Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Nhlanganiso Ivan Madondo | -- | 3746 | 2023-03-13 13:20:47 |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Madondo, N.I.; Rathilal, S.; Bakare, B.F.; Tetteh, E.K. Additives Used in Anaerobic Digestion. Encyclopedia. Available online: https://encyclopedia.pub/entry/42127 (accessed on 07 February 2026).

Madondo NI, Rathilal S, Bakare BF, Tetteh EK. Additives Used in Anaerobic Digestion. Encyclopedia. Available at: https://encyclopedia.pub/entry/42127. Accessed February 07, 2026.

Madondo, Nhlanganiso Ivan, Sudesh Rathilal, Babatunde Femi Bakare, Emmanuel Kweinor Tetteh. "Additives Used in Anaerobic Digestion" Encyclopedia, https://encyclopedia.pub/entry/42127 (accessed February 07, 2026).

Madondo, N.I., Rathilal, S., Bakare, B.F., & Tetteh, E.K. (2023, March 13). Additives Used in Anaerobic Digestion. In Encyclopedia. https://encyclopedia.pub/entry/42127

Madondo, Nhlanganiso Ivan, et al. "Additives Used in Anaerobic Digestion." Encyclopedia. Web. 13 March, 2023.

Copy Citation

Anaerobic digestion involves the degradation of a biodegradable substance, such as sewage sludge by anaerobic microorganisms in an oxygen-free system.

anaerobic digestion

anaerobic additives

syntrophic activity

metabolic activity

catalytic activity

enzymatic activity

cation exchange activity

1. Anaerobic Digestion

The method that is perhaps the most efficient and most promising in the treatment of some biochemical wastes, as well as wastewater and complex solid wastes, is anaerobic digestion, mainly because of the number of advantages it has compared to the other methods [1]. Advantages of the anaerobic digestion process include reduction of greenhouse gas emissions, conversion of carbon dioxide energy to methane, accommodation of high loading rates, and removal of pathogens [2][3][4]. Due to these benefits, the anaerobic digestion process is, thus, worth further investigation.

Anaerobic digestion involves the degradation of a biodegradable substance, such as sewage sludge by anaerobic microorganisms in an oxygen-free system [5]. The microorganisms feed on the organic matter, thereby converting it into biogas that is predominated by an energy-containing substance, methane, as well as carbon dioxide [6][7][8][9][10][11]. In an oxygen-free environment, anaerobic digestion can convert almost 90% of the energy kept in the biological matter into methane. The 10% of the biological matter that remains in wastewater is firstly dewatered and then disposed of. The anaerobic process is an effective method for several wastewater products, for instance, agricultural, industrial, and municipal wastewater.

1.1. Biochemical Mechanisms Found in Anaerobic Digestion

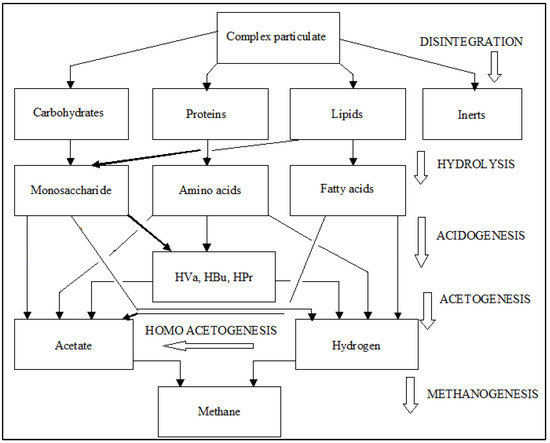

The overall digestion process involves both microbiological and physiochemical mechanisms, where the product of one stage is used as a feedstock for the subsequent stage. In detail, the process of anaerobic treatment usually involves the hydrolysis stage, acidogenesis stage, acetogenesis stage, and methanogenesis stage as illustrated in Figure 1 [12]. The hydrolysis stage is the only stage that includes physiochemical mechanisms (i.e., that involves the use of extracellular enzymes), and the other stages involve microbiological mechanisms (i.e., it involves the use of intracellular enzymes).

Figure 1. The anaerobic microbiological process diagram [13].

Wastewater such as sewage sludge normally entails complex constituents, namely carbohydrates, proteins, and lipids [14]. These biochemical constituents are not easily biodegraded by anaerobic microbes which means that they have to be broken down into smaller size molecules that are enough to be taken by microbes. This is accomplished in the hydrolysis stage, where lipids, proteins, and carbohydrates are firstly immersed into the liquid and are biodegraded by extracellular microorganisms, namely lipases, proteases, and cellulases into long-chain fatty acids, amino acids, and saccharides, respectively.

The hydrolysis stage is normally the rate-limiting stage for complex constituents, as this stage determines the total quantity of matter available for the subsequent stage and, hence, affects the movement rate of the entire anaerobic digestion process [15][16]. Generally, pre-treatment techniques are used by most researchers to enhance the hydrolysis stage, therefore, decreasing the hydraulic time of the digestion process as well as improving biogas production. These pre-treatment techniques can either be thermal-related or chemical-related. The latter includes the supplementation of lime, ammonia, or acid, whereas the former involves the use of steam or hot water [17][18][19].

The acidogenesis stage is the first stage of fermentation and continues the degradation of products from the hydrolysis stage by acidogenesis microorganisms (acidogenic), thereby, generating many organic substrates together with ammonia, hydrogen, and carbon dioxide. This stage is energetic and normally the fastest stage in the whole anaerobic process.

The acetogenesis stage is very important for the successful production of methanogenesis products. This stage involves the biodegradation of volatile fatty acids (VFAs) by acetogenesis microorganisms, known as acetogens, into methane, acetate, carbon dioxide, hydrogen, and water. Almost all reactions taking place in the acetogenesis stage have a positive change in Gibbs’s energy. This means that the overall mechanism involved in this stage is an endothermic one. Endothermic systems in anaerobic digestion are only accomplished in syntrophic conditions, a process that takes place between acetogens and hydrogenotrophic methanogens [20].

The last stage in anaerobic digestion is the methanogenesis stage, where intermediate products that were obtained in the process are transformed by methanogens into biogas [21]. This stage is achieved by methane-forming microorganisms. Any of the three bacterial pathways can be used to produce methane in the methanogenesis stage, namely methylotrophic, acetoclastic cleavage of acetic acid, and hydrogenotrophic methanogens. All of these pathways occur simultaneously in the methanogenesis stage. In a proper working digester, approximately 72% of the produced methane takes the acetoclastic cleavage of the acetic acid pathway. The remaining 28% takes the hydrogenotrophic pathway, whereas a small amount is produced via the methylotrophic pathway.

1.2. Limitations of the Traditional Anaerobic Digestion Process

Biochemical activities, for instance, syntrophy, metabolism, catalysis, and enzyme activities control the effectiveness of the digestion process for enhanced methane production. Perhaps, the most significant factor that may hinder biochemical activities and, hence, methane production is inhibition. The nature and type of biochemical activities and mechanisms affect the stability of the anaerobic process. Anaerobic digestion has certain inherent problems depending on the type of feed and anaerobic factors, for example, mass transfer that is slow especially when the solid content is high, VFA build-up, imbalanced carbon-to-nitrogen ratio, the obstinacy of lignocellulosic deposits, inhibition due to ammonia, sulphur, and insufficient micronutrients [22][23]. Such anaerobic problems may at times result in slow methanogenic activity along with low methane yield as well as hindering the bacterial community of the anaerobic digestion system.

2. Additives Used in Anaerobic Digestion

Various methods are implemented in anaerobic digestion to reduce the effect of inhibition and enhance stability to enhance the production of methane. This includes optimizing the concentration of solids to improve mass transfer, maintaining pH in the digester by adding a buffer, co-digesting substrates to balance the carbon-to-nitrogen ratio, and pre-treating to break the lignin structure to enhance the methanogenic stage.

Alternatively, the addition of several materials as support substrates to the digestion process offers an efficiently feasible answer for the above-mentioned problems of anaerobic digestion for improved anaerobic stability [24]. This includes (1) high electrical conductivity material to enhance syntrophic action, (2) small amounts of metals for metabolism enhancement, (3) nanoparticles to enhance metabolism and catalytic action, (4) microorganisms to enhance enzymatic activity, and (5) surface-active material to enhance cation exchange action [22][25].

2.1. Syntrophic Activity

Even though the rate-limiting stage differs and depends on the kind of feed, the syntrophy activity is usually regarded as a key parameter that greatly governs the entire rate of anaerobic digestion [1]. In a digester, a well-adjusted syntrophy involving the acidogenic stage and methanogenic stage presents a thermodynamically stable digestion system that is for the conversion of VFAs. The process of converting VFA to intermediate products such as acetate, butyrate, lactate, and ethanol as a result of syntrophy microorganisms stimulates methanogenesis microorganisms to digest the intermediate products as substances for CH4 production accompanied by reacting H2/CO2.

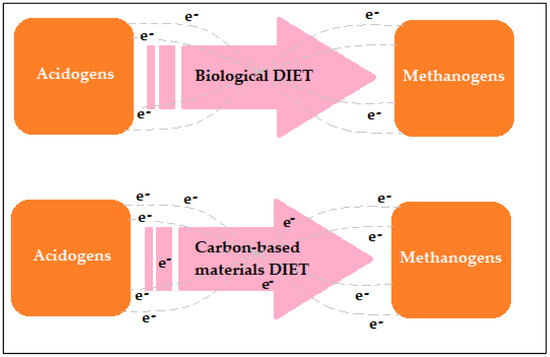

On the other hand, carbonaceous additives with high electrical conductivity promote the syntrophy action involving acid production by acidogenesis microorganisms and CH4-producing microorganisms by interspecies electron transfer (IET), a concept that involves direct interspecies electron transfer (DIET) and indirect interspecies electron transfer (IIET) [26][27][28][29]. In digesters, hydrogen and formic acid can simply be digested by methanogenesis microorganisms to generate CH4 using IIET on the condition that partial pressure is favorable to IIET. The phenomenon of syntrophy can become hindered if the hydrogen partial pressure is big, which might interrupt the IIET process, resulting in the volatile fatty acid build-up and the anaerobic digestion system becoming unstable. The DIET process, in contrast, once it occurs in the digestion process, can substitute hydrogen as the sole path of IET in the digester and assists in maintaining syntrophy action linking acetogenesis and methanogenesis microorganisms [30].

The DIET process, employing conductive substrates, is by far the most effective method for the generation of methane when compared to IET using electron carriers for instance, hydrogen, a key path of methane generation in traditional anaerobic digestion [31]. In the DIET process, the electron produced by the microorganisms is immediately taken by electron-receiving microbes as a result of networks formed by electrical conductive nanowires and cytochrome produced by microorganisms. Moreover, the process can assist in providing an ideally useful path because it has a higher negative Gibbs value (∆G0), and metabolites do not need to generate and diffuse [1].

Furthermore, the supplementation of conductive substrates to the digestion process can assist in promoting the DIET method for microorganisms that are unable to produce nanowires for IET. The rate of movement of the IET in the DIET system is about a million times higher than that in the IIET process. Therefore, the inability in the digestion system to be stable as a result of volatile fatty acids build-up at a higher loading rate can be enhanced by the DIET process. Moreover, carbonaceous conductive substrates, for instance, bio-char, carbon cloth, activated carbon, granular activated carbon, and magnetite, may operate to improve the DIET process in the digestion process as they assist in the acceleration of the volatile fatty acids build-up and present substances to methanogenesis microorganisms. Many investigators found a helpful effect on the methanogenic stage as well as stability when adding such additives for the anaerobic digestion of biochemical products and wastes [22].

Figure 2. Biological and carbon-based direct interspecies electron transfer (DIET) methods. Adapted from [22].

The utilization of biochar made by the thermal degradation of food waste as an additive to anaerobic digestion was extensively investigated by Shin et al. [32]. Adding 1% of food-waste biochar to the digester enhanced biogas generation by almost 10% and the content of methane by approximately 4%. Furthermore, the researchers discovered that biochar behaved like a medium with trace elements that encouraged the proliferation of microorganisms and enhanced the performance of anaerobic digestion. Feng et al. [33] investigated the influence of adding carbon cloth on the anaerobic digestion of biochemical wastewater at different mixing rates. The study revealed that the generation of methane can be enhanced by 10.1 to 23.0% and the efficiency of chemical oxygen demand (COD) removal was increased by 14.6% upon the addition of carbon cloth in the digester with no mixing at organic loading rates in the range of 2.1–4.2 g of COD per L-day. On the other hand, the improvement influence was only seen when the organic loading rate was very high (i.e., 4.2 g of COD per L-day) in a perfectly mixed reactor. Mostafa et al. [34] studied the effect of adding magnetite-nanoparticles and carbon nanotubes on anaerobic digestion. Both additions increased methane generation, and its favourable effect improved when the concentration of oleic acid was increased. The ultimate enhancements of 114% and 165% in comparison with the control were obtained by magnetite-nanoparticles and carbon nanotubes, respectively, at oleic acid of 4 g of COD per L. The excretion of electron shuttles, such as substances that are like protein and humic, were discovered to be enhanced by adding magnetite nanoparticles and carbon nanotubes.

2.2. Metabolic Activity

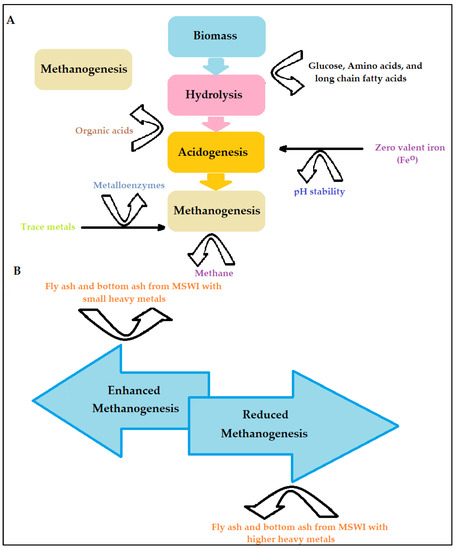

It is worth noting that, despite the potential toxic effect of metals, nearly all of them are required in anaerobic digestion for structural purposes, optimum growth, and optimal performance [35][36]. Small amounts of metals, an additive to anaerobic digestion, may be useful for the metabolism enhancement of bacterial cells (Figure 3). The use of substances, for instance, nickel, cobalt, iron, molybdenum, and other trace metals improve the metabolic activity of methanogenesis microorganisms, resulting in high methane production.

Figure 3. (A) Mechanisms of metal-based additives in anaerobic digestion. (B) Municipal solid waste incineration ash as additive in anaerobic digestion. Adapted from [22].

Most enzymes need metals as co-factors for their roles in anaerobic digestion. Perhaps the most plentiful metal present in cells is iron [35]. Because nearly all metalloenzymes found in the route of the generation of biogas have several clusters of Fe4S4, Fe3S4, or Fe2S2, iron is vital for cytochromes and the generation of methane [35][36]. Moreover, iron is an economical trace metal for enhancing methane production and the stability of the process. The process of adding iron in anaerobic digestion regularly promotes methane generation by extending the peak of the gas generation and increasing the activities of cellulase [36]. For instance, Bakari et al. [37] studied the influence of iron (F0), both steel wool and scrap iron, on the anaerobic digestion of sewage sludge. The outcome of this study revealed that: (a) steel wool performed better than scrap iron on the removals of chemical oxygen demand (COD) and phosphates (b) the optimum dosage for the removals of nutrients and the biochemical matter was 10 g/L scrap iron (c) the least removed contaminant was nitrogen (d) highest removals of COD and phosphates were 88.0%, and 98.0%, respectively. Therefore, iron-supported anaerobic digestion substantially removed the nutrients and biochemical matter from domestic sewage.

2.3. Catalytic Activity

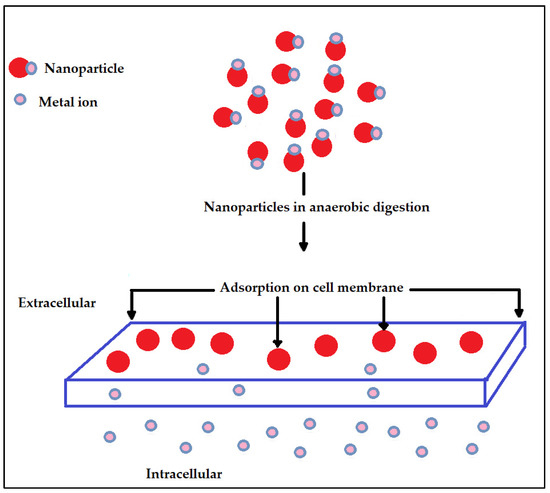

Elements of nanoscale dimensions are known as nanoparticles and range from around 1 to 100 nm [38]. The antibacterial properties, enormous energy-storing capacity, and the capability to present higher surface area (surface/volume ratio) have raised researchers’ attention to these particles in bioenergy usages. As a result of the ability of these substrates to improve catalytic capability within a big surface area for mechanisms, the nano-additives have furthermore acquired significant attention in biochemical energy.

Adding nanoparticles in anaerobic digestion (Figure 4) and also the effect of these nanoparticles on methane generation has been investigated quite often by many researchers over the past few years. Nanoparticles are presently used for detecting and removing biochemical materials including metals, algae (for example, toxins of cyanobacteria), nutrients (for example, nitrate, ammonia, and phosphate), carbon-based substances, virus, cyanide, microbes, antibiotics, and parasites. Essentially, four types of nanomaterials are currently used as useful materials for wastewater treatment purposes, namely metal oxide nanoparticles, carbonaceous nanoparticles, zero-valent nanoparticles, and dendrimers [22][38]. Córdova-Lizama et al. [39] studied the influence of cobalt and iron zero valent nanoparticles on the anaerobic digestion of waste-activated sludge. The outcome revealed that zero-valent iron nanoparticles and cobalt nanoparticles enhanced the early stages of the anaerobic digestion of waste-activated sludge. The highest hydrogen productions were found to be 5.40 and 5.74 mLH2/g volatile solids added (VSadded) for cobalt nanoparticles and zero-valent iron nanoparticles, respectively.

Figure 4. Mechanism of nanoparticles addition in anaerobic digestion [22].

García et al. [40] investigated the influence of titanium dioxide, cerium dioxide, gold, and silver nanoparticles on the activity of bacterial communities proposed for the treatment of wastewater. The outcome of the study showed that cerium dioxide nanoparticles resulted in the highest inhibition in the generation of biogas (almost 100%) and a great inhibitory action of other biochemical matters; silver nanoparticles resulted in an intermediate inhibition in generation of biogas (in the range 33–50%) and a small inhibition in the action of other biochemical matters, and titanium dioxide and gold nanoparticles resulted in only small or no inhibition for all investigated biochemical matters.

Chhetri et al. [41] developed a novel nanotechnology-based method (flocculation-based magnetic nanoparticles) to enhance the quality of groundwater. The outcome of the study demonstrated the prospective of magnetic nanosponges to enhance the groundwater quality and support the development of an economical greatest management technique (biochemical methane potential) that also uses customary coagulants at concentrated animal feeding operation and other wastewater treatment plants. The study showed that the coagulation process was improved by the usage of magnetic nanosponges, which can enhance the formation of flocs rapidly and efficiently with the ability to totally gravitate in the sedimentation tanks. The utilization of magnetic nanoparticles together with coagulants led to a higher reduction in the turbidity and total organic carbon of dairy farm wastewater in comparison with swine lagoon water, which indicated that magnetic nanosponges are more effective in enhancing the quality of water for highly contaminated lagoons.

Award et al. [42] explored the use of ultrafiltration membranes for wastewater treatment. The study also investigated the effect of the composition and type of the hydrophilic additives of nanoparticles (for example, titanium dioxide, zinc oxide, graphene oxide, etc.). It was suggested that amongst all kinds of membrane methods, ultrafiltration is regarded as a useful separation system and purification system. It was suggested that it is usually used to treat oily wastewater with <20 μm oil droplet size and <400 ppm oil content. Furthermore, another method has been tried to enhance the performance of polymeric membranes with a valuable influence by using additives, for instance, hydrophilic polymers, inorganic nanoparticles, and grafted and amphiphilic copolymers. Common inorganic particles that have been widely utilized to fabricate membranes are silicon dioxide, titanium dioxide, aluminum dioxide, magnesium oxide, graphene oxide, etc. Their use in membranes has considerably increased their antifouling properties with regards to oil products.

Kaegi et al. [43] studied the behavior of metallic silver nanoparticles in a pilot wastewater treatment system supplied with municipal wastewater. Silver nanoparticles were spiked into the non-aerated tank. Silver concentrations verified by inductively coupled plasma–mass spectrometry agreed well with estimates based on mass balance considerations. Analyses of a transmission electron microscopy (TEM) confirmed that nanoscale silver particles were absorbed to wastewater biosolids, both in the effluent and in the sludge. During the initial pulse spike, freely dispersed nanoscale silver particles were only seen in the effluent. X-ray absorption spectroscopy analyses showed that most silver in the effluent and in the sludge existed as silver sulphide. The outcome from the experimental works revealed that silver nanoparticles conversion to silver sulphide took place in the non-aerated tank within 2 h. Chemical and physical transformations of silver nanoparticles in wastewater treatment plants control the fate, the transport and also the bioavailability and the toxicity of silver nanoparticles and, thus, have to be taken into consideration in future risk assessments.

2.4. Enzymatic Activity

Preparing enzymes or adding microbes as a means of substituting the physiochemical pretreatments performed before anaerobic digestion has been studied in-depth recently. However, adding enzymes or microbes instantaneously in anaerobic digestion has not gained much attention. When anaerobic digestion is enhanced as a result of microorganisms, the process is called bioaugmentation [44]. The composition of the microbial population has an absolute influence on how the anaerobic digestion process behaves as well as its products since the performance of all biochemical mechanisms of anaerobic digestion rely on the movement of the microorganisms secreting essential enzymes, as well as the cellulosome multi-enzyme complexes, that are attached to the substance cell surface, therefore resulting in cellulosic hydrolysis.

Thus, how the anaerobic digestion system performs can be controlled by the manipulation or enrichment of the population of microbes existing in the reactors. Once the anaerobic system fails to succeed, mainly because of the bacterial population shifts, bioaugmentation with fresh microorganisms that have been added may be performed to restore the satisfactory performance of the anaerobic system. Such microbial shifts can take place when the system is stressed as well as in transitional phases, for instance, temperature variations and a decrease in pH. In such instances, the greater performance of anaerobic digestion is achievable by improving the population of microbes or the addition of microorganisms with new abilities.

However, the vital step for attaining a large quantity of designated bacterial community is selecting an inoculum as a source of microbes and the amount of inoculum to be used. Investigators usually give emphasis to the establishment of a methanogenesis population in the early phase of the anaerobic digestion system to accomplish a stable system. The large quantity of archaea responsible for the methanogenic stage is regarded as a crucial aspect in improving methane generation. Thus, most investigations focus on the methanogenesis population to stabilize the anaerobic digestion system in its early phases.

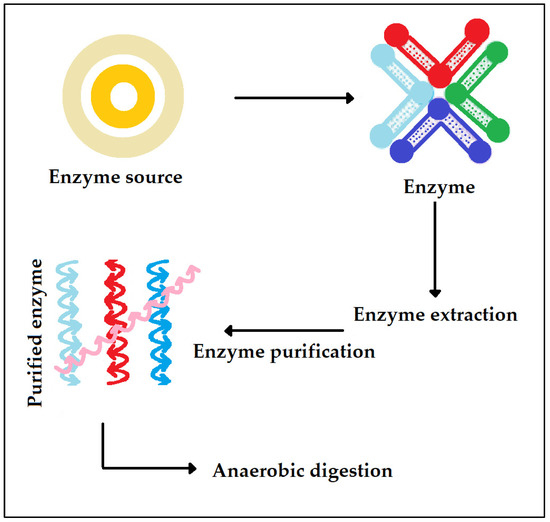

Another technique that may be used for augmenting the anaerobic digestion system is by adding enzyme preparations in digesters instead of microbes (Figure 5). Earlier studies showed enhanced methane generation from the pretreatment of lignocellulosic biomass including commercial and crude enzymes. However, enzymes can also be utilized for biomass treatment instantaneously in the anaerobic digestion process [45][46]. Enzyme addition in the anaerobic digestion process can be of great benefit because it is capable of withstanding a large range of salinity, pH, and temperature and is capable of avoiding unfavorable situations that cause inhibition in microbial activity. Enzyme addition rather than ordinary pretreatment techniques will, moreover, help to prevent the undesirable impact of produced inhibitory products on the activities of enzymes. Phenols as well as furfural produced in the pretreatment stage of the anaerobic digestion process have been shown to result in inhibition in the cellulosome activity. Furthermore, the better freedom of movement and the small size allow the enzymes to obtain greater access to the feed in comparison to microbes.

Figure 5. Extraction of enzyme for application in anaerobic digestion.

Aside from the addition of enzymes, biochemical substances can, moreover, be introduced in the anaerobic process to enhance the activity of enzymes. With regards to this, the process of adding carbon-based acids with negatively charged ions such as lactate, formate, and acetate have been found to function like promoters to improve the cellulosome activity for the duration of anaerobic digestion within 50, 100 and 200 mM concentrations, respectively. Above these values, the activity of cellulosomal enzymes is inhibited [47].

2.5. Cation Exchange Activity

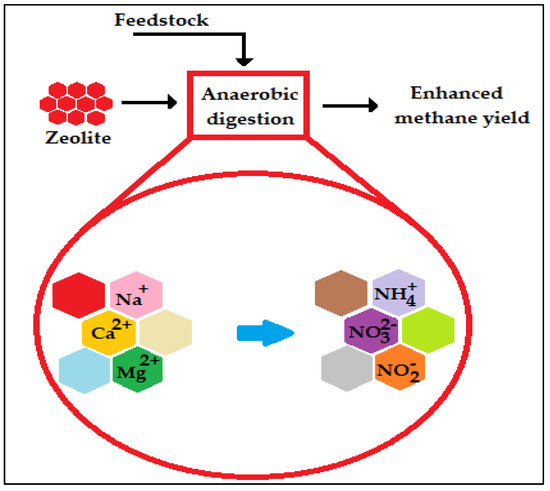

Surface-active substances, for instance, zeolites, may affect the bacterial community and their conversion in the digestion process. In addition to this, owing to the porous structure of zeolite might assist in anaerobic digestion if immobilization of organic matter is needed [48][49]. Zeolite, with its favorable features for adhering microorganisms, has also been usually used in anaerobic digestion as an ion exchanger for removing ammonium because of the existence of Mg2+, Ca2+, and Na+ positive ions in its crystal structure (Figure 6). Zeolites improve the ammonia/ammonium equilibrium in anaerobic digestion and the probability of decreasing ammonia and ammonium ions in water/wastewater [50]. This characteristic feature is also very significant for improving the performance of the anaerobic systems when treating wastewater with very high contents of nitrogen compounds, for example, poultry waste, because it avoids ammonia inhibition.

Figure 6. Cation exchange activity of zeolites [22].

A study was conducted by Wang et al. [51] on the impacts of zeolites on the anaerobic digestion process of ammonium-rich swine wastes. The use of zeolites increased the composition of methane by 19.7% and the overall methane yield by 120.9 CH4/kg VS compared to the absence of zeolites.

Essentially, zeolite is used as a surface where microorganisms can grow, as a result decreasing the lag phase and at the same time improving production in a specified period [50]. Hansson [52] investigated the effect of the zeolite-clinoptilolite in a continuous anaerobic digester. The results indicated a substantially smaller build-up of VFAs in comparison with a control digester at an organic loading rate of 4.8 kg VS/(m3·day) and a hydraulic retention time (HRT) of 30 days. The same observation was found upon the addition of zeolites in a batch reactor, which also revealed a declined lag phase.

However, the cation exchange characteristics of zeolite, makes this substrate not desirable for the solid-state anaerobic process. Stress can be made utilizing zeolite in dry anaerobic digestion of slaughterhouses, sludge, and food waste since these substrates contain high content of nitrogen.

References

- Mostafa, A.; Im, S.; Song, Y.C.; Ahn, Y.; Kim, D.H. Enhanced Anaerobic Digestion by Stimulating DIET Reaction. Processes 2020, 8, 424.

- El Mashad, H.M.; Barzee, T.J.; Franco, R.B.; Zhang, R.; Kaffka, S.; Mitloehner, F. Anaerobic Digestion and Alternative Manure Management Technologies for Methane Emissions Mitigation on Californian Dairies. Atmosphere 2023, 14, 120.

- Shapovalov, Y.; Zhadan, S.; Bochmann, G.; Salyuk, A.; Nykyforov, V. Dry Anaerobic Digestion of Chicken Manure: A Review. Appl. Sci. 2020, 10, 7825.

- Dalke, R.; Demro, D.; Khalid, Y.; Wu, H.; Urgun-Demirtas, M. Current status of anaerobic digestion of food waste in the United States. Renew. Sustain. Energy Rev. 2021, 151, 111554.

- Singh, R.; Paritosh, K.; Pareek, N.; Vivekanand, V. Integrated system of anaerobic digestion and pyrolysis for valorization of agricultural and food waste towards circular bioeconomy: Review. Bioresour. Technol. 2022, 360, 127596.

- Wang, S.; Xu, C.; Song, L.; Zhang, J. Anaerobic Digestion of Food Waste and Its Microbial Consortia: A Historical Review and Future Perspectives. Int. J. Environ. Res. Public Health 2022, 19, 9519.

- Goswami, L.; Kushwaha, A.; Singh, A.; Saha, P.; Choi, Y.; Maharana, M.; Patil, S.V.; Kim, B.S. Nano-Biochar as a Sustainable Catalyst for Anaerobic Digestion: A Synergetic Closed-Loop Approach. Catalysts 2022, 12, 186.

- Kazimierowicz, J.; Dębowski, M. Aerobic Granular Sludge as a Substrate in Anaerobic Digestion—Current Status and Perspectives. Sustainability 2022, 14, 10904.

- Ignatowicz, K.; Filipczak, G.; Dybek, B.; Wałowski, G. Biogas Production Depending on the Substrate Used: A Review and Evaluation Study—European Examples. Energies 2023, 16, 798.

- Kazimierowicz, J.; Dębowski, M. Characteristics of Solidified Carbon Dioxide and Perspectives for Its Sustainable Application in Sewage Sludge Management. Int. J. Mol. Sci. 2023, 24, 2324.

- Kesarwani, S.; Panwar, D.; Mal, J.; Pradhan, N.; Rani, R. Constructed Wetland Coupled Microbial Fuel Cell: A Clean Technology for Sustainable Treatment of Wastewater and Bioelectricity Generation. Fermentation 2023, 9, 6.

- Naphtali, J.; Chan, A.W.Y.; Saleem, F.; Li, E.; Devries, J.; Schellhorn, H.E. Comparative Metagenomics of Anaerobic Digester Communities Reveals Sulfidogenic and Methanogenic Microbial Subgroups in Conventional and Plug Flow Residential Septic Tank Systems. Processes 2022, 10, 436.

- Batstone, D.J.; Keller, J.; Angelidaki, I.; Kalyuzhnyi, S.V.; Pavlostathis, S.G.; Rozzi, A.; Sanders, W.T.M.; Siegrist, H.; Vavilin, V.A. The IWA Anaerobic Digestion Model No 1(ADM1). Water Sci. Technol. 2002, 45, 65–73.

- Xu, Z.X.; Ma, X.Q.; Zhou, J.; Duan, P.G.; Zhou, W.Y.; Ahmad, A.; Luque, R. The influence of key reactions during hydrothermal carbonization of sewage sludge on aqueous phase properties: A review. J. Anal. Appl. Pyrolysis 2022, 167, 105678.

- Uthirakrishnan, U.; Sharmila, V.G.; Merrylin, J.; Kumar, S.A.; Dharmadhas, J.S.; Varjani, S.; Banu, J.R. Current advances and future outlook on pretreatment techniques to enhance biosolids disintegration and anaerobic digestion: A critical review. Chemosphere 2022, 288, 132553.

- Vázquez-Fernández, A.; Suárez-Ojeda, M.E.; Carrera, J. Review about bioproduction of Volatile Fatty Acids from wastes and wastewaters: Influence of operating conditions and organic composition of the substrate. J. Environ. Chem. Eng. 2022, 10, 107917.

- Das, N.; Jena, P.K.; Padhi, D.; Mohanty, M.K.; Sahoo, G. A comprehensive review of characterization, pretreatment and its applications on different lignocellulosic biomass for bioethanol production. Biomass Conv. Bioref. 2023, 13, 1503–1527.

- Prasad, B.R.; Padhi, R.K.; Ghosh, G. A review on key pretreatment approaches for lignocellulosic biomass to produce biofuel and value-added products. Int. J. Environ. Sci. Technol. 2022, 19, 1–16.

- Olatunji, K.O.; Ahmed, N.A.; Ogunkunle, O. Optimization of biogas yield from lignocellulosic materials with different pretreatment methods: A review. Biotechnol. Biofuels 2021, 14, 159.

- Dahiya, S.; Lingam, Y.; Mohan, S.V. Understanding acidogenesis towards green hydrogen and volatile fatty acid production—Critical Analysis and Circular Economy Perspective. Chem. Eng. J. 2023, 461, 141550.

- Dong, W.; Yang, Y.; Liu, C.; Zhang, J.; Pan, J.; Luo, L.; Wu, G.; Awasthi, M.K.; Yan, B. Caproic acid production from anaerobic fermentation of organic waste—Pathways and microbial perspective. Renew. Sustain. Energy Rev. 2023, 175, 113181.

- Paritosh, K.; Yadav, M.; Chawade, A.; Sahoo, D.; Kesharwani, N.; Pareek, N.; Vivekanand, V. Additives as a Support Structure for Specific Biochemical Activity Boosts in Anaerobic Digestion: A Review. Front. Energy Res. 2020, 8, 88.

- Anukam, A.; Mohammadi, A.; Naqvi, M.; Granstrom, K. A review of the Chemistry of Anaerobic Digestion: Methods of Accelerating and Optimizing Process Efficiency. Processes 2019, 7, 504.

- Liu, M.; Wei, Y.; Leng, X. Improving biogas production using additives in anaerobic digestion: A review. J. Clean. Prod. 2021, 297, 126666.

- Liu, C.; Tong, Q.; Li, Y.; Wang, N.; Liu, B.; Xhang, X. Biogas production and metal passivation analysis during anaerobic digestion of pig manure: Effects of a magnetic Fe3O4/FA composite supplement. R. Soc. Chem. 2019, 9, 4488–4498.

- Xu, X.J.; Yan, J.; Yuan, Q.K.; Wang, X.T.; Yuan, Y.; Ren, N.Q.; Lee, D.J.; Chen, C. Enhanced methane production in anaerobic digestion: A critical review on regulation based on electron transfer. Bioresour. Technol. 2022, 364, 128003.

- Castilho, T.G.; Rodrigues, J.A.D.; García, J.; Subtil, E.L. Recent advances and perspectives in the use of conductive materials to improve anaerobic wastewater treatment: A systematic review approached. J. Water Process Eng. 2022, 50, 103193.

- González, J.; Sánchez, M.E.; Gómez, X. Enhancing Anaerobic Digestion: The Effect of Carbon Conductive Materials. C 2018, 4, 59.

- Lee, C. Engineering Direct Interspecies Electron Transfer for Enhanced Methanogenic Performance. In Renewable Energy Technologies for Energy Efficient Sustainable Development; Sinharoy, A., Lens, P.N.L., Eds.; Applied Environmental Science and Engineering for a Sustainable Future; Springer: Cham, Switzerland, 2022.

- Li, L.; Xu, Y.; Dai, X.; Dai, L. Principles and advancements in improving anaerobic digestion of organic waste via direct interspecies electron transfer. Renew. Sustain. Energy Rev. 2021, 148, 111367.

- Park, J.H.; Kang, H.J.; Park, K.H.; Park, H.D. Direct interspecies electron transfer via conductive materials: A perspective for anaerobic digestion applications. Bioresour. Technol. 2018, 254, 300–311.

- Shin, D.C.; Kim, I.-T.; Jung, J.; Jeong, Y.; Lee, Y.-E.; Ahn, K.-H. Increasing Anaerobic Digestion Efficiency Using Food-Waste-Based Biochar. Fermentation 2022, 8, 282.

- Feng, D.; Xia, A.; Huang, Y.; Zhu, X.; Zhu, X.; Liao, Q. Effects of carbon cloth on anaerobic digestion of high concentration organic wastewater under various mixing conditions. J. Hazard. Mater. 2022, 5, 423.

- Mostafa, A.; Im, S.; Song, Y.-C.; Kang, S.; Kim, D.-H. Enhanced Anaerobic Digestion of Long Chain Fatty Acid by Adding Magnetite and Carbon Nanotubes. Microorganisms 2020, 8, 333.

- Paulo, L.; Stams, A.; Sousa, D. Methanogens, sulphate and heavy metals: A complex system. Rev. Environ. Sci. Biotechnol. 2015, 14, 537–553.

- Zhang, H.; Tian, Y.; Zheng, L.; Li, S.; Hao, H.; Yin, M.; Cao, Y.; Huang, H. Process Analysis of Anaerobic Fermentation Exposure to Metal Mixtures. Int. J. Environ. Res. Public Health 2019, 16, 2458.

- Bakari, O.; Njau, K.N.; Noubactep, C. Fe0-Supported Anaerobic Digestion for Organics and Nutrients Removal from Domestic Sewage. Water 2022, 14, 1623.

- Rahman, K.; Melville, S.; Imamul Huq, S.; Khoda, S. Understanding bioenergy production and optimisation at the nanoscale—A review. J. Exp. Nanosci. 2016, 11, 762–775.

- Córdova-Lizama, A.; Carrera-Figueiras, C.; Palacios, A.; Castro-Olivera, P.M.; Ruiz-Espinoza, J. Improving hydrogen production from the anaerobic digestion of waste activated sludge: Effects of cobalt and iron zero valent nanoparticles. Int. J. Hydrog. Energy 2022, 47, 30074–30084.

- García, A.; Delgado, L.; Torà, J.A.; Casals, E.; González, E.; Puntes, V.; Font, X.; Carrera, J.; Sánchez, A. Effect of cerium dioxide, titanium dioxide, silver, and gold nanoparticles on the activity of microbial communities intended in wastewater treatment. J. Hazard. Mater. 2012, 199–200, 64–72.

- Chhetri, T.; Cunningham, G.; Suresh, D.; Shanks, B.; Kannan, R.; Upendran, A.; Afrasiabi, Z. Wastewater Treatment Using Novel Magnetic Nanosponges. Water 2022, 14, 505.

- Award, E.S.; Sabirova, T.M.; Tretyakova, N.A.; Alsalhy, Q.F.; Figoli, A.; Salih, I.K. A Mini-Review of Enhancing Ultrafiltration Membranes (UF) for Wastewater Treatment: Performance and Stability. Chem. Eng. 2021, 5, 34.

- Kaegi, R.; Voegelin, A.; Sinnet, B.; Zuleeg, S.; Hagendorfer, H.; Burkhardt, M.; Siegrist, H. Behavior of Metallic Silver Nanoparticles in a Pilot Wastewater Treatment Plant. Environ. Sci. Technol. 2011, 45, 3902–3908.

- Li, Y.Z.; Inoue, D.; Ike, M. Mitigating ammonia-inhibition in anaerobic digestion by bioaugmentation: A review. J. Water Process Eng. 2023, 52, 103506.

- Parawira, W. Enzyme research and applications in biotechnological intensification of biogas production. Crit. Rev. Biotechnol. 2012, 32, 172–186.

- Heerenklage, J.; Rechtenbach, D.; Atamaniuk, I.; Alassali, A.; Raga, R.; Koch, K. Development of a method to produce standardised and storable inocula for biomethane potential tests–preliminary steps. Renew. Energy 2019, 143, 753–761.

- Xu, C.; Qin, Y.; Li, Y.; Ji, Y.; Huang, J.; Song, H. Factors influencing cellulosome activity in consolidated bioprocessing of cellulosic ethanol. Bioresour. Technol. 2010, 101, 9560–9569.

- Yu, C.; Li, D.; Wang, Q.; Zhang, Z.; Yang, Y. Improving Anaerobic Methane Production from Ammonium-rich Piggery Waste in a Zeolite-fixed Bioreactor and Evaluation of Ammonium Adsorbed on Zeolite A-3 as Fertilizer. Int. J. Waste Resour. 2014, 4, 1000106.

- Ciezkowska, M.; Bajda, T.; Decewicz, P.; Dziewit, D.; Drewniak, L. Effect of Clinoptilolite and Halloysite Addition on Biogas Production and Microbial Community Structure during Anaerobic Digestion. Materials 2020, 13, 4127.

- Lauka, D.; Pastare, L.; Blumberga, D.; Romagnoli, F. Preliminary analysis of anaerobic digestion process using Cerathophyllum demersum and low carbon content additives: A batch test study. In Proceedings of the International Scientific Conference “Environmental and Climate Technologies—CONECT 2014”, Riga, Latvia, 14–16 October 2014; pp. 25–31.

- Wang, Q.; Yang, Y.; Yu, C.; Huang, H.; Kim, M.; Feng, C.; Zhang, Z. Study on a fixed zeolite bioreactor for anaerobic digestion of ammonium-rich swine wastes. Bioresour. Technol. 2011, 102, 7064–7068.

- Hansson, A. Mechanism of Zeolite Activity in Biogas Co-Digestion. Master’s Thesis, Linkoping University of Technology, Linkoping, Sweden, 2011.

More

Information

Subjects:

Engineering, Chemical; Green & Sustainable Science & Technology; Nanoscience & Nanotechnology

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

2.4K

Entry Collection:

Wastewater Treatment

Revision:

1 time

(View History)

Update Date:

13 Mar 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No