3.3. Magnetically Separable Chitosan Composites

Magnetically separable composites based on various biopolymers are widely used for removal of different heavy metals from aqueous solutions

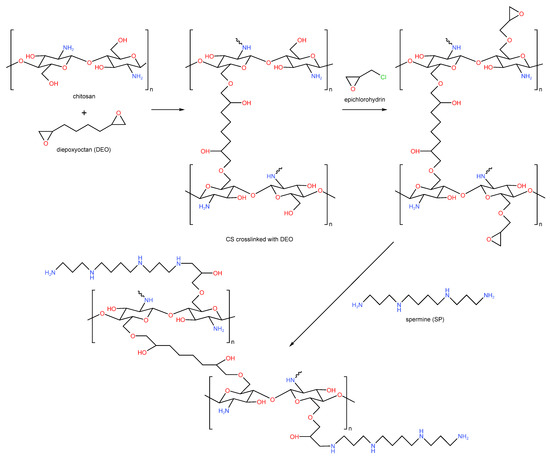

[38][124]. Incorporating magnetic materials into the CS matrix and shaping CS in various forms such as beads, membranes, hydrogels, etc., greatly boosts the separation problem of CS

[39][115].

Moreover, Fan et al.

[40][125] used two methods for the preparation of magnetic CS beads. The first method (embedding method) was based on the most widespread approach—preliminarily synthesis of Fe

3O

4 NPs, mixing of magnetic NPs with CS solution, and dripping of Fe

3O

4–CS solution in NaOH solution with further crosslinking with GA. The second method (chemical coprecipitation method) was based on the dissolution of CS and precursors of magnetic particles (Fe(II) and Fe(III)salts) in 3% acetic acid with subsequent dripping of this mixture in NaOH solution and crosslinking with GA. Thus, two series of magnetic CS beads with different Fe

3O

4/CS mass ratios were prepared.

Synthesized magnetic CS beads were used for the adsorption of Ag

+, Cu

2+, Hg

2+, Cr

3+ and Cr

6+ from aqueous solutions and recovery studies. Compared to the adsorption recovery index, the effort vector data visualization was more straightforward and easier to use. While comparing the two magnetic CS bead synthesis methods based on the proposed effort vector data visualization, it was found

[40][125] that both synthesis methods allow for similar efficiency of heavy metal adsorption and data distribution. Independent of the synthesis method, CS beads containing 0.3 g of CS and 0.7 g of Fe

3O

4 NPs revealed best performance for the adsorption of the chosen heavy metal ions.

Though most researchers prefer to synthesize CS-based materials in the form of beads, which possess low flow resistance and are hence convenient for continuous mode operation, for special applications, CS films and coatings can be obtained.

CS nanocomposite films were prepared

[41][126] using in situ precipitation of magnetic particles. The method of synthesis was based on the above-described chemical coprecipitation. The difference was in the shaping of the resulting material: a film was obtained by pouring the mixture (CS and iron salts) into Teflon Petri dishes and subsequently drying and rinsing it with NaOH solution; no crosslinking agents were added.

4. Chitosan as Catalytic Support

4.1. Catalytic Metal–Chitosan Composites

The lives of NPs can be divided into three stages: preparation, storage and application. The stabilization of particles’ physical and chemical characteristics is critical and must be carefully controlled

[42][132]. Metal deposition on CS is a promising area of research in the field of catalysis, since CS is a source of various functional groups that can effectively bind metal ions or NPs

[43][44][133,134]. In the resulting catalytic materials, CS can serve as a reducing agent (due to the presence of hydroxymethyl and amino groups) and stabilizer as well, which is able to control the sizes of metal NPs to some extent.

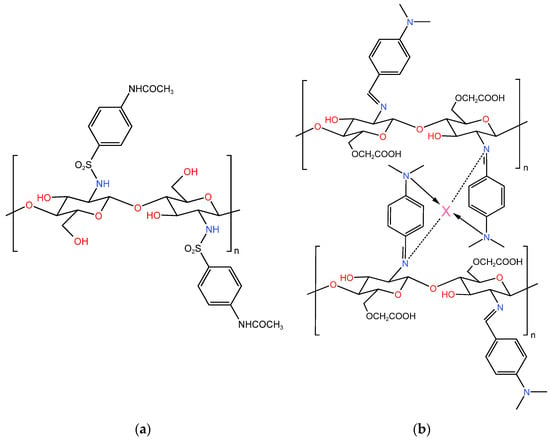

Any modifications to CS influence the concentration of functional groups and contribution of different interactions (hydrogen bonds, electrostatic interactions, π–π stacking interactions, etc.). For example, it was found that the DD and molecular weight of CS influences the sizes of Au NPs. At low CS concentration (0.005% and 0.01% (

w/

v)), individual spherical Au NPs with a mean diameter of about 10 nm were obtained regardless of chitosan DD and Mw, while anisotropic Au NPs were obtained at a concentration above 0.05% (

w/

v)

[45][135].

The growth of larger polygonal Au NPs was promoted as the higher concentration and lower DD CS was used. Chitooligomers (2.4 kDa, DD 94%) showed the highest reduction ability for Au(III) and the synthesized Au NPs exhibited aggregation. In general, it was concluded that the DD and concentration of CS is more important than Mw

[45][135].

4.2. Chitosan-Containing Composite Biocatalysts

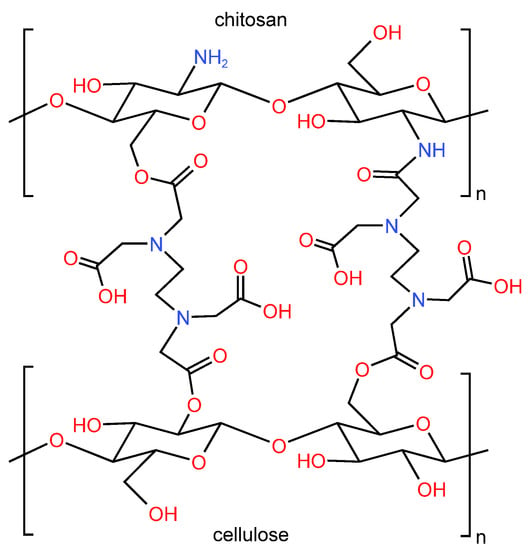

CS is widely used for the immobilization of enzymes as a part of support for covalent binding or encapsulation

[46][47][48][49][50][51][167,168,169,170,171,172]. The ability of CS to shape beads/microspheres, microcapsules, fibers, membranes, coatings, sponges and gels has expanded its applicability as a support for the immobilization of a wide range of biomolecules and enzymes

[52][173]. However, despite the advantages of using CS as a support for enzyme immobilization, CS beads and fibers are quite fragile and mechanically unstable

[53][54][174,175].

As previously mentioned, the mechanical properties of CS-based materials can be increased via covalent crosslinking (i.e., with GA or ECH). However, the cytotoxicity of the aforementioned crosslinking agents may hinder the use of CS hydrogels for pharmaceutical and biomedical applications. Thus, in contrast to CS-based adsorbents and metal-containing catalysts, toxic GA is replaced with the safer TPP at the crosslinking stage. For example, Ji et al.

[55][176] used CM prepared by dripping of CS acid solution in the solution of sodium TPP (crosslinking agent) for further co-immobilization of 7α- and 7β hydroxysteroid dehydrogenases (HSDH). It is noteworthy that the immobilization of these enzymes was carried out by preliminary activation of CM with GA that is common for enzyme deposition on heterogeneous supports. CM-immobilized HSDHs were used for the conversion of taurochenodeoxycholic acid (a component of chicken bile). The catalytic reaction reached equilibrium within 4 h. The yield of reaction product (tauroursodeoxycholic acid) was about 62% after equilibrium and the content of tauroursodeoxycholic acidin the reaction product was as high as 33.16%

[55][176]. A similar procedure was applied by Singh et al.

[56][177] for the immobilization of extracellular inulinase from

Kluyveromyces marxianus on CS beads. Under the optimized conditions, a maximum yield 65.5% of immobilized inulinase was obtained. The maximum hydrolysis of inulin—84.5%—was observed at 125 rpm after 4 h using an immobilized enzyme. The developed immobilized biocatalyst was successfully used for the hydrolysis of inulin for 14 batches.

De Freitas et al.

[57][179] immobilized β-galactosidase produced by the yeast

Kluyveromyces lactis NRRL Y1564 and delivered an enzymatic activity of 4418.37 U/g

cell after 12 h of processing on the CS particles without any crosslinker (CS was dissolved in 2% acetic acid, and then coagulating agent (KOH) was added during stirring). After coagulation, CS particles were activated with GA, ECH or glycidol. GA was chosen as an optimal activating agent. The biocatalyst obtained by immobilization in CS–GA allowed for the effective hydrolyzation lactose of milk (42.8% of conversion) and produced lactulose (17.32 g/L).

5. Conclusions

CS provides a number of opportunities for the production of environmentally friendly adsorbents and catalytic supports due to the existence of functional groups andthe ability to form different shapes (fibers, membranes, beads, NPs, etc.).

For adsorption purposes, the general trend is the use of crosslinking agents (preferably covalent crosslinking) and grafting of functional groups, resulting in a noticeable increase in thenumber of adsorption sites. However, this approach (CS modification) is rarely used in catalysis, especially inthe development of biocatalysts, since the high adsorption ability of CS with respect to both inorganic and organic components may have a negative influence on the biocatalysts’ efficiency. Thus, in the case of biocatalysts, CS can be used as a surface modifier of solid supports in an amount of less than 1 wt.%. This also contributes to the maximum availability of active centers of the immobilized enzymes.

At the same time, in the case of metal-catalyzed catalytic reactions, the high adsorption ability of CS can be used for the development of catalytic systems, in which the inorganic part entrapped by CS is a catalytically active phase while organic adsorbate is the subject of catalytic transformation. Thus, modified (grafted), CS-based materials are promising catalytic supports. In the composition of catalytic supports, crosslinking agents are typically not used, as well as certain shaping at a macro-level of the resulting catalytic materials.

The use of CS in biocatalytic processes is based primarily on its excellent gel-forming ability and the presence of amino groups available for interactions in its composition. Thanks to gelation, it is possible to synthesize various stable forms of solid supports for the immobilization of enzymes. Amino groups of CS are used for the covalent crosslinking of enzymes via activating agents due to the formation of Schiff’s bases (GA) or amide bonds (carbodiimides), as well as the crosslinking of CS itself in order to form particles of a certain shape. The combination of these properties allows for the achievement of high activity and the operational stability of synthesized biocatalytic systems. CS is most widely used for the immobilization of oxidoreductases (peroxidases, LACs and GOxs) and hydrolases (e.g., LIPs).

Magnetically separable catalysts/biocatalysts obviously have the advantage of easy separation from the reaction mixture, but most of these catalysts have the limitation of sensitivity to low pH. Thus, the further improvement of magnetically separable CS-based composites is a promising area of research.