| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Sonil Nanda | -- | 1880 | 2023-10-12 18:20:13 | | | |

| 2 | Lindsay Dong | Meta information modification | 1880 | 2023-10-16 02:12:58 | | | | |

| 3 | Lindsay Dong | Meta information modification | 1880 | 2023-10-23 05:18:22 | | |

Video Upload Options

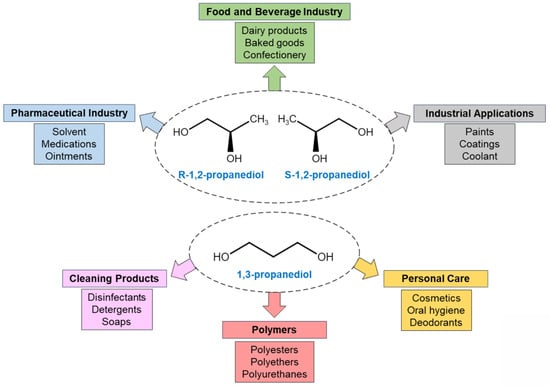

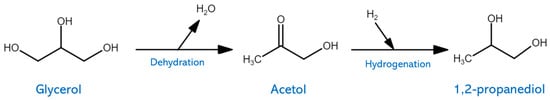

Significant research efforts have been focused on the catalytic transformation of glycerol for the synthesis of value-added chemicals owing to the rising prices of petroleum resources. Glycerol is an important byproduct due to its application to produce acrolein, glyceric acid, glycerol carbonate, and propanediol. Cu-based catalysts require the selective cleavage of the secondary C–O bond against the cleavage of the C–C bond in the hydrogenolysis of glycerol in order to produce 1,2-propanediol. Acid-catalyzed glycerol dehydration and metal-catalyzed intermediate hydrogenation are the two steps in glycerol hydrogenolysis. Glycerol hydrogenolysis has been primarily attempted in the liquid phase over different metal catalysts synthesized via the impregnation, co-precipitation, solid combustion and decomposition of metal–organic frameworks.

1. Introduction

Glycerol or glycerin is a valuable byproduct in biodiesel production. Biodiesel can generate about 10 wt% glycerol as the main byproduct using hydrolysis and transesterification reactions. Crude waste effluents produced from biodiesel refineries contain glycerol, water, methanol and free fatty acids as well as organic and inorganic salts [1]. Glycerol and its derivatives have found diverse value-added applications in many industrial sectors such as pharmaceuticals, personal care, food processing, resins, explosives, cellophane, detergents, fabrics and others.

Pure glycerol is a sugary, colorless, odorless, viscous, non-toxic, biodegradable and hygroscopic liquid at room temperature. It is completely soluble in water due to the presence of three hydroxyl groups. Although it is chemically stable, glycerol is a reactive molecule owing to the formation of primary and secondary aromatic compounds. The glycerol backbone is central to all lipids known as triglycerides. The thermophysical properties of glycerol and polyethylene glycol have been investigated based on the deep eutectic solvent [2]. It was found that the use of deep eutectic solvent increased the thermal conductivity of glycerol with increasing temperature. In another study conducted by Hu et al. [3], the density of crude glycerol samples changed due to the presence of fatty acids methyl esters and water. Furthermore, the viscosity of five crude glycerol samples varied between 15 and 1213 mPa.s owing to their different compositions.

2. Thermocatalytic Conversion of Glycerol to Propanediol

| Catalyst | Preparation Method | Process Conditions | Main Observations | Reference |

|---|---|---|---|---|

| 10Nb/Pd-Zr-Al | Impregnation |

|

|

Cai et al. [24] |

| 15Co0.5Cu/TiO2 | Co-impregnation |

|

|

Mondach et al. [25] |

| Copper carbide composite | Co-precipitation |

|

|

Liu et al. [23] |

| Cu/Al2O3 | Wet impregnation |

|

|

Azri et al. [26] |

| Cu/Mg-supported SiO2 | Chemisorption-hydrolysis |

|

|

Kumar et al. [27] |

| Cu-Al-Zn | Co-precipitation |

|

|

Mishra et al. [28] |

| CuNi30MgAl | Wet impregnation |

|

|

Mendonça et al. [29] |

| Ni/Dolomite | Impregnation |

|

|

Azri et al. [30] |

| Pt/WO3/zirconium phosphate | Sequential wet impregnation |

|

|

Bhowmik et al. [31] |

| Pt-In | Successive impregnation method |

|

|

Zhang et al. [12] |

| Ru-Cu/CaO-ZrO2 | Successive incipient wetness impregnation |

|

|

Salgado et al. [32] |

References

- Reddy, S.N.; Nanda, S.; Kozinski, J.A. Supercritical water gasification of glycerol and methanol mixtures as model waste residues from biodiesel refinery. Chem. Eng. Res. Des. 2016, 113, 17–27.

- Singh, A.; Walvekar, R.; Khalid, M.; Wong, W.Y.; Gupta, T.C.S.M. Thermophysical properties of glycerol and polyethylene glycol (PEG 600) based DES. J. Mol. Liquids 2018, 252, 439–444.

- Hu, S.; Luo, X.; Wan, C.; Li, Y. Characterization of crude glycerol from biodiesel plants. J. Agric. Food Chem. 2012, 60, 5915–5921.

- Restrepo, J.B.; Paternina-Arboleda, C.D.; Bula, A.J. 1,2-propanediol production from glycerol derived from biodiesel’s production: Technical and economic study. Energies 2021, 1, 5081.

- Grand View Research. Propylene Glycol Market Report. Available online: https://www.grandviewresearch.com/industry-analysis/propylene-glycol-market-report (accessed on 17 August 2023).

- Sun, Y.Q.; Shen, J.T.; Yan, L.; Zhou, J.J.; Jiang, L.L.; Chen, Y.; Xiu, Z.L. Advances in bioconversion of glycerol to 1,3-propanediol: Prospects and challenges. Process Biochem. 2018, 71, 134–146.

- Vivek, N.; Hazeena, S.H.; Alphy, M.P.; Kumar, V.; Magdouli, S.; Sindhu, R.; Pandey, A.; Binod, P. Recent advances in microbial biosynthesis of C3–C5 diols: Genetics and process engineering approaches. Bioresour. Technol. 2021, 322, 124527.

- Polaris Market Research. 1,3-Propanediol Market. Available online: https://www.polarismarketresearch.com/industry-analysis/1-3-propanediol-market (accessed on 17 August 2023).

- Bellè, A.; Kusada, K.; Kitagawa, H.; Perosa, A.; Castoldi, L.; Polidoro, D.; Selva, M. Carbon-supported WOx–Ru-based catalysts for the selective hydrogenolysis of glycerol to 1,2-propanediol. Catal. Sci. Technol. 2022, 12, 259–272.

- Miao, G.; Shi, L.; Zhou, Z.; Zhu, L.; Zhang, Y.; Zhao, X.; Sun, Y. Catalyst design for selective hydrodeoxygenation of glycerol to 1,3-propanediol. ACS Catal. 2020, 10, 15217–15226.

- Wang, S.; Jiang, J.; Gu, M.; Gao, F.; Shen, Z. Catalytic production of 1,2-propanediol from sucrose over a functionalized Pt/deAl-beta zeolite catalyst. RSC Adv. 2023, 13, 734–741.

- Zhang, X.; Cui, G.; Wei, M. PtIn alloy catalysts toward selective hydrogenolysis of glycerol to 1,2-propanediol. Ind. Eng. Chem. Res. 2020, 59, 12999–13006.

- Bauer, R.; du Toit, M.; Kossmann, J. Influence of environmental parameters on production of the acrolein precursor 3-hydroxypropionaldehyde by Lactobacillus reuteri DSMZ 20016 and its accumulation by wine lactobacilli. Int. J. Food Microbiol. 2010, 137, 28–31.

- Wischral, D.; Zhang, J.; Cheng, C.; Lin, M.; Souza, L.M.G.; Pessoa, F.L.P.; Yang, S.T. Production of 1,3-propanediol by Clostridium beijerinckii DSM 791 from crude glycerol and corn steep liquor: Process optimization and metabolic engineering. Bioresour. Technol. 2016, 212, 100–110.

- Pyne, M.E.; Sokolenko, S.; Liu, X.; Srirangan, K.; Bruder, M.R.; Aucoin, M.G.; Moo-Young, M.; Chung, D.A.; Chou, C.P. Disruption of the reductive 1,3-propanediol pathway triggers production of 1,2-propanediol for sustained glycerol fermentation by Clostridium pasteurianum. Appl. Environ. Microbiol. 2016, 82, 5375–5388.

- Yang, B.; Liang, S.; Liu, H.; Liu, J.; Cui, Z.; Wen, J. Metabolic engineering of Escherichia coli for 1,3-propanediol biosynthesis from glycerol. Bioresour. Technol. 2018, 267, 599–607.

- Wang, X.L.; Zhou, J.J.; Shen, J.T.; Zheng, Y.F.; Sun, Y.Q.; Xiu, Z.L. Sequential fed-batch fermentation of 1,3-propanediol from glycerol by Clostridium butyricum DL07. Appl. Microbiol. Biotechnol. 2020, 104, 9179–9191.

- Lama, S.; Seol, E.; Park, S. Development of Klebsiella pneumoniae J2B as microbial cell factory for the production of 1,3-propanediol from glucose. Metab. Eng. 2020, 62, 116–125.

- Wu, Y.; Lin, Y.H. Fermentation redox potential control on the 1,3-propanediol production by Lactobacillus panis PM1. Process Biochem. 2022, 114, 139–146.

- Wong, N.; Jantama, K. Engineering Escherichia coli for a high yield of 1,3-propanediol near the theoretical maximum through chromosomal integration and gene deletion. Appl. Microbiol. Biotechnol. 2022, 106, 2937–2951.

- Drożdżyńska, A.; Wawrzyniak, J.; Kubiak, P.; Przybylak, M.; Białas, W.; Czaczyk, K. Optimization and modeling of Citrobacter freundii AD119 growth and 1,3-propanediol production using two-step statistical experimental design and artificial neural networks. Sensors 2023, 23, 1266.

- Zhao, H.; Zheng, L.; Li, X.; Chen, P.; Hou, Z. Hydrogenolysis of glycerol to 1,2-propanediol over Cu-based catalysts: A short review. Catal. Today 2020, 355, 84–95.

- Liu, S.; Yu, Z.; Lu, C.; Wang, Y.; Sun, F.; Sun, Z.; Liu, Y.; Shi, C.; Wang, A. Copper carbide composite catalyst for hydrogenolysis of glycerol to 1,2-propanediol. Fuel 2023, 334, 126763.

- Cai, F.; Jin, F.; Hao, J.; Xiao, G. Selective hydrogenolysis of glycerol to 1,2-propanediol on Nb-modified Pd−Zr−Al catalysts. Catal. Comm. 2019, 131, 105801.

- Mondach, W.; Chanklang, S.; Somchuea, P.; Witoon, T.; Chareonpanich, M.; Faungnawakij, K.; Sohn, H.; Seubsai, A. Highly efficient TiO2-supported Co–Cu catalysts for conversion of glycerol to 1,2-propanediol. Sci. Rep. 2021, 11, 1.

- Azri, N.; Irmawati, R.; Nda-Umar, U.I.; Saiman, M.I.; Taufiq-Yap, Y.H. Effect of different supports for copper as catalysts on glycerol hydrogenolysis to 1,2-propanediol. J. King Saud Univ. Sci. 2021, 33, 101417.

- Kumar, P.; Shah, A.K.; Lee, J.H.; Park, Y.H.; Štangar, U.L. Selective hydrogenolysis of glycerol over bifunctional copper–magnesium-supported catalysts for propanediol synthesis. Ind. Eng. Chem. Res. 2020, 59, 6506–6516.

- Mishra, N.K.; Kumar, P.; Srivastava, V.C.; Štangar, U.L. Synthesis of Cu-based catalysts for hydrogenolysis of glycerol to 1,2-propanediol with in-situ generated hydrogen. J. Environ. Chem. Eng. 2021, 9, 105263.

- Mendonça, V.G.S.; Freitas, I.C.; Manfro, R.L.; Souza, M.M.V.M. Effect of MgO addition to Cu-Ni/Al2O3 catalysts on glycerol hydrogenolysis in continuous reactor without external hydrogen. Appl. Catal. A Gen. 2022, 645, 118838.

- Azri, N.; Irmawati, R.; Nda-Umar, U.I.; Saiman, M.I.; Taufiq-Yap, Y.H. Promotional effect of transition metals (Cu, Ni, Co, Fe, Zn)–supported on dolomite for hydrogenolysis of glycerol into 1,2-propanediol. Arab. J. Chem. 2021, 14, 103047.

- Bhowmik, S.; Enjamuri, N.; Darbha, S. Hydrogenolysis of glycerol in an aqueous medium over Pt/WO3/zirconium phosphate catalysts studied by 1H NMR spectroscopy. New J. Chem. 2021, 45, 5013–5022.

- Salgado, A.L.P.; Araújo, F.C.; Soares, A.V.H.; Xing, Y.; Passos, F.B. Glycerol hydrogenolysis over Ru-Cu bimetallic catalysts supported on modified zirconias. Appl. Catal. A Gen. 2021, 626, 118359.

- Kunthakudee, N.; Khemthong, P.; Luadthong, C.; Panpranot, J.; Mekasuwandumrong, O.; Witoon, T.; Faungnawakij, K. CuAl2O4–CuO–Al2O3 catalysts prepared by flame-spray pyrolysis for glycerol hydrogenolysis. Mol. Catal. 2022, 523, 111426.

- Wei, R.; Qu, X.; Xiao, Y.; Fan, J.; Geng, G.; Gao, L.; Xiao, G. Hydrogenolysis of glycerol to propanediols over silicotungstic acid catalysts intercalated with CuZnFe hydrotalcite-like compounds. Catal. Today 2021, 368, 224–231.

- Sharma, R.V.; Kumar, P.; Dalai, A.K. Selective hydrogenolysis of glycerol to propylene glycol by using Cu:Zn:Cr:Zr mixed metal oxides catalyst. Appl. Catal. A Gen. 2014, 477, 147–156.

- Pandey, D.K.; Singh, S.P.; Dalai, A.K.; Biswas, P. Kinetics of glycerol dehydration-hydrogenation reaction in the vapor phase in a fixed bed down flow tubular reactor over a bi-functional Cu-Zn/MgO catalyst. Catal. Today 2022, 404, 190–200.

- Khandelwal, K.; Boahene, P.; Nanda, S.; Dalai, A.K. Hydrogen production from supercritical water gasification of model compounds of crude glycerol from biodiesel industries. Energies 2023, 16, 3746.

- Okolie, J.A.; Tabat, M.E.; Gunes, B.; Epelle, E.I.; Mukherjee, A.; Nanda, S.; Dalai, A.K. A techno-economic assessment of biomethane and bioethanol production from crude glycerol through integrated hydrothermal gasification, syngas fermentation and biomethanation. Energy Convers. Manag. X 2021, 12, 100131.

- Yang, G.Y.; Shao, S.; Ke, Y.H.; Liu, C.L.; Ren, H.F.; Dong, W.S. PtAu alloy nanoparticles supported on thermally expanded graphene oxide as a catalyst for the selective oxidation of glycerol. RSC Adv. 2015, 5, 37112–37118.

- Tran, T.V.; Nguyen, D.T.C.; Nguyen, H.T.T.; Nanda, S.; Vo, D.V.N.; Do, S.T.; Nguyen, T.V.; Thi, T.A.D.; Bach, L.G.; Nguyen, T.D. Application of Fe-based metal-organic framework and its pyrolysis products for sulfonamide treatment. Environ. Sci. Pollut. Res. 2019, 26, 28106–28126.

- Zhang, X.; Cui, G.; Feng, H.; Chen, L.; Wang, H.; Wang, B.; Zhang, X.; Zheng, L.; Hong, S.; Wei, M. Platinum–copper single atom alloy catalysts with high performance towards glycerol hydrogenolysis. Nat. Comm. 2019, 10, 5812.

- Cong, W.J.; Nanda, S.; Li, H.; Fang, Z.; Dalai, A.K.; Kozinski, J.A. Metal-organic framework-based functional catalytic materials for biodiesel production: A review. Green Chem. 2021, 23, 2595–2618.

- Ke, Y.; Zhu, C.; Li, J.; Liu, H.; Yuan, H. Catalytic oxidation of glycerol over Pt supported on MOF-derived carbon nanosheets. ACS Omega 2022, 7, 46452–46465.

- Xiong, L.; Qi, H.; Zhang, S.; Zhang, L.; Liu, X.; Wang, A.; Tang, J. highly selective transformation of biomass derivatives to valuable chemicals by single-atom photocatalyst Ni/TiO2. Adv. Mater. 2023, 35, 2209646.

- Lari, G.M.; Pastore, G.; Haus, M.; Ding, Y.; Papadokonstantakis, S.; Mondelli, C.; Pérez-Ramírez, J. Environmental and economical perspectives of a glycerol biorefinery. Energy Environ. Sci. 2018, 11, 1012–1029.

- Loy, A.C.M.; Ng, W.L.; Samudrala, S.P.; Bhattacharya, S. Technical, economic, and environmental potential of glycerol hydrogenolysis: A roadmap towards sustainable green chemistry future. Sustain. Energy Fuels 2023, 7, 2653–2669.