Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Marcin Kolodziejski | -- | 4915 | 2023-03-19 10:09:04 | | | |

| 2 | Catherine Yang | Meta information modification | 4915 | 2023-03-20 02:11:50 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Kolodziejski, M.; Michalska-Pozoga, I. Marine Battery Energy Storage Systems on Ships. Encyclopedia. Available online: https://encyclopedia.pub/entry/42324 (accessed on 01 March 2026).

Kolodziejski M, Michalska-Pozoga I. Marine Battery Energy Storage Systems on Ships. Encyclopedia. Available at: https://encyclopedia.pub/entry/42324. Accessed March 01, 2026.

Kolodziejski, Marcin, Iwona Michalska-Pozoga. "Marine Battery Energy Storage Systems on Ships" Encyclopedia, https://encyclopedia.pub/entry/42324 (accessed March 01, 2026).

Kolodziejski, M., & Michalska-Pozoga, I. (2023, March 19). Marine Battery Energy Storage Systems on Ships. In Encyclopedia. https://encyclopedia.pub/entry/42324

Kolodziejski, Marcin and Iwona Michalska-Pozoga. "Marine Battery Energy Storage Systems on Ships." Encyclopedia. Web. 19 March, 2023.

Copy Citation

The shipping industry is going through a period of technology transition that aims to increase the use of carbon-neutral fuels. There is a significant trend of vessels being ordered with alternative fuel propulsion. Shipping’s future fuel market will be more diverse, reliant on multiple energy sources. One of very promising means to meet the decarbonisation requirements is to operate ships with sustainable electrical energy by integrating local renewables, shore connection systems and battery energy storage systems (BESS).

battery energy storage systems

ship hybrid/electric propulsion

ship propulsion electrification

1. Hybrid-Electric Propulsion in the Offshore Industry

One of the first ships with battery/hybrid propulsion was Viking Lady (Figure 1). She was purposely built as the research ship for the FellowSHIP research program. The program was established in collaboration between Eidesvik, Wärtsilä Norway and DNV GL. The main purpose of the project was to explore the use of fuel cells, hybrid and battery technology in the shipping industry. It took place from 2003 to 2018; however, the initial phases were dedicated to research on fuel cells.

Figure 1. The offshore supply vessel Viking Lady [1].

Research on BESS commenced in 2011. The aim of this part of the project was to investigate how the introduction of energy storage (lithium-ion battery) in the propulsion system can improve efficiency and performance, reducing emissions simultaneously. The propulsion system of the Viking Lady was converted to a battery hybrid-electric system. The conversion included the installation of a 442 kWh Li-ion battery to the power system (Figure 2).

Figure 2. Battery-hybrid propulsion system on board the Viking Lady [2].

The main aim of this phase of the FellowSHIP project was to develop the hybrid-electric design concepts and to carry out the measurements and tests of the battery system during the ship’s operation and subsequently to promote marine hybrid battery systems [2][3]. The results of the research were very promising [4]:

-

Fuel consumption was reduced by 10–15%;

-

NOX emissions were reduced by 25%;

-

GHG emissions were reduced by 30%;

-

Maintenance costs were reduced due via:

- −

-

Substantial decrease in engine running hours;

- −

-

Minimized low load running;

- −

-

Extended intervals between major overhauls;

- −

-

Limited unplanned maintenance.

-

Improved machinery performance, utilization and flexibility.

Windfarm support vessels are another segment of the maritime industry that will benefit from BESS as a means of propulsion. There are several types of ships involved in activities related to windfarm operation. Service operation vessels (SOV) are designed for repair duties and maintenance activities required to keep wind turbines in operation. They are also used to transport cargo and personnel between windfarms and shore-based support facilities. Another type of vessel involved in windfarm construction is the wind turbine installation vessel (WTIV). As the name suggests, this type of vessel is used for installation of new wind turbines. Usually, WTIV is a jack-up platform equipped with a dynamic positioning system, cranes and a large deck area, which allows installation of more than 10 turbines per outing. Cable-laying vessels (CLV) also play an important role in the installation of new windfarms. They are usually diesel-electric dynamic positioning vessels, similar to those used in the oil and gas industry. Crew transfer vessels are specialised short-range vessels that transport personnel daily to and from windfarms. Usually, they are high-speed catamarans. Windfarm support vessels have very similar operational characteristics to offshore platform support vessels—similar to them, they are often dynamic positioning vessels. Savings on fuel and maintenance is similar to those of platform support vessels.

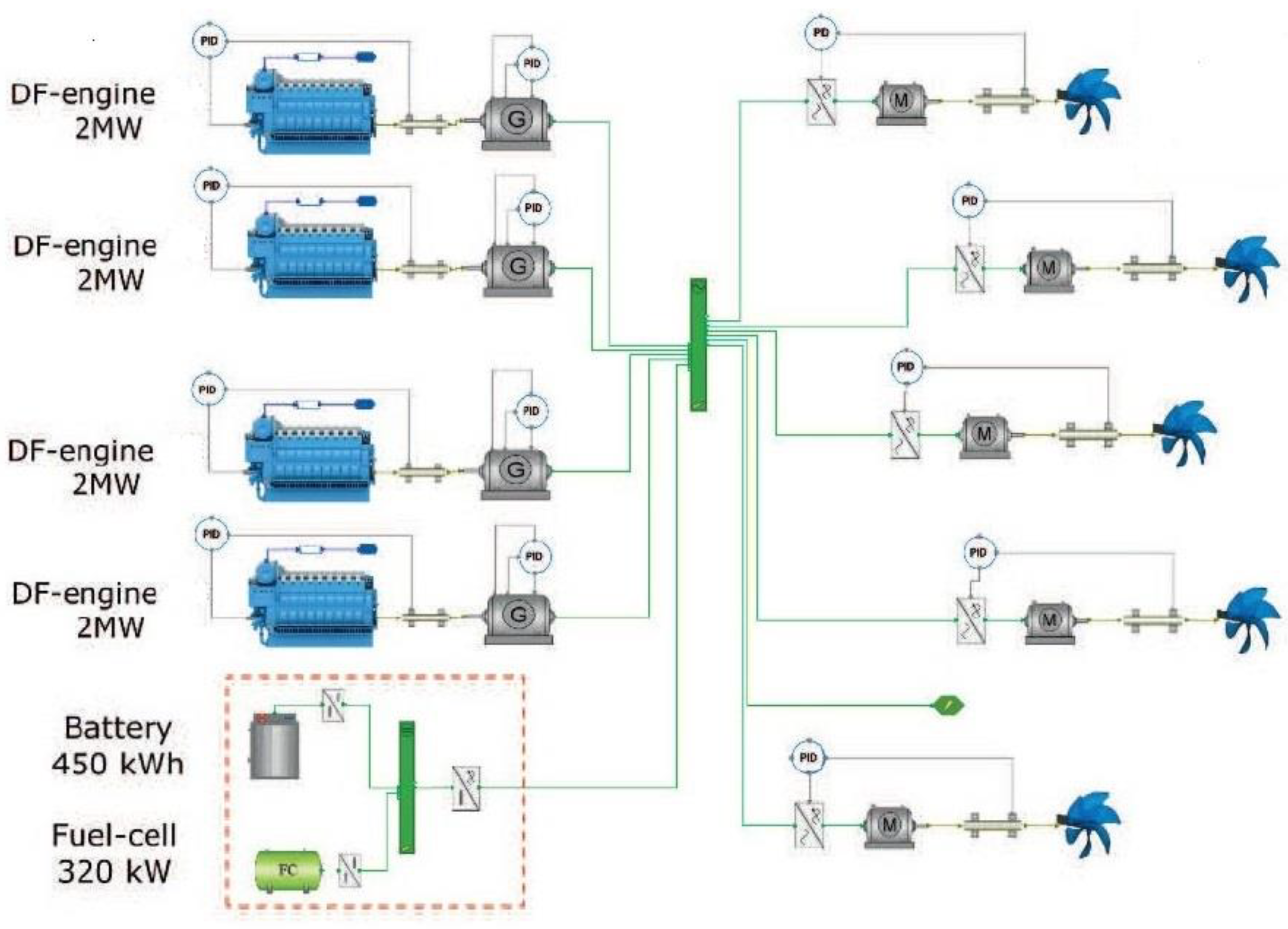

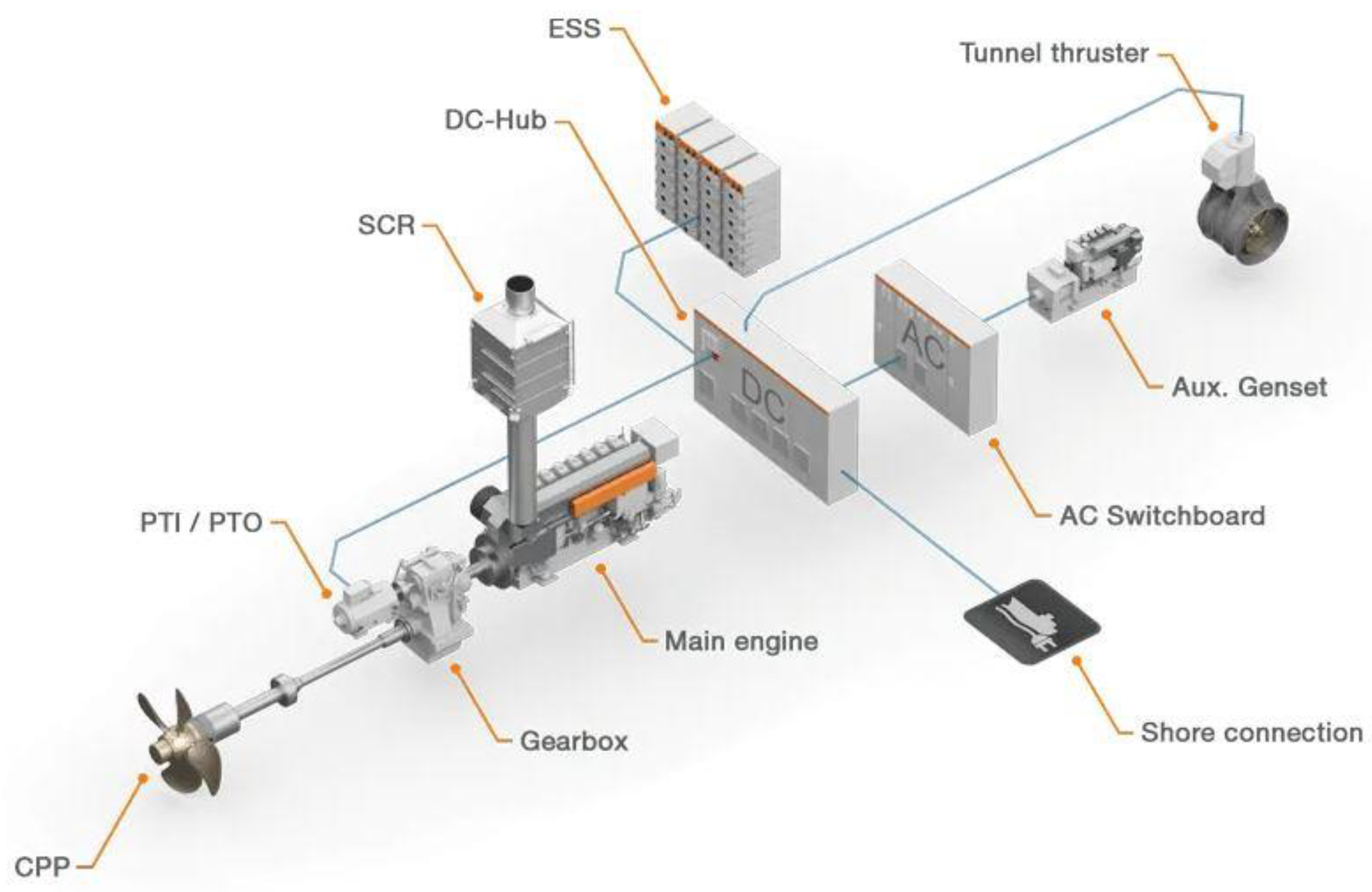

There are projects to implement hybrid propulsion/BESS on shuttle tankers too. Shuttle tankers are an alternative to pipelines for transporting crude oil from offshore to onshore facilities. Approximately 50% of oil in the North Sea is shipped onshore onboard shuttle tankers. Conventional shuttle tanker propulsion consists of two-stroke diesel engines used for propulsion during transit. Four-stroke auxiliary engines are used to provide power for the thruster system used during dynamic positioning. Today, due to an aging fleet, almost 40 per cent of shuttle tankers operating in the North Sea are due to be renewed. A hybrid propulsion system based on a combination of diesel, gas, electric and BESS offers shuttle tankers the perfect system to meet the requirements of various operation modes (mainly transit and dynamic positioning when loading offshore). Operational flexibility from an efficient propulsion system, unmatched manoeuvring capabilities and high redundancy are essential to ensuring safe operation of the vessel. Figure 3 shows the typical setup of a diesel/gas electric battery hybrid propulsion system.

Figure 3. Typical setup of a diesel/gas electric battery hybrid propulsion system [5].

A diesel electric propulsion can be powered by diesel/dual fuel driven generator sets or by the installed BESS. The batteries provide a dynamic system that allows for electric propulsion powered by BESS and peak-shaving. This system also increases propulsion redundancy. A diesel–electric hybrid system can also reduce the running hours of the engines and reduce maintenance-related expenditure.

One of the first e-shuttle tankers, Aurora Spirit, was delivered in January 2021. The ship has a length of 177 m, draft of 16.5 m and beam of 46 m. Its gross tonnage is 90,000 t and it can carry 137,500 m3 of cargo. The 130,000 dwt hybrid vessel with batteries operates on both liquefied natural gas (LNG) as the primary fuel, and a mixture of LNG and recovered volatile organic compounds (VOCs) as secondary fuel. A battery system supplying power to the thrusters also makes the vessel unique in its segment. In a conventional propulsion system, the propeller is rotated by a combustion engine through a shaft linking engine with the propeller, Aurora Spirit’s engines feed the ship electric grid and excess power is stored in the batteries. The efficiency of the system is improved due to electric propulsion; the requirement for the mechanical power can be reduced by 14%, which reduces the overall fuel consumption compared with conventional power distribution systems [6]. The ship reduced CO2 emissions by over 40 per cent. NOx emissions were reduced by over 80 per cent. SOx emissions were eliminated by nearly 100 per cent compared to traditional shuttle tankers [7]. With batteries installed, the hybrid energy system supports the power management system. The energy stored in the batteries allows the engines to be operated in a load region where fuel consumption is optimal (with highest efficiency). The batteries manage the dynamic load changes and the engines operate at constant optimal and stable load. Engines can also operate at high load with no need to start additional generators due to sudden load increase [6]. Those load increases are compensated for with energy from the batteries. The battery-powered propulsion system integrates the Corvus Orca energy storage system (ESS) with 610 kWh capacity. Aurora Spirit’s sea trials confirmed that its batteries offset the load on the engines [8].

2. Electric Propulsion Ferries

One of the first commercial electric vessel projects developed in Norway was a ferry that was required to improve by at least 20% of energy/environment efficiency compared with a conventional propulsion vessel. The ferry, MF Ampere, shown on Figure 4, was the world’s first large-size all-electric battery-powered car ferry at the time.

Figure 4. MF AMPERE—the world’s first all-electric car ferry [9].

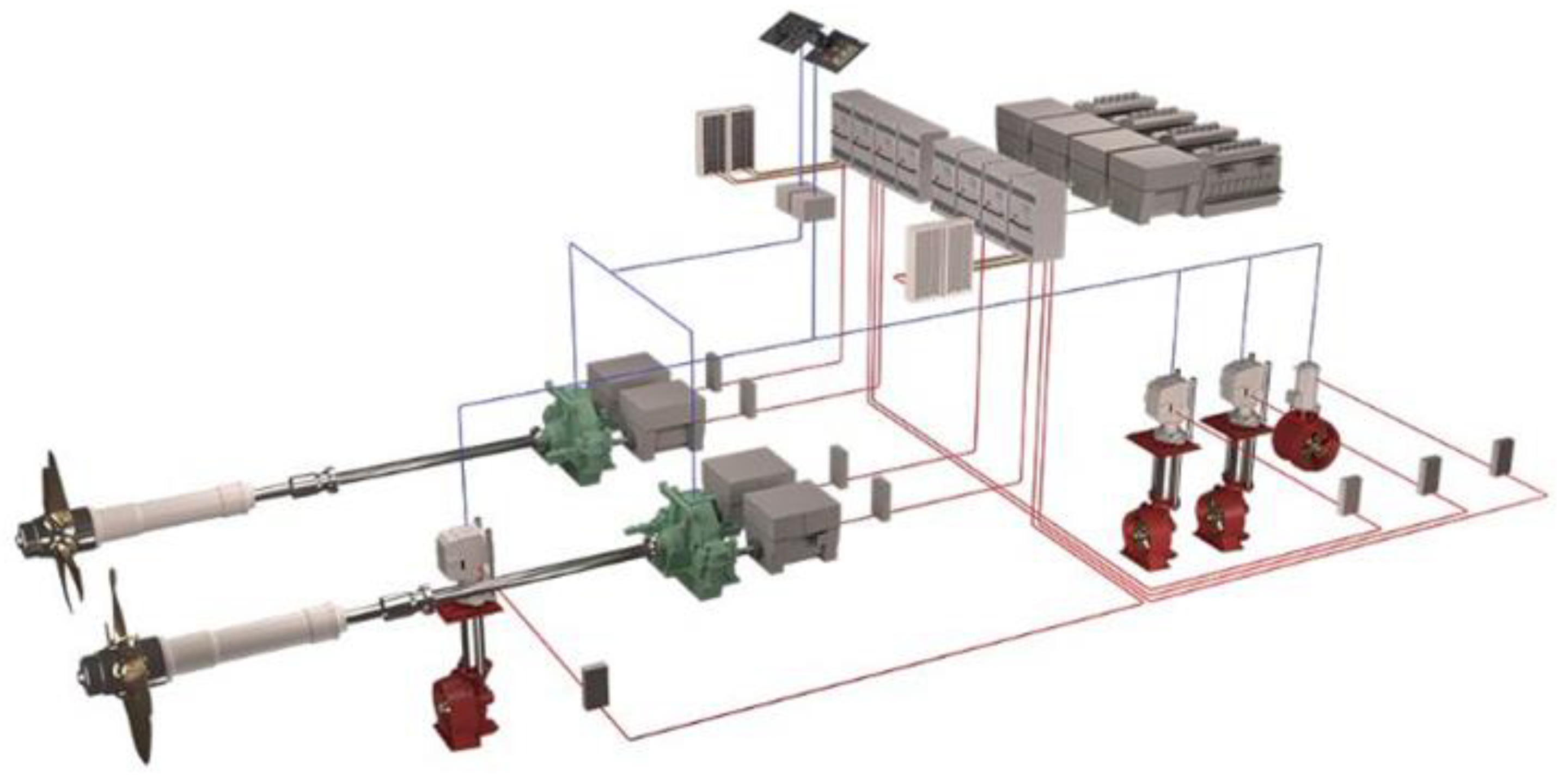

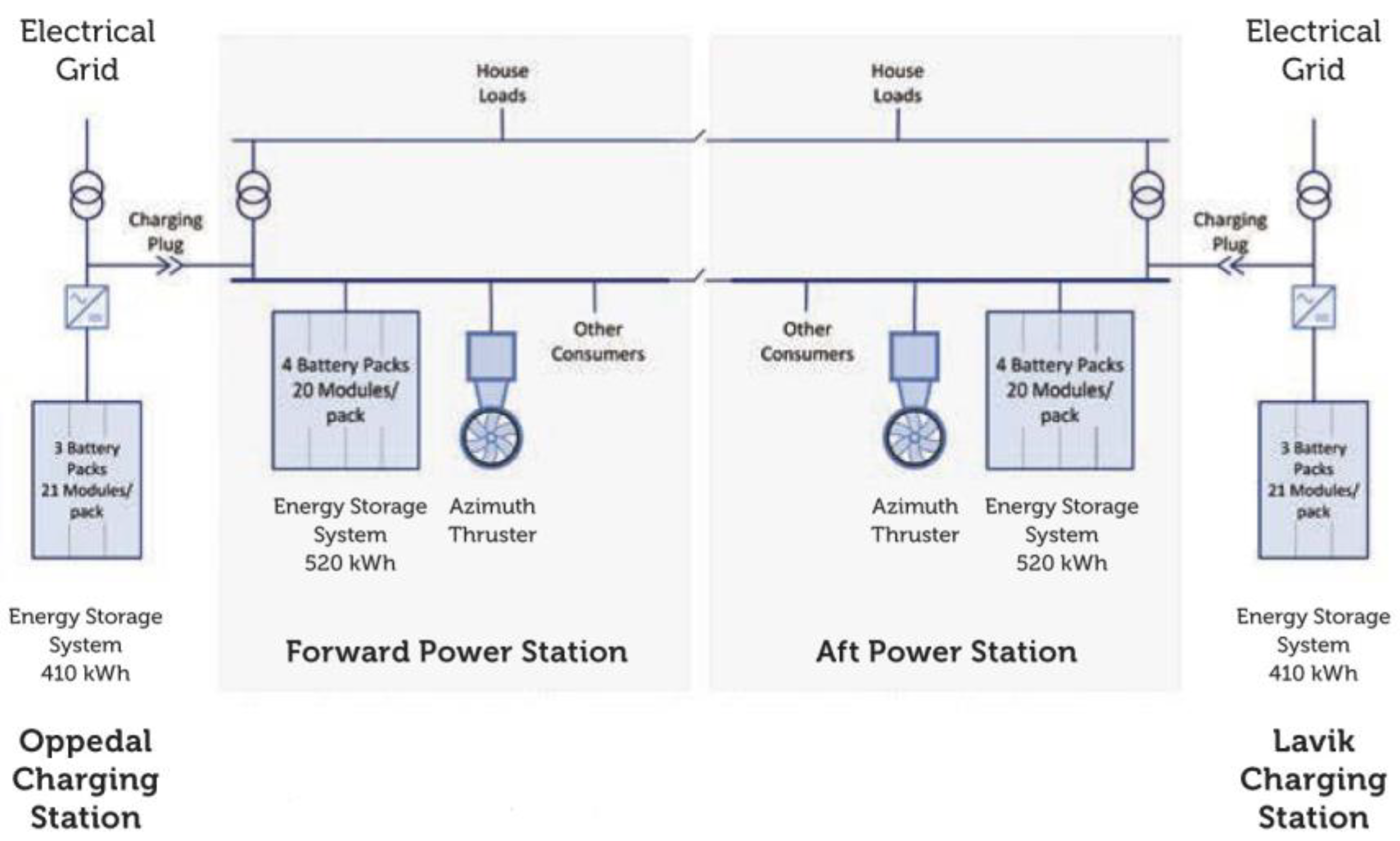

The ship’s delivery was in October 2014, and it entered service in May 2015. The ferry operates at a 5.7 km distance in the Sognefjord. It usually makes thirty-four trips every day, 20 min each. It is equipped with a 1090 kWh battery with a charging time of 9 min. A single-line diagram of the ship’s propulsion system is shown in Figure 5.

Figure 5. MF Ampere—single line diagram [10].

According to [9], annual savings, compared with a conventional ferry, are 1000 m3 of fuel, obviously resulting in a huge reduction in CO2 emissions. Moreover, maintenance costs are reduced by 20–25%.

The world’s largest hybrid-electric, plug-in vessel, when delivered in 2019, was Color Hybrid. The ship measures 160 m in length and 27.1 m in the beam. The vessel can carry 2000 passengers and 500 cars. It is equipped with 5 MW batteries that can be charged with environmentally friendly power. The maximum speed of the ship is 17 knots, she sails in and out of the fjord of Sandefjord with no emissions. Her batteries can provide electricity to sail 12 NM. The battery pack weighs 65 tons and can operate for up to 60 min. It can be recharged in one hour. The ferry is equipped with Bergen B33:45L in-line diesel engines compliant with International Maritime Organisation Tier 2 and Tier 3 rules. The “Ulstein hybrid propulsion concept” installed on Color Hybrid is a combination of diesel–electric and diesel–mechanic systems that proves to be more economical than traditional diesel electric system. It combines reduced fuel consumption at low loads with better performance and efficiency at high loads. The new ship reduces the emission of NOx, sulphur compounds and harmful greenhouse gases into the atmosphere. The combination of battery hybrid propulsion with high-voltage shore connection enables no emissions from the ship when sailing in and out of the fjord [11]. Color Hybrid is shown in Figure 6.

Figure 6. Color Hybrid, the world’s largest plug-in hybrid vessel [12].

In 2020, the European Commission founded a four-year innovation project—the E-ferry project. Its purpose was to introduce an all-electric car and passenger ferry. The idea behind the project was to design a ferry that was to operate across longer distances. The project was an initiative aiming at the realization of the Danish Green Ferry Vision, which commenced in 2015. Design and building phases were originally planned for two years, but due to the delays, the first vessel, the E-ferry named “Ellen” (Figure 7), was put in operation in 2019.

Figure 7. First e-ferry, Ellen [13].

She is a small–medium sized car and passenger ferry, designed to meet the needs for transportation in island communities and coastal zones. The ferry can transport 31 cars or 4–5 trucks, and between 147 (winter) and 196 (summer) passengers. The ship’s drivetrain and power management system were provided by Danfoss Editron, a division of Danfoss. The Editron system contains two 750 kW propulsion electric motors and two 250 kW thruster electric motors. Danfoss also supplied the shoreside charging station with a charging arm for the vessel’s 4300 kW BESS, which, in 2019, was the largest BESS installed for marine application so far [13].

The Ellen operates in Denmark. The vessel started its ferry service between the southern Danish ports of Fynshav and Søby in August 2019. In the medium term, the ship’s electricity requirements are to be covered completely by renewable energy sources, so that the ferry can be operated in a CO2-neutral way [2][14]. The power consumption of the ferry is 1400–1700 kWh of energy from the batteries per round trip, which covers the 22 NM in less than 2 h. The vessel timetable allows 15–40 min breaks for charging the BESS, so after some charging breaks the batteries are not fully charged and their capacity reduces during daily vessel service. When the ferry completes her last round trip during the day, the BESS capacity is reduced to around 30% [15]. Then, Ellen is fully charged again during the night break.

The energy efficiency of the propulsion system is 85% (grid to propellor). This figure doubles the efficiency of a typical, conventional diesel ferry (fuel tank-to-propeller). With an average consumption of 1600 kWh per trip, the Ellen’s performance is actually better than had been anticipated during the initial studies. The low energy consumption per trip combined with fast charger and correctly selected battery capacity has proven that the E-ferry prototype can be a commercial alternative to conventional propulsion ferries [15]. In June 2022, Ellen established the world-record of a 90 km voyage on a single battery charge.

In April 2022 MAN Energy Solutions was awarded a contract for the delivery of four dual-fuel MAN B&W 6S60ME-GI (gas injection) engines for two new-build hybrid-electric Ro–Ro vessels currently under construction for CLdN. The 234 m long vessels have a lane capacity of 8000 m. They are scheduled to be delivered in 2025. Both ships will have a hybrid-electric propulsion system consisting of two 11 MW ME-GI engines and two 6 MW electric propulsion motors, Power Take Off and two 678 kWh batteries. This configuration will allow for an average speed of 16–17 kts in fully electric mode. The new-build ships, compared to the similar-size vessels currently operated by CLdN, will reduce CO2 emissions by 40% while being NOx Tier III-compliant [16].

3. High Speed Ferries/High Speed Vessels

As high speed ferries usually operate at relatively short distances, their electrification/hybridization is possible. A typical single-line diagram of the high speed vessel propulsion system is presented in Figure 8.

Figure 8. Single-line diagram of the high-speed vessel’s propulsion system [17].

According to [2], battery hybridisation (plug in hybrid) of short-range ferries could save up to 85% fuel. The fully electric high-speed ferries save 100% fuel, and as they are all battery-powered, emissions are eliminated too, on the condition that batteries are charged from the “green” electricity source. For longer distances though, a hybrid solution is required.

The world’s first fully electric passenger fast ferry was constructed in Norway. It entered service between Stavanger and surrounding islands in October 2022. The vessel is named Medstraum; it is shown in Figure 9.

Figure 9. High-speed craft MS Medstraum [18].

The superstructure and hull are built from aluminium, which is easy to recycle and has low weight for reduced energy consumption. The high-speed craft MS Medstraum can operate at 23 knots for an entire hour on battery power alone. The catamaran, carrying 147 passengers, operates with a passing time of 35–40 min. CO2 emissions are expected to be reduced by 1500 tonnes per year. The battery is the lightweight Corvus Dolphin Power ESS, with a charging power of 2.3 MW and battery capacity of 1524 kWh [18].

The UK-based Uber Boat by Thames Clipper is building the country’s first hybrid high-speed passenger ferries. Two new vessels are to be launched early next year (2023). The two hybrid-electric vessels are capable of transporting 230 passengers. When the ships enter into service, they will help achieve the target of London becoming a zero carbon city by 2030. The vessels will not require shore-based charging stations. The new ships will utilize excess power from engines using biofuel to recharge their batteries. The vessels have a hybrid-electric design, so they can only operate on battery power while transporting sightseers and commuters. The batteries will be recharged using biofuel engines when outside of central London. The power generated by the biofuel engines will be fed to the onboard AC supply and charge the BESS—there will be no need for separate diesel-driven auxiliary generator sets. When operated in PTI (power-take-in) mode, the energy stored in the BESS can be fed back into the ships’ propulsion. It is possible for the ships to sail on battery propulsion only or to combine the BESS with engines using biofuel, reducing emissions and fuel consumption [19][20].

4. Hybrid Harbour Tugs

Another sector of the maritime industry that has the potential for hybrid propulsion implementation is that of harbour tugs. Ports are imposing more and more stringent regulations on exhaust and noise emissions. Those demands for cleaner operation can be easily met by the implementation of BESS (with hybrid-electric propulsion). Using a combination of electric power, BESS and combustion engines, a hybrid tug optimizes engine loading, resulting in lower specific fuel consumption, higher efficiency, lower emissions and lower fuel consumption. This setup also improves the dynamics of the system response due to faster propulsion reaction. A hybrid-electric propulsion would decrease operational costs. Better system flexibility will lead to improved engine efficiency—the combustion engine runs at high and constant loading. Reduction of the engine’s running hours will cut maintenance costs and prolong engine life [21][22][23][24].

The first hybrid tugboat in the world was developed and operated by Kotug. Its propulsion consists of three 360° azimuth thruster propellers. The azimuths allow for the tug’s manoeuvring and station-keeping with a better precision than with conventional propellors. The conventional Rotortug propulsion consists of three Caterpillar 3512C-HD engines. The same engines are also used in the hybrid E-Kotug to maintain equipment uniformity between Rotortug and E-Kotug. The Caterpillar engines have the highest efficiency when operated at 80–100% of maximum power. However, conventional propulsion tugs (Rotortugs) spent maybe 5% of service time using this level of engine load. The E-Kotug operates in two different modes. Towage is carried out using a conventional propulsion system. BESS is used with low load demand—when the tug is in transit or is manoeuvring through the harbour. The vessel’s battery power comes from a pack made up of 18 cells connected in series. Each cell stores 6.5 kWh of energy, for a total capacity of 117 kWh. The cell used is the Corvus’ air-cooled AT6500-250-48, a lithium nickel manganese cobalt oxide cell with a rated lifetime energy storage of 32,500 kWh and a lifespan of at least 5000 cycles. Each one has a 150 Ah capacity, while weighing 70 kg and measuring 59 × 38 × 33 cm. As well as its 48 V operating voltage, each cell provides a maximum voltage of 50.4 V, a minimum voltage of 38.4 V and a continuous current of 450 A. The main benefit of the hybrid system is a reduction of the maintenance costs, because the engines’ running hours are roughly halved, from 2000 h per year to 1000 [25][26].

The white paper for Wärtsilä HY Tug Propulsion Systems [27] presents a study on the performance, fuel consumption and emission levels of hybrid/electric tugs compared to equivalent conventional tugs. The research was based on the Wärtsilä HY Tug 75TBP series. The following five alternative propulsion systems were evaluated in the report:

-

Diesel–Mechanic—either fixed pitch (FPP) or controllable pitch (CPP) propellors, high- or medium-speed engines: This is a conventional tug propulsion with two diesel main engines directly driving the propellers. This propulsion system is used as a basis for comparison purposes.

-

Diesel–Mechanic—either FPP or CPP with power take-in (PTI): In addition to the direct-drive diesel engines, the system is equipped with a PTI (power take-in). The electric motors are powered by the auxiliary generator.

-

Diesel–Mechanic hybrid configuration—either FPP or CPP with power take-in/power take-out and a battery: In this setup, the propulsion is supported by a BESS. The genset can operate at variable rpm. The batteries can be charged by the PTOs, the diesel driven generator or from an onshore charging connection. Figure 10 shows the single-line diagram of the diesel–mechanic hybrid system.There are different modes of operation in a diesel–mechanic hybrid configuration:

-

Electric mode: Both engines are stopped, and all consumers are supplied from the batteries. Propulsion is run using PTI. Maximum propulsion power is 920 kW (max 21 min with 600 kWh battery capacity), 10 knots eco-speed.

-

Hybrid/electric mode: The diesel engines’ start/stop control depends on the charge of the battery. The engines provide power and recharge the batteries when they are at low charge.

-

Hybrid mode: One of the diesel engines supplies the PTO and runs the propeller. The other thruster is powered by the PTI. Batteries support propulsion during peak shaving and required power boosts. Maximum speed is 10 knots.

-

Power boost mode: The diesel engines and PTI provide power simultaneously. Maximum continuous propulsion: 3420 kW; maximum peak propulsion: 4350 kW with battery support for a maximum of 22 min.

-

-

Diesel–electric—with FPP: This configuration features a diesel–electric version with variable speed of the main engines and direct current grid distribution. It is separated into two independent propulsion subsystems.

-

Diesel–electric hybrid configuration—FPP with a battery. Same configuration as diesel electric but has less power installed due to the reduced number of the engines’ cylinders and one generator set replaced by BESS. Figure 11 shows the single-line diagram of the diesel–electric hybrid system.There are four different modes of operation in diesel–electric hybrid configuration:

-

Electric mode: Both engines are stopped, and all consumers are supplied from the batteries. Maximum propulsion power is 1400 kW, 10 knots eco-speed, 29 min operating time on batteries.

-

Hybrid/electric mode: The diesel engines’ start/stop control depends on the charge of the battery. Engines provide power and recharge the batteries when they are at low charge.

-

One-generator mode: One of the diesel engines supplies the power. The batteries take the boost from sudden load peaks. Maximum continuous propulsion: 1400 kW. Batteries provide boosts for the propellers of up to 2920 kW for 14 min.

-

Two-generator mode (power boost): The batteries and diesel generators provide power together. Batteries support the propulsion during peak shaving and required power boosts. Maximum continuous propulsion: 2940 kW; maximum peak propulsion: 4150 kW with battery support for a maximum of 17 min.

-

Figure 10. Single-line diagram of the diesel–mechanic hybrid system [28].

Figure 11. Single-line diagram of the diesel–electric hybrid system [28].

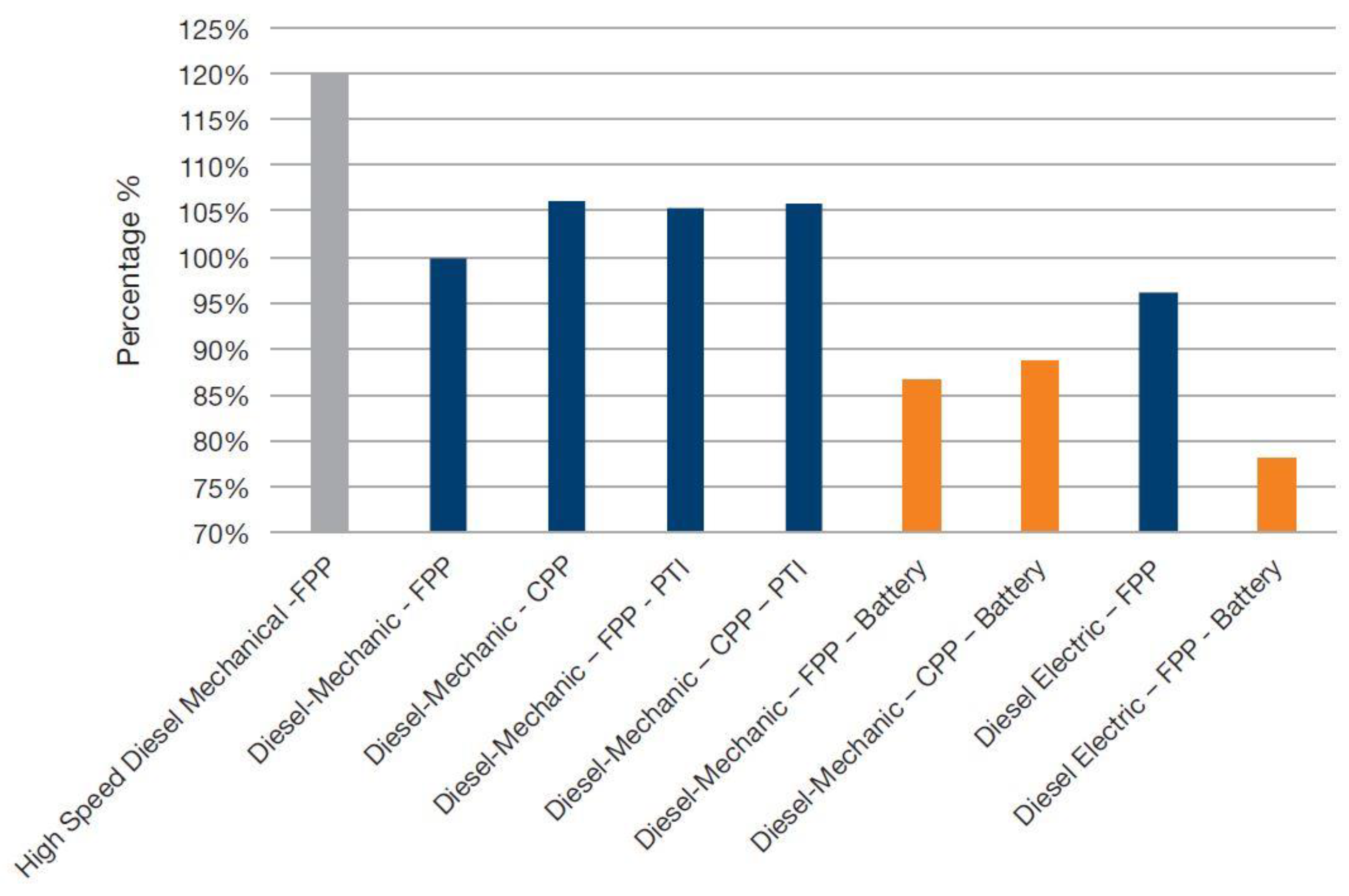

The fuel consumption comparison presented in a prior study [27] was based on a specific fuel consumption (SFC) per kWh of power delivered to the thrusters. Figure 12 shows the SFC for the different types of tugs propulsion. Hybrid propulsion (systems with batteries) have 11–22% lower fuel consumption compared to a conventional diesel–mechanic, medium-speed engine’s FPP propulsion.

Figure 12. Fuel consumption comparison of different tug propulsion systems [27].

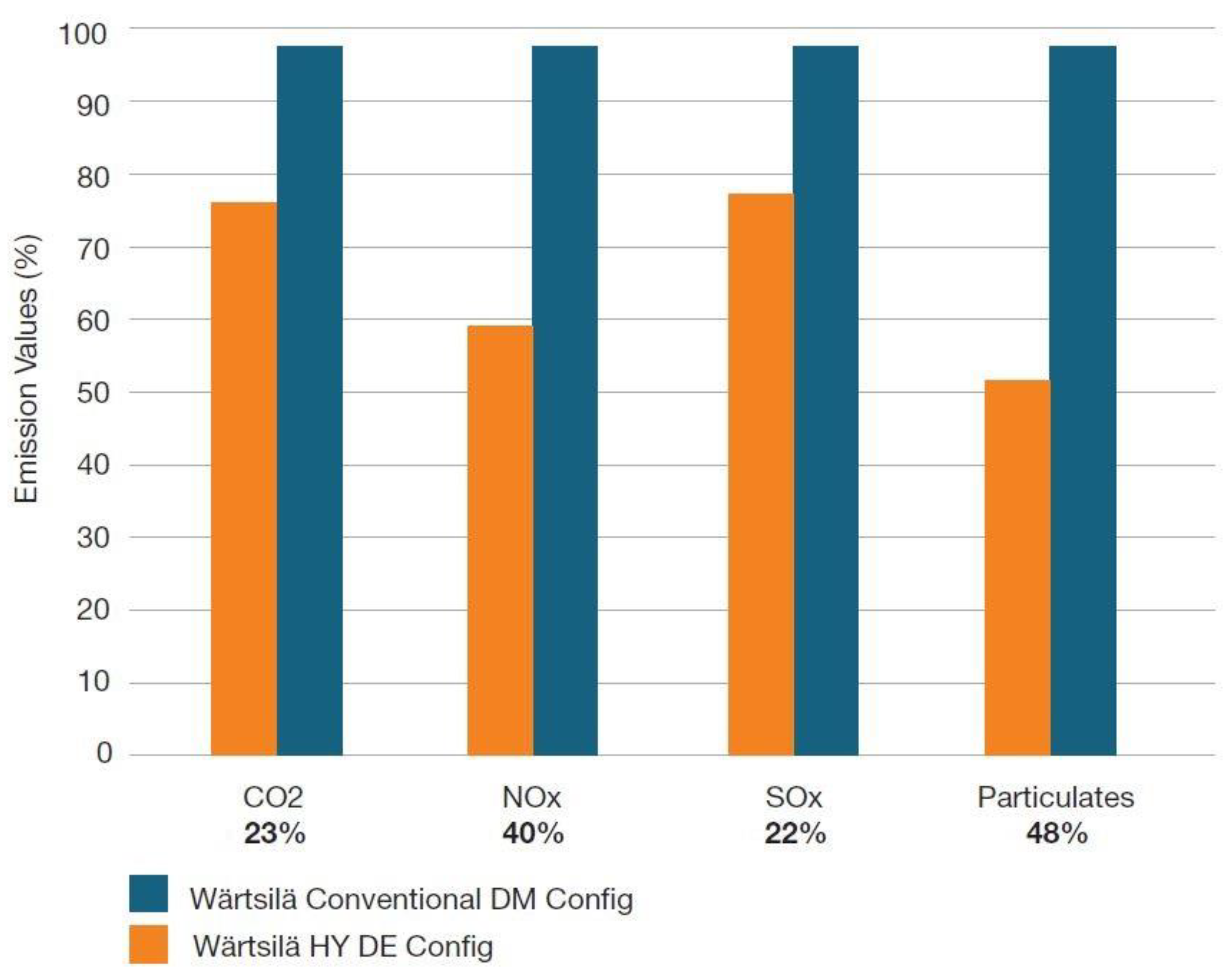

Figure 13 describes the difference between the emissions of CO2, NOx, SOx and particulates for the presented types of tugs’ propulsion. Hybrid propulsion substantially reduces emissions, CO2 is reduced by 23%, NOx by 40%, SOx by 22% and particulates emissions are reduced by 48%.

Figure 13. Emission comparison of different tug propulsion systems [27].

The diesel generators’ running hours are reduced by up to 58% due to the flexibility in enabling the engines to operate with maximum efficiency and because of the energy storage of the BESS. As the propulsion system’s overhaul intervals are based on running hours, the maintenance costs are reduced substantially.

5. Fully Electric Autonomous Ships

Yara Birkeland (Figure 14) is the world’s first zero-emission, fully electric and autonomous container ship.

Figure 14. Yara Birkeland, the first fully electric and autonomous container ship [29].

The vessel was put into commercial operation in Porsgrunn in the spring of 2022. During the first two years of operation, the vessel will go through a gradual transition towards full autonomous sailing. The first part of the project is the installation of a removeable navigation bridge with equipment for manoeuvring and navigation. It will be removed when the ship commences autonomous operation. The mooring, loading and discharging will be carried out automatically by electric cranes and equipment. The ship will be equipped with an automatic mooring system—berthing and unberthing will be executed without human intervention and will not require special implementations dockside. A remote operation centre (ROC) will perform voyage planning, deal with emergency and exception handling, carry out operational monitoring, decision support, condition monitoring, surveillance of the autonomous ship and its surroundings and other aspects associated with a safe operation [2][29][30][31]. The vessel is a 120 TEU open-top container ship with a deadweight of 3400 mt. The propulsion and manoeuvring of the vessel are handled by an electrical system consisting of a battery package of 6.7 megawatt hours, two electrical azipull pods 2 × 900 kW and two tunnel thrusters 2 × 700 kW. This electric vessel operates at an average speed of 6 knots (maximum 13 knots). According to the manufacturer, the Leclanché Marine Rack System (MRS) ensures optimum temperature control of the cells and their permanently reliable operation over a service life of at least 10 years [29]. The ship sails between three ports in Norway within a range of 12 NM from the coast. Using radars, GPS, sensors and cameras, the ship will be able to manoeuvre around vessel traffic and to navigate between the ports on its own. The vessel will reduce approximately 700 tonnes of CO2 emissions per year [30].

6. Hybrid Electric Passenger Vessels

The first hybrid propulsion passenger ship was the MS Roald Amundsen, which was delivered in July 2019. The polar passenger vessel integrates a dynamic positioning (DP) system, Aquarius 100 stabilisers and an ACON automation system. It has a length of 140 m, height of 29 m, draught of 5.3 m and a width of 23 m. She can accommodate 530 passengers. The combination of BESS hybrid propulsion with its hull structure and high efficiency of electric power systems reduces fuel consumption and CO2 emissions by approximately 20%. The MS Roald Amundsen polar passenger ship was the first hybrid-electric vessel of this type powered by an innovative BESS and four Bergen B33:45 engines and batteries [32].

7. BESS on Fishing Vessels

The fishing vessels segment of the maritime industry, due to its specific operations characteristics, is also a very promising area for the implementation of hybrid-electric propulsion/BESS. The fishing industry has potential for installing BESS, and several ships are already doing so. The ship’s BESS has proven faultless after three years of operation. The 11-metre vessel has a 195 kWh ESS consisting of 30 Corvus AT6500 lithium polymer battery modules [33]. The fishing boat also has a small 50 kW auxiliary generator and can be charged overnight by plugging into the electrical grid [34]. As Karoline was a pilot project, the vessel’s BESS performance was closely monitored by the manufactures of the hybrid-electric system. The data were collected and used to develop new hybrid-electric ships featuring an optimal mix of conventional and electric power sources for different tasks [35].

In 2022, Ulstein developed a hybrid battery propulsion solution for a new trawler that is expected to provide large reductions in diesel consumption and emissions. Figure 15 shows an image of the hybrid propulsion trawler ULSTEIN FX101’s design.

Figure 15. Image of the hybrid propulsion trawler ULSTEIN FX101 [36].

The new trawler will have an efficient hybrid system with two propellers that can combine battery power with both diesel–electric and diesel–mechanical propulsion. This will make the fishing vessel very fuel-efficient compared to a trawler with traditional propulsion. It has been estimated that this hybrid system, together with other energy-saving measures on board, will provide at least a 25 percent reduction in fuel consumption and emissions compared to a similar modern trawler performing this type of combination fishing, and the savings can, in some operations, exceed 40 per cent. The battery system has a large energy capacity (approx. 1130 kWh), which can not only support the ship in case of extra power needs but also means that the vessel can stay quayside for many hours before a diesel engine must start or shore power is connected. The ship is also equipped with a modern shore connection that can fully utilise the port facilities that are currently under development. This means that the entire ship can be supplied from shore, and the large battery can also be charged by shore power. This will help eliminate the need of running the diesel engines while quayside.

The batteries support the diesel engines when the trawler is operated with one diesel engine only in diesel–electric mode. The battery will deal the short-term increases in power demand, subsequently saving vast amounts of energy. The BESS has large power reserves and quick responsiveness—diesel engines will be able to work dynamically and handle load increases. The batteries will store returned power from the trawler’s winches (fitted with power regeneration systems) [37].

8. Green Coastal Shipping Program

Norway has introduced the Green Coastal Shipping Program with a vision to establish the world’s most environmentally friendly and effective shipping. Those eco-friendly ships are to be powered, among others, by BESS. This is a long term project; however, the initial five pilot programs have already been selected and all of them involve hybrid propulsion/BESS. Those programs are [38][39]:

-

NorLines’ future cargo ferry with LNG/battery hybrid propulsion and zero-emission port sailing and port operation, including electric cranes with energy recovery.

-

The second pilot involved Teekay’s next-generation low emission shuttle tanker. The goal of the second pilot was to investigate the possibility of using alternative fuels (LNG and/or VOC) combined with redundant power generation for offshore dynamic positioning operations. Another goal of this program was to evaluate the potential use of BESS and of a hybrid solution.

-

The third pilot program involves an electric-hybrid aquaculture vessel specified by the Cargo Freighters’ Association and ABB.

-

Similarly, the Norwegian Gas Association and Øytank Bunkersservice are exploring the benefits of hybridizing a bulk vessel that is planned to be converted to a low-cost LNG bunker vessel with gas propulsion.

-

The fifth pilot program was initiated by the Port of Risavika, which plans to electrify its port operations, including heavy-duty vehicles and crane operations, and to offer cold ironing services. Part of the plan is also to offer to charge ships with plug-in hybrid solutions.

9. Deep-Sea Vessels

Deep-sea vessels, due to the long voyages and their energy requirements, will probably use other alternative fuels to meet the decarbonisation requirement set by the International Maritime Organization. With current technology, batteries are not feasible as the source of energy. Their installation is technically possible; however, from a cost–benefit analysis point of view it would not make sense. The exception to the above statement might be deep-sea vessels with heavy cranes that have an energy recovery function installed. The other exception is short sea shipping. The decarbonisation requirement set by IMO combined with aging ships creates new opportunities within this segment. Recent orders in the short sea segment indicate a very visible decline in the number of conventional propulsion ships with a single main engine coupled with a fixed pitch propeller. Hybrid-electric propulsion systems in combination with alternative fuels are becoming more and more popular with ship owners. Nowadays, the new standard is a mechanical-hybrid setup. It consists of one or two main engines coupled with a controllable pitch propeller (CPP), power take off/power take in (PTO/PTI) shaft generator, BESS and a shore connection [40]. Figure 16 presents the typical arrangement of hybridised CPP arrangement for short sea shipping.

Figure 16. Hybridised CPP arrangement for short sea shipping [40].

With this new standard (mechanical hybrid setup), one or two main engines provide all the required propulsion and ancillary power for the vessel. There is a controllable pitch propeller coupled with the main engine through a gearbox, and a PTO/PTI shaft generator. Batteries can supply propulsion power via PTI of the shaft generator. The main engine can be decoupled from the propeller and the vessel can operate on battery power only (with zero emissions) when in port.

References

- Viking Lady. Available online: https://corvusenergy.com/projects/viking-lady/ (accessed on 12 November 2022).

- European Maritime Safety Agency. Study on Electrical Energy Storage for Ships by DNV GL; Report No.: 2019-0217, Rev. 04. Document No.: 11B59ZDK-1. Date: 2020-05-05.; EMSA European Maritime Safety Agency: Lisbon, Portugal, 2020.

- Viking Lady. Available online: https://www.wartsila.com/marine/customer-segments/references/offshore/viking-lady (accessed on 12 November 2022).

- DNV, Batteries As Power Sources in DP Systems Power and Design. Dynamic Positioning Conference 2018. Available online: https://dynamic-positioning.com/proceedings/dp2018 (accessed on 12 November 2022).

- Hybrid Propulsion Shuttle Tanker. Available online: https://www.brunvoll.no/ship-segments/shuttle-tank (accessed on 12 November 2022).

- Hybrid Propulsion Shuttle Tanker. Available online: https://www.wartsila.com/insights/article/the-new-shuttle-tanker (accessed on 12 November 2022).

- Hybrid Propulsion Shuttle Tanker. Available online: https://www.theexplorer.no/solutions/teekay--shuttle-tankers-use-their-own-emissions-as-fuel/ (accessed on 12 November 2022).

- Aurora Spirit. Available online: https://www.ship-technology.com/projects/aurora-spirit-e-shuttle-tanker/ (accessed on 12 November 2022).

- MF Ampere. Available online: https://corvusenergy.com/projects/mf-ampere/ (accessed on 12 November 2022).

- MF Ampere. Available online: https://corvusenergy.com/an-ocean-of-opportunities/ (accessed on 12 November 2022).

- Color Hybrid. Available online: https://www.ship-technology.com/projects/color-hybrid-ferry/ (accessed on 12 November 2022).

- Color Hybrid. Available online: https://www.colorline.com/about-us/worlds-largest-plug-in-hybrid-ship (accessed on 12 November 2022).

- Electric ferry Ellen. Available online: https://www.ship-technology.com/news/ellen-electric-ferry-denmark/ (accessed on 12 November 2022).

- Electric Ferries in the Baltic Sea Region Compendium. Available online: https://www.bsr-electric.eu/use-cases/e-ferries (accessed on 12 November 2022).

- Electric Ferries. Available online: http://www.conf.eferry.eu/ (accessed on 12 November 2022).

- Hybrid RO-RO Ships. Available online: https://www.electrichybridmarinetechnology.com/news/environmental/man-energy-solutions-to-provide-hybrid-propulsion-for-cldn-ro-ro-vessels.html (accessed on 12 November 2022).

- Hybrid High Speed Vessels. Available online: https://www.brunvoll.no/ship-segments/hsv-hybrid (accessed on 12 November 2022).

- Hybrid High Speed Ferries. Available online: https://corvusenergy.com/battery-powered-fast-ferry-ms-medstraum-named-ship-of-the-year/ (accessed on 12 November 2022).

- Hybrid High Speed Vessels. Available online: https://www.offshore-energy.biz/uber-boat-building-uks-1st-hybrid-high-speed-passenger-ferry/ (accessed on 12 November 2022).

- Hybrid High Speed Vessels. Available online: https://www.danfoss.com/en/about-danfoss/news/dps/danfoss-power-solutions-editron-division-to-power-the-uk-s-first-high-speed-hybrid-passenger-ferries/ (accessed on 12 November 2022).

- Hybrid Tugs. Available online: https://www.man-es.com/marine/products/hybrid-propulsion-for-tugs (accessed on 12 November 2022).

- Nishio, T.; Kifune, H. A Study on Fuel Saving Effect in Hybrid Propulsion System for Tugboat. In Proceedings of the AMEC 2016 + 7th PAAMES—Green and Sustainable Development in Shipping and Engineering, Hong Kong, China, 13–14 October 2016.

- Kutz, R. Design challenges of an innovative pusher-tug with a hybrid power unit. In Proceedings of the Electric & Hybrid Marine World Expo Conference, Fort Lauderdale, FL, USA, 11–13 January 2016.

- The ABB ETG (Electric Tug). Electric and Hybrid Tug—Analysis, April 2022. Available online: https://library.e.abb.com/ (accessed on 12 November 2022).

- Hybrid Tugs. Available online: https://www.kotug.com/fleet/ (accessed on 12 November 2022).

- Hybrid Tugs. Available online: https://www.emobility-engineering.com/ekotug-rotortug-powertrain/ (accessed on 12 November 2022).

- Wärtsilä Marine Solutions Business White Paper—Wärtsilä HY Tug Propulsion Systems. Available online: https://www.wartsila.com/insights/business-areas/marine-power/white-papers (accessed on 12 November 2022).

- Hybrid Tugs. Available online: https://www.wartsila.com/docs/default-source/product-files/sd/tugs/w%C3%A4rtsil%C3%A4-hy-tug-series/wartsila-hytug-external-presentation-sept-2017.pdf?sfvrsn=236e6644_8 (accessed on 12 November 2022).

- Yara Birkeland. Available online: https://www.offshore-energy.biz/yara-birkeland-worlds-1st-fully-electric-boxship-prepares-for-commercial-ops/ (accessed on 12 November 2022).

- Yara Birkeland. Available online: https://www.kongsberg.com/maritime/support/themes/autonomous-ship-project-key-facts-about-yara-birkeland/ (accessed on 12 November 2022).

- Yara Birkeland. Available online: https://www.yara.com/knowledge-grows/game-changer-for-the-environment/ (accessed on 12 November 2022).

- Roald Amundsen. Available online: https://www.ship-technology.com/projects/ms-roald-amundsen-polar-cruise-ship/ (accessed on 12 November 2022).

- F/V Karoline. Available online: https://corvusenergy.com/projects/karoline-2/ (accessed on 12 November 2022).

- Electric Fishing Vessel. Available online: https://maritimecleantech.no/project/first-electric-fishing-vessel/ (accessed on 12 November 2022).

- Electric Fishing Vessel. Available online: https://www.theexplorer.no/solutions/selfa-arctic--the-worlds-first-hybrid-fishing-boat/ (accessed on 12 November 2022).

- Hybrid Trawler. Available online: https://ulstein.com/news/bluewild-contracts-new-factory-trawler-with-design-from-ulstein (accessed on 12 November 2022).

- Electric Fishing Vessel. Available online: https://ulstein.com/news/hybrid-propulsion-system-can-give-a-boost-for-future-emission-reduction-in-the-fishing-fleet (accessed on 12 November 2022).

- DNV GL Publication in Focus –The Future Is Hybrid—A Guide to Use of Batteries in Shipping. Available online: https://www.dnv.com/maritime/publications/future-is-hybrid-download.html (accessed on 12 November 2022).

- Green Shipping Program. Available online: https://greenshippingprogramme.com/ (accessed on 12 November 2022).

- Hybrid Short Sea Vessels. Available online: https://www.wartsila.com/insights/article/decarbonisation-drives-innovation-in-short-sea-shipping (accessed on 12 November 2022).

More

Information

Subjects:

Engineering, Marine

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

5.5K

Revisions:

2 times

(View History)

Update Date:

20 Mar 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No