| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Linda Nikoshvili | -- | 2859 | 2023-03-14 16:25:44 | | | |

| 2 | Lindsay Dong | + 4 word(s) | 2863 | 2023-03-15 08:42:10 | | |

Video Upload Options

Composite materials including organic–inorganic systems have drawn special attention due to their enhanced properties such as adsorbents and heterogeneous catalysts. At the same time, large-scale production of environmentally benign functionalized biopolymers, such as chitosan (CS), allows for constantly developing new materials, since CS reveals remarkable properties as a stabilizing agent for metal-containing compounds and enzymes and as an adsorbent of organic molecules.

1. Introduction

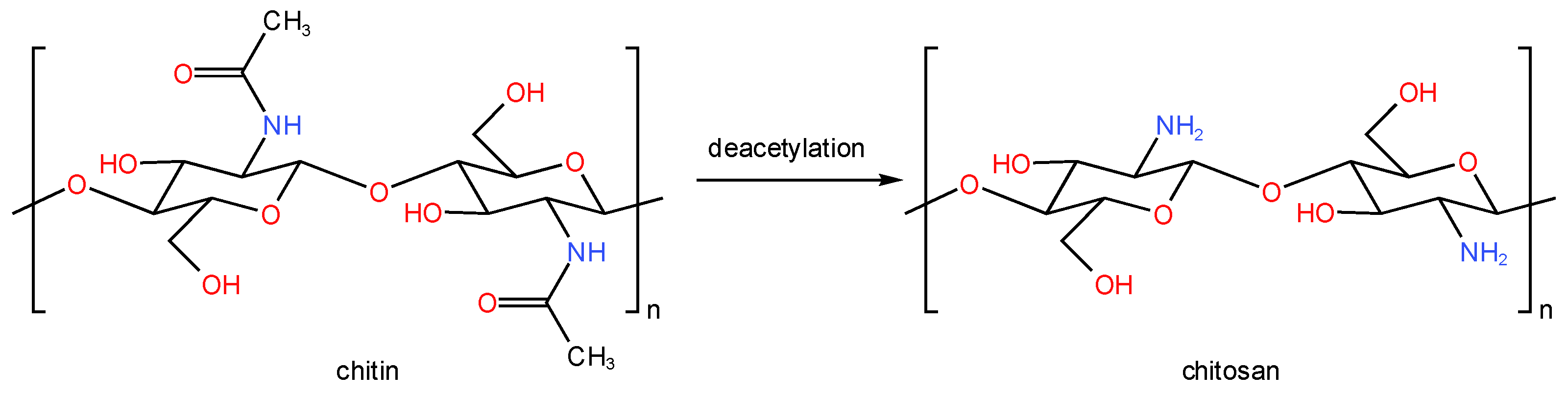

2. Chitosan Modifications

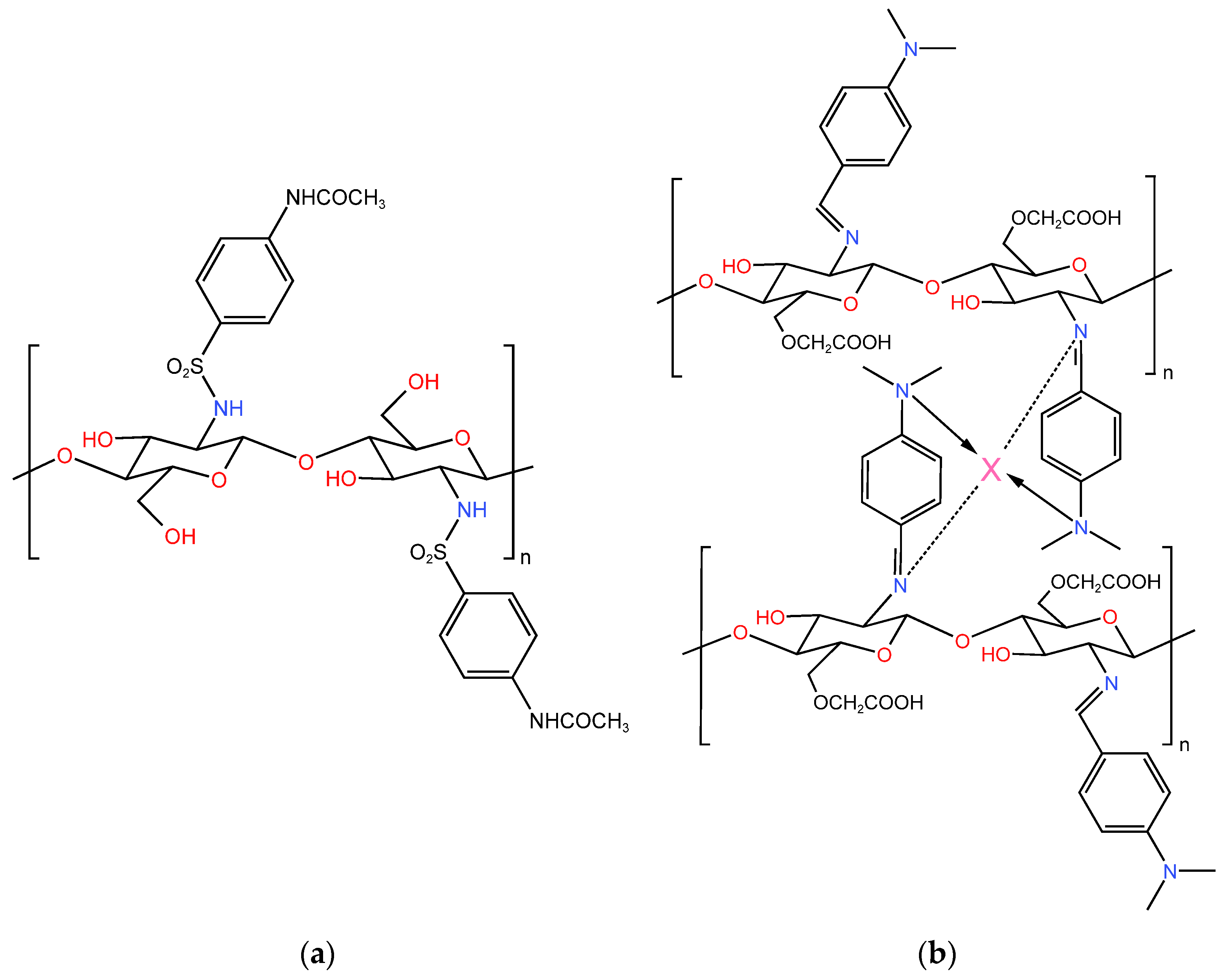

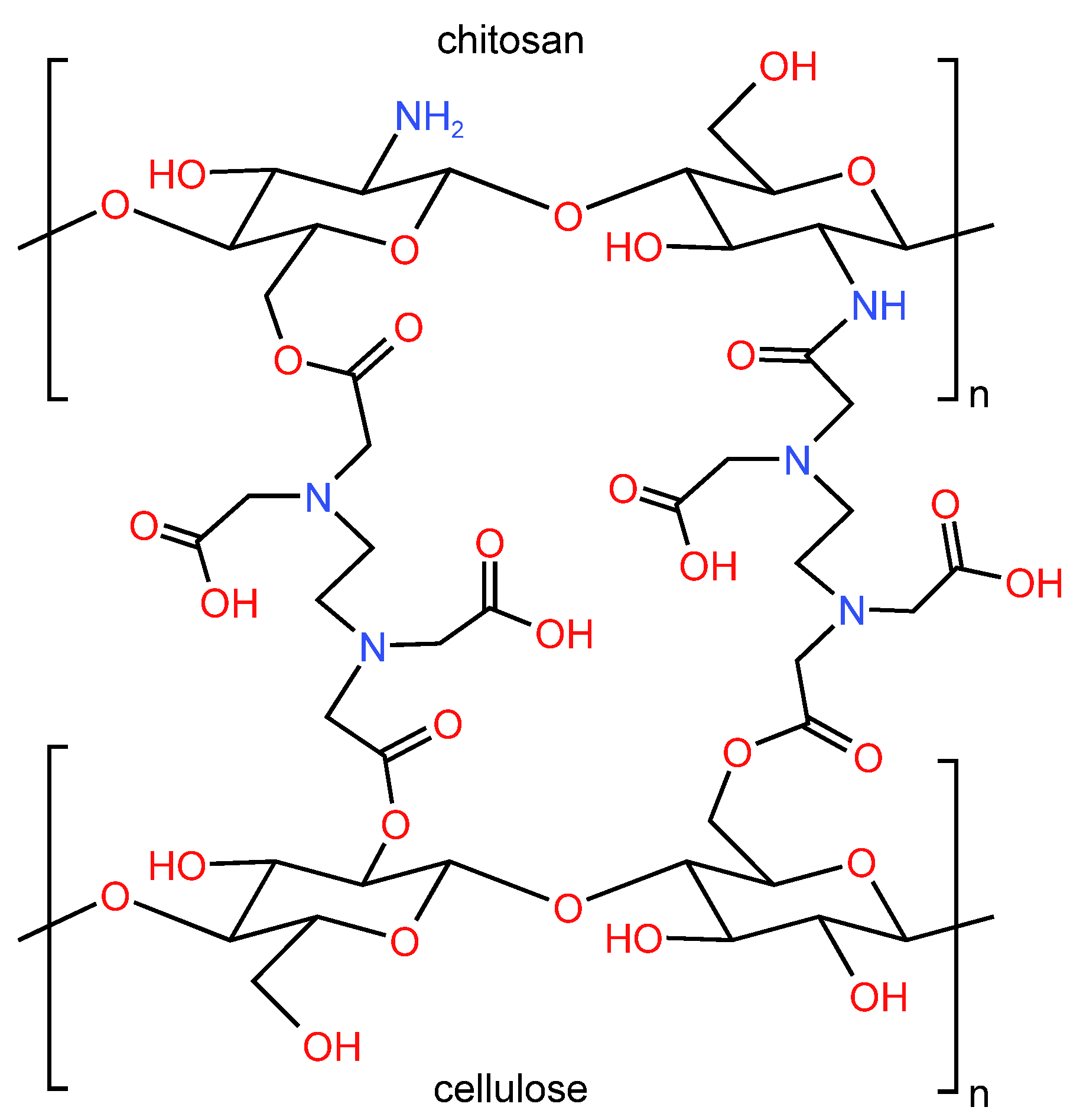

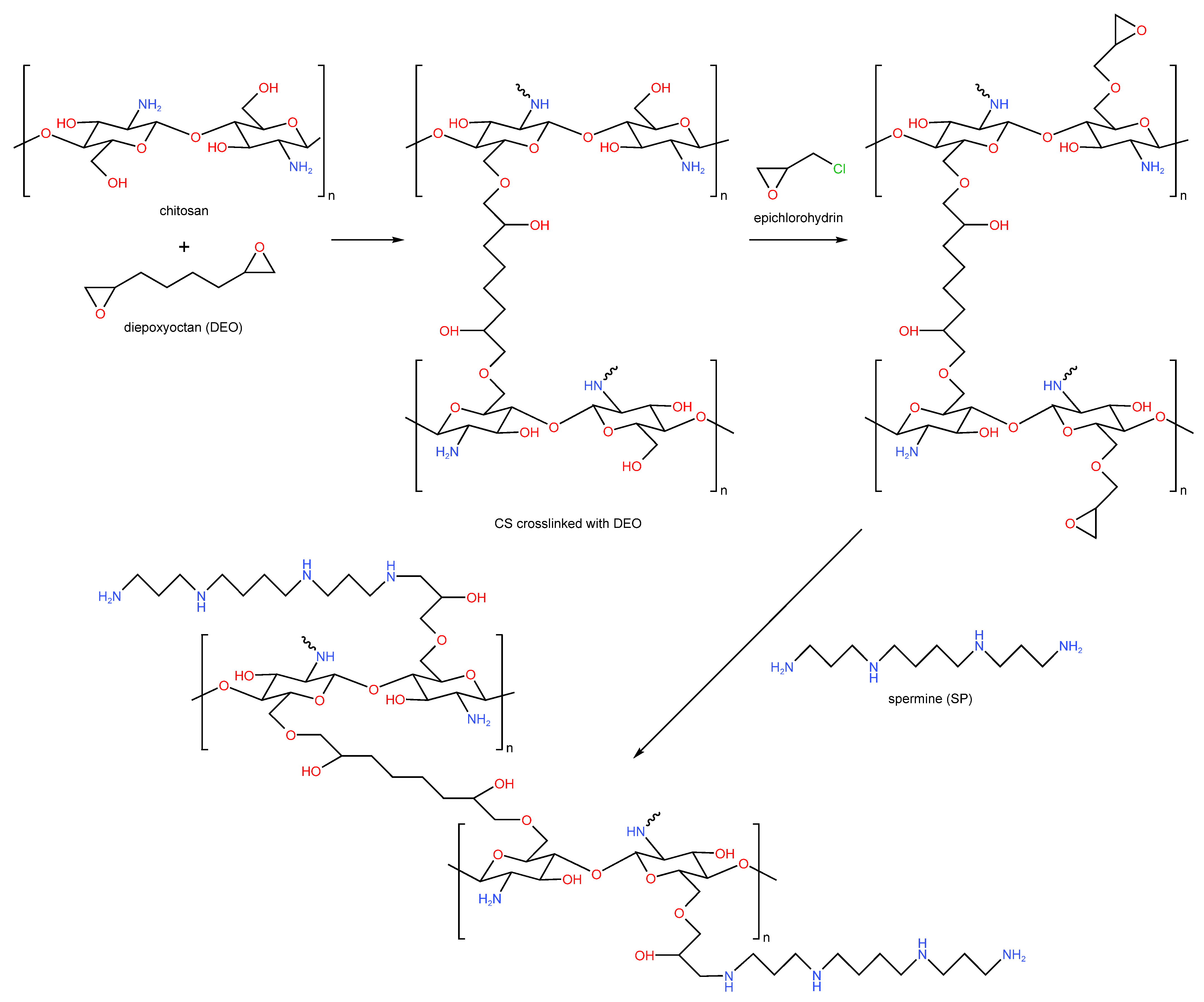

2.1. Grafting of Functional Groups

2.2. Gelation

Gelation is one of the most widely used methods of CS modification [27]. Polymer hydrogels are hydrophilically crosslinked macromolecular systems capable of retaining significant amounts of water, while preserving the properties inherent in solids (certain shape, mechanical properties of the material during tensile and shear deformations). This combination of properties determines a wide range of their applications: sorbents, gas separation and ion-exchange membranes, structure-forming agents for food industry, drug carriers, artificial tissues and materials for soft and intraocular lenses [28][29].

Gels that meet these requirements can be obtained through physical interactions, which include electrostatic, hydrogen and van der Waals bonds arising between polymer chains [30][31][32].

2.3. Formation of Nanoparticles

3. Chitosan-Containing Materials and Composites as Adsorbents

3.1. Structured Chitosan Materials

3.2. Chitosan-Based Organic/Inorganic Composite Adsorbents

3.3. Magnetically Separable Chitosan Composites

4. Chitosan as Catalytic Support

4.1. Catalytic Metal–Chitosan Composites

4.2. Chitosan-Containing Composite Biocatalysts

5. Conclusions

References

- Aranaz, I.; Alcántara, A.R.; Civera, M.C.; Arias, C.; Elorza, B.; Heras Caballero, A.; Acosta, N. Chitosan: An Overview of Its Properties and Applications. Polymers 2021, 13, 3256.

- Boominathan, T.; Sivaramakrishna, A. Recent Advances in the Synthesis, Properties, and Applications of Modified Chitosan Derivatives: Challenges and Opportunities. Top. Curr. Chem. 2021, 379, 19.

- Crini, G. Historical Review on Chitin and Chitosan Biopolymers. Environ. Chem. Lett. 2019, 17, 1623–1643.

- Zhang, M.; Zhang, F.; Li, C.; An, H.; Wan, T.; Zhang, P. Application of Chitosan and Its Derivative Polymers in Clinical Medicine and Agriculture. Polymers 2022, 14, 958.

- Chitosan Market Size, Share & Trends Analysis Report by Application (Pharmaceutical & Biomedical, Water Treatment, Cosmetics, Food & Beverage), by Region (APAC, North America, Europe, MEA), and Segment Forecasts, 2020–2027; Report ID: 978-1-68038-798-8; Grand View Research: San Francisco, CA, USA, 2020; Available online: https://www.grandviewresearch.com/industry-analysis/global-chitosan-market (accessed on 1 February 2023).

- Kumar, N.; Joshi, N.C. Adsorption Applications of Synthetically Prepared PANI-CuO Based Nanocomposite Material. J. Ind. Chem. Soc. 2022, 99, 100551.

- Toumi, I.; Djelad, H.; Chouli, F.; Benyoucef, A. Synthesis of Hybrid Material and Evaluations in Adsorption of Congo Red and Methylene Blue Dyes: Structural Characterization and Adsorption Performance. J. Inorg. Organomet. Polym. 2022, 32, 112–121.

- El-Shazly, A.H.; Elkady, M.; Abdelraheem, A. Investigating the Adsorption Behavior of Polyaniline and Its Clay Nanocomposite towards Ammonia Gas. Polymers 2022, 14, 4533.

- Hajjaoui, H.; Soufi, A.; Boumya, W.; Abdennouri, M.; Barka, N. Polyaniline/Nanomaterial Composites for the Removal of Heavy Metals by Adsorption: A Review. J. Compos. Sci. 2021, 5, 233.

- Peñas-Sanjuán, A.; López-Garzón, R.; López-Garzón, J.; Pérez-Mendoza, M.; Melguizo, M. Preparation of a Poly-alkylamine Surface-functionalized Carbon with Excellent Performance as a Pd(II) Scavenger. Carbon 2012, 50, 2350–2352.

- Choi, W.; Min, K.; Kim, C.; Ko, Y.S.; Jeon, J.W.; Seo, H.; Park, Y.-K.; Choi, M. Epoxide-functionalization of Polyethyleneimine for Synthesis of Stable Carbon Dioxide Adsorbent in Temperature Swing Adsorption. Nat. Commun. 2016, 7, 12640.

- Huang, X.; Wang, L.; Zhang, J.; Du, X.; Wu, S.; Wang, H.; Wei, X. A Novel ε-Polylysine-modified Microcrystalline Cellulose Based Antibacterial Hydrogel for Removal of Heavy Metal. Int. J. Biol. Macromol. 2020, 163, 1915–1925.

- Rivas, B.L.; Maureira, A.; Guzmán, C. Poly(L-lysine) as a Polychelatogen to Remove Toxic Metals Using Ultrafiltration and Bactericide Properties of Poly(L-lysine)–Cu2+ Complexes. Polym. Bull. 2011, 67, 763–774.

- Xue, W.; Liu, B.; Zhang, H.; Ryu, S.; Kuss, M.; Shukla, D.; Hu, G.; Shi, W.; Jiang, X.; Lei, Y.; et al. Controllable Fabrication of Alginate/poly-L-ornithine Polyelectrolyte Complex Hydrogel Networks as Therapeutic Drug and Cell Carriers. Acta Biomater. 2022, 138, 182–192.

- Huang, K.-S.; Sheu, Y.-R.; Chao, I.-C. Preparation and Properties of Nanochitosan. Polym. Plast. Technol. Eng. 2009, 48, 1239–1243.

- Ma, F.; Wang, Z.; Zhao, H.; Tian, S. Plasma Depolymerization of Chitosan in the Presence of Hydrogen Peroxide. Int. J. Mol. Sci. 2012, 13, 7788–7797.

- Prasertsung, I.; Damrongsakkul, S.; Saito, N. Degradation of β-Chitosan by Solution Plasma Process (SPP). Polym. Degrad. Stab. 2013, 98, 2089–2093.

- Li, J.; Cai, J.; Fan, L. Effect of Sonolysis on Kinetics and Physicochemical Properties of Treated Chitosan. J. Appl. Polym. Sci. 2008, 109, 2417–2425.

- Tsao, C.T.; Chang, C.H.; Lin, Y.Y.; Wu, M.F.; Han, J.L.; Hsieh, K.H. Kinetic Study of Acid Depolymerization of Chitosan and Effects of Low Molecular Weight Chitosan on Erythrocyte Rouleaux Formation. Carbohydr. Res. 2011, 346, 94–102.

- Pierre, G.; Salah, R.; Gardarin, C.; Traikia, M.; Petit, E.; Delort, A.-M.; Mameri, N.; Moulti-Mati, F.; Michaud, P. Enzymatic Degradation and Bioactivity Evaluation of C-6 Oxidized Chitosan. Int. J. Biol. Macromol. 2013, 60, 383–392.

- Thadathil, N.; Velappan, S.P. Recent Developments in Chitosanase Research and Its Biotechnological Applications: A Review. Food Chem. 2014, 150, 392–399.

- Nurunnabi, M.; Revuri, V.; Huh, K.M.; Lee, Y.-K. Chapter 14—Polysaccharide Based Nano/microformulation: An Effective and Versatile Oral Drug Delivery System. In Nanostructures for Oral Medicine. Micro and Nano Technologies; Andronescu, E., Grumezescu, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 409–433.

- Coquery, C.; Negrell, C.; Caussé, N.; Pébère, N.; David, G. Synthesis of New High Molecular Weight Phosphorylated Chitosans for Improving Corrosion Protection. Pure Appl. Chem. 2019, 91, 509–521.

- Olshannikova, S.S.; Malykhina, N.V.; Lavlinskaya, M.S.; Sorokin, A.V.; Yudin, N.E.; Vyshkvorkina, Y.M.; Lukin, A.N.; Holyavka, M.G.; Artyukhov, V.G. Novel Immobilized Biocatalysts Based on Cysteine Proteases Bound to 2-(4-Acetamido-2-sulfanilamide) Chitosan and Research on Their Structural Features. Polymers 2022, 14, 3223.

- Suresh, R.; Deepa, M.; Sudha, P.N.; Gomathi, T.; Pavithra, S.; Moganavally, P. Synthesis, Characterization, Biological and Catalytic Activity of Carboxymethyl Chitosan Schiff Base Metal Complexes. IJMS 2022, 51, 423–431.

- Rostami, N.; Dekamin, M.G.; Valiey, E.; Fanimoghadam, H. Chitosan-EDTA-Cellulose Network as a Green, Recyclable and Multifunctional Biopolymeric Organocatalyst for the One-pot Synthesis of 2-Amino-4H-pyran Derivatives. Sci. Rep. 2022, 12, 8642.

- ALSamman, M.T.; Sánchez, J. Recent Advances on Hydrogels Based on Chitosan and Alginate for the Adsorption of Dyes and Metal Ions from Water. Arab. J. Chem. 2021, 14, 103455.

- Dragan, E.S.; Dinu, M.V. Advances in Porous Chitosan Based Composite Hydrogels: Synthesis and Applications. React. Funct. Polym. 2020, 146, 104372.

- Ahmad, Z.; Salman, S.; Khan, S.A.; Amin, A.; Rahman, Z.U.; Al-Ghamdi, Y.O.; Akhtar, K.; Bakhsh, E.M.; Khan, S.B. Versatility of Hydrogels: From Synthetic Strategies, Classification, and Properties to Biomedical Applications. Gels 2022, 8, 167.

- Berger, J.; Reist, M.; Mayer, J.M.; Felt, O.; Gurny, R. Structure and Interactions in Chitosan Hydrogels Formed by Complexation or Aggregation for Biomedical Applications. Eur. J. Pharm. Biopharm. 2004, 57, 35–52.

- Boucard, N.; Viton, C.; Domard, A. New Aspects of the Formation of Physical Hydrogels of Chitosan in a Hydroalcoholic Medium. Biomacromolecules 2005, 6, 3227–3237.

- Sánchez-Cid, P.; Jiménez-Rosado, M.; Romero, A.; Pérez-Puyana, V. Novel Trends in Hydrogel Development for Biomedical Applications: A Review. Polymers 2022, 14, 3023.

- Naskar, S.; Sharma, S.; Kuotsu, K. Chitosan-Based Nanoparticles: An Overview of Biomedical Applications and Its Preparation. J. Drug Deliv. Sci. Technol. 2019, 49, 66–81.

- Shoueir, K.R.; El-Desouky, N.; Rashad, M.M.; Ahmed, M.K.; Janowska, I.; El-Kemary, M. Chitosan Based-Nanoparticles and Nanocapsules: Overview, Physicochemical Features, Applications of a Nanofibrous Scaffold, and Bioprinting. Int. J. Biol. Macromol. 2021, 167, 1176–1197.

- Liu, X.; Zhang, Y.; Ju, H.; Yang, F.; Luo, X.; Zhang, L. Uptake of Methylene Blue on Divinylbenzene Cross-Linked Chitosan/Maleic Anhydride Polymer by Adsorption Process. Colloids Surf. A Physicochem. Eng. Asp. 2021, 629, 127424.

- Vakili, M.; Deng, S.; Liu, D.; Li, T.; Yu, G. Preparation of Aminated Cross-Linked Chitosan Beads for Efficient Adsorption of Hexavalent Chromium. Int. J. Biol. Macromol. 2019, 139, 352–360.

- Altun, T. Preparation and Application of Glutaraldehyde Cross-Linked Chitosan Coated Bentonite Clay Capsules: Chromium(VI) Removal from Aqueous Solution. J. Chil. Chem. Soc. 2020, 65, 4790–4797.

- Warkara, S.G.; Meena, J. Synthesis and Applications of Biopolymer/FeO Nanocomposites: A Review. JNMES 2022, 25, 7–16.

- Omer, A.M.; Dey, R.; Eltaweil, A.S.; El-Monaem, E.M.A.; Ziora, Z.M. Insights into Recent Advances of Chitosan-Based Adsorbents for Sustainable Removal of Heavy Metals and Anions. Arab. J. Chem. 2022, 15, 103543.

- Fan, C.; Li, K.; He, Y.; Wang, Y.; Qian, X.; Jia, J. Evaluation of Magnetic Chitosan Beads for Adsorption of Heavy Metal Ions. Sci. Total Environ. 2018, 627, 1396–1403.

- Kloster, G.A.; Valiente, M.; Marcovich, N.E.; Mosiewicki, M.A. Adsorption of Arsenic onto Films Based on Chitosan and Chitosan/Nano-Iron Oxide. Int. J. Biol. Macromol. 2020, 165, 1286–1295.

- Kang, H.; Buchman, J.T.; Rodriguez, R.S.; Ring, H.L.; He, J.; Bantz, K.C.; Haynes, C.L. Stabilization of Silver and Gold Nanoparticles: Preservation and Improvement of Plasmonic Functionalities. Chem. Rev. 2019, 119, 664–699.

- Bashal, A.H.; Riyadh, S.M.; Alharbi, W.; Alharbi, K.H.; Farghaly, T.A.; Khalil, K.D. Bio-Based (Chitosan-ZnO) Nanocomposite: Synthesis, Characterization, and Its Use as Recyclable, Ecofriendly Biocatalyst for Synthesis of Thiazoles Tethered Azo Groups. Polymer 2022, 14, 386.

- Verma, D.K.; Malik, R.; Meena, J.; Rameshwari, R. Synthesis, Characterization and Applications of Chitosan Based Metallic Nanoparticles: A Review. J. Appl. Nat. Sci. 2021, 13, 544–551.

- Sun, L.; Li, J.; Cai, J.; Zhong, L.; Ren, G.; Ma, Q. One Pot Synthesis of Gold Nanoparticles Using Chitosan with Varying Degree of Deacetylation and Molecular Weight. Carbohyd. Polym. 2017, 178, 105–114.

- Krajewska, B. Application of Chitin- and Chitosan-based Materials for Enzyme Immobilizations: A Review. Enzyme Microb. Technol. 2004, 35, 126–139.

- Biró, E.; Németh, Á.S.; Sisak, C.; Feczkó, T.; Gyenis, J. Preparation of Chitosan Particles Suitable for Enzyme Immobilization. J. Biochem. Biophys. Methods 2008, 70, 1240–1246.

- Malmiri, H.J.; Jahanian, M.A.G.; Berenjian, A. Potential Applications of Chitosan Nanoparticles as Novel Support in Enzyme Immobilization. Am. J. Biochem. Biotechnol. 2012, 8, 203–219.

- Wang, D.; Jiang, W. Preparation of Chitosan-based Nanoparticles for Enzyme Immobilization. Int. J. Biol. Macromol. 2019, 126, 1125–1132.

- Verma, M.L.; Kumar, S.; Das, A.; Randhawa, J.S.; Chamundeeswari, M. Chitin and Chitosan-based Support Materials for Enzyme Immobilization and Biotechnological Applications. Environ. Chem. Lett. 2020, 18, 315–323.

- Nunes, Y.L.; de Menezes, F.L.; de Sousa, I.G.; Cavalcante, A.L.G.; Cavalcante, F.T.T.; da Silva Moreira, K.; de Oliveira, A.L.B.; Mota, G.F.; da Silva Souza, J.E.; de Aguiar Falcão, I.R.; et al. Chemical and Physical Chitosan Modification for Designing Enzymatic Industrial Biocatalysts: How to Choose the Best Strategy? Int. J. Biol. Macromol. 2021, 181, 1124–1170.

- Bilal, M.; Iqbal, H.M.N. Naturally-derived Biopolymers: Potential Platforms for Enzyme Immobilization. Int. J. Biol. Macromol. 2019, 130, 462–482.

- Chatterjee, S.; Lee, M.W.; Woo, S.H. Enhanced Mechanical Strength of Chitosan Hydrogel Beads by Impregnation with Carbon Nanotubes. Carbon 2009, 47, 2933–2936.

- Wahba, M.I. Porous Chitosan Beads of Superior Mechanical Properties for the Covalent Immobilization of Enzymes. Int. J. Biol. Macromol. 2017, 105, 894–904.

- Ji, Q.; Wang, B.; Li, C.; Hao, J.; Feng, W. Co-Immobilised 7a- and 7b-HSDH as Recyclable Biocatalyst: High-Performance Production of TUDCA from Waste Chicken Bile. RSC Adv. 2018, 8, 34192–34201.

- Singh, R.S.; Singh, R.P.; Kennedy, J.F. Immobilization of yeast inulinase on chitosan beads for the hydrolysis of inulin in a batch system. Int. J. Biol. Macromol. 2017, 95, 87–93.

- de Freitas, M.F.M.; Hortencio, L.C.; de Albuquerque, T.L.; Rocha, M.V.P.; Goncalves, L.R.B. Simultaneous Hydrolysis of Cheese Whey and Lactulose Production Catalyzed by β-Galactosidase from Kluyveromyces lactis NRRL Y1564. Bioprocess Biosyst. Eng. 2020, 43, 711–722.