2. Conceptual Shapes of PVA/PVP-Based Hydrogels in Crops

Various techniques are viable for generating a range of applications using hydrogels. One of the most widely used and scalable techniques for practical applications is solution casting. This process involves pouring the bulk solution into an inert mold of the desired shape or using a doctor blade to cast a thin film. This method is straightforward, allows for easy adjustment of film thickness, is cost-effective, and can be employed with various polymer components to produce homogeneous castings. Nonetheless, if a high level of mechanical strength is required, this method may not be adequate [

149,

150,

151]. Injection molding is a molding technology that involves melting polymers using a screw and an external heating device, followed by injecting the molten material into a mold to produce the desired product as the mold cools. This process is repetitive, allowing for rapid production, and it is compatible with both pure and composite materials. Injection molding can create complex geometries with high precision. However, this method does face certain challenges, including limitations in terms of suitable materials with appropriate rheological properties, process complexities, and equipment-related challenges [

152,

153,

154]. Compression molding is a closed molding process wherein raw materials are placed within a cavity mold under controlled heat and pressure conditions to create a range of composite products known for their relatively high mechanical strength. The preparation of raw materials and the compression molding process, including specified applied pressures, heat levels, and durations, are critical parameters that significantly influence the mechanical performance of the final product. This method is highly reproducible and widely adopted in industrial settings due to its cleanliness, cost-effectiveness, efficiency, and the fact that it can be performed without solvents. However, because it necessitates pretreatment of raw materials and involves multiple variables such as compression force, heat, and duration, achieving optimal working conditions may require thorough investigation and optimization [

155,

156,

157]. Three-dimensional printing represents the most modern technique among the four mentioned. It can be categorized into four primary printing methods:

-

Extrusion printing: In this method, continuous filaments serve as the building blocks;

-

Inkjet printing: This technique utilizes low-viscosity inks, often combined with in situ or post-fabrication processing to achieve mechanically stable structures;

-

Stereolithography printing: Stereolithography employs photopolymerizable prepolymer solutions;

-

Laser-assisted printing: Laser beams are employed to construct intricate structures from ink droplets.

The primary advantage of 3D printing is its ability to create complex hierarchical multi-material structures at a reduced cost. Additionally, these printers are user-friendly and can be quickly adjusted to meet specific parameters. However, it is essential to prepare printing formulas with precise rheological specifications to ensure the desired mechanical structure. Furthermore, it is worth noting that, as of now, these printers have not yet reached the levels of industrial output achievable by the traditional shaping methods previously mentioned [

158,

159,

160].

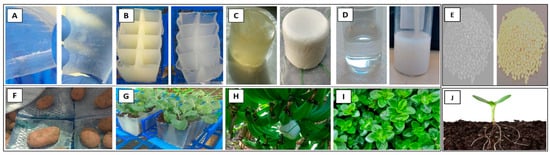

One approach involves creating uniform shapes that are laden with fertilizers and pesticides. This section introduces specific configurations, including hydrogel coatings infused with HP (

Figure 5A,F). These coatings are produced by applying hydrogel precursor solutions onto polymeric sheets using the Mayer rod technique [

65,

161]. The outcome is the production of coated sheets, facilitating the creation of an atmosphere saturated with active ingredient vapor or direct contact with the crops (

Figure 2F). In cases where a bulk form is required, castings are produced by pouring the hydrogel precursor solutions into a designated mold with the desired shape [

10]. The resulting castings manifest as hydrogel seedling plates infused with HP and urea (

Figure 2B,G) or as capsules loaded with thymol (

Figure 2C,H). These structures possess the capability to release active substances into the root systems of plants or emit fumes that envelop fruits, depending on the specific configuration.

Figure 2. PVA/PVP-based hydrogels composed of 15 w% PVA and 6 w% PVP engineered into various forms for plant and crop protection: neat and loaded with 6 w% HP coatings on polymeric sheets (A left and right, respectively), implemented as potato crop bags stored in 2–10 °C refrigerated room (F). Seedling plates unloaded and loaded with HP (B left and right, respectively), for implanting seedlings placed in greenhouse (temperature: 18–24 °C, relative humidity: 40–80%). (G). Capsules loaded and unloaded (C left and right, respectively) with 5% thymol (w/w) anchored on banana plantations are protected by net sheets and grow in mediterranean weather all year (H). Spray formulation, unloaded and loaded with 5 w% thymol (D left and right, respectively) utilized on seedling foliage placed in greenhouse (I); uncoated and coated encapsulations of fertilizer granules (E left and right, respectively) implemented in plant soil placed in greenhouse (J).

An additional form comprises liquid hydrogel formulations derived from diluted PVA and PVP precursor solutions incorporated with HP and thymol. These formulations are specifically designed for direct spraying applications. The resultant solutions are applied onto the foliage of seedlings, forming a protective coating (

Figure 5D,I). An additional form of encapsulation of urea granules constitutes an alternative technique for developing safeguarded fertilizers, mitigating issues related to swift decomposition, leaching, or evaporation (

Figure 5E,J). This encapsulation methodology can be achieved by utilizing a sugar-coating machine or through the application of a hot coat sprayer apparatus [

162].

3. Recent Agricultural Applications and Results with PVA/PVP-based Hydrogels

A plethora of studies extensively investigated the individual applications of PVA and PVP within an agricultural context [

52,

163,

164]. Nevertheless, the amalgamation of PVA and PVP (PVA/PVP) for agricultural purposes remains relatively novel. As a result, there is a lack of comprehensive works in the literature on these hydrogels and their derivatives. The present review encompasses a range of studies, including both our recent contributions and research conducted by other groups. A recent study introduces the development of Nervilia fordii extract-loaded electrospun PVA/PVP nanocomposites for antioxidant packaging [

130]. This innovative approach holds the potential to revolutionize agrifood preservation by providing nanofibers with a significantly increased surface area, leading to superior spatial antioxidant release compared to traditional bulk hydrogels. Furthermore, the resulting morphology of these fibers remained unchanged when loaded with antioxidants, in contrast to the discussed loaded hydrogels, which exhibited significant morphological changes compared to their unloaded counterparts. Both our work and the aforementioned study offer efficient loading methods, improved thermo-stability of active substances, and promising results for applications in preserving tested products.

These studies shed light on the various pesticidal capabilities of these hydrogels and their derivatives against crop viruses and fungi [

4,

32]. Additionally, these hydrogels function as carriers for fertilizers with promising results for plants growth [

39,

41,

63], enabling their controlled and gradual release. A correlated and advantageous outcome of hydrogel utilization, which holds true in this specific case as well, is the capacity to retain water and subsequently release it over a period. This stands in contrast to scenarios involving irrigation without the incorporation of hydrogels into soils, where water tends to seep rapidly, leading to its loss. Hence, it is conceivable that this could serve as a potential enhancer for soil conditioning. The applications were executed through diverse preparations and formulations of the PVA/PVP composition, tailored to suit various purposes (

Table 1).

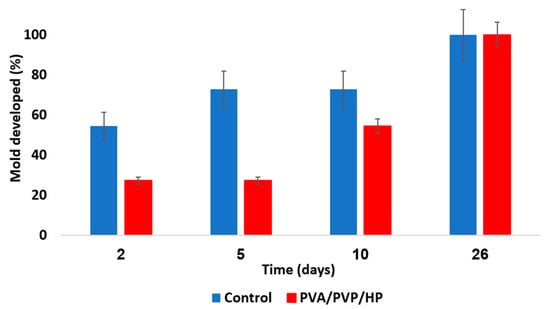

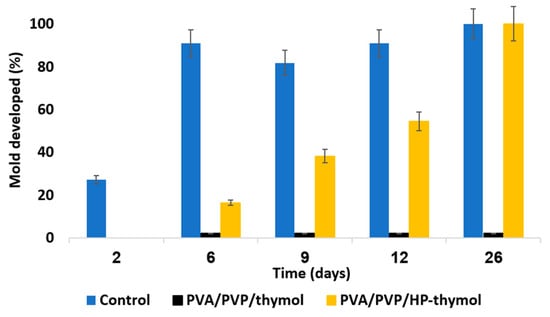

Representative results from our recent studies demonstrated the effective results of these hydrogels against various pests as shown in

Figure 3,

Figure 4,

Figure 5 and

Figure 6, respectively [

65,

116].

Figure 3. Mold growth rate over several days. Uncoated PE sheets (blue) are a control. PVA/PVP/HP hydrogel coated sheets (red) contain an entrapped anti-mold component.

Figure 4. Mold growth rate over several days as a function of coating type. The PVA/PVP hydrogel PE coated sheets (blue) are a control. PE sheets coated with PVA/PVP/thymol (1.25 w% thymol precursor, black) or PVA/PVP/HP-thymol (0.63% each of HP and thymol precursors, orange) present coatings with entrapped anti-mold components.

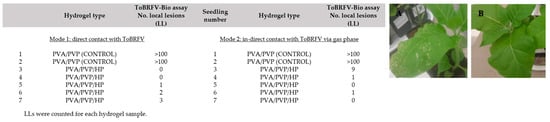

Figure 5. Biological assay of ToBRFV on Nicotiana tabacum. 35 (A) Control tobacco plants (control treatment with no active molecule) developed symptoms of local lesions (LLs) on leaves following ToBRFV infection. (B) No ToBRFV LL symptoms were developed following hydrogen peroxide-loaded hydrogel treatment.

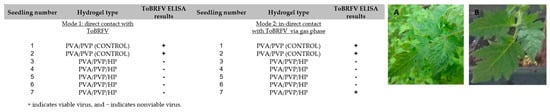

Figure 6. Biological assay of ToBRFV on tomato plants. (A) Seedlings infected with ToBRFV after being inoculated in a control PVA/PVP hydrogel. (B) Tobacco seedling infected with the virus after being inoculated in a PVA/PVP/HP hydrogel.