Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Martin Scheurer | -- | 3728 | 2023-10-24 11:15:34 | | | |

| 2 | Jason Zhu | Meta information modification | 3728 | 2023-10-25 03:31:40 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Scheurer, M.; Friese, D.; Penzel, P.; Dittel, G.; Bhat, S.; Overhage, V.; Hahn, L.; Heins, K.; Cherif, C.; Gries, T. Novel Manufacturing Methods for Textile-Reinforced Concrete. Encyclopedia. Available online: https://encyclopedia.pub/entry/50724 (accessed on 07 February 2026).

Scheurer M, Friese D, Penzel P, Dittel G, Bhat S, Overhage V, et al. Novel Manufacturing Methods for Textile-Reinforced Concrete. Encyclopedia. Available at: https://encyclopedia.pub/entry/50724. Accessed February 07, 2026.

Scheurer, Martin, Danny Friese, Paul Penzel, Gözdem Dittel, Shantanu Bhat, Vanessa Overhage, Lars Hahn, Kira Heins, Chokri Cherif, Thomas Gries. "Novel Manufacturing Methods for Textile-Reinforced Concrete" Encyclopedia, https://encyclopedia.pub/entry/50724 (accessed February 07, 2026).

Scheurer, M., Friese, D., Penzel, P., Dittel, G., Bhat, S., Overhage, V., Hahn, L., Heins, K., Cherif, C., & Gries, T. (2023, October 24). Novel Manufacturing Methods for Textile-Reinforced Concrete. In Encyclopedia. https://encyclopedia.pub/entry/50724

Scheurer, Martin, et al. "Novel Manufacturing Methods for Textile-Reinforced Concrete." Encyclopedia. Web. 24 October, 2023.

Copy Citation

Textile-reinforced concrete (TRC) is a composite material consisting of a concrete matrix with a high-performance reinforcement made of technical textiles. TRC offers unique mechanical properties for the construction industry, enabling the construction of lightweight, material-minimized structures with high load-bearing potential. In addition, compared with traditional concrete design, TRC offers unique possibilities to realize free-form, double-curved structures.

textile-reinforced concrete

buildtech

composites

1. Introduction

The construction industry is a very important part of the global economy, making up about 13% of global gross domestic product and employing about 7% of the global working population [1]. At the same time, the construction sector is responsible for about 33% of global energy consumption, about 40% of global raw material consumption, and about 40% of global solid waste generation [2][3][4]. Therefore, any initiative to reduce global greenhouse gas emissions will have to take the construction sector into account [2].

Megatrends such as increasing global population, increasing urbanization, and increasing amount of used living space per resident lead to a further projected increase in materials and energy used in the construction industry [5]. Continuing construction business as usual may more than double global raw material extraction until 2050 [6][7].

These facts and figures demonstrate the importance of a paradigm shift in the construction industry. While more construction for the increasing global population is inevitable, sustainability concerns need to be addressed swiftly and comprehensibly. Regulators in several countries are planning to or have already introduced measures to limit resource and energy usage in the construction industry [8].

One of the main drivers of greenhouse gas emissions and energy use in the construction industry is the production of ordinary cement, which itself is responsible for about 8% of global greenhouse gas emissions [9]. Cement is a component of concrete (the other components being water and aggregates, such as sand or gravel). Concrete is the second most used material in the world, only surpassed by water [10]. Concrete has a high compressive strength but low tensile strength. If tensile or bending loads are present, concrete is commonly reinforced, often using steel bars or grids, which carry the tensile load [11]. However, since the steel reinforcement corrodes when in contact with air, a minimum concrete cover is required to protect the steel reinforcement from corrosion [12]. This minimum concrete cover is often thicker than required by the present loads, leading to increased and mechanically redundant material usage [13].

Novel materials with lower energy and material usage as well as lower greenhouse gas emissions are one possibility to reduce the impact of the construction industry. One possible novel material combination, which has been researched since the late 1990s, is textile-reinforced concrete (TRC). In TRC, the steel reinforcement is substituted by a reinforcement made of technical textiles [13]. These textiles are usually made of high-performance materials such as glass or carbon fibers, which do not corrode when in contact with air and therefore enable the reduction in the concrete cover to a minimum [14]. Thereby, TRC enables the construction of lightweight, thin-walled concrete elements, such as bridges [15], precast elements [16][17][18], and facades [19][20][21]. Another application of TRC is in the retrofitting of existing concrete structures [22][23]. Another example of the use of TRC is the building “CUBE” in Dresden, Germany, which is the first building constructed entirely from TRC [24].

2. Robot-Based Manufacturing Methods for Reinforcement Textiles

Robot-supported manufacturing technologies enable the production of resource-saving and cost-efficient but also freely formable and arbitrarily designable textile reinforcement structures for concrete constructions. These promising technologies are based on industrial six-axis robots, which are highly versatile machines that can be programmed to perform various tasks in manufacturing and other industries. They are capable of precise and repetitive movements, making them ideal for tasks that require speed, accuracy, and consistency. Industrial robots can also operate without fatigue and in hazardous environments or perform tasks that are too dangerous for humans. A six-axis industrial robot has six degrees of freedom, allowing the robot to perform translational (X, Y, Z) and rotational (A, B, C) movements. This allows the robot to work in three dimensions and move its tools to any position within its reach, enabling the on-demand creation of free-form textile reinforcement structures. Six-axis robots are widely used in the automotive, electronics, and aerospace industries due to their beneficial properties such as productivity, increases in quality from high-precision and high-repetition accuracy, variable adaptability, and reduced labor costs by replacing humans with robots. Thanks to their highly variable movement capabilities, they are also able to manipulate yarn-guiding tools in order to deposit the yarn, for instance, on a yarn fixation rack, on winding cores, or simply free in space. For this purpose, carbon fiber heavy tows (CFHT) Tenax-E STS 40 E23 48K (Teijin Carbon Europe GmbH, Wuppertal, Germany) with a fineness of about 3200 tex are often used to efficiently manufacture the nonmetallic reinforcement structures [25].

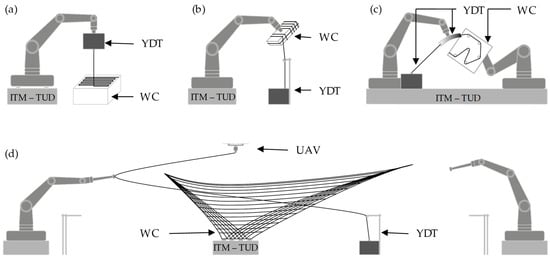

To pave the way for novel resource-saving and cost-efficient textile reinforcement structures, researchers have developed distinctive robot-based machine technologies. Several robotic yarn deposition technologies already exist or are currently being developed for the production of textile reinforcement structures for the construction industry or fiber-reinforced plastics for the composites market. All robotic manufacturing technologies consist of several functional modules, namely the manipulating robot, the yarn deposition tool—which performs the function of storing, guiding, and impregnating the yarn—and the workpiece carrier, which is used to temporarily fix the reinforcement structure. However, they all differ in their mode of operation. There are robotic manufacturing processes that have been developed to meet the needs of the construction industry (focusing on the reinforcement of concrete components) and those that have emerged from other industries (e.g., architecture or automotive). Basically, there are different ways to produce textile reinforcement structures—either by manipulating the yarn placement tool, where the workpiece carrier is fixed, or by moving the workpiece carrier while the yarn placement tool stands still, as in the winding, using a winding core [26][27]. Figure 1a,b show the two basic process principles of robotic yarn deposition technologies, where a single robot moves either the tool or the workpiece carrier. Collaboratively used robot systems consist of various six-axis robots and, in some cases, of additional unmanned aerial vehicles (UAVs) and climbing robots, as in the translational cross-winding technique or the filament-winding technique by means of UAVs [28][29]. They are also being used to produce large-scale shell elements with membranous outer appearance exclusively using both preimpregnated and freshly impregnated rovings [29][30].

2.1. Process Principle A

The technological design by von Zuben et al. is shown in Figure 1a using freshly impregnated carbon fiber heavy tows ((CFHTs), used here is a roving Tenax-E STS 40 E23 48K from Teijin company, and the matrix is Biresin CR84/CH120-6 from SIKA company)—the yarn spool and the impregnation unit are both manipulated by the robot—for the production of planar and lattice-like reinforcement structures [15]. Here, yarn impregnation is only performed immediately prior to yarn deposition. The operation consists of the robot manipulating the yarn deposition tool. The workpiece carrier is fixed. Von Zuben et al. focus on the use of conventional epoxy resin as an impregnation agent; so, the plant technology is also designed for this two-component resin system [31]. This manufacturing principle can already be used to produce planar 2D reinforcement structures with cut-free geometries.

2.2. Process Principle B

Another technological approach, shown in Figure 1b, is the winding technique using a winding core. The workpiece carrier is manipulated by the robot arm, while the yarn tool is stationary on the floor [32]. An impregnation bath with a yarn eye for precise deposition can be used as the yarn tool. Michel et al. used a mineral impregnation of the carbon fibers. Due to the homogeneity of the mineral material, a high bond to the concrete is achieved, and the roving can be processed flexibly within a process window of four hours after impregnation [33]. Alternatively, preimpregnated CFHTs can be used to produce extremely lightweight reinforcement structures with graded fiber distribution, such as a reinforcing cage for a balcony [27].

2.3. Process Principle C

The 3D coreless filament winding technology with two cooperating robots by Minsch et al., shown in Figure 1c, is another production technology being developed [34]. The 3D coreless filament winding uses a translational cross-winding technique to produce truss-like structures. The yarn impregnation process is conducted off the robotic manipulation on a fixed impregnation unit. The freshly impregnated carbon fiber yarn is delivered directly afterwards to the filament winding tube. The yarn is a Toray T620SC-24000-50C roving (CFHT) in combination with epoxy resin Hexion MGS LR385 and hardener LH 386. The robot simply manipulates the freely fed yarn using a yarn guide tube, as the impregnation tool is stationary on the floor and the yarn is therefore impregnated outside the robot handling process. This technology was originally developed in response to the challenge of providing lightweight materials for energy-reduced manufacturing processes in the automotive industry.

2.4. Process Principle D

A fourth robot-assisted technology for direct yarn deposition is shown in Figure 1d with the collaboratively working multirobot system by Knippers et al. [35][36]. This robotic system uses robotic systems consisting of six-axis robots, UAVs, and optionally, climbing robots [29][37]. The workpiece carrier is fixed, and the individual robots manipulate the preimpregnated yarn. The yarn impregnation tool is also stationary. In a different application, where the textile topology is more complex or the deposition process requires additional degrees of freedom, Knippers et al. use a rotating, single-axis workpiece carrier to provide additional uniaxial motion [38].

The ability to produce planar and grid-like two-dimensional textile reinforcements, as well as complex hierarchical and internally branched three-dimensional textile reinforcement structures, is the main advantage of the presented robotic manufacturing technologies [31][35][41]. Thus, one-dimensional structures as reinforcement bars (rebars), simple two-dimensional structures as grid-like reinforcement mats, and even more sophisticated three-dimensional textile reinforcement structures with spatial branchings and load-adapted fiber orientations such as reinforcement cages or bionic reinforcement topologies for pillars can be provided by these robot-based manufacturing technologies [14].

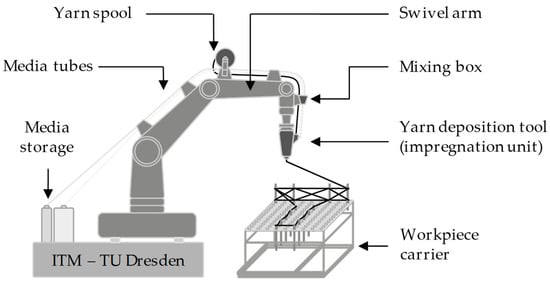

2.5. Future Process Principle E

A technological outlook is represented by the novel robotic manufacturing process with a robotic yarn impregnation and an intelligent yarn fixation module in Figure 2, which will be implemented in the near future. The yarn impregnation module consists of several submodules, which are mounted at different points of the robot. The impregnation material storage and their feed pumps are designed as a kind of backpack solution. They are mounted on the main axis (axis 1). The yarn spool, the piston rod cylinder for regulating the yarn tension, and the mixing chamber are mounted on the robot’s swivel arm. Here, various impregnation agents as two-component polymer systems and aqueous water dispersions are supposed to be homogenized. In the future, it should also be possible to process photopolymers with this impregnation module. The yarn fixation module, controlled by the higher-level programmable logic controller, is located within reach of the robot arm. The controller of the yarn fixation module interacts with the robot controller via a PROFIBUS interface. This allows the recipe sequence of the fixation module to be matched to the generated winding paths. The 3D yarn fixation module is integrated into a robotic system that consists of a protective robot cell and the industrial robot with the yarn impregnation tool attached to it. The geometrical dimensions of the yarn fixation module allow the realization of proper textile reinforcement structures for the construction industry. To ensure geometric accessibility of the yarn fixation module by the robot-guided yarn tool without collision, the individually controllable support rods can only be extended when necessary for the yarn placement process. In this way, the fixation module provides supporting points in space corresponding to the required fixation points, without obstructing the placement paths by machine parts. Supporting points, and therefore even rods, can be ignored if they are not required for the fixation of the yarns (3200 tex carbon fiber heavy tow).

Figure 2. Developed robot-assisted manufacturing technology (principle E) with functional modules working hand in hand in order to produce complex, bionic 3D textile reinforcement structures [41].

3. Production of Shaped TRC Elements Based on Adpative Molds

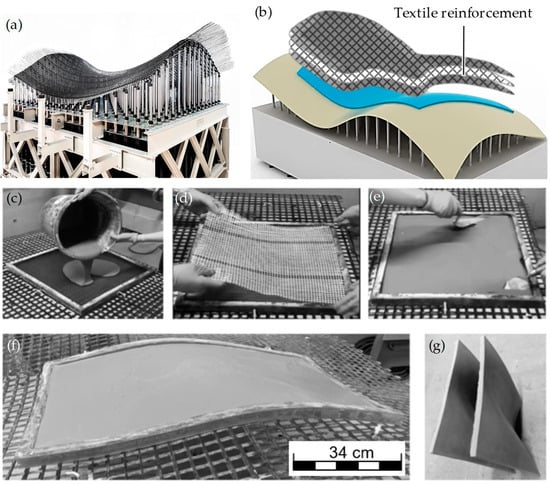

Adaptive formwork systems are suitable for the economical production of free-form concrete parts. They are based on multipoint tooling technology or pin-type tools. The basic principle is that a large number of pins or props are variably adjusted in height. This stepped representation of the desired geometry is smoothed with an elastic layer. A formwork of rubber or other elastic material is placed on the elastic layer, which is later filled with concrete and demolded. After completion, the same conformable form can be redesigned for a differently shaped panel [42].

Since textiles are thinner and more flexible than steel rebars, TRC elements can adopt curved shapes more easily, as well as achieve tighter or sharper curves (smaller curvature radii) compared with what is allowed by steel reinforcement. Reduced concrete cover and light weight makes TRC a more suitable option for adaptive molds, because their reduced thickness makes it easier to obtain curved shapes (thicker elements are harder to curve). Additionally, TRC reinforcement grids can be fabricated more efficiently than steel-reinforced reinforcement grids [42].

Preliminary studies are currently being conducted at ITA to investigate concrete penetration and positioning of the textiles in the free-form TRC panels prefabricated with adaptive molds. Figure 3 illustrates the casting of TRC panels on an adaptive mold. The coated and uncoated textiles with different textile architecture and materials are tested for their suitability with adaptive molds. The demonstrator TRC panels fabricated with an adaptive mold at ITA are depicted in Figure 3. An alternative way to use the adaptive mold is to apply concrete after deforming the mold into the desired shape. This is possible through the use of shotcrete (this method is already used with CNC-milled molds) and through the use of robotic techniques for placing textiles, such as automatic fiber placement and automatic tape placement, which are widely used in the composites industry. Commercially, adaptive formwork is already available from Adapa AS, Aalborg, Denmark. Computer-aided control means that the production of multicurved components requires less effort than with conventional formwork systems [43].

Figure 3. Precasting of TRC with adaptive mold at ITA: (a) industry-scale adaptive mold form ADAPA AS; (b) schematic; (c) filling silicon mold with first layer of concrete in flat position; (d) placement of textile reinforcement; (e) pouring second layer of concrete; (f) deforming on the adaptive mold; (g) precast TRC panels.

A great deal of research is still needed to improve the understanding of these new materials and to find suitable applications. The greatest challenge is the series production of such TRC double-curved or free-form structures in a precast plant and their transfer to the construction market. To achieve this, the benefits of the advances made in the above projects must be combined in a single process chain, with the involvement of architects closely associated with the builders and investors. The following research questions are proposed to be addressed in the future:

- -

-

Definition of design potentials and aesthetic trends in construction for TRC elements.

- -

-

Classification of building components with regard to form specifications and derivation of ideal textile architectures for the classified component groups.

- -

-

Fabrication of component-specific textile reinforcements.

- -

-

Shaping of TRC in the fresh state.

- -

-

In situ integration of insulating materials on the TRC panels in the precast plant.

- -

-

Integration of anchoring elements into the textile reinforcement.

- -

-

Design of a process chain for series production of functionally integrated curved TRC panels.

- -

-

Preparation of the implementation of a complete process chain for the form-flexible production of TRC components.

4. Textile Reinforcement for Additive Manufacturing of Concrete

Additive manufacturing methods have made great advancements in various industries in recent years, including the construction industry. Especially, digital fabrication with concrete (often called 3D concrete printing (3DCP)) has received a lot of interest in academia and industry alike, promising faster and safer fabrication of concrete elements and even whole buildings. While large advances have been made, many research challenges for 3DCP remain. Chief among them is the integration of reinforcement structures into the manufacturing process, since reinforcements are mandatory for nearly all structural applications. Various approaches to integrate reinforcements into 3DCP have been developed, researched, and classified, as presented by Mechtcherine et al. [44]. While most of the current approaches use steel-based reinforcements, as is common in the construction industry (e.g., [45][46][47]), some research into the usage of textile solutions has been performed.

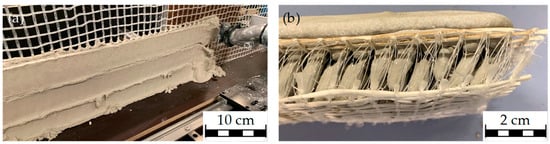

The simplest solution for the integration of textile reinforcements into 3DCP is the integration of randomly oriented short fibers into the printed concrete, as preformed, for example, by [48][49]. However, the strength increase that can be reached by this approach is limited. Another possibility is the integration of rovings or yarns into the printed concrete layers, as, for example, researched by [50]. This approach offers improved bending strength of the layers but does not improve the interlayer connection or strength. To improve this interlayer strength, the integration of (at least) two-dimensional textiles is necessary. These two-dimensional textiles are often grid-like structures (e.g., biaxial noncrimp fabrics as used in conventional TRC) and can be applied at various steps of the digital concrete production process. They can be applied as an initial reinforcement cage onto which the concrete is added (e.g., [51][52]), placed during the digital concrete production (e.g., [53]), or added as an additional reinforcement layer after digital concrete production is concluded (e.g., [54][55]).

Two approaches for the integration of multidimensional textile reinforcements into 3DCP are presented in Figure 4 below. In both approaches, the textile is fixed in place prior to the additive concrete manufacturing process, and the concrete is added to the textile [56]. Differing from the approaches described above, the concrete can penetrate through the textile and encloses the textile within the concrete matrix. Initial trials into the approach presented in Figure 4a showed the same performance for TRC specimens produced by using 3DCP and using traditional TRC casting methods [57][58]. For the approach presented in Figure 4b, initial trials show that adhesion between a spacer fabric made from AR-glass and a printed concrete matrix is sufficient [59][60][61].

Figure 4. Two approaches for the textile reinforcement of 3D concrete printing: (a) printing though a two-dimensional, grid like textile; (b) specimen made by printing onto a three-dimensional spacer fabric.

3DCP is a highly topical research area offering interesting and relevant solutions to many of the challenges the construction industry faces today, especially regarding workplace safety and loss of workforce. Since the integration of a reinforcement is a key challenge for the widespread application of 3DCP, solutions to this challenge are highly relevant. Textile reinforcements are uniquely suited for the integration into 3DCP, since they offer high-performance reinforcement that only needs minimal concrete cover, while being lightweight and easy to handle. However, research into the integration of textile reinforcements in 3DCP is only beginning, and many promising research approaches (integration method, type of textile, etc.) and challenging questions (regarding material, processing, performance, etc.) remain.

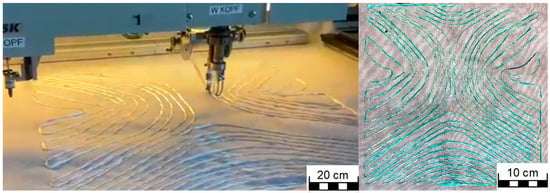

5. Load-Path-Oriented Textile Reinforcement Using Tailored Fiber Placement

The technological developments in fiber-reinforced plastics (FRP) manufacturing offer great potential to be transferred to the processing of textile-reinforced concrete. The development of FRP opens up the potential for high strength, stiffness, and light weight of structural components. To achieve full performance, the anisotropic fibers need to be oriented to match the load being applied. In most cases, however, layered structures of unidirectional (UD) yarns, known as multiaxial laminates, are used for composite fabrication. This is mainly due to the availability of semifinished textile products (e.g., woven and nonwoven) and well-established numerical methods for the design of multiaxial laminates [62]. However, this leads to a significantly reduced component performance. Tailored fiber placement (TFP) is a new automated textile process for the production of reinforcing structures. TFP is an embroidery-based, tow-steering process that enables complete control over fiber placement and directionality in a composite preform. During the process, a reinforcing roving is stitched to a base material using numerical control. The results are highly engineered composite structures that take full advantage of the anisotropic nature of fiber reinforcement. This process allows the consistent transfer of calculated locally optimum fiber quantities and orientations into fiber preforms. TFP has become well-established in the automotive or aerospace industries, but it still is not a common solution for the construction industry. However, recently, there has been an in-creased used of this technology in the building and architecture sector, and some examples of experimental or academic nature are presented below.

In the case of concrete precast panels, the TFP machine lays the rovings on top of a substrate that can be permeable (i.e., an open fabric with gaps through which fresh concrete can flow and thus embed the fibers properly) or removable (i.e., a closed fabric that must be removed to allow concrete to fully embed the carbon fibers). An example of load-path-oriented advanced textile reinforcements is shown in Figure 5. To increase the productivity of TFP, a new process called Tailored Fiber Placement high-Volume TFP (hV) was developed by Hightex Verstärkungsstrukturen GmbH, Klipphausen, Germany, allowing placement of up to 2000 g/h of 50K rovings.

Figure 5. Load-path-oriented advanced textile reinforcement for freeform concrete panels using tailored fiber placement (TFP).

Finally, one of the main limitations of TFP elements is their characteristic flat (2D) fabrication state, which remains in their final shape. In order to eliminate this constraint and produce freeform elements, research has been conducted at the ICD and ITKE institutes of the University of Stuttgart, in which “technical” carbon fibers or “natural” flax fibers (embedded on oil-based or bio-based epoxy resins) are used to produce nonconcrete structures with 3D or “2.5 D” geometries. Examples of this are the “Tailoring Self-Formation” [63], “FlexFlax Stool” [64], and “Biomimetic NFRP Stools” [65] projects. In most of these projects, the density and direction of the rovings is adjusted to the naturally occurring load paths (in order to achieve structural efficiency or to help generate the desired final shape of the element (due to localized stiffness variations)) [63].

The development of novel load-path-oriented structures is linked to issues of manufacturability, product-related sustainability assessment, and further development of the composite material itself. New and innovative design strategies enable a completely different design methodology, reduce resource and energy consumption, and at the same time ensure high serviceability, load-bearing safety, and durability. Further research on the aforementioned aspects needs to be performed for the tailored fiber placement technology, thereby establishing TFP as a novel manufacturing technique for textile reinforcements used in building panels.

References

- Barbosa, F.; Woetzel, J.; Mischke, J.; Ribeirinho, M.J.; Sridhar, M.; Parsons, M.; Bertram, N.; Brown, S. Reinventing Construction: A Route to Higher Productivity. 2017. Available online: https://www.mckinsey.com/~/media/mckinsey/business%20functions/operations/our%20insights/reinventing%20construction%20through%20a%20productivity%20revolution/mgi-reinventing-construction-a-route-to-higher-productivity-full-report.pdf (accessed on 31 July 2023).

- United Nations Environment Programme. 2021 Global Status Report for Buildings and Construction: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector, Nairobi. 2021. Available online: https://globalabc.org/sites/default/files/2021-10/GABC_Buildings-GSR-2021_BOOK.pdf (accessed on 31 July 2023).

- Backes, J.G.; Traverso, M. Application of Life Cycle Sustainability Assessment in the Construction Sector: A Systematic Literature Review. Processes 2021, 9, 1248.

- Choi, J. Strategy for reducing carbon dioxide emissions from maintenance and rehabilitation of highway pavement. J. Clean. Prod. 2019, 209, 88–100.

- World Economic Forum. Shaping the Future of Construction: A Breakthrough in Mindset and Technology. 2016. Available online: https://www3.weforum.org/docs/WEF_Shaping_the_Future_of_Construction_full_report__.pdf (accessed on 31 July 2023).

- Sameer, H.; Bringezu, S. Life cycle input indicators of material resource use for enhancing sustainability assessment schemes of buildings. J. Build. Eng. 2019, 21, 230–242.

- UNEP. Resource Efficiency: Potential and Economic Implications. A Report of the International Resource Panel. 2017. Available online: https://wedocs.unep.org/bitstream/handle/20.500.11822/21230/resource_efficiency_potential_economic_implications.pdf?sequence=1&%3BisAllowed= (accessed on 31 July 2023).

- Pasanen, P.; Tikka, S.; Le Gouvello, L.; Koukoulopoulos, K.; Kalfountzos, V.; Bounds, L. Decarbonizing Construction: Guidance for Investors and Developers to Reduce Embodied Carbon; World Business Council for Sustainable Development: Geneva, Switzerland, 2021.

- Hatzfeld, T.; Schlüter, D.; Scope, C.; Krois, K.; Guenther, E.; Etzold, B.; Curbach, M. Rethinking residential energy storage: GHG minimization potential of a Carbon Reinforced Concrete facade with function integrated supercapacitors. Build. Environ. 2022, 224, 109520.

- Gagg, C.R. Cement and concrete as an engineering material: An historic appraisal and case study analysis. Eng. Fail. Anal. 2014, 40, 114–140.

- Wight, J.K. Reinforced Concrete: Mechanics and Design, 7th ed.; Pearson: Boston, MA, USA; Amsterdam, The Netherlands; London, UK, 2016; ISBN 978-1-292-10600-7.

- Bentur, A.; Diamond, S.; Berke, N.S. Steel Corrosion in Concrete: Fundamentals and Civil Engineering Practice, 1st ed.; E & FN Spon: London, UK, 1997; ISBN 0419225307.

- Hegger, J.; Voss, S. Investigations on the bearing behaviour and application potential of textile reinforced concrete. Eng. Struct. 2008, 30, 2050–2056.

- Friese, D.; Scheurer, M.; Hahn, L.; Gries, T.; Cherif, C. Textile reinforcement structures for concrete construction applications—A review. J. Compos. Mater. 2022, 56, 4041–4064.

- Rempel, S.; Kulas, C.; Will, N.; Bielak, J. Extremely Light and Slender Precast Pedestrian-Bridge Made Out of Textile-Reinforced Concrete (TRC). In High Tech Concrete: Where Technology and Engineering Meet; Hordijk, D.A., Luković, M., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 2530–2537. ISBN 978-3-319-59470-5.

- Kromoser, B.; Preinstorfer, P.; Kollegger, J. Building lightweight structures with carbon-fiber-reinforced polymer-reinforced ultra-high-performance concrete: Research approach, construction materials, and conceptual design of three building components. Struct. Concr. 2019, 20, 730–744.

- May, S.; Steinbock, O.; Michler, H.; Curbach, M. Precast Slab Structures Made of Carbon Reinforced Concrete. Structures 2019, 18, 20–27.

- Raupach, M.; Morales Cruz, C. Textile-Reinforced Concrete: Selected Case Studies. In Textile Fibre Composites in Civil Engineering; Elsevier: Amsterdam, The Netherlands, 2016; pp. 275–299. ISBN 9781782424468.

- O’Hegarty, R.; Kinnane, O. Review of precast concrete sandwich panels and their innovations. Constr. Build. Mater. 2020, 233, 117145.

- Tomoscheit, S.; Gries, T.; Horstmann, M.; Hegger, J. Project Life INSUSHELL: Reducing the Carbon Footprint in Concrete Construction. Int. J. Sustain. Build. Technol. Urban Dev. 2011, 2, 162–169.

- Shams, A.; Stark, A.; Hoogen, F.; Hegger, J.; Schneider, H. Innovative sandwich structures made of high performance concrete and foamed polyurethane. Compos. Struct. 2015, 121, 271–279.

- Adam, V.; Bielak, J.; Dommes, C.; Will, N.; Hegger, J. Flexural and Shear Tests on Reinforced Concrete Bridge Deck Slab Segments with a Textile-Reinforced Concrete Strengthening Layer. Materials 2020, 13, 4210.

- Koutas, L.N.; Tetta, Z.; Bournas, D.A.; Triantafillou, T.C. Strengthening of Concrete Structures with Textile Reinforced Mortars: State-of-the-Art Review. J. Compos. Constr. 2019, 23, 03118001.

- Tietze, M.; Kirmse, S.; Kahnt, A.; Schladitz, F.; Curbach, M. The ecological and economic advantages of carbon reinforced concrete—Using the C 3 result house CUBE especially the BOX value chain as an example. Civ. Eng. Des. 2022, 4, 79–88.

- Friese, D.; Mersch, J.; Hahn, L.; Cherif, C. (Eds.) Development of a Yarn Guiding and Impregnation Technology for Robot-Asissted Fiber Manufacturing of 3d Textile Reinforcement Structures; Zenodo: Honolulu, HI, USA, 2023.

- Michel, A.; Zernsdorf, K.; Mechtcherine, V. Mineral-bonded carbon fiber reinforcement for novel concrete construction technologies. In Proceedings of the International Textile Conference, Dresden, Germany, 28–29 November 2019; ADDITC 2019; Institute für Textilmaschinen und Textile Hochleistungswerkstofftechnik: Dresden, Germany, 2019; p. 84.

- Mechtcherine, V.; Michel, A.; Liebscher, M.; Schneider, K.; Großmann, C. Neue Carbonfaserbewehrung für digitalen automatisierten Betonbau. Beton Stahlbetonbau 2019, 114, 947–955.

- Minsch, N. Process and Method Development for the Generative Manufacturing of Complex Lightweight Structures in Hybrid Design. Ph.D. Thesis, Technische Universität Dresden, Dresden, Germany, 2018.

- Solly, J.; Frueh, N.; Saffarian, S.; Prado, M. ICD/ITKE Research Pavilion 2016/2017: Integrative Design of a Composite Lattice Cantilever. In Proceedings of the IASS 2018 Creativity in Structural Design, Cambridge, MA, USA, 16–20 July 2018.

- Mindermann, P.; Gil Pérez, M.; Knippers, J.; Gresser, G.T. Investigation of the Fabrication Suitability, Structural Performance, and Sustainability of Natural Fibers in Coreless Filament Winding. Materials 2022, 15, 3260.

- von Zuben, M.; Cherif, C. Robot based Technology for the Production Novel Resource-Saving and Cost-Efficient Textile Reinforcement Structures for Direct further Proceedings into Prefabricated Parts. In Proceedings of the 19th World Textile Conference on Textiles at the Crossroads, AUTEX2019, Ghent, Belgium, 11–15 June 2019.

- Mechtcherine, V.; Michel, A.; Liebscher, M.; Schneider, K.; Großmann, C. Mineral-impregnated carbon fiber composites as novel reinforcement for concrete construction: Material and automation perspectives. Autom. Constr. 2020, 110, 103002.

- Schneider, K.; Michel, A.; Liebscher, M.; Terreri, L.; Hempel, S.; Mechtcherine, V. Mineral-impregnated carbon fibre reinforcement for high temperature resistance of thin-walled concrete structures. Cem. Concr. Compos. 2019, 97, 68–77.

- Minsch, N.; Müller, M.; Gereke, T.; Nocke, A.; Cherif, C. Novel fully automated 3D coreless filament winding technology. J. Compos. Mater. 2018, 52, 3001–3013.

- Knippers, J. BUGA Faserpavillon: Bundesgartenschau Heilbronn. 2019. Available online: https://www.janknippers.com/de/archives/portfolio-type/faserpavillon-bundesgartenschau-heilbronn-2019 (accessed on 1 December 2021).

- Knippers, J.; Koslowski, V.; Solly, J.; Fildhuth, T. Modular coreless filament winding for lightweight systems in architecture. In Proceedings of the CICE 2016 8th International Conference on Fibre-Reinforced Polymer (FRP) Composites in Civil Engineering, Hong Kong, China, 14–16 December 2016; CICE: Hong Kong, China, 2016.

- Dörstelmann, M. FibR GmbH. Exhibition Architecture and Mobile Structures. Available online: https://www.fibr.tech/gallery (accessed on 23 November 2021).

- Gil Pérez, M.; Guo, Y.; Knippers, J. Integrative material and structural design methods for natural fibres filament-wound composite structures: The LivMatS pavilion. Mater. Des. 2022, 217, 110624.

- Minsch, N.; Herrmann, F.H.; Gereke, T.; Nocke, A.; Cherif, C. Analysis of Filament Winding Processes and Potential Equipment Technologies. Procedia CIRP 2017, 66, 125–130.

- Minsch, N.; Müller, M.; Gereke, T.; Nocke, A.; Cherif, C. 3D truss structures with coreless 3D filament winding technology. J. Compos. Mater. 2018, 53, 2077–2089.

- Friese, D.; Hahn, L.; Cherif, C. Biologically Inspiried Load Adapted 3D Textile Reinforcement Structures. Mater. Sci. Forum 2022, 1063, 101–110.

- Hawkins, W.J.; Herrmann, M.; Ibell, T.J.; Kromoser, B.; Michaelski, A.; Orr, J.J.; Pedreschi, R.; Pronk, A.; Schipper, H.R.; Shepherd, P.; et al. Flexible formwork technologies—A state of the art review. Struct. Concr. 2016, 17, 911–935.

- Bhat, S.; Dittel, G.; Knobel, A.; Gries, T. Investigation of the drapeability of elastic adapted Textile Reinforced Concrete Elements for double curved concrete elements. In Proceedings of the SAMPE 2022 Technical Proceedings, Charlotte, NC, USA, 23–26 May 2022; SAMPE: Diamond Bar, CA, USA, 2022.

- Mechtcherine, V.; Buswell, R.; Kloft, H.; Bos, F.P.; Hack, N.; Wolfs, R.; Sanjayan, J.; Nematollahi, B.; Ivaniuk, E.; Neef, T. Integrating reinforcement in digital fabrication with concrete: A review and classification framework. Cem. Concr. Compos. 2021, 119, 103964.

- Classen, M.; Ungermann, J.; Sharma, R. Additive Manufacturing of Reinforced Concrete—Development of a 3D Printing Technology for Cementitious Composites with Metallic Reinforcement. Appl. Sci. 2020, 10, 3791.

- Asprone, D.; Auricchio, F.; Menna, C.; Mercuri, V. 3D printing of reinforced concrete elements: Technology and design approach. Constr. Build. Mater. 2018, 165, 218–231.

- Marchment, T.; Sanjayan, J. Mesh reinforcing method for 3D Concrete Printing. Autom. Constr. 2020, 109, 102992.

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Law, R.; Gibb, A.; Thorpe, T. Hardened properties of high-performance printing concrete. Cem. Concr. Res. 2012, 42, 558–566.

- Panda, B.; Chandra Paul, S.; Jen Tan, M. Anisotropic mechanical performance of 3D printed fiber reinforced sustainable construction material. Mater. Lett. 2017, 209, 146–149.

- Neef, T.; Müller, S.; Mechtcherine, V. Integration of Mineral Impregnated Carbon Fibre (MCF) into Fine 3D-Printed Concrete Filaments. In Proceedings of the Third RILEM International Conference on Concrete and Digital Fabrication, Loughborough, UK, 27–29 June 2022; Buswell, R., Blanco, A., Cavalaro, S., Kinnell, P., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 397–403, ISBN 978-3-031-06115-8.

- Willmann, J.; Block, P.; Hutter, M.; Byrne, K.; Schork, T. Robotic Fabrication in Architecture, Art and Design 2018; Springer International Publishing: Cham, Switzerland, 2019; ISBN 978-3-319-92293-5.

- Taha, N.; Walzer, A.N.; Ruangjun, J. Robotic AeroCrete A novel robotic spraying and surface treatment technology for the production of slender reinforced concrete elements. In Blucher Design Proceedings. 37 Education and Research in Computer Aided Architectural Design in Europe and XXIII Iberoamerican Society of Digital Graphics, Joint Conference (N. 1), Porto, Portugal, 11–13 September 2019; Editora Blucher: São Paulo, Brazil, 2019; pp. 245–256.

- Nikravan, A.; Aydogan, O.G.; Dittel, G.; Scheurer, M.; Bhat, S.; Ozyurt, N.; Gries, T. Implementation of Continuous Textile Fibers in 3D Printable Cementitious Composite. In Building for the Future: Durable, Sustainable, Resilient; Ilki, A., Çavunt, D., Çavunt, Y.S., Eds.; Springer Nature: Cham, Switzerland, 2023; pp. 1243–1252. ISBN 978-3-031-32518-2.

- Lindemann, H.; Gerbers, R.; Ibrahim, S.; Dietrich, F.; Herrmann, E.; Dröder, K.; Raatz, A.; Kloft, H. Development of a Shotcrete 3D-Printing (SC3DP) Technology for Additive Manufacturing of Reinforced Freeform Concrete Structures. In Proceedings of the First RILEM International Conference on Concrete and Digital Fabrication—Digital Concrete 2018, Zurich, Switzerland, 10–12 September 2018; Wangler, T., Flatt, R.J., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 287–298, ISBN 978-3-319-99518-2.

- Mechtcherine, V.; Nerella, V.N.; Will, F.; Näther, M.; Otto, J. On-site, large-scale, monolithic 3D concrete printing. Constr Print Technol. 2020, 2, 14–22.

- Scheurer, M.; Dittel, G.; Gries, T. Potential for the Integration of Continuous Fiber-Based Reinforcements in Digital Concrete Production. In Proceedings of the Second RILEM International Conference on Concrete and Digital Fabrication, Online, 6–9 July 2020; Bos, F.P., Lucas, S.S., Wolfs, R.J., Salet, T.A., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 701–711, ISBN 978-3-030-49915-0.

- Dittel, G.; Scheurer, M.; Dringenberg, S.; Jitton, J.V.; Gries, T. Digital Concrete Production with Vertical Textile Reinforcement. Open Conf. Proc. 2022, 1, 35–43.

- Dittel, G.; Dringenberg, S.; Gries, T. Through Textile to Reinforced 3D Concrete Printing. In Building for the Future: Durable, Sustainable, Resilient; Ilki, A., Çavunt, D., Çavunt, Y.S., Eds.; Springer Nature: Cham, Switzerland, 2023; pp. 1094–1103. ISBN 978-3-031-32518-2.

- Lüling, C.; Biehl, S.; Tennert, R.; Dittel, G.; Chernyshova, M.; Gries, T. 6dTEX: Lightweight building components made of 3D textiles in combination with 3D printing. In Proceedings of the Powerskin Conference, Aachen, Germany, 8 December 2022; Auer, T., Knaack, U., Schneider, J., Hildebrand, L., Santucci, D., Eds.; Druckzentrum: Neumünster, Germany, 2022; pp. 119–134.

- Lüling, C.; Carl, T. Fuzzy 3D Fabrics & Precise 3D Printing: Combining Research with Design-Build Investigations. In Proceedings of the International Conference on Education and Research in Computer Aided Architectural Design in Europe 2022, Ghent, Belgium, 13–16 September 2022; eCAADe: Liverpool, UK, 2022.

- Neef, T.; Dittel, G.; Scheurer, M.; Gries, T.; Mechtcherine, V. Utilizing Textiles as Integrated Formwork for Additive Manufacturing with Concrete. In Building for the Future: Durable, Sustainable, Resilient; Ilki, A., Çavunt, D., Çavunt, Y.S., Eds.; Springer Nature: Cham, Switzerland, 2023; pp. 1285–1292. ISBN 978-3-031-32518-2.

- Spickenheuer, A.; Scheffler, C.; Bittrich, L.; Haase, R.; Weise, D.; Garray, D.; Heinrich, G. Tailored Fiber Placement in Thermoplastic Composites. TLS 2018, 1, 114–127.

- Lotte, S.-B.; Georgia, M.; Axel, K.; Suzuki, S. Tailoring Self-Formation fabrication and simulation of membrane-actuated stiffness gradient composites. In Proceedings of the IASS Symposium 2018—Creativity in Structural Design, Cambridge, MA, USA, 16–20 July 2018.

- Costalonga Martins, V.; Cutajar, S.; van der Hoven, C.; Baszyński, P.; Dahy, H. FlexFlax Stool: Validation of Moldless Fabrication of Complex Spatial Forms of Natural Fiber-Reinforced Polymer (NFRP) Structures through an Integrative Approach of Tailored Fiber Placement and Coreless Filament Winding Techniques. Appl. Sci. 2020, 10, 3278.

- Rihaczek, G.; Klammer, M.; Başnak, O.; Petrš, J.; Grisin, B.; Dahy, H.; Carosella, S.; Middendorf, P. Curved Foldable Tailored Fiber Reinforcements for Moldless Customized Bio-Composite Structures. Proof of Concept: Biomimetic NFRP Stools. Polymers 2020, 12, 2000.

More

Information

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.3K

Revisions:

2 times

(View History)

Update Date:

25 Oct 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No