| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Aziz RACHID | -- | 2360 | 2023-02-25 10:33:44 | | | |

| 2 | Lindsay Dong | Meta information modification | 2360 | 2023-02-27 04:01:47 | | | | |

| 3 | Lindsay Dong | + 4 word(s) | 2364 | 2023-02-27 04:03:10 | | |

Video Upload Options

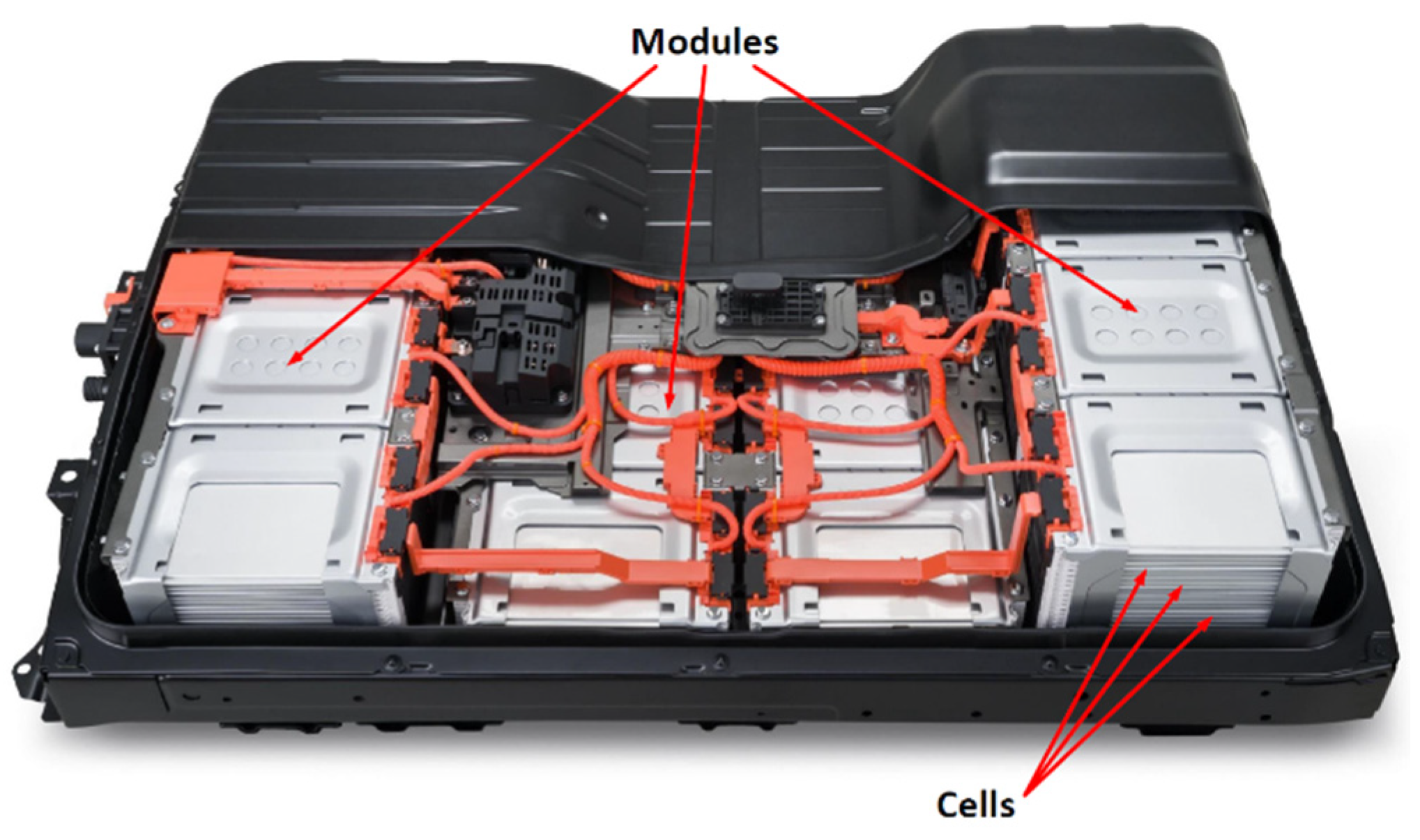

The high-voltage battery is a crucial element for electric vehicles (EVs) traction systems. It is the primary energy source that must be regularly recharged to reach the autonomy declared by the manufacturer. Therefore, an EV charging system is required to ensure the battery charging process.

1. Classification and Topologies of EV Charger

1.1. EV Chargers Classification

| EV Chargers | Description |

|---|---|

| Offboard chargers | All the components required for the EV charging and discharging process are inside the public EV charging station [3][4]. |

| On-board chargers | Some components required for the battery-charging process are embedded inside the EV. |

| Unidirectional chargers | The electrical energy transfer is one-way from the EV charging station to the EV battery. Therefore, only the G2V operation mode is possible. |

| Bidirectional chargers | The electrical energy flow can be from or to the EV battery. Thus, V2X technology can be ensured by this type of charger [5]. |

| Dedicated chargers | All equipment making up the charger is exclusively utilized to guarantee the EV charging or discharging process. |

| Integrated chargers | When the EV is linked to the electricity network, the traction system constituents (Motors, inverters, etc.) are used to guarantee the EV charging or discharging process [6]. |

| Conductive chargers | A dedicated electrical cable links the EV to the electricity network. |

| Wireless Power Transfer Chargers [7] |

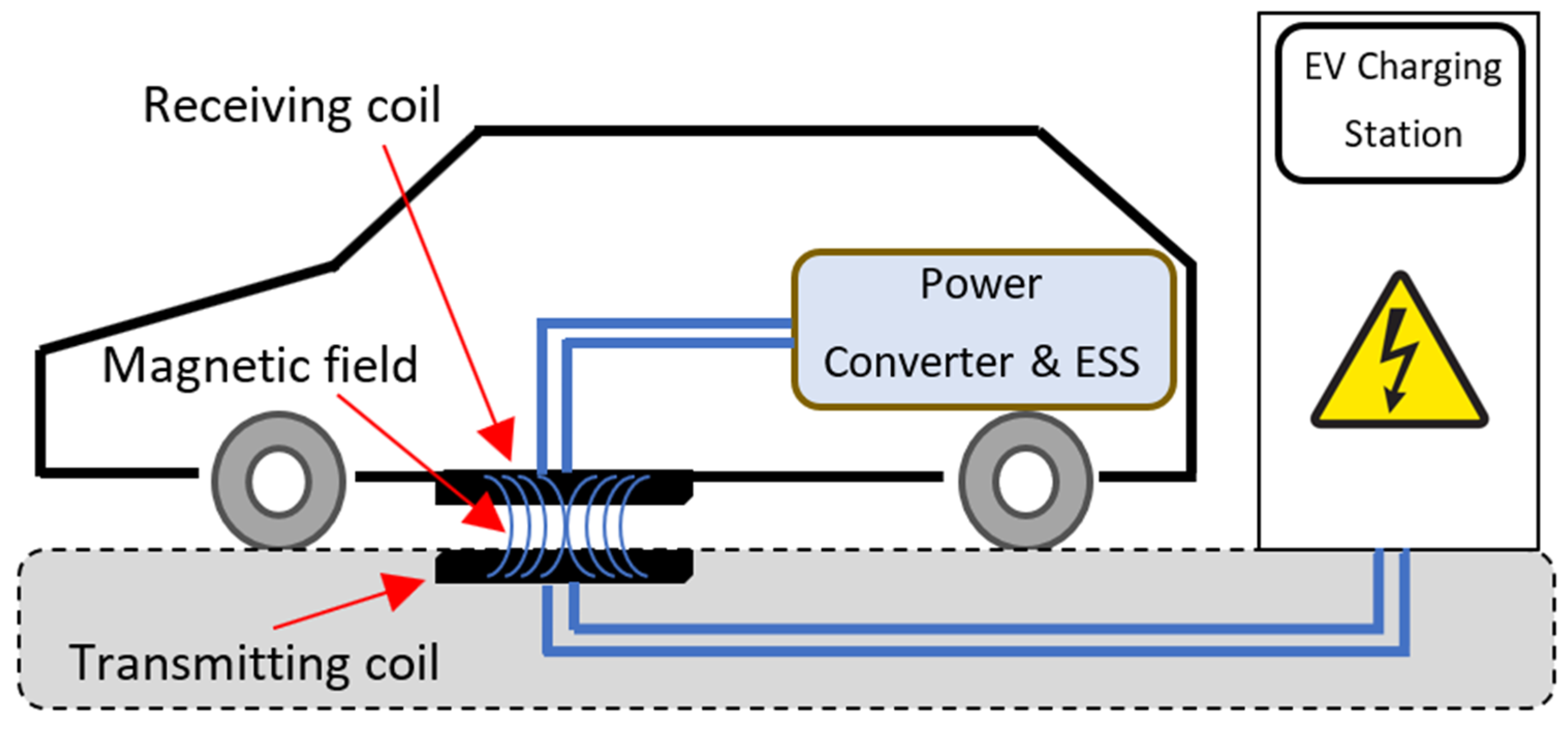

It is a contactless charging technology. No cables are utilized between the EV and the electricity network [8]. Instead, the electrical energy transfer is based on electromagnetic induction [9]. Figure 6 illustrates the concept of this EV charger type [10]. Compared with conductive chargers, these inductive chargers present various advantages [11]. Especially the convenience for the user and the intrinsic galvanic insulation, while the cost and the need for custom hardware inside the EV are the main drawbacks [12][13]. |

| Single-stage & Dual-stage chargers |

The first one consists of a single power conversion: only one ac-dc or one dc-dc power converter. The second one involves double power stages: ac-dc and dc-dc power conversions. |

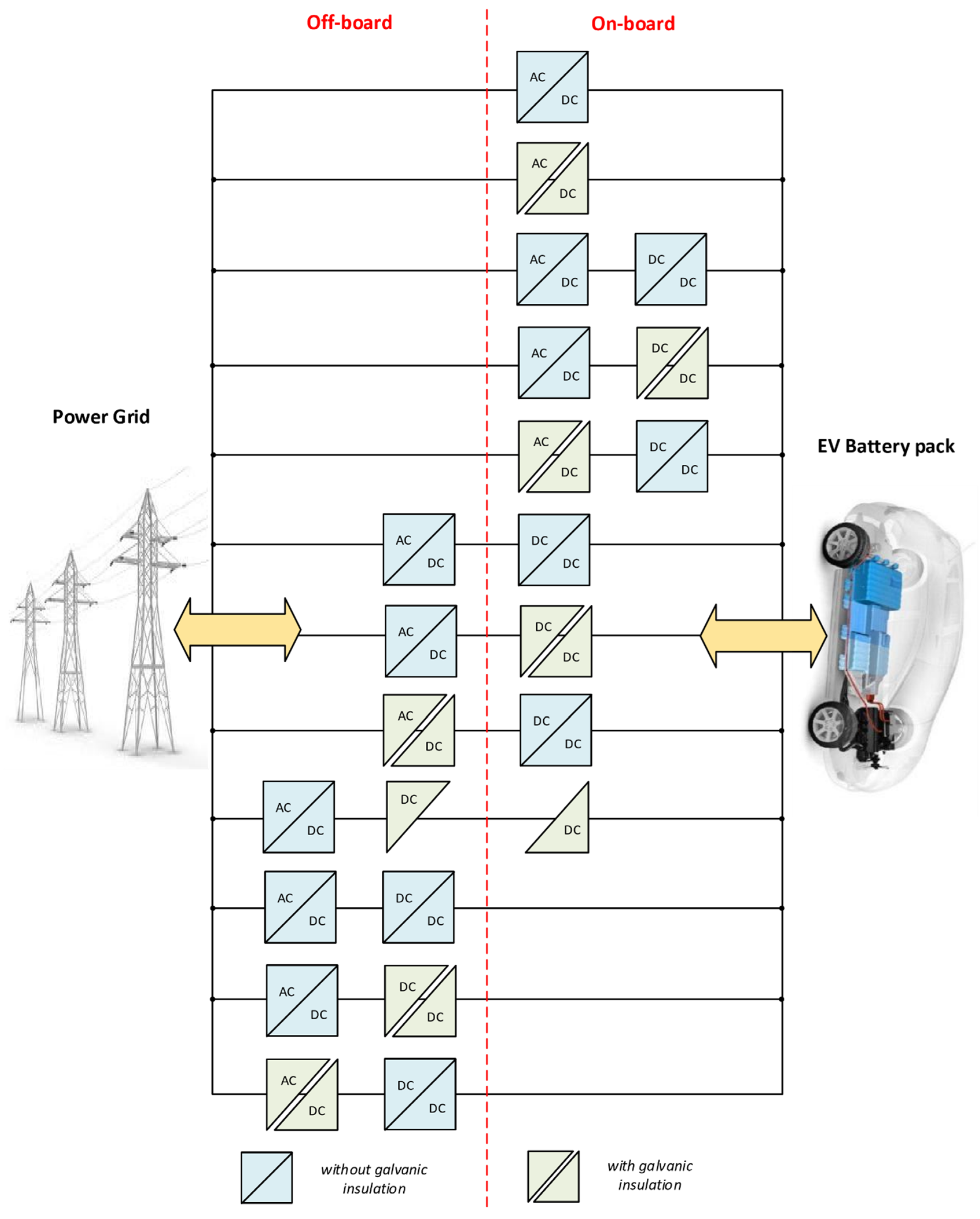

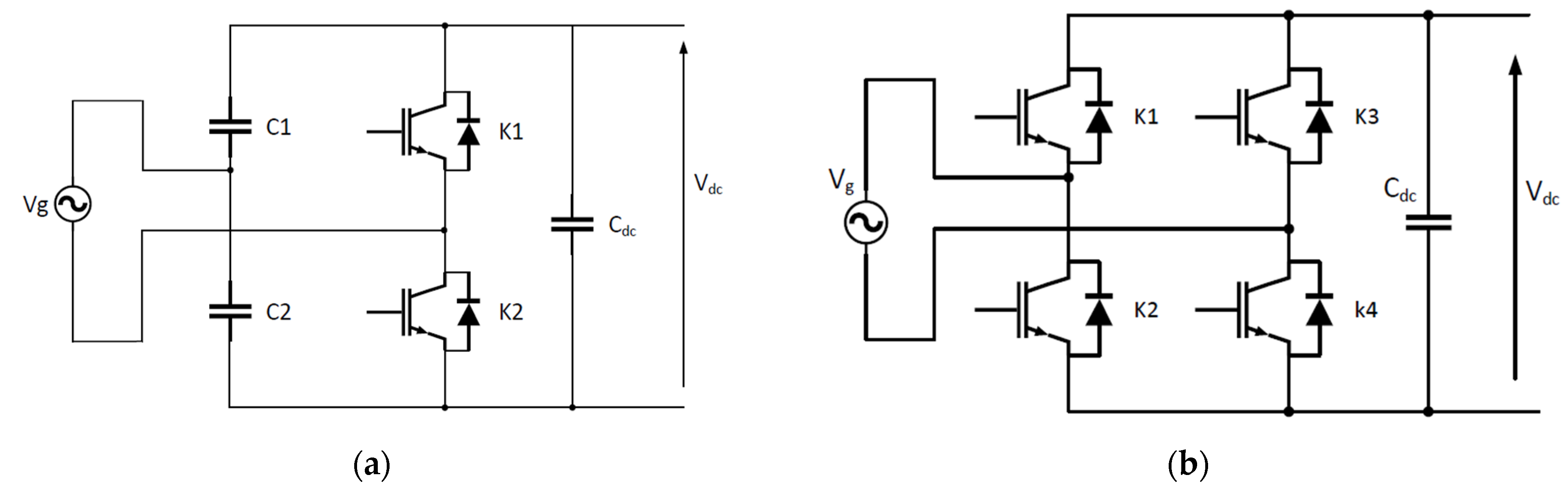

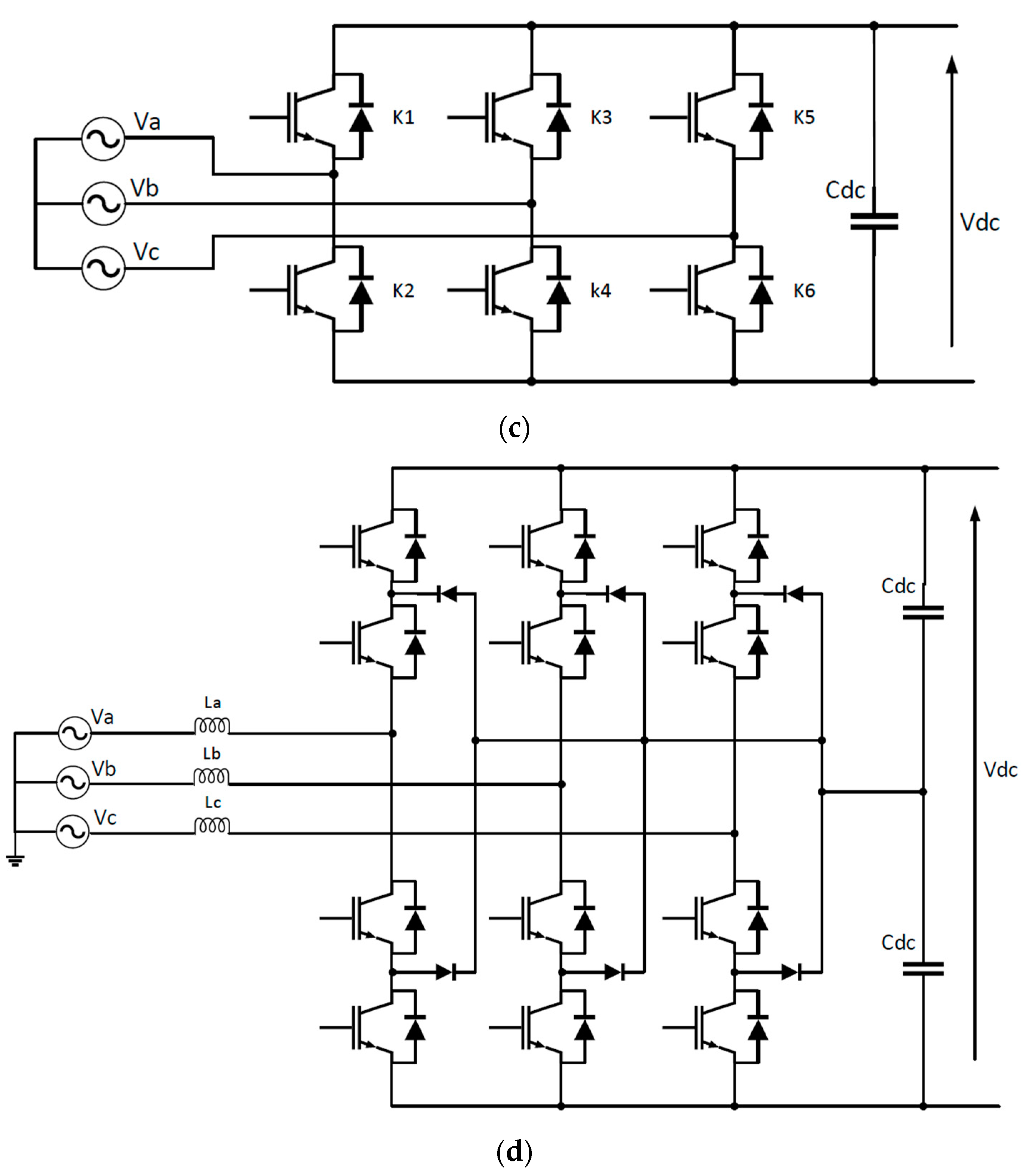

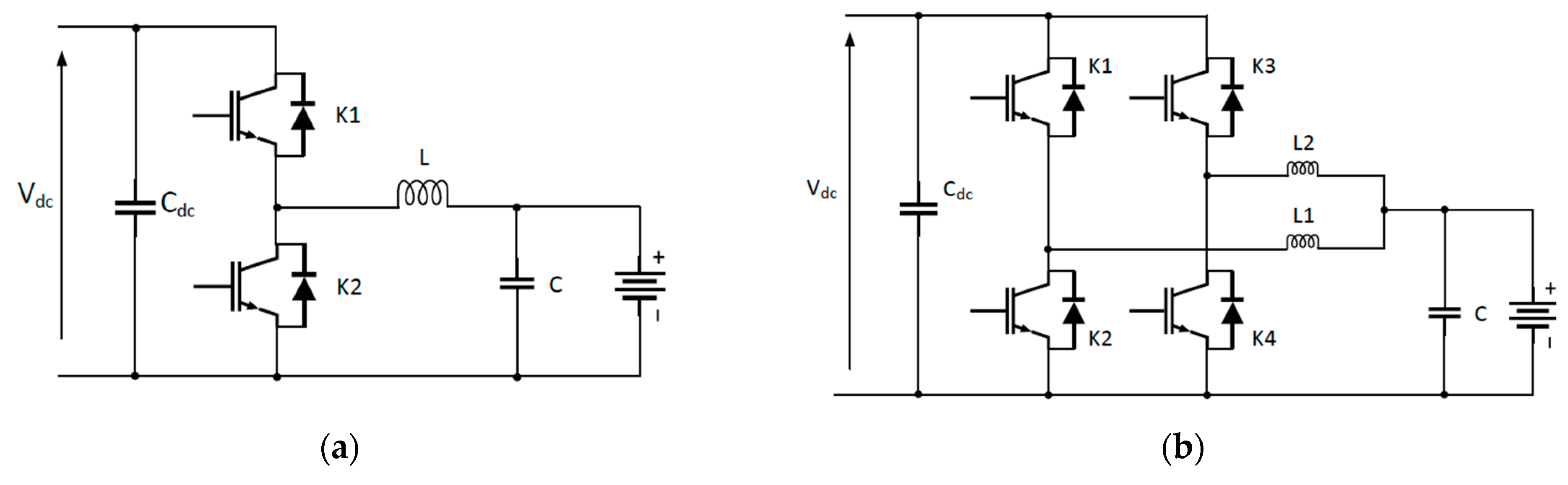

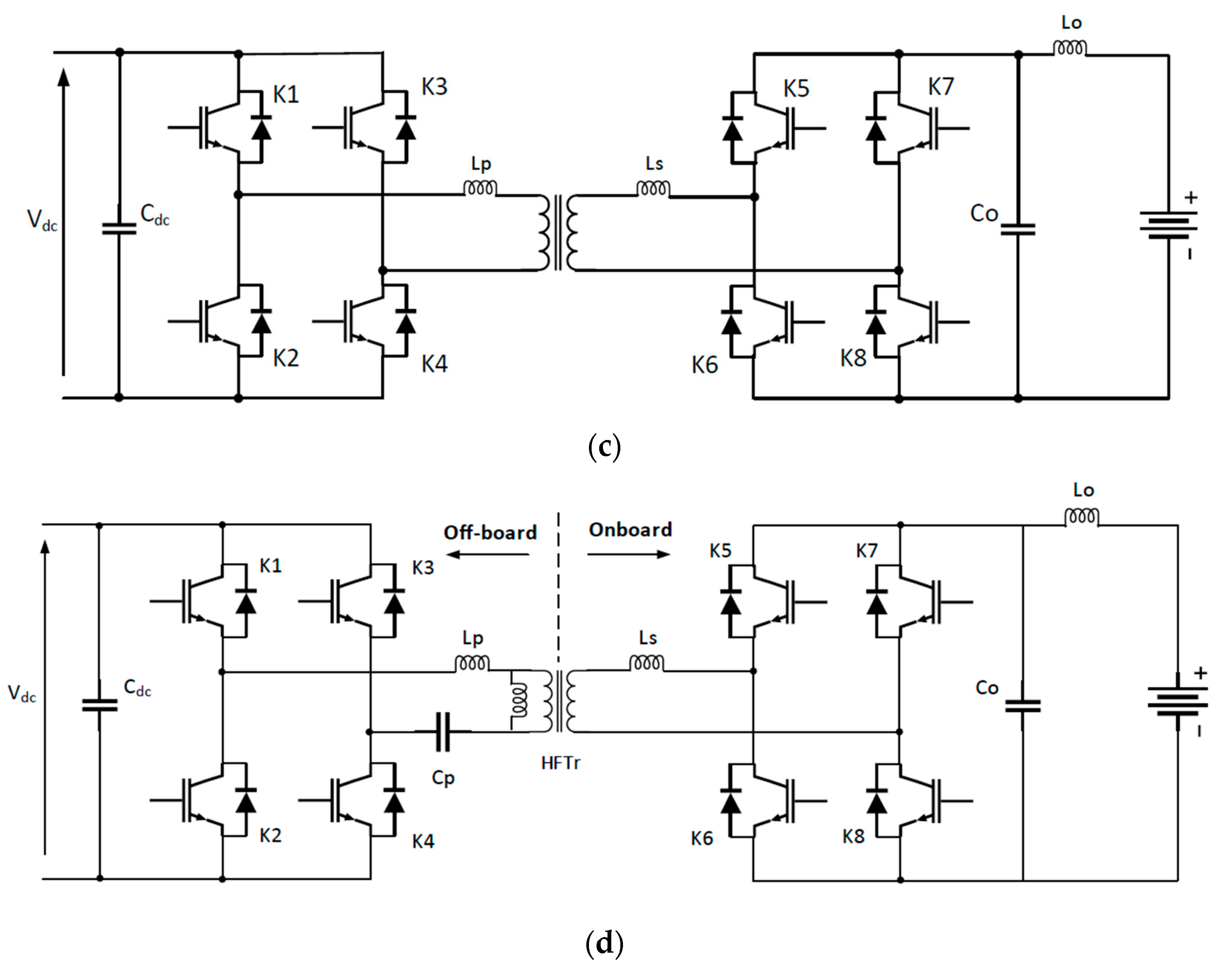

1.2. EV Charger Topologies

3. EV Charging Standards

3.1. SAE J1772 Standard

| Charging Level | Specifications |

|---|---|

| AC Level 1 |

|

| AC Level 2 |

|

| DC Level 1 |

|

| DC Level 2 |

|

3.2. IEC 61851 Standard

3.3. China GB Standards

| Standard Code | GB Standard Title |

|---|---|

| GB/T 20234.1-2015 |

|

| GB/T 20234.2-2015 |

|

| GB/T 20234.3-2015 |

|

| GB/T 27930-2015 |

|

| GB/T 28569-2012 |

|

| GB/T 29317-2012 |

|

| GB/T 29318-2012 |

|

| GB/T 38775-2020 |

|

4. EV Charging Couplers

4.1. SAE J1772 Coupler

4.2. IEC Type 2 Coupler

4.3. CCS Combo Coupler

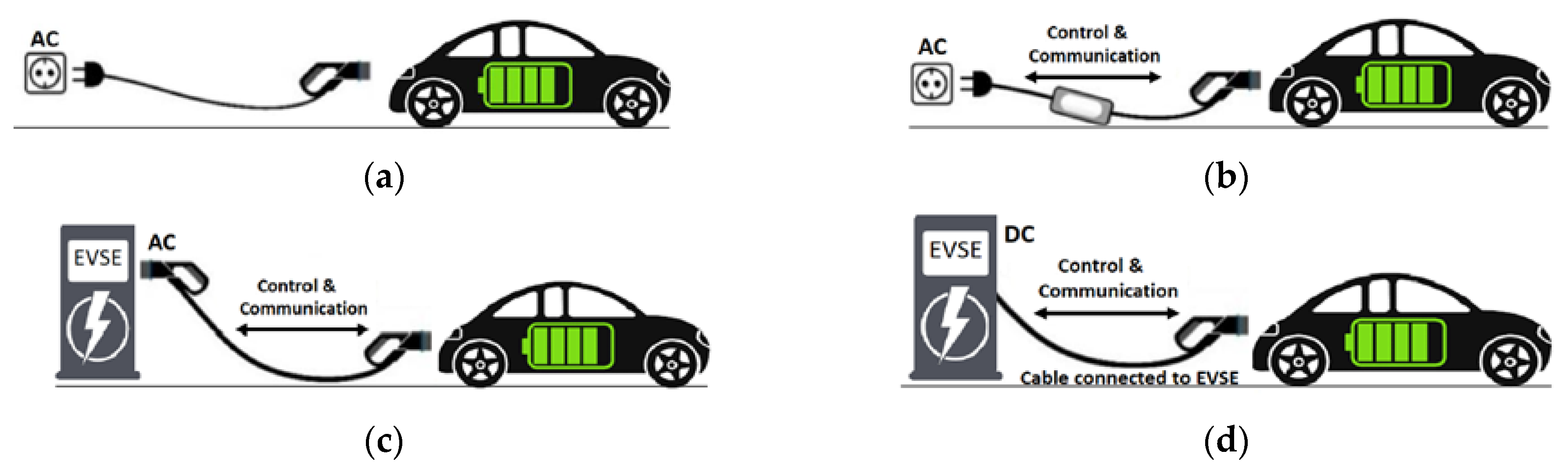

4.4. CHAdeMO Coupler

4.5. GB/T Coupler

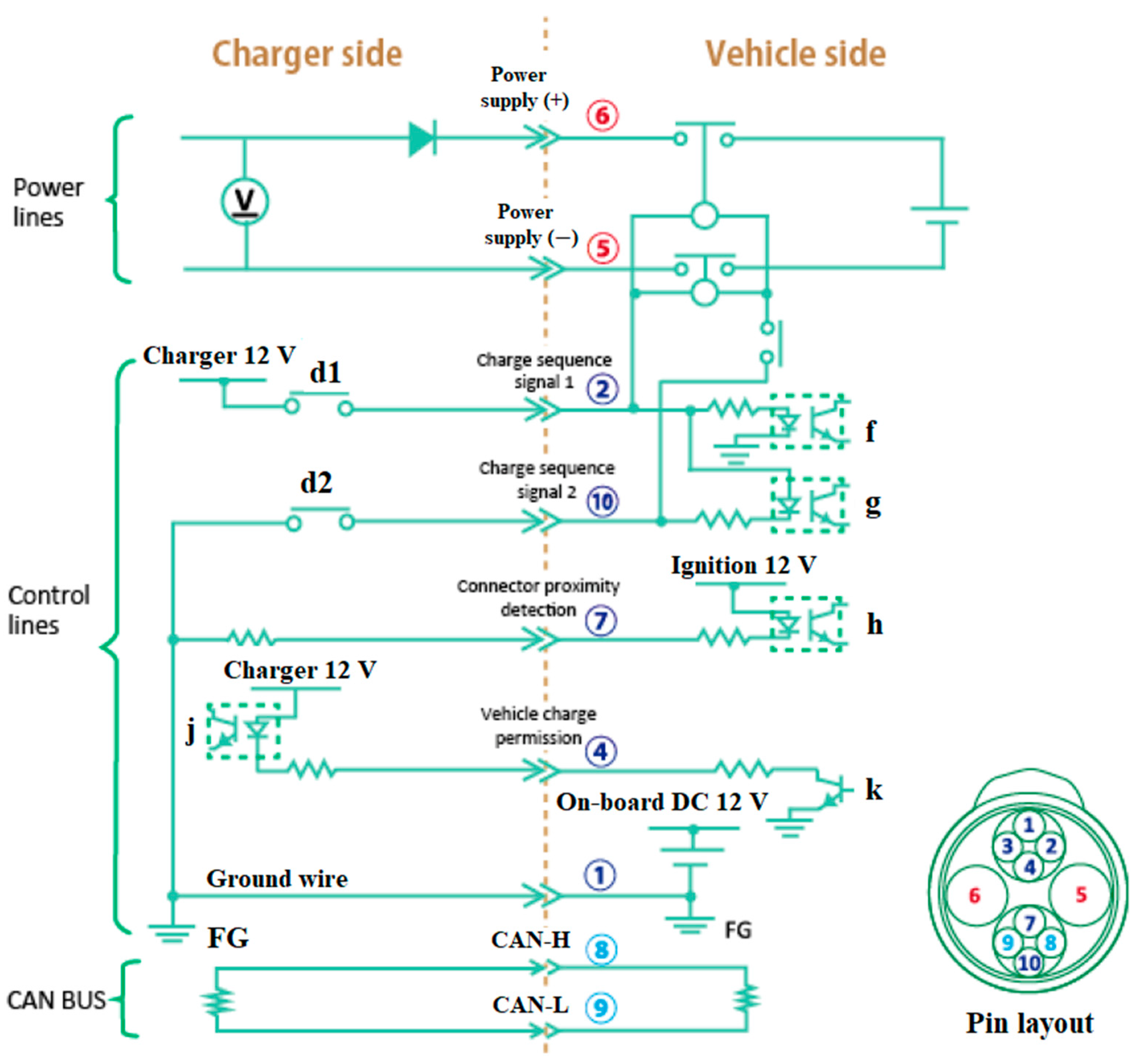

With the support of the governments of China and Japan, the CHAdeMO Organization and the China electricity council (CEC) have lately been working on a new international high-power DC charging standard that is backward compatible with existing CHAdeMO and GB/T standards. Figure 9 shows the new GB/T- CHAdeMO coupler prototype, which was revealed during the CHAdeMO general assembly with a charging power of up to 900 kW (1500 V @ 600 A) [41][42][43].

4.6. Tesla Coupler

5. EV Batteries

References

- Kisacikoglu, M.C. Vehicle-to-Grid (V2G) Reactive Power Operation Analysis of the EV/PHEV Bidirectional Battery Charger. Ph.D. Thesis, University of Tennessee, Knoxville, TN, USA, 2013.

- Xiao, X.; Molin, H.; Kourtza, P.; Collin, A.; Harrison, G.; Djokic, S.; Meyer, J.; Müller, S.; Möller, F. Component-Based Modelling of EV Battery Chargers. In Proceedings of the 2015 IEEE Eindhoven PowerTech, Eindhoven, The Netherlands, 29 June–2 July 2015; pp. 1–6.

- Ronanki, D.; Kelkar, A.; Williamson, S.S. Extreme Fast Charging Technology—Prospects to Enhance Sustainable Electric Transportation. Energies 2019, 12, 3721.

- Kumar, P.; Nikolovski, S.; Dong, Z.Y. (Eds.) Internet of Energy Handbook, 1st ed.; CRC Press: Boca Raton, FL, USA, 2021; ISBN 978-0-367-49964-8.

- Rachid, A.; Fadil, H.E.; Rachid, K.; Lassioui, A.; Idrissi, Z.E. H-Infinity Control of Bidirectional Dc-Dc Power Converter for V2G BEV Charger. In Proceedings of the 2020 International Symposium on Advanced Electrical and Communication Technologies (ISAECT), Marrakech, Morocco, 25–27 November 2020; pp. 1–6.

- Sousa, T.J.C.; Pedrosa, D.; Monteiro, V.; Afonso, J.L. A Review on Integrated Battery Chargers for Electric Vehicles. Energies 2022, 15, 2756.

- Lebrouhi, B.E.; Khattari, Y.; Lamrani, B.; Maaroufi, M.; Zeraouli, Y.; Kousksou, T. Key Challenges for a Large-Scale Development of Battery Electric Vehicles: A Comprehensive Review. J. Energy Storage 2021, 44, 103273.

- Rubino, L.; Capasso, C.; Veneri, O. Review on Plug-in Electric Vehicle Charging Architectures Integrated with Distributed Energy Sources for Sustainable Mobility. Appl. Energy 2017, 207, 438–464.

- Mohamed, A.A.S.; Shaier, A.A.; Metwally, H.; Selem, S.I. A Comprehensive Overview of Inductive Pad in Electric Vehicles Stationary Charging. Appl. Energy 2020, 262, 114584.

- Lassioui, A.; Fadil, H.E.; Rachid, A.; El-Idrissi, Z.; Bouanou, T.; Belhaj, F.Z.; Giri, F. Modelling and Sliding Mode Control of a Wireless Power Transfer System for BEV Charger. Int. J. Model. Identif. Control 2020, 34, 171–186.

- Amjad, M.; Farooq-i-Azam, M.; Ni, Q.; Dong, M.; Ansari, E.A. Wireless Charging Systems for Electric Vehicles. Renew. Sustain. Energy Rev. 2022, 167, 112730.

- Lassioui, A.; Fadil, H.E.; Rachid, A.; Belhaj, F.Z.; Tarkany, O.; Bajit, A. Characteristics Analysis of Wireless Power Transfer System for Electric Vehicle Charging Applications. In Proceedings of the 2018 International Symposium on Advanced Electrical and Communication Technologies (ISAECT), Rabat, Morocco, 21–23 November 2018; pp. 1–6.

- Lassioui, A.; El Fadil, H.; Belhaj, F.Z.; Rachid, A. Battery Charger for Electric Vehicles Based ICPT and CPT—A State of the Art. In Proceedings of the 2018 Renewable Energies, Power Systems & Green Inclusive Economy (REPS-GIE), Casablanca, Morocco, 23–24 April 2018; pp. 1–6.

- Monteiro, V.; Afonso, J.A.; Sousa, T.J.C.; Cardoso, L.L.; Pinto, J.G.; Afonso, J.L. Vehicle Electrification: Technologies, Challenges, and a Global Perspective for Smart Grids. In Innovation in Energy Systems; Ustun, T.S., Ed.; IntechOpen: Rijeka, Croatia, 2019.

- Mutarraf, M.U.; Guan, Y.; Xu, L.; Su, C.-L.; Vasquez, J.C.; Guerrero, J.M. Electric Cars, Ships, and Their Charging Infrastructure—A Comprehensive Review. Sustain. Energy Technol. Assess. 2022, 52, 102177.

- Ahmed, I.; Adil, H.M.M.; Ahmed, S.; Ahmad, I.; Rehman, Z. Robust Nonlinear Control of Battery Electric Vehicle Charger in Grid to Vehicle and Vehicle to Grid Applications. J. Energy Storage 2022, 52, 104813.

- Rachid, A.; EL Fadil, H.; Lassioui, A.; Giri, F. Advanced Control of Bidirectional Three-Phase BEV Charger with V2X Technology. Int. J. Model. Identif. Control 2019, 33, 344–357.

- Rachid, A.; El Fadil, H.; Giri, F.; Lassioui, A. Nonlinear Output Feedback Control of V2G Single-Phase on-Board BEV Charger. Asian J. Control 2020, 22, 1848–1859.

- Rachid, A.; Fadil, H.E.; Koundi, M.; Idrissi, Z.E.; Tahri, A.; Giri, F.; Guerrero, J.M. PQ Theory-Based Control of Single-Stage V2G Three-Phase BEV Charger for High-Voltage Battery. IFAC-Pap. 2019, 52, 73–78.

- Rachid, A.; Fadil, H.E.; Giri, F. Dual Stage CC-CV Charge Method for Controlling DC-DC Power Converter in BEV Charger. In Proceedings of the 2018 19th IEEE Mediterranean Electrotechnical Conference (MELECON), Marrakech, Morocco, 2–7 May 2018; pp. 74–79.

- Rachid, K.; EL Fadil, H.; Rachid, A.; Bouanou, T.; Gaouzi, K.; Belhaj, F.Z. Nonlinear Output Feedback Control of Bidirectional Dc-Dc Power Converter for V2X BEV Charger: Theoretical Analysis and Experimental Results. In Proceedings of the International Symposium on Advanced Electrical and Communication Technologies (ISAECT2020), Kenitra, Morocco, 25–27 November 2020; pp. 1–6.

- Ashfaq, M.; Butt, O.; Selvaraj, J.; Rahim, N. Assessment of Electric Vehicle Charging Infrastructure and Its Impact on the Electric Grid: A Review. Int. J. Green Energy 2021, 18, 657–686.

- Sayed, K.; Gabbar, H. Electric Vehicle to Power Grid Integration Using Three-Level AC/DC Converter and PI-Fuzzy Controller. Energies 2016, 9, 532.

- Tahir, M. Electric Vehicles and Vehicle-to-Grid Technology. Master’s Thesis, The Arctic University of Norway, Tromsø, Norway, 2017.

- Grbović, P. Interface DC–DC Converters. In Ultra-Capacitors in Power Conversion Systems; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2013; pp. 216–315. ISBN 978-1-118-69363-6.

- Zhang, T. Smart Electric Vehicle Charging: Mitigating Supply-Demand Disparity Through User Incentives—ProQuest. Ph.D. Thesis, University of California, Los Angeles, CA, USA, 2018.

- Ayob, A.; Mohd Faizal Wan Mahmood, W.; Mohamed, A.; Zamri Che Wanik, M.; Mohd Siam, M.; Sulaiman, S.; Hanifah Azit, A.; Azrin Mohamed Ali, M. Review on Electric Vehicle, Battery Charger, Charging Station and Standards. RJASET 2014, 7, 364–373.

- SAE International J1772_201001: SAE Electric Vehicle and Plug in Hybrid Electric Vehicle Conductive Charge Coupler—SAE International. Available online: https://www.sae.org/standards/content/j1772_201001/ (accessed on 26 July 2022).

- Paulraj, P. Charging Basics 102: Electric Vehicle Charging Levels, Modes and Types Explained | North America vs. Europe Charging Cables and Plug Types. E-Mobility Simplified|Basics of Electric Vehicles and Charging 2019. Available online: https://www.emobilitysimplified.com/2019/10/ev-charging-levels-modes-types-explained.html (accessed on 27 July 2022).

- SAE International J1772_201710: SAE Electric Vehicle and Plug in Hybrid Electric Vehicle Conductive Charge Coupler—SAE International. Available online: https://www.sae.org/standards/content/j1772_201710/ (accessed on 26 July 2022).

- Wikipedia, The Free Encyclopedia. Wikipedia contributors SAE J1772. 2020. Available online: https://en.wikipedia.org/w/index.php?title=SAE_J1772&oldid=965111434 (accessed on 26 July 2022).

- Hanauer, D. Mode 2 Charging—Testing and Certification for International Market Access. World Electr. Veh. J. 2018, 9, 26.

- International Electrotechnical Commission IEC 61851-1:2017: Electric Vehicle Conductive Charging System—Part 1: General Requirements 2017. Available online: https://webstore.iec.ch/publication/33644 (accessed on 26 July 2022).

- GB China National Standards. Available online: http://www.gbstandards.org/ (accessed on 28 July 2022).

- Hicks, M. English: SAE J1772 Plug (Cropped from the Original Photo). 2012. Available online: https://commons.wikimedia.org/wiki/File:SAE_J1772_7058855567.jpg (accessed on 26 July 2022).

- Hackaday. Lewin Day EV Charging Connectors Come In Many Shapes And Sizes. 2022. Available online: https://hackaday.com/2022/04/28/ev-charging-connectors-come-in-many-shapes-and-sizes/ (accessed on 28 July 2022).

- Recharge électrique. Tom Définition: C’est quoi une prise de recharge Type 2? 2020. Available online: https://www.recharge-electrique.com/definition-prise-recharge-electrique-type-2/ (accessed on 26 July 2022).

- Rivera, S.; Kouro, S.; Vazquez, S.; Goetz, S.M.; Lizana, R.; Romero-Cadaval, E. Electric Vehicle Charging Infrastructure: From Grid to Battery. IEEE Ind. Electron. Mag. 2021, 15, 37–51.

- Enel X Way The Different EV Charging Connector Types. Available online: https://evcharging.enelx.com/resources/blog/552-ev-charging-connector-types (accessed on 26 July 2022).

- Aitor Ubierna (ITE). Samuel Sánchez (ITE) D8.2 WiseGRID FastV2G and Other Innovative Optimized Storage Solutions 2018. Available online: https://cdn.nimbu.io/s/76bdjzc/channelentries/8qd2nl6/files/D8.2_WiseGRID_FastV2G_Design.pdf?aopz8sn (accessed on 26 July 2022).

- Dong, L.Y.; Yoshida, M.D. ChaoJi Standard 2020. Available online: https://www.chademo.com/wp2016/wp-content/uploads/ChaoJi202006/ChaoJi_Presenataion_EN.pdf (accessed on 18 July 2022).

- Kane, M. Here Is the Prototype for the New GB/T—CHAdeMO Plug and Inlet. Available online: https://insideevs.com/news/356958/prototype-new-gbt-chademo-plug-inlet/ (accessed on 26 July 2022).

- Berman, B. CHAdeMO 3.0 to Harmonize Global EV Quick Charging Standards. Available online: https://www.sae.org/site/news/2020/05/chademo-3.0-to-harmonize-global-ev-quick-charging-standards (accessed on 29 July 2022).

- David Herron Types of Electric Car Charging Connectors, and Compatibility: A Field Guide to Electric Vehicle Service Equipment. Available online: https://greentransportation.info/ev-charging/range-confidence/chap4-charging/4-evse-field-guide.html (accessed on 26 July 2022).

- Ahmad, A.; Khan, Z.A.; Saad Alam, M.; Khateeb, S. A Review of the Electric Vehicle Charging Techniques, Standards, Progression and Evolution of EV Technologies in Germany. Smart Sci. 2018, 6, 36–53.

- Adegbohun, F.; von Jouanne, A.; Lee, K.Y. Autonomous Battery Swapping System and Methodologies of Electric Vehicles. Energies 2019, 12, 667.

- Aleksander Chudy Battery Swapping Stations for Electric Vehicles. Inform. Autom. Pomiary W Gospod. I Ochr. Środowiska 2021, 11, 36–39.

- Pistoia, G.; Liaw, B. (Eds.) Behaviour of Lithium-Ion Batteries in Electric Vehicles; Green Energy and Technology; Springer International Publishing: Cham, Switzwerland, 2018; ISBN 978-3-319-69949-3.

- Sayed, K. Zero-Voltage Soft-Switching DC–DC Converter-Based Charger for LV Battery in Hybrid Electric Vehicles. IET Power Electron. 2019, 12, 3389–3396.

- Ghalkhani, M.; Habibi, S. Review of the Li-Ion Battery, Thermal Management, and AI-Based Battery Management System for EV Application. Energies 2023, 16, 185.