Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Suzana Maria Loures de Oliveira Marcionilio | -- | 2234 | 2023-08-21 18:48:11 | | | |

| 2 | Dean Liu | -8 word(s) | 2226 | 2023-08-22 02:42:13 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Pimentel Prates, M.; De Oliveira Loures Marcionílio, S.M.; Borges Machado, K.; Medeiros De Araújo, D.; Martínez-Huitle, C.A.; Leão Arantes, A.L.; Ferreira Da Silva Gadêlha, J.E. Fenton. Encyclopedia. Available online: https://encyclopedia.pub/entry/48290 (accessed on 09 February 2026).

Pimentel Prates M, De Oliveira Loures Marcionílio SM, Borges Machado K, Medeiros De Araújo D, Martínez-Huitle CA, Leão Arantes AL, et al. Fenton. Encyclopedia. Available at: https://encyclopedia.pub/entry/48290. Accessed February 09, 2026.

Pimentel Prates, Matheus, Suzana Maria De Oliveira Loures Marcionílio, Karine Borges Machado, Danyelle Medeiros De Araújo, Carlos A. Martínez-Huitle, Arizeu Luiz Leão Arantes, José Eduardo Ferreira Da Silva Gadêlha. "Fenton" Encyclopedia, https://encyclopedia.pub/entry/48290 (accessed February 09, 2026).

Pimentel Prates, M., De Oliveira Loures Marcionílio, S.M., Borges Machado, K., Medeiros De Araújo, D., Martínez-Huitle, C.A., Leão Arantes, A.L., & Ferreira Da Silva Gadêlha, J.E. (2023, August 21). Fenton. In Encyclopedia. https://encyclopedia.pub/entry/48290

Pimentel Prates, Matheus, et al. "Fenton." Encyclopedia. Web. 21 August, 2023.

Copy Citation

The use of new technologies for the removal of pollutants from wastewater has become globally necessary due to the complexity and facilities defined by conventional treatments. Advanced oxidative processes, specifically the Fenton process, have become widely applied given their low cost and ease of use.

scientometrics

wastewater

advanced oxidative processes

pollution

1. Introduction

According to the 2017 UNESCO report on water-resource development [1] contemporary production and lifestyles are closely associated with strict demands for high drinking water quality, but production and lifestyle have led to serious water pollution. Therefore, the same report states that about 80% of the wastewater is still globally returned to the environment without adequate treatment. Then, to mitigate the resulting pollution, regulatory agencies currently require on-site treatment of generated effluents. Several technologies are used for effluent treatment, including filtration, reverse osmosis, adsorption, and coagulation–flocculation [2][3][4][5]. However, new processes are being established to compare the results and increase the efficiency of the removal of persistent, refractory, and nonbiodegradable pollutants, such as drugs, pesticides, dyes, organic solvents, phenols, oily effluents, and agroindustrial wastes, such as stillage [6][7].

To degrade certain types of pollutants, chemical treatment, which generates oxidizing agents, particularly hydroxyl radicals (•OH), must be used. Currently, the most effective methods for degrading organic pollutants in wastewater and contaminated soil are advanced oxidative processes (AOPs), which include the Fenton approach. The Fenton process produces •OH through a homogeneous reaction (takes place via the reaction from a mixture of hydrogen peroxide and ferrous salts). These oxidants are highly reactive and nonselective, reacting with a wide range of organic compounds and, consequently, degrading them into water, carbon dioxide, and inorganic ions [8]. For the by-products, the type of reaction that occurs between •OH and the intermediate products will depend on the structure of the target compound.

Treatment processes based on the Fenton reaction have been effectively applied to treat various types of industrial effluents and municipal sewage treatment plants, as a single-, pre- and/or post-treatment methods [9]. For example, it can be used to treat leachate from landfill, from vinasse, as post-treatment of biodigested vinasse, in the treatment of effluents from the wood industry, in the removal of endocrine disruptors as well as to remove other environmental micro pollutants from the pharmaceutical industry, from hospital wastes, from university laboratories, from pesticides residues, and others [9][10].

2. Time Trends in Studies Using Fenton

Considering WoS and Scopus databases, the search identified a total of 1073 and 1653 articles in indexed journals, respectively, until 2022, with the earliest indexed publication on the theme in Scopus dating back to 1992. Among these articles, 141 and 390 contained the term “Fenton” in their title but these did not employ the technique in their study. These papers were excluded from further analysis as they were not aligned with the objectives of this systematic review. In total, 932 and 1263 articles (WoS and Scopus databases, respectively) on the implementation of the Fenton technique to remove any form of pollutant were considered.

In regard to the use of the WoS database, it is important to indicate that WoS is mainly designed for researchers to find published literature, and it could be restricted for bibliometric studies. Then, it is not suitable to directly use all different types and levels of the WoS database for bibliometric study. For example, Data Citation Index, Derwent Innovations Index, Zoological Record, Social Sciences Citation Index, Arts & Humanities Citation Index, Conference Proceedings Citation Index—Social Sciences & Humanities, Book Citation Index—Social Sciences & Humanities, Current Chemical Reactions, and Index Chemicus. In fact, a minor number of articles was identified by the WoS search. Then, the information was collected once again with the same methodology previously used but the Scopus database was utilized.

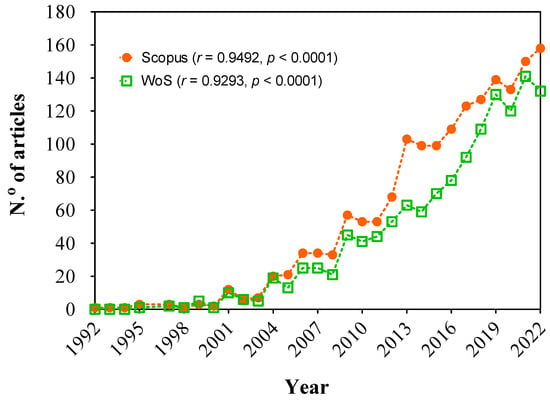

Comparing the results obtained in the two databases (Figure 1), it is observed that WoS is less comprehensive than Scopus. This may be due to the Scopus database having a larger, internationally diverse database as well as a range of intelligent tools that can be used to aid the research process, such as journal rankings, author profiles, the number of articles published by a journal in a given year, and the frequency of use of scientific terms. Therefore, Scopus was used to elaborate the systematic review, examining the results obtained. Additionally, WoS results were reported as Supplementary Materials (SM) in order to illustrate the similarities.

Figure 1. Comparison of the number of articles, between WoS and Scopus databases, using the same search methodology. Temporal trend in number of articles published in WoS and Scopus database.

Figure 1 illustrates the increase in the number of articles over time (Pearson’s r = 0.95 and 0.93, for WoS and Scopus databases, respectively, with p < 0.001); a more pronounced growth in publications is attained since 2013 and, notably, in the years 2020 and 2022.

The findings revealed a trend over a period of thirty years in which the number of publications featuring AOPs has increased. This pattern is consistent with the macro-level explorations of chemical, electrochemical, photochemical, and photoelectrochemical technologies designed to remove organic pollutants from wastewaters [11]. The growing demand for the treatment of effluents that contain complex and recalcitrant pollutants is driving the use of the Fenton method [12]. Furthermore, the Fenton process is a versatile technique that can be combined with other technologies, as highlighted by Ramos et al. (2021) [13], who described the use of Fenton in a systematic review on textile dye treatment. Fenton is a homogeneous reaction, which occurs via a chemical reaction of the mixture of Fe2+ and H2O2, which leads to the rise of homogeneous hydroxyl radicals (•OH) [9]. The use of Fenton is due to the growing demand for wastewater treatment containing increasingly complex and difficult to remove recalcitrant pollutants. It means that, with this type of oxidant, it is possible to treat different and varied ranges of residues, allowing for a low cost and reaction time, as well as avoiding the use of large technological devices [9].

From 2017 to 2022, researchers have incorporated statistical tools such as Takeuchi’s method using the Mini Tap program, as well as the response surface methodology (RSM) with designs including the Box–Behnken design, Box–Wilson statistical design, central composite design (CCD), Central Composite Design in MINITAB®16 software, and other arrangements, such as the orthogonal array test and single-factor experiments, orthogonal experiments, and the regression quadratic equation [14][15][16][17][18][19][20][21]. Furthermore, the use of new reaction forms has increased, as described below.

Table 1 displays the nine categories of pollutants that were degraded using Fenton during 1992–2022, across 1263 studies. Among these studies, 90 focused on the use of Fenton to concurrently degrade various compounds, specifically those falling under the categories of pharmaceuticals, hygiene/cleaning products, and dyes.

Table 1. Temporal trend in number of articles published between 1992 and 2022, and Pearson correlation (r) in relation to number of articles published per year × type of compounds degraded by Fenton.

| Variable | No. of Articles | r | p |

|---|---|---|---|

| No. of articles | 1263 | 0.93 | <0.001 |

| Dye | 227 | 0.85 | <0.001 |

| Drugs | 114 | 0.81 | <0.001 |

| Phenol | 62 | 0.81 | <0.001 |

| Organic compounds | 216 | 0.87 | <0.001 |

| Hygiene and cleaning | 11 | 0.42 | 0.02 |

| Pesticide | 22 | 0.59 | <0.001 |

| Inorganic compounds/metals | 40 | 0.82 | <0.001 |

| Vinasse | 5 | 0.32 | 0.09 |

| Other compounds | 418 | 0.69 | <0.001 |

The table above displays the results of studies that focused on the removal of pollutants using the Fenton technique. Among these studies, the majority focused on the removal of dyes (227; 18%), organic compounds (216; 17%), and pharmaceuticals (114; 9%); fewer were focused on removing phenol (62; 5%), inorganic compounds/metals (40; 3%), pesticides (22; 1.7%), hygiene and cleaning products (11; 0.87%), and vinasse (5; 0.39%). However, a large proportion of the studies (418; 33.1%) examined the use of the Fenton technique to remove a diverse range of other compounds, including solvents, polymers, organic molecules, wastewater from kitchens, dairies, slaughterhouses, tanneries, petroleum industry, mining, biodiesel, edible oil refineries, tertiary pulp treatment, wood industries and municipal effluents, bacteria, oilseed, and olive-oil industries [22][23]. Researchers noted an increase in the number of articles over time for all compounds evaluated (Table 1); however, this increase occurred to a greater extent for dyes (r = 0.85; p < 0.001), organic compounds (0.87, p < 0.001), pharmaceuticals (r = 0.81; p < 0.001), phenol (r = 0.81; p < 0.001), inorganic compounds/metals (r = 0.82, p < 0.001), pesticides (r =0.59; p < 0.001), hygiene and cleaning products (r = 0.42; p = 0.02), vinasse (r = 0.32; p = 0.09), and other types of specific composite products (r = 0.69; p < 0.001). These results are in agreement with the bibliometric analysis of WoS (see Figures S1 and S2 in the Supplementary Materials)

Regarding the treatment of wastewater with dyes, studies on this topic have increased in the last 10 years of the study period (2012–2022; r = 0.85 with time) [24][25][26]. Studies on the removal of organic compounds increased after 2015 (r = 0.87), showing that organic compounds were the most commonly used matrix in Fenton studies [27][28][29] in comparison with pharmaceuticals [30][31][32], phenols [33][34], pesticides [35][36], inorganic compounds [37][38], hygiene and cleaning products [39][40].

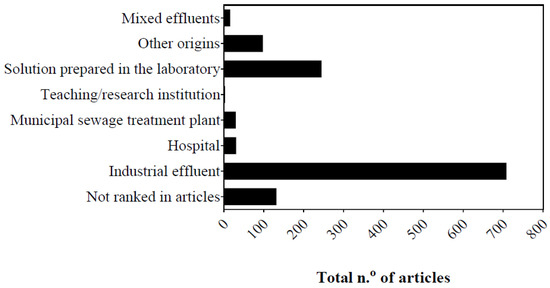

Figure 2 presents the sources of the pollutants listed in Table 1. However, 132 studies did not specify the origin of the treated matrix. Among those that were identified, 16 studies used the Fenton method to simultaneously degrade products from different sources, such as industrial effluent/laboratory-prepared solution (9), hospital effluent/laboratory-prepared solution (2), industrial effluent/other sources (1), industrial effluent/municipal wastewater treatment plant (WWTP) (1), and municipal WWTP/laboratory-prepared solution (2).

Figure 2. Temporal trend in number of articles published between 1992 and 2022 in Scopus database, considering origin of effluents degraded by Fenton.

Most researchers have used Fenton for the degradation of industrial compounds (708; 56%), followed by laboratory-prepared solutions (synthetic effluent) (245; 19%), and other specific sources (98; 7.7%), such as sewage treatment plants (30; 2.4%), hospital sources (31; 2.5%), and research or educational institutions (3; 0.23%).

The volume of studies also correlates with the evolution and growth in the use of industrial processes and technologies over time, substantially increasing from the 2000s onward (Figure 1). Additionally, the search for new tools for sustainable industrial development involves introducing less environmentally harmful disposal techniques and then improving these techniques.

3. Size and Reaction Conditions of Fenton Reaction Studies

Most studies on Fenton reactions have been conducted on the laboratory-bench scale, representing 98.3% of the studies analyzed, followed by those on the pilot and industrial scales. On the laboratory-bench scale, a smaller volume of effluent is used under controlled laboratory conditions, even though these effluents are representative of industrial effluents, as shown in Figure 2.

Only 1.3% of the analyzed publications were conducted on the pilot scale, which is a method used for limiting the problems experienced with laboratory-bench-scale studies. However, pilot-scale studies are hindered by the operational costs associated with their implementation and execution. For example, Ferreira et al., (2020) [41] discussed the effect in a pilot plant process combining Fenton reaction with other AOPs and, then, the results showed that these kind of combinations are promising options for reducing the water footprint of biorecalcitrant industrial wastewaters. Moreover, 0.07% of direct studies have been conducted on the industrial scale, 0.07% of studies have used a combination of scales, and 0.31% of the studies did not specify the scale used.

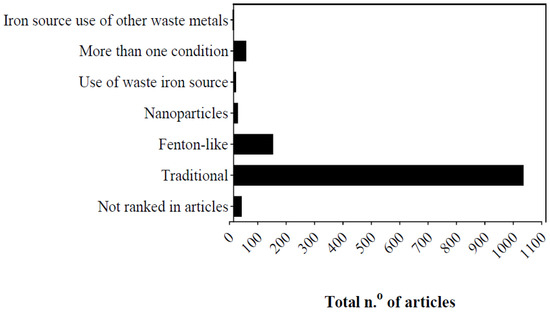

Most studies (80.9%) used traditional reaction conditions (1022), followed by Fenton-like reactions (140) (Figure 3).

Figure 3. Fenton reaction arrangements on 30-year time scale.

In the first case in Figure 3 on the y-axis, under ideal and optimized conditions, the compounds to be treated are catalytically oxidized in the presence of iron salts and hydrogen peroxide, in a pH range of 3.0 to 4.0. At values higher than 4.0, the rate of decomposition of hydrogen peroxide into water and oxygen markedly increases and the concentration of free iron species decreases due to the formation of iron complexes and precipitation of iron hydroxides. In the case of Fenton-like reactions, the catalyst can be other metals or complexes different from ferrous ion (Fe2+). Various monovalent and divalent cations and complexes have been considered, as noted by Jonshon and Mehrvar (2022). Researchers found that 0.87% of articles reported the use of Fe2+ ions from secondary sources, such as industrial WWTP and mining sludge, whereas 1.3% of articles reported the use of Fe nanoparticles. The type of iron (hydro)oxide, whether natural or synthetic, solid, ionic, complex, or nano, affects the mechanism of •OH formation. Researchers identified this information; according to Figure 3, the use of Fenton-like reactions with cation exchange, nanoparticles, and the combination of these conditions in the same treatment has been increasing. Pereira et al. (2012) [42] discussed catalytic forms of iron oxide [43], as well as other metal nanoparticles [44] and complex ions [45].

For pH values below 3.0, the formation of hydroxyl radicals decreases, which becomes nonexistent at pH 1.0 [46]. Under these standard conditions, the reaction time is shorter and, consequently, the removal of compounds is lower compared with those of other AOPs [47]. Notably, only under acidic conditions does the •OH radical dominate, which favors the chemical oxidation process. Moreover, under normal reaction conditions, a certain amount of flocculated material accumulates, which is subsequently removed by decantation, due to the formation and complexation of iron salts [48] and the formation of highly valent oxidizing species, such as FeO3+ (Fe (V)) and the ferryl ion, FeO2+ (Fe (IV)) [49]. The concentration of hydrogen peroxide in the reaction must also be evaluated, as the excessive use of hydrogen peroxide in the reaction medium acts as a scavenger of hydroxyl radicals. The concentration of iron ions is also important for the process, ranging from 3 to 15 mg/L as, under the above conditions, the scavenging of hydroxyl radicals occurs, which decreases the efficiency of the reaction [50].

In a single study, different reactive means can be combined with the aim of comparing their efficacy. Researchers found that in 3.5% of the cases, the efficiencies of the traditional Fenton reaction, Fenton-like reactions, and parallel-shaped nanoparticles were tested in comparison with that of a single process.

Regarding the amount of organic matter removed, in the majority of studies, 884, more than 50% of the COD and TOC, was removed. However, only 30 studies reported that the Fenton treatment removed less than 50% of the COD and/or TOC, which was also reported in the literature [51]. For 349 studies, the reduction in COD and/or TOC was not reported.

References

- Boretti, A.; Rosa, L. Reassessing the projections of the World Water Development Report. Clear. Water 2019, 2, 15.

- Khaya, P.S.; Babatunde, F.B.; Joseph, K.B. The Treatment Effect of Chemical Coagulation Process in South African Brewery Wastewater: Comparison of Polyamine and Aluminum-Chlorohydrate coagulants. Comparison of Polyamine and Aluminum-Chlorohydrate coagulants. Water 2022, 14, 2495.

- Konradt, N.; Kuhlen, J.G.; Rohns, H.-P.; Schmitt, B.; Fischer, U.; Binder, T.; Schumacher, V.; Wagner, C.; Kamphausen, S.; Müller, U.; et al. Removal of Trace Organic Contaminants by Parallel Operation of Reverse Osmosis and Granular Activated Carbon for Drinking Water Treatment. Membranes 2021, 11, 33.

- Dharupaneedi, S.P.; Sanna, K.N.; Mallikarjuna, N.; Kakarla, R.R.; Shyam, S.S.; Tejraj, M.A. Membrane-based separation of potential emerging pollutants. Sep. Purif. Technol. 2019, 210, 850–866.

- Mayer, F.; Bhandari, R.; Gäth, S. Critical review on life cycle assessment of conventional and innovative waste-to-energy technologies. Sci. Total Environ. 2019, 672, 708–721.

- Saravanan, A.; Deivayanai, V.C.; Senthil Kumar, P.; Rangasamy, G.; Hemavathy, R.V.; Harshana, T.; Gayathri, N.; Alagumalai, K. A detailed review on advanced oxidation process in treatment of wastewater: Mechanism, challenges and future outlook. Chemosphere 2022, 308, 136524.

- Yu, H.Y.; Jenn, F.S.; Yujen, S.; Jianmin, W.; Po, Y.W.; Chin, P.H. Hazardous wastes treatment technologies. Water Environ. Res. 2020, 92, 1833–1860.

- Lyngsie, G.; Krumina, L.; Tunlid, A.; Persson, P. Generation of hydroxyl radicals from reactions between a dimethoxyhydroquinone and iron oxide nanoparticles. Sci. Rep. 2018, 8, 10834.

- Nidheesh, P.V.; Ganiyu, S.O.; Martínez-Huitle, C.A.; Mousset, E.; Olvera-Vargas, H.; Trellu, C.; Zhou, M.; Oturan, M.A. Recent advances in electro-Fenton process and its emerging applications. Crit. Rev. Environ. Sci. Technol. 2023, 53, 887–913.

- Deng, F.; Jiang, J.; Sirés, I. State-of-the-art review and bibliometric analysis on electro-Fenton process. Carbon Lett. 2022, 33, 17–34.

- Brillas, E. A review on the photoelectro-Fenton process as efficient electrochemical advanced oxidation for wastewater remediation. Treatment with UV light, sunlight, and coupling with conventional and other photo-assisted advanced technologies. Chemosphere 2020, 250, 126198.

- Diaw, P.A.; Oturan, N.; Gaye Seye, M.D. Removal of the herbicide monolinuron from waters by the electro-Fenton treatment. J. Electroanal. Chem. 2020, 864, 114087.

- Ramos, M.D.N.; Santana, C.S.; Velloso, C.C.V.; da Silva, A.H.M.; Magalhães, F.M.; Aguiar, A. A review on the treatment of textile industry effluents through Fenton processes. Process Saf. Environ. Prot. 2021, 155, 366–386.

- Bu, J.; Liu, H.; Lin, C. Fenton’s reagent-enhanced supercritical water oxidation of wastewater released from 3-hydroxypyridine production. RSC Adv. 2019, 9, 29317–29326.

- Varank, G.; Yazici, G.S.; Demir, A. A comparative study of electrocoagulation and electro-Fenton for food industry wastewater treatment: Multiple response optimization and cost analysis. Sep. Sci. Technol. 2018, 53, 2727–2740.

- Ibarra-Taquez, H.N.; Dobrosz-Gómez, I.; Gómez, M.-Á. Optimización Multiobjetivo del Proceso Fenton en el Tratamiento de Aguas Residuales provenientes de la Producción de Café Soluble. Inf. Tecnol. 2018, 29, 111–122.

- Ajmi, K.; Vismara, E.; Manai, I.; Haddad, M.; Hamdi, M.; Bouallagui, H. Polyvinyl acetate processing wastewater treatment using combined Fenton’s reagent and fungal consortium: Application of central composite design for conditions optimization. J. Hazard. Mater. 2018, 358, 243–255.

- Dwivedi, K.; Morone, A.; Chakrabarti, T.; Pandey, R.A. Evaluation and optimization of Fenton pretreatment integrated with granulated activated carbon (GAC) filtration for carbamazepine removal from complex wastewater of pharmaceutical industry. J. Environ. Chem. Eng. 2018, 6, 3681–3689.

- Abedinzadeh, N.; Shariat, M.; Monavari, S.M.; Pendashteh, A. Evaluation of color and COD removal by Fenton from biologically (SBR) pre-treated pulp and paper wastewater. Process Saf. Environ. Prot. 2018, 116, 82–91.

- Cheng, Y.; Chen, Y.; Lu, J.; Nie, J.; Liu, Y. Fenton treatment of bio-treated fermentation-based pharmaceutical wastewater: Removal and conversion of organic pollutants as well as estimation of operational costs. Environ. Sci. Pollut. Res. 2018, 25, 12083–12095.

- Gilpavas, E.; Arbeláez-Castaño, P.E.; Medina-Arroyave, J.D.; Gómez-Atehortua, C.M. Tratamiento de aguas residuales de la industria textil mediante coagulación química acoplada a procesos fenton intensificados con ultrasonido de baja frecuencia. Rev. Int. Contam. Ambient. 2018, 34, 157–167.

- Ben Ayed, S.; Azam, M.; Al-Resayes, S.I.; Ayari, F.; Rizzo, L. Cationic Dye Degradation and Real Textile Wastewater Treatment by Heterogeneous Photo-Fenton, Using a Novel Natural Catalyst. Catalysts 2021, 11, 1358.

- Oñate, J.; Arenas, A.; Ruiz, A.; Rivera, K.; Pelaez, C. Evaluation of Mutagenic and Genotoxic Activity in Vinasses Subjected to Different Treatments. Water Air Soil Pollut. 2015, 226, 144.

- Ghosh, K.; Ghosh, J.; Giri, P.K. Accordion-like multilayered two-dimensional Ti3C2TxMXenes for catalytic elimination of organic dyes from wastewater via the Fenton reaction. ACS Appl. Nano Mater. 2022, 5, 16451–16461.

- Yan, X.; Li, H.; Feng, J.; Hou, B.; Yan, W.; Zhou, M. Activated Carbon Assisted Fenton-like Treatment of Wastewater Containing Acid Red G. Catalysts 2022, 12, 1358.

- Miao, S.; Gao, H.; Xia, H.; Mao, X.; Zhang, L.; Shi, M.; Zhang, Y. Accelerated Fenton degradation of azo dye wastewater via a novel Z-scheme CoFeN-g-C3N4 heterojunction photocatalyst with excellent charge transfer under visible light irradiation. Dalton Trans. 2022, 51, 17192–17202.

- Sanabria, P.; Scunderlick, D.; Wilde, M.L.; Lüdtke, D.S.; Sirtori, C. Solar photo-Fenton treatment of the anti-cancer drug anastrozole in different aqueous matrices at near-neutral pH: Transformation products identification, pathways proposal, and in silico (Q)SAR risk assessment. Sci. Total Environ. 2021, 754, 142300.

- Shen, X.; Cai, Z.; Hu, J.; Sun, B. Highly Efficient Microwave-Assisted Fenton Degradation of Toluene Nitration Wastewater over Microwave-Responsive Catalyst of Fe3O4−BiOCl. Chem. Sel. 2022, 7, e202200804.

- Lin, Z.; Zhang, C.; Su, P.; Lu, W.; Zhang, Z.; Wang, X.; Hu, W. Fenton Process for Treating Acrylic Manufacturing Wastewater: Parameter Optimization, Performance Evaluation, Degradation Mechanism. Water 2022, 14, 2913.

- Yazdanbakhsh, A.R.; Mohammadi, A.S.; Alinejad, A.A.; Hassani, G.; Golmohammadi, S.; Mohseni, S.M.; Sardar, M.; Sarsangi, V. Reduction of non-Betalactam Antibiotics COD by Combined Coagulation and Advanced Oxidation Processes. Water Environ. Res. 2016, 88, 2121–2131.

- Nisapai, W.; Paikamnam, A.; Sriprom, P.; Neramittagapong, S.; Theerakulpisut, S.; Lin, C.; Neramittagapong, A. Degradation of Penicillin G contaminant in synthesized wastewater by Fenton-like reaction. Eng. Appl. Sci. Res. 2022, 49, 622–629.

- Yang, K.; Liu, M.; Weng, X.; Owens, G.; Chen, Z. Fenton-like oxidation for the simultaneous removal of estrone and β-estradiol from wastewater using biosynthesized silver nanoparticles. Sep. Purif. Technol. 2022, 285, 120304.

- Li, H.; Liu, X.; Chen, X.; Chen, Y.; Li, Y.; Motkuri, R.K.; Dai, Z.; Kumar, A.; Fang, T.; Shen, J. Novel catalysts with multivalence copper for organic pollutants removal from wastewater with excellent selectivity and stability in Fenton-like process under neutral pH conditions. Water Environ. Res. 2022, 94, e10816.

- Hassan, A.A.; Gheni, S.A.; Ahmed, S.M.R.; Abdullah, G.H.; Harvey, A. Aromatic free Fenton process for rapid removal of phenol from refinery wastewater in an oscillatory baffled reactor. Arab. J. Chem. 2022, 15, 103635.

- Berberidou, C.; Kokkinos, P.; Poulios, I.; Mantzavinos, D. Homogeneous photo-Fenton degradation and mineralization of model and simulated pesticide wastewaters in lab- and pilot-scale reactors. Catalysts 2022, 12, 1512.

- Lin, S.; Lu, Y.; Ye, B.; Zeng, C.; Liu, G.; Li, J.; Luo, H.; Zhang, R. Pesticide wastewater treatment using the combination of the microbial electrolysis desalination and chemical-production cell and Fenton process. Front. Environ. Sci. Eng. 2019, 14, 12.

- Liu, W.; Yu, Y. A novel strategy for treating chromium complex wastewater: The combination of a Fenton-like reaction and adsorption using cobalt/iron-layered double hydroxide as catalyst and adsorbent. J. Clean. Prod. 2022, 370, 133337.

- Arita, S.; Agustina, T.E.; Ilmi, N.; Pranajaya, V.D.W.; Gayatri, R. Treatment of laboratory wastewater by using Fenton reagent and combination of coagulation-adsorption as pretreatment. J. Ecol. Eng. 2022, 23, 8210–8220.

- Cüce, H.; Aydin Temel, F. Classical-Fenton and photo-Fenton oxidation of wastewater arising from cosmetic automobile care products. Environ. Prog. Sustain. Energy 2021, 40, e13701.

- Riadi, L.; Tanuwijaya, A.D.; Je, R.R.; Altway, A. Fenton’s Oxidation of Personal Care Product (PCP) Wastewater: A Kinetic Study and the Effects of System Parameters. Int. J. Technol. Manag. 2021, 12, 298–308.

- Ferreira, L.C.; Salmerón, I.; Peres, J.A.; Tavares, P.B.; Lucas, M.S.; Malato, S. Advanced Oxidation Processes as sustainable technologies for the reduction of elderberry agro-industrial water impact. Water Resour. Ind. 2020, 24, 100137.

- Pereira, M.; Oliveira, L.; Murad, E. Iron oxide catalysts: Fenton and Fenton-like reactions—A review. Clay Miner. 2012, 47, 285–302.

- Xu, Y.; Guo, X.; Zha, F.; Tang, X.; Tian, H. Efficient photocatalytic removal of orange II by a Mn3O4-FeS2/Fe2O3 heterogeneous catalyst. J. Environ. Manag. 2020, 253, 109695.

- Kumar, S.; Alka; Tarun; Saxena, J.; Bansal, C.; Kumari, P. Visible light-assisted photodegradation by silver tungstate-modified magnetite nanocomposite material for enhanced mineralization of organic water contaminants. Appl. Nanosci. 2020, 10, 1555–1569.

- Fu, D.M.; Messele, S.A.; Fortuny, A.; Stuber, F.; Fabregat, A.; Font, J.; Bengoa, C. Efficient elimination of tyrosol in a zero valent iron-EDTA system at mild conditions. Chem. Eng. J. 2015, 260, 199–208.

- Sirés, I.; Brillas, E. Upgrading and expanding the electro-Fenton and related processes. Curr. Opin. Electrochem. 2021, 27, 100686.

- Chen, Y.; Cheng, Y.; Guan, X. A Rapid Fenton treatment of bio-treated dyeing and finishing wastewater at second-scale intervals: Kinetics by stopped-flow technique and application in a full-scale plant. Relat. Cient. 2019, 9, 9689.

- Fischbacher, A.; Sonntag, C.; von Schmidt, T.C. Hydroxyl radical yields in the Fenton process under various pH, ligand concentrations and hydrogen peroxide/Fe(II) ratios. Chemosphere 2017, 182, 738–744.

- Peng, L.; Duan, X.; Shang, Y.; Gao, B.; Xu, X. Engineered carbon supported single iron atom sites and iron clusters from Fe-rich Enteromorpha for Fenton-like reactions via nonradical pathways. Appl. Catal. B 2021, 287, 119963.

- Ebrahiem, E.E.; Al-Maghrabi, M.N.; Mobarki, A.R. Removal of organic pollutants from industrial wastewater by applying photo-Fenton oxidation technology. Arab. J. Chem. 2017, 10, S1674–S1679.

- Lisiée, M.; Gonçalves, P.; Eugênia, O.F.; Ostroski, I.C. Cosmetic wastewater primary treatment by fenton process and final polishing adsorption. Rev. Eletrôn. Gest. Educ. Tecnol. Ambient. 2020, 24, e13.

More

Information

Subjects:

Green & Sustainable Science & Technology

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

969

Revisions:

2 times

(View History)

Update Date:

22 Aug 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No