Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Shlomo Margel | -- | 2174 | 2023-11-17 16:32:02 | | | |

| 2 | Jessie Wu | + 1 word(s) | 2175 | 2023-11-20 04:42:23 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Malka, E.; Margel, S. Engineering of PVA/PVP Hydrogels for Agricultural Applications. Encyclopedia. Available online: https://encyclopedia.pub/entry/51760 (accessed on 06 March 2026).

Malka E, Margel S. Engineering of PVA/PVP Hydrogels for Agricultural Applications. Encyclopedia. Available at: https://encyclopedia.pub/entry/51760. Accessed March 06, 2026.

Malka, Eyal, Shlomo Margel. "Engineering of PVA/PVP Hydrogels for Agricultural Applications" Encyclopedia, https://encyclopedia.pub/entry/51760 (accessed March 06, 2026).

Malka, E., & Margel, S. (2023, November 17). Engineering of PVA/PVP Hydrogels for Agricultural Applications. In Encyclopedia. https://encyclopedia.pub/entry/51760

Malka, Eyal and Shlomo Margel. "Engineering of PVA/PVP Hydrogels for Agricultural Applications." Encyclopedia. Web. 17 November, 2023.

Copy Citation

Hydrogels have gained significant popularity in agricultural applications in terms of minimizing waste and mitigating the negative environmental impact of agrochemicals. The utilization of environmentally friendly, shapable hydrogels composed of polyvinyl alcohol (PVA) and polyvinylpyrrolidone (PVP) in various casings for crop protection are examined against different pests, fertilizing, and watering. To activate their effectiveness, PVA/PVP hydrogels were loaded with both hydrophilic and hydrophobic environmentally friendly pesticides, namely hydrogen peroxide (HP), the essential oil thymol, and urea as a fertilizer, either separately or in combination.

PVA/PVP

agricultural applications

PVA/PVP-based hydrogels

controlled release

1. Structural Chemistry and Classification of Agricultural Polyvinyl Alcohol/Polyvinylpyrrolidone-Based Hydrogels

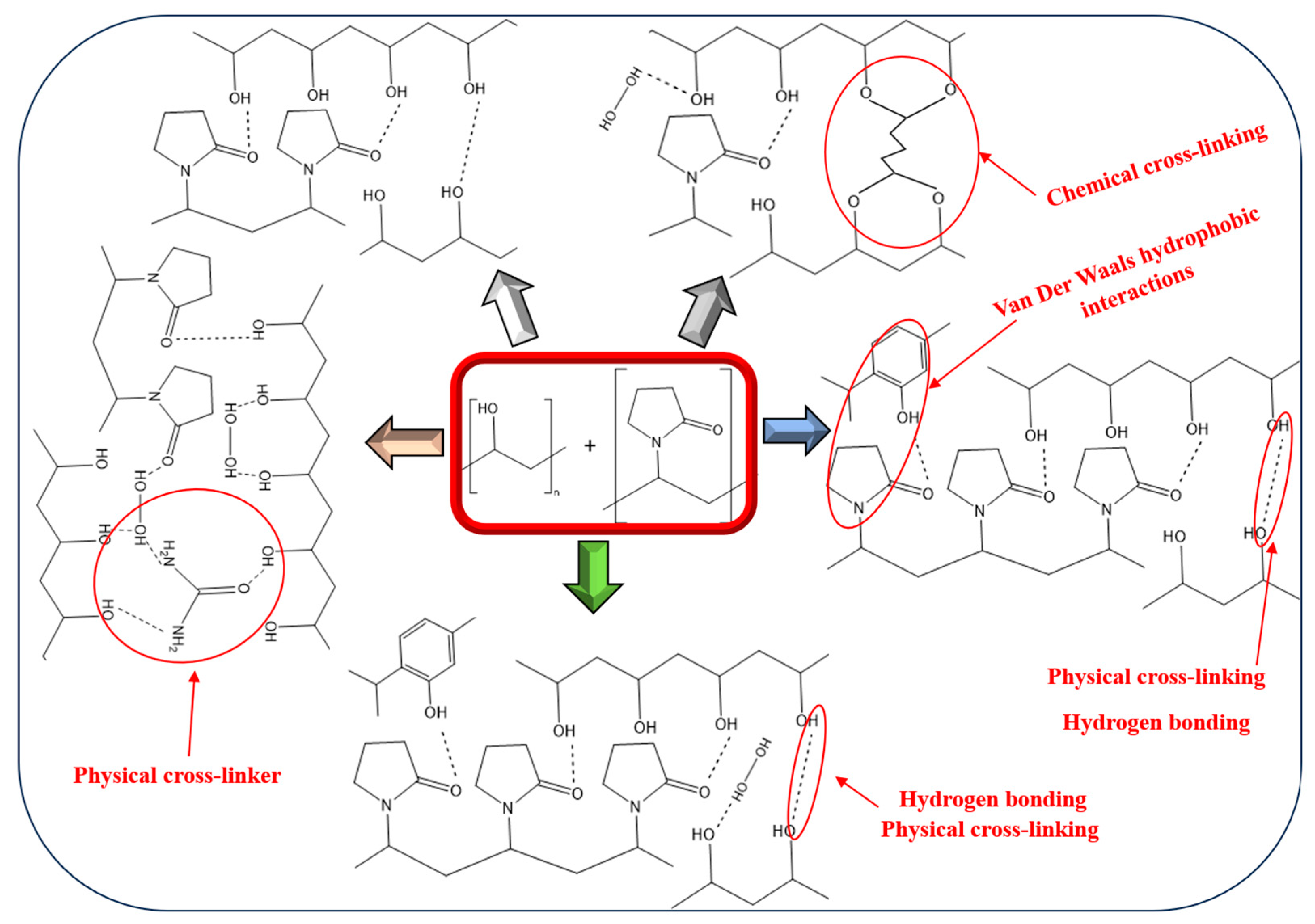

The fundamental structure of polyvinyl alcohol (PVA)/polyvinylpyrrolidone (PVP) hydrogels can be achieved through the establishment of physical hydrogen bonds between distinct homopolymer chains [1][2][3]. PVP acts as a highly effective proton acceptor [4][5][6], while PVA serves as a proton donor [7]. The more complex structure involves chemical cross-linking, e.g., via glutaraldehyde, leading to the development of copolymer chains along the backbone or the formation of acetals through interactions involving side chains, introducing possibly more rigid structures [8][9][10]. However, both structures serve as excellent carriers and retainers of water for plants, owing to their hydrophilic side groups. These structures can be loaded with hydrophilic fertilizer and pesticide compounds, such as urea and HP, respectively, as well as hydrophobic ones, like thymol.

In the scenario of hydrophilic loaded substances, their retained and slow-release forms are primarily established through branched hydrogen bond interactions between the polymeric caging structure of the hydrogels and these solutes. For instance, urea fertilizer solute comprises amide groups, functioning as a physical cross-linker, while its carbonyl head contributes to additional physical interactions regarding HP pesticide solute, which has the capacity to engage in hydrogen bonding with PVA and form complexes with PVP [11][12]. In the context of thymol, Van der Waals hydrophobic interactions are feasible mainly with PVP due to thymol’s hydrophobic terpene side. Additionally, its hydroxyl group stemming from the phenolic hydrophilic side can participate in hydrogen bonding interactions (Figure 1 blue arrow). In scenarios involving the loading of multiple substances, the possibility of additional interactions between them arises. For instance, the coexistence of urea with HP can result in the formation of a complex [13]. Additional potential hydrogen bond interactions can take place between thymol and urea [14]. However, given that HP is recognized as a distinct oxidizer, the presence of thymol could potentially lead to certain oxidative side reactions [15].

Figure 1. Representative agricultural PVA/PVP hydrogel structures: PVA and PVP precursors (in the red frame), physically cross-linked unloaded PVA/PVP (white arrow) and entrapped with HP and urea (peach arrow), PVA/PVP/thymol (blue arrow), PVA/PVP/HP/thymol (green arrow), chemically cross-linked PVA/PVP/HP (grey arrow) hydrogels.

2. Conceptual Shapes of Polyvinyl Alcohol/Polyvinylpyrrolidone-Based Hydrogels in Crops

Various techniques are viable for generating a range of applications using hydrogels. One of the most widely used and scalable techniques for practical applications is solution casting. This process involves pouring the bulk solution into an inert mold of the desired shape or using a doctor blade to cast a thin film. This method is straightforward, allows for easy adjustment of film thickness, is cost-effective, and can be employed with various polymer components to produce homogeneous castings. Nonetheless, if a high level of mechanical strength is required, this method may not be adequate [16][17][18]. Injection molding is a molding technology that involves melting polymers using a screw and an external heating device, followed by injecting the molten material into a mold to produce the desired product as the mold cools. This process is repetitive, allowing for rapid production, and it is compatible with both pure and composite materials. Injection molding can create complex geometries with high precision. However, this method does face certain challenges, including limitations in terms of suitable materials with appropriate rheological properties, process complexities, and equipment-related challenges [19][20][21]. Compression molding is a closed molding process wherein raw materials are placed within a cavity mold under controlled heat and pressure conditions to create a range of composite products known for their relatively high mechanical strength. The preparation of raw materials and the compression molding process, including specified applied pressures, heat levels, and durations, are critical parameters that significantly influence the mechanical performance of the final product. This method is highly reproducible and widely adopted in industrial settings due to its cleanliness, cost-effectiveness, efficiency, and the fact that it can be performed without solvents. However, because it necessitates pretreatment of raw materials and involves multiple variables such as compression force, heat, and duration, achieving optimal working conditions may require thorough investigation and optimization [22][23][24]. Three-dimensional printing represents the most modern technique among the four mentioned. It can be categorized into four primary printing methods:

-

Extrusion printing: In this method, continuous filaments serve as the building blocks;

-

Inkjet printing: This technique utilizes low-viscosity inks, often combined with in situ or post-fabrication processing to achieve mechanically stable structures;

-

Stereolithography printing: Stereolithography employs photopolymerizable prepolymer solutions;

-

Laser-assisted printing: Laser beams are employed to construct intricate structures from ink droplets.

The primary advantage of 3D printing is its ability to create complex hierarchical multi-material structures at a reduced cost. Additionally, these printers are user-friendly and can be quickly adjusted to meet specific parameters. However, it is essential to prepare printing formulas with precise rheological specifications to ensure the desired mechanical structure. Furthermore, it is worth noting that, as of now, these printers have not yet reached the levels of industrial output achievable by the traditional shaping methods previously mentioned [25][26][27].

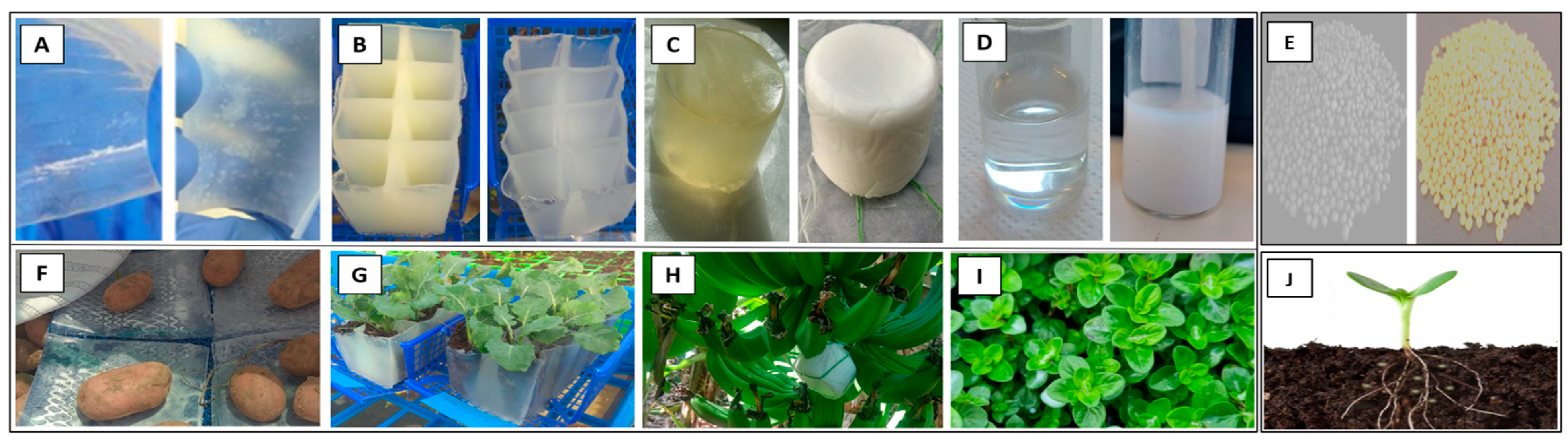

One approach involves creating uniform shapes that are laden with fertilizers and pesticides. This section introduces specific configurations, including hydrogel coatings infused with HP (Figure 5A,F). These coatings are produced by applying hydrogel precursor solutions onto polymeric sheets using the Mayer rod technique [28][29]. The outcome is the production of coated sheets, facilitating the creation of an atmosphere saturated with active ingredient vapor or direct contact with the crops (Figure 2F). In cases where a bulk form is required, castings are produced by pouring the hydrogel precursor solutions into a designated mold with the desired shape [30]. The resulting castings manifest as hydrogel seedling plates infused with HP and urea (Figure 2B,G) or as capsules loaded with thymol (Figure 2C,H). These structures possess the capability to release active substances into the root systems of plants or emit fumes that envelop fruits, depending on the specific configuration.

Figure 2. PVA/PVP-based hydrogels composed of 15 w% PVA and 6 w% PVP engineered into various forms for plant and crop protection: neat and loaded with 6 w% HP coatings on polymeric sheets (A left and right, respectively), implemented as potato crop bags stored in 2–10 °C refrigerated room (F). Seedling plates unloaded and loaded with HP (B left and right, respectively), for implanting seedlings placed in greenhouse (temperature: 18–24 °C, relative humidity: 40–80%). (G). Capsules loaded and unloaded (C left and right, respectively) with 5% thymol (w/w) anchored on banana plantations are protected by net sheets and grow in mediterranean weather all year (H). Spray formulation, unloaded and loaded with 5 w% thymol (D left and right, respectively) utilized on seedling foliage placed in greenhouse (I); uncoated and coated encapsulations of fertilizer granules (E left and right, respectively) implemented in plant soil placed in greenhouse (J).

An additional form comprises liquid hydrogel formulations derived from diluted PVA and PVP precursor solutions incorporated with HP and thymol. These formulations are specifically designed for direct spraying applications. The resultant solutions are applied onto the foliage of seedlings, forming a protective coating (Figure 5D,I). An additional form of encapsulation of urea granules constitutes an alternative technique for developing safeguarded fertilizers, mitigating issues related to swift decomposition, leaching, or evaporation (Figure 5E,J). This encapsulation methodology can be achieved by utilizing a sugar-coating machine or through the application of a hot coat sprayer apparatus [31].

3. Recent Agricultural Applications and Results with Polyvinyl Alcohol/Polyvinylpyrrolidone-based Hydrogels

A plethora of studies extensively investigated the individual applications of PVA and PVP within an agricultural context [32][33][34]. Nevertheless, the amalgamation of PVA and PVP (PVA/PVP) for agricultural purposes remains relatively novel. As a result, there is a lack of comprehensive works in the literature on these hydrogels and their derivatives. The present research encompasses a range of studies, including both researchers' recent contributions and research conducted by other groups. A recent study introduces the development of Nervilia fordii extract-loaded electrospun PVA/PVP nanocomposites for antioxidant packaging [35]. This innovative approach holds the potential to revolutionize agrifood preservation by providing nanofibers with a significantly increased surface area, leading to superior spatial antioxidant release compared to traditional bulk hydrogels. Furthermore, the resulting morphology of these fibers remained unchanged when loaded with antioxidants, in contrast to the discussed loaded hydrogels, which exhibited significant morphological changes compared to their unloaded counterparts. Both researchers' work and the aforementioned study offer efficient loading methods, improved thermo-stability of active substances, and promising results for applications in preserving tested products.

These studies shed light on the various pesticidal capabilities of these hydrogels and their derivatives against crop viruses and fungi [36][37]. Additionally, these hydrogels function as carriers for fertilizers with promising results for plants growth [38][39][40], enabling their controlled and gradual release. A correlated and advantageous outcome of hydrogel utilization, which holds true in this specific case as well, is the capacity to retain water and subsequently release it over a period. This stands in contrast to scenarios involving irrigation without the incorporation of hydrogels into soils, where water tends to seep rapidly, leading to its loss. Hence, it is conceivable that this could serve as a potential enhancer for soil conditioning. The applications were executed through diverse preparations and formulations of the PVA/PVP composition, tailored to suit various purposes (Table 1).

Table 1. Hydrogels and their PVA/PVP derivatives, designed for agricultural applications or possessing properties suitable for agricultural use.

| Hydrogel Type | Application Method | Purpose | Reference |

|---|---|---|---|

| Physical cross-linked PVA/PVP loaded with hydrogen peroxide | Loaded hydrogels in direct contact with the virus or exposure via released vapor | Virucide: eradication of Tomato Brown Rugose Fruit Virus (ToBRV) | [30] |

| Physical cross-linked PVA/PVP loaded with varied thymol and hydrogen peroxide ratios | Hydrogel coatings placed on top of hay | Fungicide: prevention of mold growth on hay | [28] |

| Physical cross-linked PVA/PVP | Coatings encapsulated urea granules | Slow-release fertilizer and soil conditioner | [41] |

| Chemical cross-linked PVA/PVP with epoxy resin and zeolite | Membrane slow release of urea | Slow-release fertilizer | [42] |

| Chemical cross-linked with biochar copolymer PVA/PVP | Coating material encapsulates urea granules | Slow-release fertilizer | [43] |

| Physical cross-linked Chitosan/PVA/PVP | Films loaded with chitosan nanoparticles | Fungicide: prevention of fungus growth on strawberry | [44] |

| Chemical cross-linked PVA/PVP | Films loaded with plant extracts | Broad-band antimicrobial activity | [45] |

| Physical cross-linked PVA/PVP | Coatings encapsulate urea | Slow-release fertilizer | [46] |

| Physical cross-linked PVA/PVP | Films loaded with cyanine derivatives and their Cu2+ complexes | Broad-band antimicrobial activity | [47] |

| Physical cross-linked PVA/PVP/Glycerol | Coated seeds loaded with pro-microbial inoculant | Plant growth-promoting bacteria | [48] |

| PVA/PVP/Cellulose | Films loaded with ZnO and cellulose | Antimicrobial activity | [49] |

| Physical cross-linked PVA/PVP | Films loaded with ZnO:Fe modified with vitamin C nanoparticles | UV protection and antimicrobial activity | [50] |

| Physical cross-linked PVA/PVP | Films loaded with anthocyanin | UV and visible radiation protectant | [51] |

| Chemical cross-linked CMC/PVA/PVP | Nanofiber mats | Moisture reducer: fruit and vegetable preservatives | [52] |

| Physical cross-linked PVA/PVP/PEG | Coatings loaded with celery leaf extract on aluminum foil | Insect repellent | [53] |

| Chemical cross linked PVA/PVP | Microneedles loaded with epsilon-poly-L-lysine | Reduction of fungal infections in citrus fruit pericarp | [54] |

| Physical cross-linked PVA/PVP | Protective solution for the preparation of silver nanoparticles | Antimicrobial activity | [55] |

| Physical cross-linked PVA and PVP | Coated seeds loaded with pro-microbial inoculant | Plant growth-promoting bacteria | [56] |

| Physical cross-linked PVA/PVP | Films loaded with CuO | Antimicrobial activity | [57] |

| Physical cross-linked PVA/PVP | Films loaded with OrmocarpumCochinchinense Leaf Extract | Antifungal and antimicrobial activity | [58] |

| Physical cross-linked PVA and PVP | Encapsulation of living bacteria in dry coatings | Bioremediation | [59] |

| Physical cross-linked PVA and PVP | Nanofibers loaded with hormones | Plant growth-promoting hormones | [60] |

| Physical cross-linked PVA/PVP | Nanoribbons loaded with magnesium oxide | Soil enrichment | [61] |

| Physical cross-linked PVA/PVP | Nanofibers | General use in agriculture | [62] |

| Physical cross-linked PVA/PVP | Nanocomposite films loaded with crystalline nanocellulose | Food packaging | [63] |

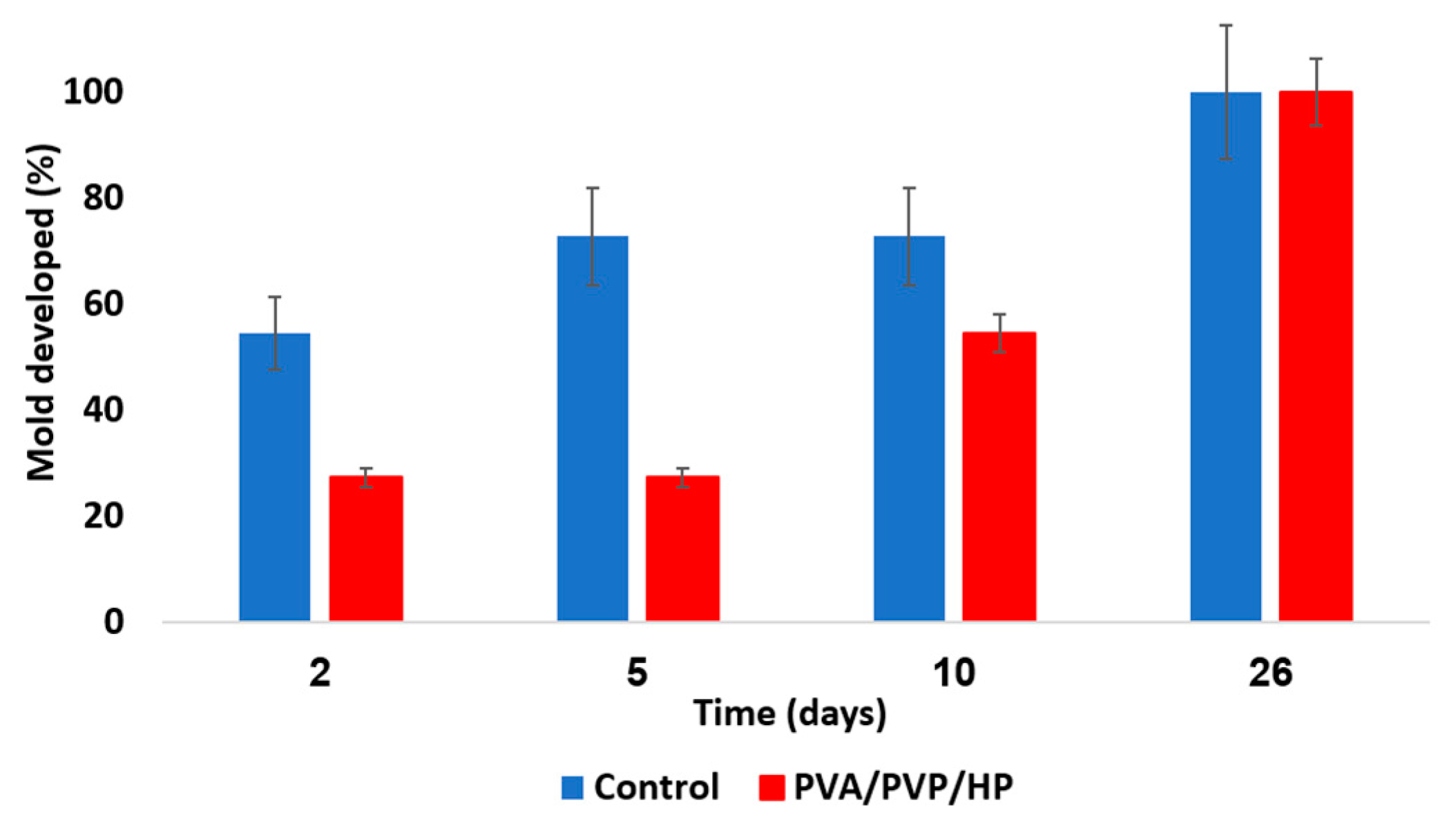

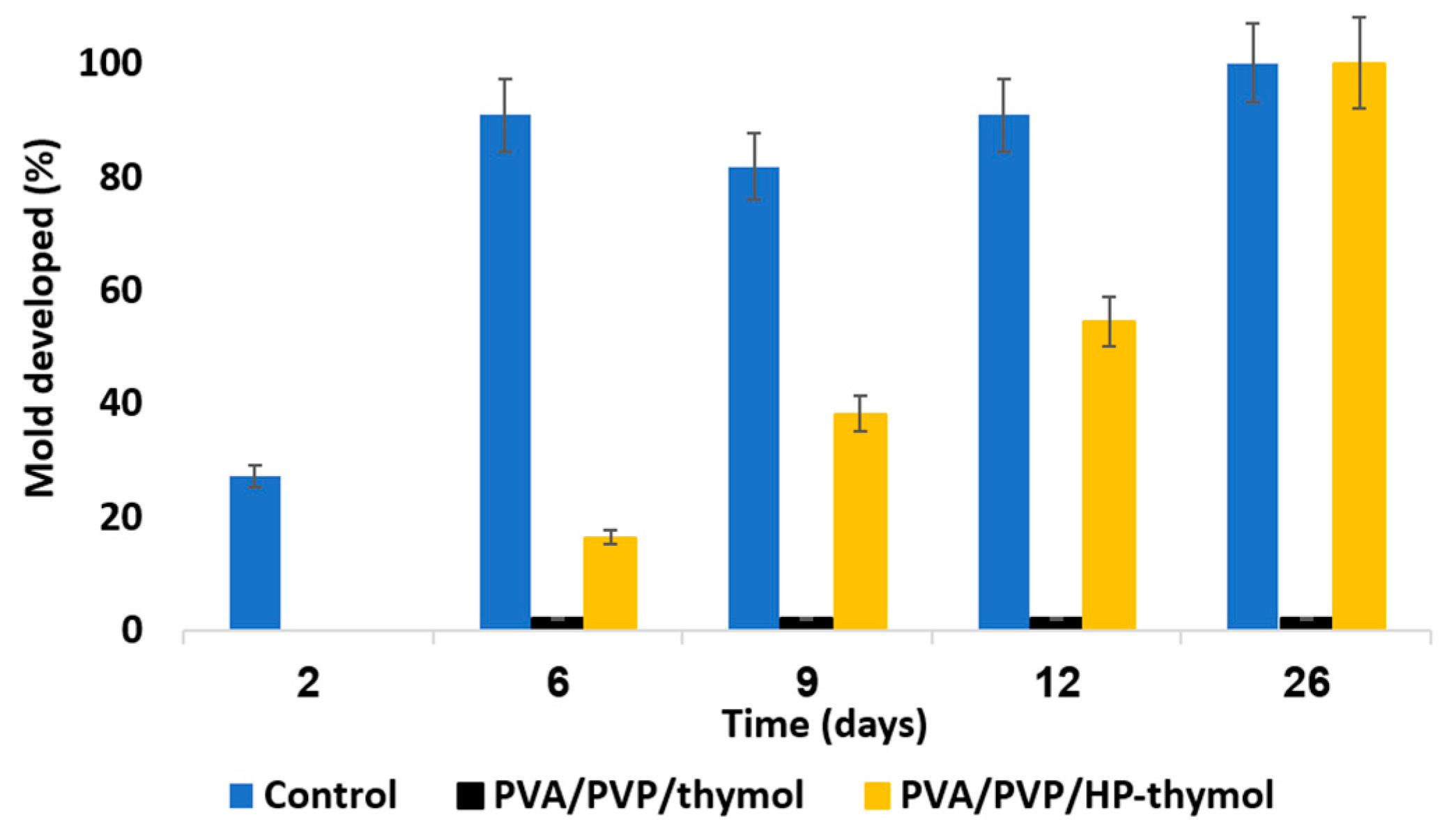

Representative results from researchers' recent studies demonstrated the effective results of these hydrogels against various pests as shown in Figure 3, Figure 4, Figure 5 and Figure 6, respectively [28][64].

Figure 3. Mold growth rate over several days. Uncoated PE sheets (blue) are a control. PVA/PVP/HP hydrogel coated sheets (red) contain an entrapped anti-mold component.

Figure 4. Mold growth rate over several days as a function of coating type. The PVA/PVP hydrogel PE coated sheets (blue) are a control. PE sheets coated with PVA/PVP/thymol (1.25 w% thymol precursor, black) or PVA/PVP/HP-thymol (0.63% each of HP and thymol precursors, orange) present coatings with entrapped anti-mold components.

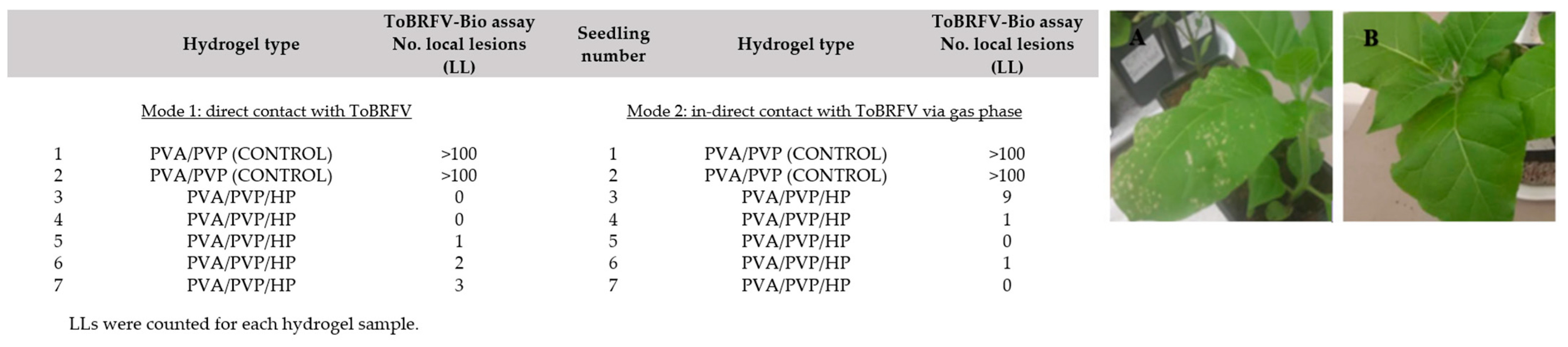

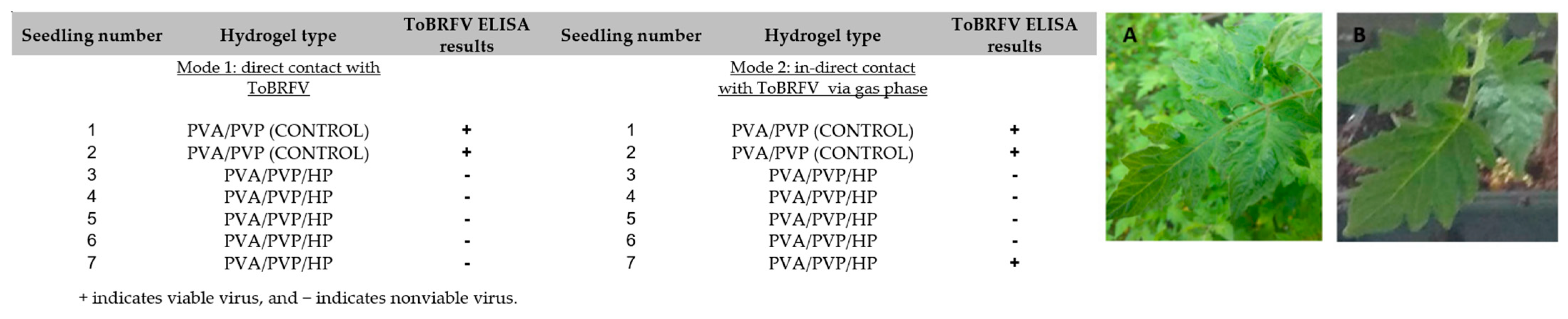

Figure 5. Biological assay of ToBRFV on Nicotiana tabacum. 35 (A) Control tobacco plants (control treatment with no active molecule) developed symptoms of local lesions (LLs) on leaves following ToBRFV infection. (B) No ToBRFV LL symptoms were developed following hydrogen peroxide-loaded hydrogel treatment.

Figure 6. Biological assay of ToBRFV on tomato plants. (A) Seedlings infected with ToBRFV after being inoculated in a control PVA/PVP hydrogel. (B) Tobacco seedling infected with the virus after being inoculated in a PVA/PVP/HP hydrogel.

References

- Mondal, D.; Mollick, M.M.R.; Bhowmick, B.; Maity, D.; Bain, M.K.; Rana, D.; Mukhopadhyay, A.; Dana, K.; Chattopadhyay, D. Effect of Poly(Vinyl Pyrrolidone) on the Morphology and Physical Properties of Poly(Vinyl Alcohol)/Sodium Montmorillonite Nanocomposite Films. Prog. Nat. Sci. Mater. Int. 2013, 23, 579–587.

- Jin, S.G. Production and Application of Biomaterials Based on Polyvinyl Alcohol (PVA) as Wound Dressing. Chem Asian J 2022, 17.

- Wang, Y.; Wei, Q. Editorial on the Special Issue “Modification of Hydrogels and Their Applications in Biomedical Engineering”. Gels 2023, 9, 263.

- Ben Ammar, N.E.; Essid, R.; Saied, T.; Şen, M.; Elkahoui, S.; Hamzaoui, A.H. Synthesis and Characterization of Radiation Cross-Linked PVP Hydrogels and Investigation of Its Potential as an Antileishmanial Drug Carrier. Polym. Bull. 2020, 77, 1343–1357.

- Barbosa, E.J.; Ferraz, H.G. Gellan Gum and Polyvinylpyrrolidone (PVP) as Binding Agents in Extrusion/Spheronization Pellet Formulations. Acta Pharm. 2019, 69, 99–109.

- Odunayo, A.B.; Kayode, F.I.; Benjamin, A.A.; Adekola, A.I.; Ruth, O.O. Evaluation of the Binding Property of Some Binders in Metronidazole Tablet Formulation. Int. J. Pharm. Chem. 2021, 7, 22.

- Darabi, M.A.; Khosrozadeh, A.; Wang, Y.; Ashammakhi, N.; Alem, H.; Erdem, A.; Chang, Q.; Xu, K.; Liu, Y.; Luo, G.; et al. An Alkaline Based Method for Generating Crystalline, Strong, and Shape Memory Polyvinyl Alcohol Biomaterials. Adv. Sci. 2020, 7, 1902740.

- Bhuiyan, M.A.Q.; Shaifur Rahman, M.D.; Rahaman, M.S.; Shajahan, M.; Dafader, N.C. Improvement of Swelling Behaviour of Poly (Vinyl Pyrrolidone) and Acrylic Acid Blend Hydrogel Prepared By the Application of Gamma Radiation. Org. Chem. Curr. Res. 2015, 4, 2.

- Ghobashy, M.M. Ionizing radiation-induced polymerization. In Ionizing Radiation Effects and Applications; IntechOpen: London, UK, 2018; pp. 113–134.

- Wang, Y.; Li, J.; Muhammad, N.; Wang, Z.; Wu, D. Hierarchical Networks of Anisotropic Hydrogels Based on Cross-Linked Poly(Vinyl Alcohol)/Poly(Vinylpyrrolidone). Polymer 2022, 251, 124920.

- Panarin, E.F.; Kalninsh, K.K.; Pestov, D.V. Complexation of Hydrogen Peroxide with Polyvinylpyrrolidone: Ab Initio Calculations. Eur. Polym. J. 2001, 37, 375–379.

- Liu, B.; Wang, Y.N.; Ding, W.; Shi, B. Preparation of Oxidised Polyvinyl Alcohol Using Hydrogen Peroxide and Its Application for Collagen Modification. J. Soc. Leather Technol. Chem. 2019, 103, 14–20.

- Taliansky, S. Urea-Hydrogen Peroxide Complex. Synlett 2005, 12, 1962–1963.

- Sasson, E.; Agazani, O.; Malka, E.; Reches, M.; Margel, S. Engineered Cross-Linked Silane with Urea Polymer Thin Durable Coatings onto Polymeric Films for Controlled Antiviral Release of Activated Chlorine and Essential Oils. J. Funct. Biomater. 2023, 14, 270.

- de Faria, E.H.; Pimenta, G.; Matias, F.; e Silva, M.L.A.; Silva Filho, A.A.D.; Srgio, P.; Jos, E.; Jorge, K. Green Oxidation Reactions of Drugs Catalyzed by Bio-Inspired Complexes as an Efficient Methodology to Obtain New Active Molecules. In Biomimetic Based Applications; IntechOpen: London, UK, 2011.

- Liang, J.; Luo, J.; Sun, Q.; Yang, X.; Li, R.; Sun, X. Recent Progress on Solid-State Hybrid Electrolytes for Solid-State Lithium Batteries. Energy Storage Mater. 2019, 21, 308–334.

- Bidadi, H.; Olad, A.; Parhizkar, M.; Mohammadi Aref, S.; Ghafouri, M. Nonlinear Properties of ZnO-Polymer Composites Prepared by Solution-Casting Method. Vacuum 2013, 87, 50–54.

- Zhang, S.; He, Y.; Yin, Y.; Jiang, G. Fabrication of Innovative Thermoplastic Starch Bio-Elastomer to Achieve High Toughness Poly(Butylene Succinate) Composites. Carbohydr. Polym. 2019, 206, 827–836.

- Emerson, A.E.; Mccall, A.B.; Brady, S.R.; Slaby, E.M.; Weaver, J.D. Hydrogel Injection Molding to Generate Complex Cell Encapsulation Geometries. ACS Biomater. Sci. Eng. 2022, 8, 4002–4013.

- Turner, J.G.; White, L.R.; Estrela, P.; Leese, H.S. Hydrogel-Forming Microneedles: Current Advancements and Future Trends. Macromol. Biosci. 2021, 21, e2000307.

- Fu, H.; Xu, H.; Liu, Y.; Yang, Z.; Kormakov, S.; Wu, D.; Sun, J. Overview of Injection Molding Technology for Processing Polymers and Their Composites. ES Mater. Manuf. 2020, 8, 3–23.

- Cao, D.; Malakooti, S.; Kulkarni, V.N.; Ren, Y.; Liu, Y.; Nie, X.; Qian, D.; Griffith, D.T.; Lu, H. The Effect of Resin Uptake on the Flexural Properties of Compression Molded Sandwich Composites. Wind. Energy 2022, 25, 71–93.

- Guerrero, P.; Muxika, A.; Zarandona, I.; de la Caba, K. Crosslinking of Chitosan Films Processed by Compression Molding. Carbohydr. Polym. 2019, 206, 820–826.

- Jaafar, J.; Siregar, J.P.; Tezara, C.; Hamdan, M.H.M.; Rihayat, T. A Review of Important Considerations in the Compression Molding Process of Short Natural Fiber Composites. Int. J. Adv. Manuf. Technol. 2019, 105, 3437–3450.

- Liu, F.; Li, W.; Liu, H.; Yuan, T.; Yang, Y.; Zhou, W.; Hu, Y.; Yang, Z. Preparation of 3D Printed Chitosan/Polyvinyl Alcohol Double Network Hydrogel Scaffolds. Macromol. Biosci. 2021, 21, 2000398.

- Kalossaka, L.M.; Sena, G.; Barter, L.M.C.; Myant, C. Review: 3D Printing Hydrogels for the Fabrication of Soilless Cultivation Substrates. Appl. Mater. Today 2021, 24, 101088.

- Puza, F.; Lienkamp, K. 3D Printing of Polymer Hydrogels—From Basic Techniques to Programmable Actuation. Adv. Funct. Mater. 2022, 32, 2205345.

- Malka, E.; Caspi, A.; Cohen, R.; Margel, S. Fabrication and Characterization of Hydrogen Peroxide and Thymol-Loaded PVA/PVP Hydrogel Coatings as a Novel Anti-Mold Surface for Hay Protection. Polymers 2022, 14, 5518.

- Zhou, L.; Yu, M.; Yao, L.; Lai, W.Y. Mayer Rod-Coated Organic Light-Emitting Devices: Binary Solvent Inks, Film Topography Optimization, and Large-Area Fabrication. Adv. Eng. Mater. 2022, 24, 2101558.

- Wei, X.; Bao, X.; Yu, L.; Liu, H.; Lu, K.; Chen, L.; Bai, L.; Zhou, X.; Li, Z.; Li, W. Correlation Between Gel Strength of Starch-Based Hydrogel and Slow-Release Behavior of Its Embedded Urea. J. Polym. Environ. 2020, 28, 863–870.

- Salawi, A. Pharmaceutical Coating and Its Different Approaches, A Review. Polymers 2022, 14, 3318.

- Aly, E. Effect of Water Regimes and Polyvinyl Alcohol on Faba Bean Yield, Chemical Composition and Water Use Efficiency. J. Soil Sci. Agric. Eng. 2020, 11, 769–777.

- Krishnamoorthy, V.; Elumalai, G.; Rajiv, S. Environment Friendly Synthesis of Polyvinylpyrrolidone Nanofibers and Their Potential Use as Seed Coats. N. J. Chem. 2016, 40, 3268–3276.

- Vaňharová, L.; Julinová, M.; Jurča, M.; Minařík, A.; Vinter, Š.; Šašinková, D.; Wrzecionko, E. Environmentally Friendly Polymeric Films Based on Biocarbon, Synthetic Zeolite and PVP for Agricultural Chemistry. Polym. Bull. 2022, 79, 4971–4998.

- Wen, P.; Hu, T.G.; Wen, Y.; Li, K.E.; Qiu, W.P.; He, Z.L.; Wang, H.; Wu, H. Development of Nervilia fordii extract-loaded electrospun pva/pvp nanocomposite for antioxidant packaging. Foods 2021, 10, 1728.

- Zhang, S.; Zhai, Y.; Zhang, Z. Study on medical polyvinyl alcohol (PVA)/polyvinyl pyrrolidone (PVP) hydrogel burns dressing. In Proceedings of the 2011 International Conference on Electronic and Mechanical Engineering and Information Technology, EMEIT 2011, Harbin, China, 12–14 August 2011; Volume 9, pp. 4485–4488.

- Pestov, A.; Privar, Y.; Slobodyuk, A.; Boroda, A.; Bratskaya, S. Chitosan Cross-Linking with Acetaldehyde Acetals. Biomimetics 2022, 7, 10.

- Hu, H.; Tian, Y.; Kong, Z.; Ying, W.B.; Chen, C.; Li, F.; Zhang, R.; Zhu, J. A High Performance Copolyester with “Locked” Biodegradability: Solid Stability and Controlled Degradation Enabled by Acid-Labile Acetal. ACS Sustain. Chem. Eng. 2021, 9, 2280–2290.

- Frihart, C.R.; Wescott, J.M.; Chaffee, T.L.; Gonner, K.M. Formaldehyde Emissions from Urea-Formaldehyde-and No-Added-Formaldehyde-Bonded Particleboard as Influenced by Temperature and Relative Humidity. For. Prod. J. 2012, 62, 551–558.

- Tay, J.-W.; Choe, D.-H.; Mulchandani, A.; Rust, M.K. Hydrogels: From Controlled Release to a New Bait Delivery for Insect Pest Management. J. Econ. Entomol. 2020, 113, 2061–2068.

- Wanapu, C.; Pinpeangchan, S.; Wanapu, C. Impact of Nitrogen Fertilizer (Encapsulated Urea Fertilizer) in Process of Controlled-Release Their Effect on Growth of Chinese Kale (Brassica alboglabra Bailey). Glob. Adv. Res. J. Agric. Sci. 2015, 4, 173–181.

- Sun, H.; Lei, T.; Liu, J.; Guo, X.; Lv, J. Physicochemical Properties of Water-Based Copolymer and Zeolite Composite Sustained-Release Membrane Materials. Materials 2022, 15, 8553.

- Chen, S.; Yang, M.; Ba, C.; Yu, S.; Jiang, Y.; Zou, H.; Zhang, Y. Preparation and Characterization of Slow-Release Fertilizer Encapsulated by Biochar-Based Waterborne Copolymers. Sci. Total Environ. 2018, 615, 431–437.

- Ventura-Aguilar, R.I.; Díaz-Galindo, E.P.; Bautista-Baños, S.; Mendoza-Acevedo, S.; Munguía-Cervantes, J.E.; Correa-Pacheco, Z.N.; Bosquez-Molina, E. Monitoring the Infection Process of Rhizopus Stolonifer on Strawberry Fruit during Storage Using Films Based on Chitosan/Polyvinyl Alcohol/Polyvinylpyrrolidone and Plant Extracts. Int. J. Biol. Macromol. 2021, 182, 583–594.

- Abdul, S.; Soud, S.; Hasson, B.A.; Ismail, A. Synthesis and characterization of plant extracts loaded PVA/PVP blend films and evaluate their biological activities. EurAsian J. BioSci. 2020, 14, 2921–2931.

- Chen, S.; Han, Y.; Yang, M.; Zhu, X.; Liu, C.; Liu, H.; Zou, H. Hydrophobically Modified Water-Based Polymer for Slow-Release Urea Formulation. Prog Org Coat 2020, 149.

- Marcelo, G.A.; Galhano, J.; Duarte, M.P.; Kurutos, A.; Capelo-Martínez, J.L.; Lodeiro, C.; Oliveira, E. Functional Cyanine-Based PVA:PVP Polymers as Antimicrobial Tools toward Food and Health-Care Bacterial Infections. Macromol. Biosci. 2022, 22, e2200244.

- Hussain, Z.; Khan, M.A.; Iqbal, F.; Raffi, M.; Hafeez, F.Y. Electrospun Microbial-Encapsulated Composite-Based Plasticized Seed Coat for Rhizosphere Stabilization and Sustainable Production of Canola (Brassica napus L.). J. Agric. Food Chem. 2019, 67, 5085–5095.

- Pokhrel, S.; Karki, P. Peanut Shells Cellulose Based Biodegradable Nanocomposites with Polyvinyl Pyrrolidone (PVP) and Polyvinyl Alcohol (PVA). Macromol. Symp. 2023, 409, 2200183.

- Narasimhamurthy, K.N.; Daruka Prasad, B.; Radha Krushna, B.R.; Sharma, S.C.; Ponnazhagan, K.; Francis, D.; Nijalingappa, T.B.; Nasreen Taj, M.; Nagabhushana, H. Nanocomposites of PVA-PVP and l-Ascorbic Acid Modified ZnO:Fe via Ultrasonic Irradiation as a Green Technique: Latent Fingerprint Detection, Food Packing and Anti-Bacterial Applications. Inorg. Chem. Commun. 2023, 156, 111161.

- Akraa, M.; Kadhim, H.; Salah, A.S.; Akraa, M.A.; Jawad, M.; Kadhim, H.; Abbas, S.J.; Hasan, A.S. Simulation and Preparation of an Eco-Food Container by Using Bio-Additive of Beet Juice in Polyvinyl Alcohol/Polyvinylpyrrolidone Blend: Physical Application The Effects of the PEDOT:PSS Acidity on the Performance and Stability of P3HT:PCBM-Based OSCs View Project Nanotechnology View Project Simulation and Preparation of an Eco-Food Container by Using Bio-Additive of Beet Juice in Polyvinyl Alcohol/Polyvinylpyrrolidone Blend: Physical Application. TEST Eng. Manag. 2020, 83, 16669–16676.

- Hashmi, M.; Ullah, S.; Ullah, A.; Saito, Y.; Haider, M.K.; Bie, X.; Wada, K.; Kim, I.S. Carboxymethyl Cellulose (Cmc) Based Electrospun Composite Nanofiber Mats for Food Packaging. Polymers 2021, 13, 302.

- Astuti, R.D. Patch Formulation of Celery Leaves Extract (Apium Graveolens L.) As Mosquito Repellent. In Proceedings of the First International Conference on Health, Social Sciences and Technology (ICoHSST 2020), Palembang, Indonesia, 20–21 October 2020; Atlantis Press: Amsterdam, The Netherlands, 2021; pp. 83–87.

- Jiang, L.; Huang, H.; Shi, X.; Wu, J.; Ye, J.; Xu, Q.; Fang, S.; Wu, C.; Luo, R.; Lu, C.; et al. Biocontrol Microneedle Patch: A Promising Agent for Protecting Citrus Fruits from Postharvest Infection. Pharmaceutics 2023, 15, 1219.

- Badineni, V.; Maseed, H.; Arla, S.K.; Yerramala, S.; Vijaya Kumar Naidu, B.; Kaviyarasu, K. Effect of PVA/PVP Protective Agent on the Formation of Silver Nanoparticles and Its Photocatalytic and Antimicrobial Activity. Mater. Today Proc. 2019, 36, 121–125.

- Mohamed, S.S.; Hassan, M.A.; Abdelgani, M.E. Effect of High Temperature on Rhizobia Survival on Different Leguminous Seeds Inoculated with Liquid Formulations. Glob. Adv. Res. J. Agric. Sci. 2020, 9, 2315–5094.

- El-Kader, M.F.H.A.; Elabbasy, M.T.; Adeboye, A.A.; Menazea, A.A. Nanocomposite of PVA/PVP Blend Incorporated by Copper Oxide Nanoparticles via Nanosecond Laser Ablation for Antibacterial Activity Enhancement. Polym. Bull. 2022, 79, 9779–9795.

- Narayanan, A.; Marimuthu, M.; Mani, A.; Vasu, G.; Subhadra, R. Studies on the Antimicrobial Activity of Ormocarpum Cochinchinense Leaf Extract/PVA-PVP Blended Polymer. ChemistrySelect 2023, 8, e202203512.

- Reich, S.; Kaiser, P.; Mafi, M.; Schmalz, H.; Rhinow, D.; Freitag, R.; Greiner, A. High-Temperature Spray-Dried Polymer/Bacteria Microparticles for Electrospinning of Composite Nonwovens. Macromol. Biosci. 2019, 19, e1800356.

- Raja, K.; Prabhu, C.; Subramanian, K.S.; Govindaraju, K. Electrospun Polyvinyl Alcohol (PVA) Nanofibers as Carriers for Hormones (IAA and GA3) Delivery in Seed Invigoration for Enhancing Germination and Seedling Vigor of Agricultural Crops (Groundnut and Black Gram). Polym. Bull. 2021, 78, 6429–6440.

- El-Gamal, S.; Elsayed, M. Positron Annihilation and Electrical Studies on the Influence of Loading Magnesia Nanoribbons on PVA-PVP Blend. Polym. Test 2020, 89, 106681.

- Hashmi, M.; Ullah, S.; Ullah, A.; Akmal, M.; Saito, Y.; Hussain, N.; Ren, X.; Kim, I.S. Optimized Loading of Carboxymethyl Cellulose (Cmc) in Tri-Component Electrospun Nanofibers Having Uniform Morphology. Polymers 2020, 12, 2524.

- Khatun, M.A.; Sultana, S.; Islam, Z.; Kabir, M.S.; Hossain, M.S.; Nur, H.P.; Chowdhury, A.M.S. Extraction of Crystalline Nanocellulose (CNC) from Date Palm Mat Fibers and Its Application in the Production of Nanocomposites with Polyvinyl Alcohol and Polyvinylpyrrolidone Blended Films. Results Eng. 2023, 17, 101031.

- Malka, E.; Dombrovsky, A.; Margel, S. Preparation and Characterization of a Novel PVA/PVP Hydrogel Containing Entrapped Hydrogen Peroxide for Agricultural Applications. ACS Agric. Sci. Technol. 2022, 2, 430–436.

More

Information

Subjects:

Polymer Science

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.3K

Revisions:

2 times

(View History)

Update Date:

20 Nov 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No