomenon that involves the separation of dyes in the size range of 0.1–0.10 μm [49]. In this process, the waste materials or dyes are remediated from the liquid with the help of a microporous membrane. Ultrafiltration is another membrane-based method. Collivignarelli et al. [50] reported that dye color removal capabilities are acquired from wastewater with the help of ultrafiltration. The reactive black dye solution uses an ultrafiltration ceramic membrane and decolorizes the dye at different concentrations [51]. Reverse osmosis is also a membrane filtration mechanism that is used for the treatment of industrial wastewater that contains dyes [52][53]. Several researchers have reported the application of filtration technology for the treatment of wastewater containing dyes [54][55][56].

2.4. Fenton Process

The two major approaches for the degradation of dyes present in textile water are Fenton and photo-Fenton [57][58]. These processes are carried out by using a Fenton reagent, namely H2O2, and a soluble iron (II) salt mixture [59][60][61]. In a study by Ledakowicz et al. [62], it was reported that the degradation of three dyes (add red 27, reactive blue 81, and add blue 62) occurred with the use of a Fenton reagent. They concluded that this reaction is very simple and fast. In another study, Chen et al. [63] used the stopped flow technique to study the degradation of methylene blue and rhodamine B with Fenton reagent. Zawadzki and Deska [64] published a review concerning the degradation of dyes by combining advanced oxidation processes with different methods, such as utilizing ozone, hydrogen peroxide, and persulfate to degrade rhodamine B. They concluded that degradation is achieved by using UV in a photo-assisted ozonation, which was the most effective method among all of the techniques tested.

2.5. Ozonation

Dye remediation using ozonation is another important treatment technology. Shriram and Kanmani [65] concluded in their study that H2O2, UV radiation, etc., are used in the ozonation process. They provided a detailed study about the mechanism, influencing factors, and initiators of ozonation. Venkatesh and colleagues [66] reported dye remediation by means of combined ozonation and anaerobic treatment strategies. They reported that the cost of ozonation can be reduced using an upflow anaerobic sludge blanket reactor. In another study, Cardoso et al. [67] reported nanomaterial-based catalysts for the ozonation process in the remediation of dyes. They used copper (II)-doped carbon dots as catalysts in catalytic ozonation. They also analyzed the degradation of four dyes, namely methyl orange, orange II sodium salt, reactive black, and remazol brilliant blue R (RBB-R). In a recent research work, Lanzetta et al. [68] reported using the ozonation process for color remediation from tanning wastewater. Further research is needed on the decolorization of wastewater using ozonation.

3. Biological Approaches

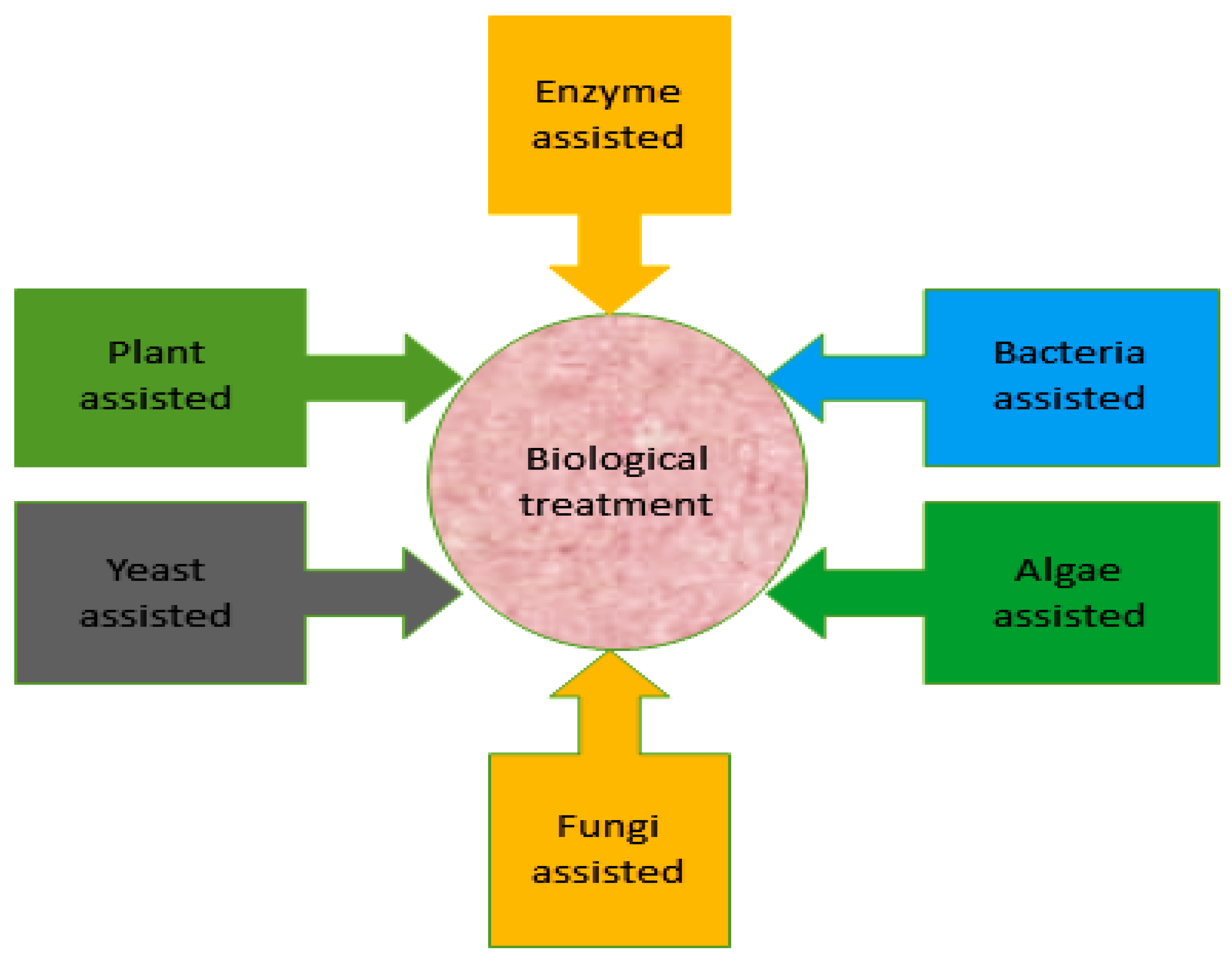

The physical and chemical techniques used in dye decolorization are costly. Traditional biological techniques are used exclusively or with chemical and physical techniques for dye decolorization. Nonetheless, advanced biological methods that are less expensive and more effective with lesser secondary sludge production are emphasized [11][69][70]. Microbial methods are effective for the bioremediation of different types of organic and inorganic pollutants [27][71][72]. On the basis of different research findings, for the decolorization of dyes, bacterial treatment serves as an efficient strategy [73]. Figure 2 presents various biological methods for the bioremediation of dyes from contaminated environments.

Figure 2. Different strategies for the bioremediation of dyes from polluted environments.

3.1. Enzymatic Method

Bioremediation by enzymes is an ingenious, favorable, environmentally friendly technique [74]. The enzymatic degradation method consists of finding the attributes of microbes or genetically modified microbes, designing enzymes to metabolize the dyes, and transforming the harmful form of dyes into harmless forms or non-toxic forms [74]. Regarding azo dye degradation, a number of studies have been conducted to understand different type of enzymatic activities that help in the degradation of toxic dyes [74][75]. A class of enzyme, azoreductase, has been described by Mendes et al. [76] as carrying out the reduction reaction causing the breakdown of azo bonds (-N=N-) present in dyes, and converting the aromatic amine into colorless water. The enzyme laccase can be used in the treatment of different toxic textile dyes [77]. Lignin and Mn peroxidase have been widely studied; peroxidase enzymes have been used in the degradation of toxic textile dyes [78]. For the bioremediation of hydrocarbons and pesticides, enzymes produced by aerobic bacteria such as Alcaligene sp. and Pseudomonas sp. are also used [74]. Enzymes produced by different types of fungi, such as lignin peroxidases, azoreductases, and laccases from white rot fungi, can also take part in the biodegradation of textile dyes [79]. In a recently published review, Pinheiro et al. [80] showed the role of different enzymes in the bioremediation of dyes.

Various researchers such as Shahid et al. [81] found that the strain MR-1/2 of multifarious Bacillus species efficiently decolorized dyes such as reactive black-5, reactive red-120, direct blue-1, and Congo red, which additionally helped in the growth of the mung bean plant by alleviating azo dye toxicity. Meanwhile, Vineh et al. [82] found 100% decolorization of most of the dyes used in the study at pH 7, 25 °C, for 60 min by using peroxidase immobilized on a functionalized reduced grapheme oxide. In another study, Navas et al. [83] reported 20–100% decolorization of dyes at pH 5–9 using laccase, which was purified and extracted from the thermophilic Thermus species. In another study, Kalsoom et al. [84] found 95% degradation of remazol turquoise blue 133G dye with peroxidase from Brassica oleracea, while Gao et al. [85] achieved 72–80% decolorization of the azo dyes reactive blue 19 and acid orange 7 at a neutral to alkaline pH at relatively high temperatures using laccase enzymes immobilized in vault nanoparticles.

3.2. Microbial Remediation

Several microbes, such as bacteria, fungi, yeast, algae, and actinomycetes, are utilized for treating textile dyes from aquatic environments [3][8][86][87][88][89][90].

Bacterial Remediation

Among all the groups of microbes, decolorization by bacteria is significant. From a biotechnological perspective, bacteria offer many advantages as they contain abundant degradative enzymes, consequently having the capacity to degrade dyes of a broad range [3][91][92]. The basic advantage of dealing with bacteria is their efficiency in growing quickly, and their ability to be cultured easily. The organic pollutants that are aromatic hydrocarbon-based and chlorinated can be catabolized by bacteria as their source of energy [93]. Bacteria also have the capability to oxidize textile dyes based on sulphur to H2SO4 [94].

Pure Bacterial Cultures

Using a pure bacterial culture with one type of bacteria, the biodecolorization of dyes has been reported in several studies. In one investigation, Louati et al. [95], found 100% decolorization of dyes at pH 8 by using Pseudomonas aeruginosa strain Gb30, whereas Montanez-Barragan et al. [96] observed above 90% decolorization of dyes at pH 6–11 with Halomonas species. Another researcher, Shi et al. [97], found 100% dye removal of Brilliant Crocein by using the bacteria Providencia rettgeri, while Fareed et al. [98] found 80–100% decolorization of dyes by using free and immobilized cells of Bacillus cereus at temperatures of 32 °C, 37 °C, and 45 °C Srinivasan et al. [99] achieved 88.35–96.30% decolorization of different azo dyes, while Du et al. [100] observed the complete decolorization of malachite green and crystal violet at pH 3–10 and a temperature of 20–45 °C after 12 h of incubation under optimal environmental conditions using Serratia species, which is a new bacterial strain identified via 16S rDNA analysis. In a recent study, Tripathi et al. [8] observed 98% dye decolorization of crystal violet dye using a native multiple metal-tolerant Aeromonas caviae MT-1 isolate.

Mixed Bacterial Cultures

For decolorizing diverse groups of dyes, bacteria of a single species are not efficient enough for their remediation, and this is one of the most prominent challenges for environmental biotechnologists [101]. Many researchers have worked on a consortium or mixed bacterial culture for the degradation of dyes. In a study, Ayed et al. [102] observed 90% dye decolorization at 35 °C using a bacterial consortium consisting of Sphingomonas paucimobilis, Pseudomonas putida, and Lactobacillus acidophilus. In another study, Guo et al. [103] found 93% decolorization at 40 °C and pH 10 of Methanil Yellow G dye using a consortium with Halomonas, Marinobacter, and Clostridii salibacter., Meanwhile, in another investigation, Joshi et al. [101] reported dye decolorization of 24–94% using a consortium of six bacterial strains: Pseudomonas stutzeri AK1, P. stutzeri AK2, P. stutzeri AK3, Bacillus sp. AK4, P. stutzeri AK5, and P. stutzeri AK6. Likewise, Bera et al. [104] reported 85% acid orange dye decolorization after nearly 23 h, with yeast as a supplementary source and a bacterial consortium called novel bacterial consortium SPB92 composed of four bacterial strains, i.e., Pseudomonas stutzeri (MW219251), Bacillus tequilensis (MW110471), B. flexus. (MW13 flexus and Kocuria rosea (MW 132411), whereas Neihsial et al. [105] found 85–97% degradation of dyes using a consortium including bacteria of different genera, like Acinetobacter, Comamonas, Trichococcus, Erwinia, Dysgonomonas, and Citrobacter. In another study, Barathi et al. [106] found that the bacterial consortium with three bacterial species, B. subtilis, Brevibacillus borstelensis, and B. firmus, was able to degrade dye at a better rate at lower concentrations of dye, but the ability of degradation decreased with elevated concentrations of dye. Several bacterial isolates have been reported for dye decolorization.

Actinomycetes

Microorganisms, particularly actinomycetes, play a significant role in the decolorization of dyes. Several researchers have reported the decolorization of dyes using actinomycetes. Zhou and Zimmermann [90] observed 3–10% decolorization of dyes by Streptomyces species. On the other hand, in recent research, Dong et al. [107] observed 99% decolorization of dyes using Streptomyces sp. S27. In another study, Adenan et al. [108] observed 64–94.7% decolorization of different dyes using actinomycetes. They reported the decolorization of triphenylmethane dyes using Streptomyces bacillaris through biosorption and biodegradation mechanisms. Raja et al. [109] studied the decolorization of amido black dye by means of actinomycetes isolated from marine sediments under aerobic conditions. They found significant 88% decolorization at a 5 ppm dye concentration. Meanwhile, Blánquez et al. [110] observed decolorization of 6–70% using the actinomycetes Streptomyces ipomoeae CECT 3341. In another study, Kameche et al. [111] studied the decolorization of the azo dye Evans blue using four strains of Streptomyces isolated from soils. They observed a 97% remediation rate at an initial 50 mg/L Evans blue concentration.

Phycoremediation

Studies suggest that azo dyes are utilized as a carbon and energy source for algae, which are then degraded into aromatic amines, subsequently being converted into simple inorganic and organic compounds [112]. For the investigation of dye decolorization from textile wastewater samples, Chlorella species, Oscillatoria species, Phormidium species, and Synechocystis have been widely used [113]. Many functional groups like carboxy, carbonyl, hydroxy, phosphoryl, and amide groups are present in algal cell walls, which help in dye decolorization [114]. In another investigation, Mahajan et al. [115] reported 70–100% decolorization of methyl red dye at pH 3.5–9.5 using Chara vulgaris L. In another study by Boulkhessaim et al. [116], they reported 45–80% decolorization of dyes using Chlorella vulgaris, whereas Dellamatrice et al. [117] observed 91% dye decolorization using Cyanobacterium phormidium. In another study, Alprol et al. [118] found 75.7% and 61.11% decolorization of dyes by using Arthrospira platensis complete dry biomass and lipid-free biomass. Meanwhile, Mansour et al. [119] reported 93% decolorization of methylene blue using A. platensis. These studies indicate that algae application for effective remediation of dye pollution is a viable and eco-friendly option for a sustainable and green environment.

Yeast-Mediated Dye Decolorization

Yeast has not been as thoroughly studied and used in the decolorization of dyes as filamentous fungi and bacteria [120]. The removal of dyes using yeast was reported in the biosorption process [120]. The decolorization of azo dye through yeasts is achieved using the enzyme azoreductase present in yeast [121]. Galactomyces geotrichum MTCC1360 has the capacity to decolorize azo dyes [122]. Researchers like Guo et al. [123] reported 92% decolorization of the azo dye Acid Scarlet GR using the newly isolated salt-tolerant yeast strain Galactomyces geotrichum GG. In another study, Ali et al. [124] reported 82% decolorization of lignin-like dyes and wastewater containing textile dyes using a recently formed oleaginous yeast consortium with three yeast cultures: Yarrowia sp. SSA1642, Barnettozyma californica SSA1518, and Sterigmatomyces halophilus SSA1511.

Phytoremediation

Phytoremediation involves the plant-mediated treatment of contaminants from the environment, and it is a cost-effective solution for the clean-up of various types of pollutants [125][126]. This process operates through several mechanisms or processes to remediate contaminants. The different phytoremediation strategies, such as phytoextraction (uptake or absorption of contaminants by roots into the shoots for metabolization), phytostabilization (compounds secreted by the plant immobilize contaminants rather than degrade them), phytovolatilization (involves translocation of contaminants by roots to aerial plant parts where they volatilize into the atmosphere), and rhizofiltration (plant roots absorb the contaminants, which are then metabolized or stored), are widely used, and accepted as a cost-effective environmental restoration technology [127][128][129][130].

In phytoremediation, plants interact at the physical, chemical, biological, and microbial levels to reduce pollutant toxicity. This employs a variety of processes depending on the form and quantity of the pollutant [128]. In their investigation, Biju et al. [131] found 75 ± 0.5% and 82 ± 0.5% decolorization of a mixture of azo dyes using Salvinia species. Rane et al. [132] observed complete decolorization of sulfonated remazol red dye and effluents of the textile industry using Alternanthera philoxeroides. In another study, Imron et al. [133] found the decolorization of 80.56 ± 0.44% of methylene blue dye using duckweed (Lemna minor), whereas Baldawi et al. [134] observed 85% decolorization of methylene blue dye using the floating plant Azolla pinnata.

References

- Younis, S.A.; Serp, P.S.; Nassar, H.N. Photocatalytic and biocidal activities of ZnTiO2 oxynitrite heterojunction with MOF-5 and G-C3N4: A case study for textile wastewater treatment under direct sunlight. J. Hazard. Mater. 2021, 410, 124562.

- Kishor, R.; Purchase, D.; Saratale, G.D.; Saratale, R.G.; Ferreira, L.F.R.; Bilal, M.; Chandra, R.; Bharagava, R.N. Ecotoxicological and health concerns of persistent coloring pollutants of textile industry wastewater and treatment approaches for environmental safety. Environ. Chem. Eng. 2021, 9, 105012.

- Garg, S.K.; Tripathi, M. Microbial strategies for discoloration and detoxification of azo dyes from textile effluents. Res. J. Microb. 2017, 12, 1–19.

- Parmar, S.; Daki, S.; Bhattacharya, S.; Shrivastav, A. Microorganism: An ecofriendly tool for waste management and environmental safety. In Development in Wastewater Treatment Research and Processes; Elsevier: Amsterdam, The Netherlands, 2022; pp. 175–193.

- Al-Tohamy, R.; Ali, S.S.; Li, F.; Okasha, K.M.; Mahmoud, Y.A.G.; Elsamahy, T.; Jiao, H.; Fu, Y.; Sun, J. A critical review on the treatment of dye-containing wastewater: Ecotoxicological and health concerns of textile dyes and possible remediation approaches for environmental safety. Ecotoxicol. Environ. Saf. 2022, 231, 113160.

- Sharma, K.; Sharma, P.; Dhiman, S.K.; Chadha, P.; Saini, H.S. Biochemical, genotoxic, histological and ultrastructural effects on liver and gills of fresh water fish Channa punctatus exposed to textile industry intermediate 2 ABS. Chemosphere 2022, 287, 132103.

- Xu, M.; Guo, J.; Suh, G. Biodegradation of textile azo dye by Shewanella decolorationis S12 under micro aerophillic conditions. Appl. Microbiol. Biotechnol. 2007, 76, 719–726.

- Tripathi, M.; Pathak, N.; Chaudhary, V.K.; Singh, P.; Singh, P.K.; Thirumalesh, B.V.; Bala, S.; Maurya, A.K.; Patel, N.; Yadav, B.K. Microbial decolorization of crystal violet dye by a native multimetal tolerant Aeromonas caviae MT-1 isolate from dye contaminated soil: Optimization and phototoxicity study. Toxicol. Int. 2023, 30, 83–93.

- Vankar, P.S. Handbook on Natural Dyes for Industrial Applications: Extraction of Dyestuff from Flowers, Leaves, Vegetables; Niir Project Consultancy Services: Delhi, India, 2016.

- Elgarahy, A.M.; Elwakeel, K.Z.; Mohammad, S.H.; Elshoubaky, G.A. A critical review of biosorption of dyes, heavy metals and metalloids from wastewater as an efficient and green process. Clean. Eng. Technol. 2021, 4, 100209.

- Tripathi, M.; Kumar, S.; Singh, D.N.; Pandey, R.; Pathak, N.; Fatima, H. Bioremediation of dye contaminated soil. In Soil Bioremediation: An Approach towards Sustainable Technology; Parray, J.A., Hashem, A., Mahmoud, A.E., Eds.; John Wiley and Sons: Hoboken, NJ, USA, 2021; pp. 115–142.

- Tripathi, M.; Singh, P.; Singh, R.; Bala, S.; Pathak, N.; Singh, S.; Chauhan, R.S.; Singh, P.K. Microbial biosorbent for remediation of dyes and heavy metal pollution: A green strategy for sustainable environment. Front. Microbiol. 2023, 14, 1168954.

- Sharma, B.; Dangi, A.K.; Shukla, P. Contemporary enzyme based technologies for bioremediation: A review. J. Environ. Manag. 2018, 210, 10–22.

- Muthu, S.S. Sustainability in the Textile Industry; Springer: Berlin/Heidelberg, Germany, 2017; pp. 1–8.

- Khan, S.; Malik, A. Toxicity evaluation of textile effluents and role of native soil bacterium in biodegradation of a textile dye. Environ. Sci. Pollut. Res.-Int. 2018, 25, 4446–4458.

- Seo, Y.H.; Park, D.; Oh, Y.K.; Yoon, S.; Han, J.I. Harvesting of microalgae cell using oxidised dye wastewater. Bioresour. Technol. 2015, 192, 802–806.

- Goswami, M.; Chaturvedi, P.; Sonwani, R.K. Application of arjuna (Terminalia arjuna) seed biochor in hybrid treatment system for the bioremediation of congo red dye. Bioresour. Technol. 2020, 307, 123203.

- Kiran, S.; Ashraf, A.; Rahmat, M. Green synthesis of magnesium oxide nanoparticles using leaves of Iresine herbstii for remediation of reactive brown 9 dye. Glob. NEST J. 2022, 24, 291–296.

- Sathishkumar, K.; Al Salhi, M.S.; Sanganyado, E.; Devanesan, S.; Arulprakash, A.; Rajasekar, A. Sequential electrochemical oxidation and bio treatment of the azo dye congo red and textile effluent. J. Photochem. Photobiol. B 2019, 200, 111655.

- Shetty, K.; Krishnakumar, G. Algal and cyanobacterial biomass as potential dye biodecolorizing material: A review. Biotechnol. Lett. 2020, 42, 2467–2488.

- Prabhakar, Y.; Gupta, A.; Kaushik, A. Using indigenous bacteria isolate Nesterenkonia lacusekhoensis for removal of azo dyes: A low cost friendly approach for bioremediation of textile wastewaters. Environ. Dev. Sustain. 2022, 24, 5344–5367.

- Zhao, J.; Dang, Z.; Muddassir, M.; Raza, S.; Zhong, A.; Wang, X.; Jin, J. A new Cd(II)-based coordination polymer for efficient photocatalytic removal of organic dyes. Molecules 2023, 28, 6848.

- Zheng, M.; Chen, J.; Zhang, L.; Cheng, Y.; Lu, C.; Liu, Y.; Singh, A.; Trivedi, M.; Kumar, A.; Liu, J. Metal organic frameworks as efficient adsorbents for drugs from wastewater. Mater. Today Commun. 2022, 31, 103514.

- Zhong, Y.; Chen, C.; Liu, S.; Lu, C.; Liu, D.; Pan, Y.; Sakiyama, H.; Muddassir, M.; Liu, J. A new magnetic adsorbent of eggshell-zeolitic imidazolate framework for highly efficient removal of norfloxacin. Dalton Trans. 2021, 50, 18016–18026.

- Zhou, S.; Lu, L.; Liu, D.; Wang, J.; Sakiyama, H.; Muddassir, M.; Nezamzadeh-Ejhieh, A.; Liu, J. Series of highly stable Cd(ii)-based MOFs as sensitive and selective sensors for detection of nitrofuran antibiotic. CrystEngComm 2021, 23, 8043–8052.

- Sharma, P.; Quanungo, K. Challenges in effluents treatment containing dye. Adv. Res. Text. Eng. 2022, 7, 1075.

- Tripathi, M.; Singh, D.N. Bioremediation: Challenges and Advancements; Bentham Science Publishers: Singapore, 2022.

- Mudhoo, A.; Ramasamy, D.L.; Bhatnagar, A.A.; Usman, M.; Sillanpaa, M. An analysis of the versatility and effectiveness of composts for sequestering heavy metal ions, dyes and xenobiotics from soils and aqueous milieus. Ecotoxicol. Environ. Saf. 2020, 197, 110587.

- Akpomie, K.G.; Conradie, J. Advances in application of cotton-based adsorbents for heavy metalstrapping, surface modifications and future perspectives. Ecotoxicol. Environ. Saf. 2020, 201, 110825.

- Samsami, S.; Mohamadizaniani, M.; Sarrafzadeh, M.H.; Rene, E.R.; Firoozbahr, M. Recent advances in the treatment of dye containing wastewater from textile industries: Overview and perspectives. Process Saf. Environ. Prot. 2020, 143, 138–163.

- Abu-Nada, A.; Abdala, A.; McKay, G. Removal of phenols and dyes from aqueous solutions using graphene and graphene composite adsorption; a review. J. Environ. Chem. Eng. 2021, 9, 105858.

- Jadhav, A.C.; Jadhav, N.C. Treatment of textile wastewater using adsorption and adsorbents. In Suitable Technologies for Textile Wastewater Treatments; Woodhead Publishing: Sawston, UK, 2021; pp. 235–373.

- Hisada, M.; Tomizawa, Y.; Kaware, Y. Removal kinetics of cationic azo-dye from aqueous solution by gamma- glutamic acid biosorbent contribution of adsorption and complexation/precipitation to basic orange 2 removal. J. Environ. Chem. Eng. 2019, 7, 103157.

- Kubra, K.T.; Sulman, M.S.; Haisan, M.N. Enhanced toxic dye removal from wastewater using biodegradable polymeric natural adsorbent. J. Mol. Liquids 2021, 328, 115468.

- Saifi, A.; Joseph, J.P.; Singh, A.P.; Pal, A.; Kumar, K. Complexation of an azo dye by cyclodextrins: A potential strategy for water purification. ACS Omega 2021, 6, 4776–4782.

- Briao, G.V.; Jahn, S.L.; Foletto, E.L.; Dotto, G.L. Highly efficient and reusable mesoporous zeolite synthesized from a biopolymer for cationic dyes adsorption. Colloids Surf. A Physicochem. Eng. Asp. 2018, 556, 43–50.

- Madan, S.; Shaw, R.; Tiwari, S.; Tiwari, S.K. Adsorption dynamics of congo red dye removal using ZnO2 functionalized high silica zeolite particles. J. Appl. Surf. Sci. 2019, 187, 907–917.

- Harja, M.; Buema, G.; Bucur, D. Recent advances in removal of Congo Red dye by adsorption using an industrial waste. Sci. Rep. 2022, 12, 6087.

- Minisy, I.M.; Salahuddin, N.A.; Ayad, M.M. Chitosan/polyaniline hybrid for the removal of cationic and anionic dyes from aqueous solutions. J. Appl. Polym. Sci. 2019, 136, 47056.

- Bober, P.; Minisy, I.M.; Acharya, U.; Pfleger, J.; Babayan, V.; Kazantseva, N.; Hodan, J.; Stejskal, J. Conducting polymer composite aerogel with magnetic properties for organic dye removal. Synth. Met. 2020, 260, 116266.

- Ayad, M.M.; Amer, W.A.; Zaghlol, S.; Minisy, I.M.; Bober, P.; Stejskal, J. Polypyrrole-coated cotton textile as adsorbent of methylene blue dye. Chem. Pap. 2018, 72, 1605–1618.

- Ahmad, A.; Setapar, M.S.H.; Chuong, C.S.; Khatoon, A.; Wani, W.A.; Kumar, R.; Rafatullah, M. Recent advances in new generation dye removal technologies; novel search for approaches to reprocess wastewater. RSC Adv. 2015, 5, 30801–30818.

- Xu, T. Ion exchange membranes: State of this development and perspective. Memb. Sci. 2005, 263, 1–29.

- Marin, N.M.; Pascu, L.F.; Demha, A.; Nita-Lazar, M.; Badea, L.; Aboul-Enein, H.Y. Removal of the acid orange 10 by an ion-exchange and microbiological methods. Int. J. Environ. Sci. Technol. 2019, 16, 6357–6366.

- Waly, A.I.; Khedr, M.A.; Ali, H.M.; Riad, B.Y.; Ahmed, I.M. Synthesis and characterization of ion- exchange based on waste cotton for dye removal from wastewater. Egypt. J. Chem. 2019, 62, 451–468.

- Bayramoglu, G.; Kunduzcu, G.; Arica, M.Y. Prepartion and characterization of strong cation exchange ter polymer resin as effective adsorbent for removal of dispersed dyes. Polym. Eng. Sci. 2020, 60, 192–201.

- Zheng, Y.; Yao, G.; Cheng, Q.; Yu, S.; Liu, M.; Gao, C. Positively charged thin–film composite hollow fibre nanofiltration membrane for the removal of cationic dyes through submerged filtration. Desalination 2013, 328, 42–50.

- Rambabu, K.; Bharath, G.; Monash, P.; Velu, S.; Banat, F.; Naushad, M.; Arthanareeswaran, G.; Show, P.L. Effective treatment of dye polluted wastewater using nanoporous CaCl2 modified polyethersulfone membrane. Process Saf. Environ. Prot. 2019, 124, 266–278.

- Cherayan, M. Ultrafiltration and Microfiltration Handbook; CRC Press: Boca Raton, FL, USA, 1998.

- Collivignarelli, M.C.; Abba, A.; Carnovale, M.; Damiani, S. Treatments for color removal from wastewater: State of the art. J. Environ. Manag. 2019, 236, 727–745.

- Alventosa-deLara, E.; Barredo-Damas, S.; Alcaina-Miranda, M.I.; Iborasa-Ciar, M.I. Ultrafiltration technology with a ceramic membrane for reactive dye removal; optimization of membrane performance. J. Hazard. Mater. 2012, 209–210, 492–500.

- Wang, A.J.; Wang, H.C.; Cheng, H.Y.; Liang, B.; Liu, W.Z.; Han, J.L.; Zhang, B.; Wang, S.S. Electrochemistry stimulated environmental bioremediation development of applicable modular electrode and system scale up. Environ. Sci. Ecotechnol. 2020, 3, 100050.

- Wang, X.; Xia, J.; Ding, S.; Zhang, S.; Li, M.; Shang, Z.; Lu, J.; Ding, J. Removing organic matters from reverse osmosis concentrate using advanced oxidation biological activated carbon process combined with Fe3+/humus–reducing bacteria. Ecotoxicol. Environ. Saf. 2020, 203, 110945.

- Lu, Z.; Hu, F.; Li, H.; Zhang, X.; Yu, S.; Liu, M.; Gao, C. Composite nano-filtration membrane with asymmetric selective separation layer for enhanced separation efficiency to anionic dye aqueous solution. J. Hazard. Mater. 2019, 368, 436–443.

- Shao, H.; Qi, Y.; Liang, S.; Qin, S.; Yu, J. Polypropylene composite hollow fibre ultrafiltration membranes with an acrylic hydrogel surface by in-situ ultrasonic wave assisted polymerization for dye removal. J. Appl. Polym. Sci. 2019, 136, 47099.

- Fradj, A.B.; Boubakri, A.; Hafiane, A.; Hamouda, S.B. Removal of azoic dyes from aqueous solutions by chitosan enhanced ultrafilteration. J. Result Chem. 2020, 2, 100017.

- Xiang, H.; Ren, G.; Yang, X.; Xu, D.; Zhang, Z.; Wang, X. A low cost solvent free method to synthesize alpha Fe2O3 nanoparticles with applications to degrade methyl orange in photofenton system. Ecotoxicol. Environ. Saf. 2020, 200, 110744.

- Zhong, J.; Yang, B.; Feng, Y.; Chen, Y.; Wang, L.-G.; You, W.-D.; Ying, G.-G. Enhanced Photo–Fenton Removal Efficiency with Core-Shell Magnetic Resin Catalyst for Textile Dyeing Wastewater Treatment. Water 2021, 13, 968.

- Saratale, R.G.; Sivapathan, S.; Saratale, G.D.; Banu, J.R.; Kim, D.S. Hydroxamic acid mediated heterogenous fenton like catalyst for efficient removal of acid red 88, textile wastewater and their phytotoxicity studies. Ecotoxicol. Environ. Saf. 2019, 167, 385–395.

- Parsons, S. Advanced Oxidation Processes for Water Wastewater Treatment; IWA Publishing: London, UK, 2004.

- Gogate, P.R.; Pandit, A.B. A review of imperative technologies for wastewater treatment 1: Oxidation technologies at ambient conditions. J. Adv. Environ. Resour. 2004, 8, 501–551.

- Ledakowicz, S.; Maciejewska, R.; Gebicka, L.; Perkowski, J. Kinetics of decolourization by Fenton’s reagent. J. Ozone Sci. Eng. 2000, 22, 195–205.

- Chen, Y.; Cheng, Y.; Guan, X.; Liu, Y.; Nie, J.; Li, C. A rapid fenton treatment of bio-treated dyeing and finishing wastewater at second scale intervals; kinetics by stopped-flow technique and application in a full scale plan. Sci. Rep. 2019, 9, 9689.

- Zawadzki, P.; Deska, M. Degradation efficiency and kinetics analysis of an advance oxidation process, utilizing ozone, hydrogen peroxide and persulfate to degrade the dye rhodamine. Catalysts 2021, 11, 974.

- Shriram, B.; Kanmani, S. Ozonation of Textile Dyeing Wastewater: A Review. 2014, 2014-15, p. 3. Available online: https://www.researchgate.net/profile/ShriramBalasubramanyan/publication/281776011_Ozonation_of_Textile_Dyeing_Wastewater_-_A_Review/links/55f7f43e08ae07629dcded7a/Ozonation-of-Textile-Dyeing-Wastewater-A-Review.pdf (accessed on 16 November 2023).

- Venkatesh, S.; Venkatesh, K.; Quaff, A.R. Dye decomposition by combined ozonation and anaerobic treatment: Cost effective technology. J. Appl. Res. Technol. 2017, 15, 340–345.

- Cardoso, R.M.F.; Cardoso, I.M.F.; da Silva, P.L.; Joaguim, C.G.; da Silva, E. Copper (2) doped carbon dots as catalyst for ozone degradation of textile dyes. Nanomaterials 2022, 12, 1211.

- Lanzetta, A.; Papirio, S.; Oliva, A.; Cesaro, A.; Pucci, L.; Capasso, E.M.; Esposito, G.; Pirozzi, F. Ozonation processes for color Removal from Urban and Leather Tanning Wastewater. Water 2023, 15, 2362.

- Bala, S.; Garg, D.; Thirumalesh, B.V.; Sharma, M.; Sridhar, K.; Inbaraj, B.S.; Tripathi, M. Recent strategies for bioremediation of emerging pollutants; a review for a green and sustainable environment. Toxics 2022, 10, 484.

- Chen, K.C.; Wu, J.Y.; Liou, D.J.; Hwang, S.C.J. Decolorization of the textile dye by newly isolated bacterial strains. J. Biotechnol. 2003, 101, 57–68.

- Patel, H.; Yadav, V.K.; Yadav, K.K.; Choudhary, N.; Kalasariya, H.; Alam, M.M.; Gacem, A.; Amanullah, M.; Ibrahium, H.A.; Park, J.W.; et al. A review: A recent and systematic approach towards microbial biodegradation of dyes from textile industries. Water 2022, 14, 3163.

- Das, S.; Cherwoo, L.; Singh, R. Decoding dye degradation: Microbial remediation of textile industry effluents. Biotechnol. Notes 2023, 4, 64–76.

- Pourbabaee, A.A.; Malakzadeh, F.; Sarbolouki, M.N.; Najafi, F. Aerobic decolorization and detoxification of disperse dye in textile effluent by a new isolate of Bacillus spp. Biotechnol. Bioeng. 2006, 93, 631–635.

- Bhandari, S.; Poudel, D.K.; Marahatha, R.; Dawadi, S.; Khadaya, K.; Phuyal, S. Microbial enzymes used in bioremediation. J. Chem. 2021, 2021, 8849512.

- Pham, V.H.T.; Kim, J.; Chang, S.; Bang, D. Investigating bio-inspired degradation of toxic dyes using potential multi-enzyme producing extremophiles. Microorganisms 2023, 11, 1273.

- Mendes, S.; Robalo, M.P.; Martins, L.O. Bacterial enzymes and multi-enzymatic systems for cleaning-up dyes from the environment. In Microbial Degradation of Synthetic Dyes in Wastewater; Springer International Publishing: Berlin/Heidelberg, Germany, 2015; pp. 27–55.

- Chandra, R. Environmental Waste Management; CRC Press: Boca Raton, FL, USA, 2016.

- Hussain, Q. Peroxidase mediated decolourization and remediation of wastewater containing industrial dyes: A review. Rev. Environ. Sci. Biotechnol. 2010, 9, 117–140.

- Lellis, B.; Polonio, C.Z.F.; Pamphile, J.A.; Polonio, J.C. Effects of textile dyes on health and the environment and bioremediation potential of living organisms. Biotechnol. Res. Innov. 2019, 3, 275–290.

- Pinheiro, L.R.S.; Gradíssimo, D.G.; Xavier, L.P.; Santos, A.V. Degradation of azo dyes: Bacterial potential for bioremediation. Sustainability 2022, 14, 1510.

- Shahid, M.; Mahmood, F.; Hussain, S.; Shahzad, T.; Haider, M.Z.; Noman, M.; Mushtaq, A.; Fatima, Q.; Ahmed, T.; Mustafa, G. Enzymatic detoxification of azo dyes by a multifarious Bacillus sp. strain MR-1/2-bearing plant growth-promoting characteristics. 3 Biotech 2018, 8, 425.

- Vineh, M.B.; Saboury, A.A.; Poostchi, A.A.; Ghasemi, A. Biodegradation of phenol and dyes with horseradish peroxidase covalently immobilized on functionalized RGO-SiO2 nano composite. Int. J. Biol. Macromol. 2020, 164, 4403–4414.

- Navas, L.E.; Carballo, R.; Levin, L.; Berretta, M.F. Fast decolorization of azo dyes in alkaline solutions by a thermostable metal-tolerant bacterial laccase and proposed degradation pathways. Extremophiles 2020, 24, 705–719.

- Kalsoom, U.; Bhatti, H.N.; Aftab, K.; Amin, F.; Jesioncowski, T.; Bilal, M. Biocatalytic potential of Brassica oleracea L. var. botrytis leaves peroxidase for efficient degradation of textile dyes in aqueous medium. J. Bioprocess. Biosyst. Eng. 2023, 46, 453–465.

- Gao, Y.; Wang, M.; Shah, K.; Kalra, S.S.; Rome, L.H.; Mahendra, S. Decolourization and detoxification of synthetic dye compounds by laccase immobilized in vault nanoparticles. Bioresour. Technol. 2022, 351, 127040.

- Zimmermann, T.; Kulla, H.G.; Leisinger, T. Properties of purified orange II azoreductase, the enzyme initiating azo dye degradation by Pseudomonas KF46. Eur. J. Biochem. 1982, 129, 197–203.

- Georgiou, D.; Hatiras, J.; Aivasidis, A. Microbial immobilization in a two-stage fixed-bed-reactor pilot plant for on-site anaerobic decolorization of textile wastewater. J. Enzym. Microb. Technol. 2005, 37, 597–605.

- Jadhav, S.B.; Phugare, S.S.; Patil, P.S.; Jadhav, J.P. Biochemical degradation pathway of textile dye removal red and subsequent toxicological evaluation by cytotoxicity, genotoxicity and oxidative stress studies. Int. Biodeterior. Biodegrad. 2011, 65, 733–743.

- Phugare, S.S.; Kalyani, D.C.; Surwase, S.N.; Jadhav, J.P. Ecofriendly degradation, decolorization and detoxification of textile effluent by a developed bacterial consortium. Ecotoxicol. Environ. Saf. 2011, 74, 1288–1296.

- Zhou, W.; Zimmermann, W. Decolorization of industrial effluents containing reactive dyes by actinomycetes. FEMS Microbiol. Lett. 1993, 107, 157–161.

- Saratale, R.G.; Saratale, G.D.; Cheng, J.S.; Govindwar, S.P. Bacterial decolorization and degradation of azo dyes. A review. J. Taiwan Inst. Chem. Eng. 2011, 42, 138–157.

- Khan, R.; Bhawan, P.; Fulekar, M.H. Microbiol decolourization and degradation of synthetic dyes: A review. Rev. Environ. Sci. Bio/Technol. 2013, 12, 75–97.

- Yang, H.Y.; Jia, R.B.; Chen, B.; Li, L. Degradation of recalcitrant aliphatic and aromatic hydrocarbons by a dioxin- degrader Rhodococcus sp. strain p52. Environ. Sci. Pollut. Res. 2014, 21, 11086–11093.

- Nguyen, T.A.; Fu, C.C.; Juang, R.S. Biosorption and biodegradation of a sulphur dye in high-strength dyeing wastewater by Acidithiobacillus thiooxidans. J. Environ. Manag. 2016, 182, 265–271.

- Louati, I.; Ellaumi-Mseddi, J.; Cheikhrouhou, W.; Hadrich, B.; Nasri, M.; Aifa, S.; Woodword, S.; Mechichi, T. Simultaneous cleanup of reactive black 5 and cadmium by a desert soil bacterium. J. Ecotoxicol. Environ. Saf. 2020, 190, 110103.

- Montanez-Barragan, B.; Sanz-Martin, J.L.; Gutierrez-Macias, P.; Barragan-Huerta, B.E. Azo-dyes decolourization under high alkalinity and salinity conditions by Halomonas sp. in batch and packed bed reactor. J. Extrem. 2020, 20, 239–247.

- Shi, Y.; Yang, Z.; Xing, L.; Zhou, J.; Ren, J.; Ming, L.; Hun, Z.; Li, X.; Zhang, D. Ethanol as an efficient cosubstrate for biodegradation of azo dyes by Providencia rettgeri, mechanistic analysis based on kinetics, pathways and genomics. Bioresour. Technol. 2021, 31, 124117.

- Fareed, A.; Zaffar, H.; Bilal, M.; Hussain, J.; Jackson, C.; Naqvi, T.A. Decolourization of azo-dyes by a novel aerobic bacterial strain Bacillus cereus strain ROC. PLoS ONE 2022, 17, e0269559.

- Srinivasan, S.; Bankole, P.O.; Sadasivam, S.K. Biodecolorization and degradation of textile azo dyes using Lysinibacilllus sphaericus MTCC9523. Front. Environ. Sci. 2022, 10, 990855.

- Du, L.; Wu, H.; Li, G.; Wei, Y.; Wang, F.; Xu, L.; Dong, X. Efficient degradation and decolorization of triphenyl methane dyes by Serratia sp. WKD under extreme environmental conditions and the mechanism. Int. Biodeterior. Biodegrad. 2023, 179, 105565.

- Joshi, A.; Hinsu, A.; Kothari, R. Evaluating the efficacy of bacterial consortium for decolourization of diazo dye mixture. J. Arch. Microbiol. 2022, 204, 515.

- Ayed, L.; Ladhari, N.; Achour, S.; Chaieb, K. Decolorization of reactive yellow 174 dye in real textile wastewater by active consortium; experimental factorial design for bioremediation process optimization. J. Text. Inst. 2020, 112, 1449–1459.

- Guo, G.; Hao, J.; Tian, F.; Liu, C.; Ding, K.; Xu, J.; Zhou, W.; Guan, Z. Decolourization and detoxification of azo dyes by halo-alkaliphilic bacterium consortium: Systematic investigations of performance, pathway and metagenome. J. Ecotoxicol. Environ. Saf. 2020, 204, 111073.

- Bera, S.P.; Shah, M.P.; Godhaniya, M. Microbial remediation of textile dye acid orange by a novel bacterial consortium SPB 92. Front. Environ. Sci. 2022, 10, 930616.

- Neihsial, R.; Singha, N.A.; Singh, A.K. Taxonomic diversity and predictive metabolic functions of a heavy metal tolerant multiple azo dye degrading bacterial consortium from textile effluents. Int. Biodeterior. Biodegrad. 2022, 171, 105421.

- Barathi, S.; Aruljothi, K.N.; Karthik, C.; Padikasan, I.A.; Ashokkumar, V. Biofilm mediated decolorization and degradation of reactive red 170 dye by the bacterial consortium isolated from the dyeing industry wastewater sediments. Chemosphere 2022, 286, 131914.

- Dong, H.; Guo, T.; Zhang, W.; Ying, H.; Wang, P.; Wang, Y.; Chen, Y. Biochemical characterization of a novel azo-reductase from Streptomyces sp. application in eco-friendly decolorization of azo-dyes wastewater. J. Int. J. Biol. Macromol. 2019, 140, 1037–1046.

- Adenan, N.H.; Lim, Y.Y.; Ting, A.S.Y. Removal of triphenylmethane dyes by Streptomyces bacillaris: A study on decolorization, enzymatic reaction and toxicity of treated dye solution. J. Environ. Manag. 2022, 318, 115520.

- Raja, M.M.M.; Raja, A.; Salique, S.M.; Gajalakshmi, P. Studies on effect of marine actinomycetes on amido black (azo dye) decolorization. J. Chem. Pharm. Res. 2016, 8, 640–644.

- Blánquez, A.; Rodríguez, J.; Brissos, V.; Mendes, S.; Martins, L.O.; Ball, A.S.; Arias, M.E.; Hernández, M. Decolorization and detoxification of textile dyes using a versatile Streptomyces laccase-natural mediator system. Saudi J. Biol. Sci. 2019, 26, 913–920.

- Kameche, K.; Amrani, S.; Mouzaoui, S.; Aït-Amar, H. Biodegradation of diazo dye Evans blue by four strains of Streptomyces isolated from soils of Algeria. Biocatal. Agric. Biotechnol. 2022, 46, 102529.

- Jamee, R.; Siddique, R. Biodegradation of synthetic dyes of textile effluent by micro-organisms: An environmentally and economically sustainable approach. Eur. J. Microb. Immunol. 2019, 9, 114–118.

- Gangola, S.; Bhatt, P.; Chaudhary, P.; Khati, P.; Kumar, N.; Sharma, A. Bioremediation of industrial waste using microbial diversity. In Microbial Biotechnology in Environmental Monitoring and Cleanup; IGI Global: Hershey, PA, USA, 2018; pp. 1–27.

- Mahalakshmi, S.; Lakshmi, D.; Menaga, U. Biodegradation of different concentration of dye (congo red dye) by using green and blue-green algae. Int. Environ. Res. 2015, 9, 735–744.

- Mahajan, P.; Kaushal, J. Phytoremediation of azo dye methyl red by microalgal Chara vulgaris L.: Kinetics and equilibrium studies. Environ. Sci. Pollut. Res. 2020, 27, 26406–26418.

- Boulkhessaim, S.; Gacem, A.; Khan, S.H.; Amari, A.; Yadav, V.K.; Harharah, H.N.; Elkhaleefa, A.M.; Yadav, K.K.; Rather, S.; Ahn, H.J.; et al. Emerging trends in the remediation of persistent organic pollutants using nanomaterials and related processes: A review. Nanomaterials 2022, 12, 2148.

- Dellamatrice, P.M.; Silva-Stenico, M.E.; de Moraes, L.A.B.; Fiore, M.F.; Monteiro, R.T.S. Degradation of textile dyes by cyanobacteria. Braz. J. Microbiol. 2017, 48, 25–31.

- Alprol, A.E.; Heneash, A.M.M.; Ashour, M.; Abulnaza, K.M.; Alhashmialmeer, D.; Mansour, A.T.; Sharawi, Z.Z.; Abu-Saled, M.A.; Abomohra, A.E.F. Potential applications of Arthrospira platensis lipid free biomass in bioremediation of organic dye from industrial textile effluents and its influence on marine rotifer (Brachionus plicatilis). Materials 2021, 16, 4446.

- Mansour, A.T.; Alprol, A.E.; Abualnaja, K.M.; El-Beltagi, H.S.; Ramadan, K.M.A.; Ashour, M. The using of nano-particles of microalgae in remediation of toxic dye from industrial wastewater: Kinetic and isotherm studies. Materials 2022, 15, 3922.

- Ngo, A.C.R.; Tischler, D. Microbial Degradation of azo dyes: Approaches and prospects for a hazard-free conversion by microorganisms. Int. J. Environ. Res. Public Health 2022, 19, 4740.

- Jafari, N.; Soudib, M.R.; Kasra-Kermanshahi, R. Biodegradation perspectives of azo dyes by yeasts. Microbiology 2014, 83, 184–197.

- Jadhav, S.U.; Kalme, S.D.; Govindwar, S.P. Biodegradation of Methyl red by Galactomyces geotrichum MTCC 1360. Int. Biodet. Biodeg. 2008, 62, 135–142.

- Guo, G.; Tian, F.; Zhao, Y.; Tang, M.; Liu, W.; Liu, C.; Xue, S.; Kong, W.; Sun, Y.; Wang, S. Aerobic decolorization and detoxification of acid scarlet GR by a newly isolated salt-tolerant yeast strain Galactomyces geotrichum GG. Int. Biodeterior. Biodegrad. 2019, 145, 104818.

- Ali, S.S.; Al-Tohamy, R.; Koupra, E.; EL-Naggar, A.H.; Kornaros, M.; Sun, J. Valorizing lignin-like dyes and textile dyeing wastewater by a newly constructed lipid producing and lignin modifying olraginous yeast consortioum valued for biodiesel and bioremediation. J. Hazard. Mater. 2021, 403, 123575.

- Salt, D.E.; Smith, R.D.; Raskin, I. Phytoremediation. Annu. Rev. Plant Physiol. Plant Mol. Biol. 1998, 49, 643–668.

- Greipsson, S. Phytoremediation. Nat. Educ. Knowl. 2011, 3, 7.

- Viana, D.G.; Filho, F.B.E.; Pires, F.R.; Soares, M.B.; Ferreira, A.D.; Bonomo, R.; Martins, L.F. In situ barium phytoremediation in flooded soil using Typha domingensis under different planting densities. Ecotoxicol. Environ. Saf. 2021, 210, 111890.

- Wei, Z.; Van Le, Q.; Peng, W.; Yang, Y.; Yang, H.; Gu, H.; Lam, S.S.; Sonne, C. A review on phytoremediation of contaminants in air, water and soil. J. Hazard. Mater. 2021, 403, 123658.

- Kafle, A.; Timilsina, A.; Gautam, A.; Adhikari, K.; Bhattarai, A.; Aryal, N. Phytoremediation: Mechanisms, plant selection and enhancement by natural and synthetic agents. Environ. Adv. 2022, 8, 100203.

- Alsafran, M.; Usman, K.; Ahmed, B.; Rizwan, M.; Saleem, M.H.; Al Jabri, H. Understanding the phytoremediation mechanisms of potentially toxic elements: A proteomic overview of recent advances. Front. Plant Sci. 2022, 13, 881242.

- Biju, L.M.; Gayathri, K.V.; Kumar, P.S.; Kavitha, R.; Rajagopal, R.; Ranasamy, G. Application of Salvinia species in remediation of reactive mix azo-dyes and Cr- its pathway eleucidation. Environ. Res. 2023, 216, 114635.

- Rane, N.R.; Chandanshive, V.V.; Watharkar, A.D.; Khandare, R.V.; Patil, T.S.; Pawar, P.K.; Govindwar, S.P. Phytoremediation of sulfonated remazol red dye and textile effluents by Alternanthera philoxeroides: An anatomical, enzymatic and pilot scale study. Water Res. 2015, 83, 271–281.

- Imron, M.F.; Kurniawan, S.B.; Soegianto, A.; Wahyudianto, F.E. Phytoremediation of methylene blue using duckweed (Lemna minor). Heliyon 2019, 5, e02206.

- Baldawi, I.A.A.; Abdullah, S.R.S.; Anuar, N.; Hasan, H.A. Phytotransformation of methylene blue from water using aquatic plant (Azolla pinnata). Environ. Technol. Innov. 2018, 11, 15–22.

More

Information

Subjects:

Biotechnology & Applied Microbiology

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.0K

Revisions:

2 times

(View History)

Update Date:

21 Nov 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No