Changes in biological properties over several generations, induced by controlling short-term evolutionary processes in the laboratory through selective pressure, and whole-genome re-sequencing, help determine the genetic basis of microorganism's adaptive laboratory evolution (ALE). Due to the versatility of this technique and the imminent urgency for alternatives to petroleum-based strategies, ALE has been actively conducted for several yeasts, primarily using the conventional species Saccharomyces cerevisiae, but also non-conventional yeasts. As a hot topic at the moment since genetically modified organisms are a debatable subject and a global consensus on their employment has not yet been attained, a panoply of new studies employing ALE approaches have emerged and many different applications have been exploited in this context. For the first time, relevant studies showing the ALE of non-conventional yeast species towards their biotechnological improvement, cataloging them according to the aim of the study, and comparing them considering the species used, the outcome of the experiment, and the employed methodology. The applicability of ALE as a powerful tool to enhance species features and improve their performance in biotechnology, with emphasis on the non-conventional yeast species are lighted, as an alternative or in combination with genome editing approaches.

1. Introduction

The main advantages of adaptive laboratory evolution (ALE) involve the ease of implementation of the method, the fact that it does not require any prior knowledge on genotype–phenotype interconnections, and the capacity to exploit phenotypes that require the combination of several intracellular pathways, such as stress tolerance and rapid cell growth, with this being a powerful adjunct to metabolic engineering

[1]. On the other hand, there are some inherent limitations associated with this practice such as the extensive time consumption of the methodology, the need for continuous and laborious monitorization of the cells, the requirement for a direct connection between the desired feature and a benefit to the microorganism, and the need for an extreme asepsis environment to avoid culture contaminations. The optimization of metabolic pathways, the improvement of fermentation rates, the emergence of resistant and tolerant phenotypes, the development of new organoleptic features, aroma innovations, greater uptake rates, morphology modifications, environmental adaptations, and the improvement of lipids accumulation are some of the features that are presently being exploited in the scope of this evolution-based strategy. It should be noted that often the selection of evolved variants, in a particular environment, leads to significant trade-offs in alternative conditions. In this line, the choice of the best phenotype for a particular biotechnological process has to weigh strains’ performances, but also the least trade-offs associated. An important detail in the search for ALE-enhanced phenotypes is the time span for the selection experiment, with a typical range varying somewhere between 100 and 2000 generations. Moreover, it is possible to obtain a fitness increase of up to 50–100% between the 100th and 500th generations, which corresponds to approximately 2 months of selection for a typical culture of

S. cerevisiae or

E. coli, then decreasing considerably during the course of ALE

[2].

2. Experimental Approaches of Adaptive Laboratory Evolution

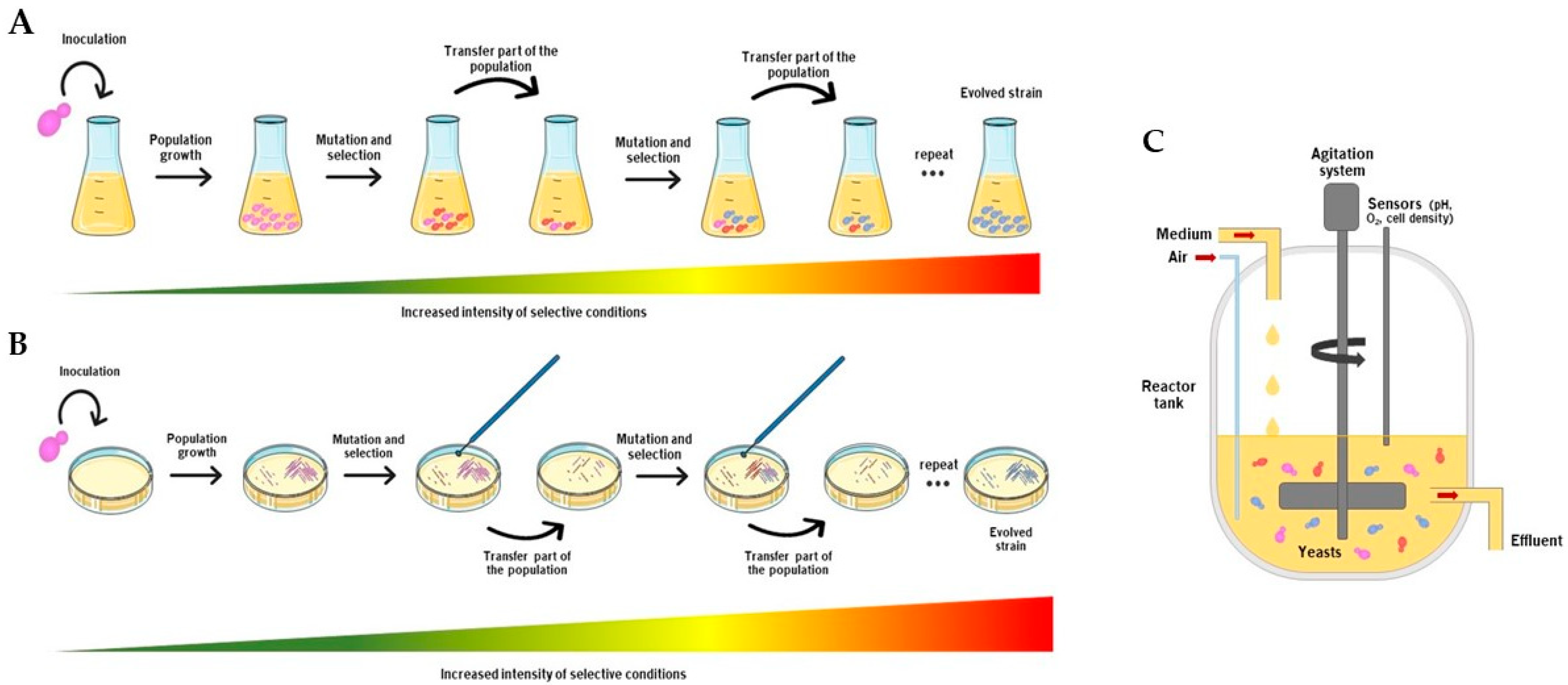

A proper experimental design is the foundation of a successful ALE experiment. Several mechanisms and strategies were tested to evolve microorganisms in the laboratory, from serial to continuous experiments (Figure 1). General considerations of these approaches are discussed in the sections below and summarized in Table 1.

Figure 1. Schematic overview of the experimental serial batch culture approach. (A) Microorganisms are cultured in flasks with liquid media, chosen to mimic a desired selective condition, for an extended period of time, and aliquots of the cells’ population are sequentially transferred to fresh media. Cells will undergo recombination and mutations, over time, generating evolved strains. (B) Colony transfer is a similar process to liquid transfer but is performed in solid medium plates. (C) Continuous cultures are usually carried out in chemostat tanks, in which fresh medium is introduced at a stable flow rate and effluent fluid emerges at the same rate, maintaining constant environmental culture conditions.

2.1. Serial Batch Cultures

Serial batch cultivation is the simplest and most popular ALE procedure. It is usually employed when the selective environment does not require constant conditions, as evolutionary constraints such as culture pH and nutrient composition will change during the culture growth. The implementation of this experiment involves the serial transfer of an aliquot of the population into new media containing the selective pressure condition

[3]. Furthermore, it could be performed in two different batches: Liquid or solid media. In a liquid environment (

Figure 1A), cells are inoculated in flasks with fresh medium to promote their growth with subsequent cultivation under the desired selective pressure. Afterward, a fraction of the culture is transferred into a fresh medium with a slight increase in the selective pressure until the appearance of a desirable mutant that will expand within the rest of the population over time. The total number of generations, although a concept that is often hard to quantify in this type of experiment, allows one to estimate the emergence of adaptive mutations, and cell densities within 10

7 and 10

9 cells per mL are commonly used. Choe et al.

[4] suggest the following equation to calculate the number of cell divisions:

Regular monitoring of cell viability, cell morphology, and residual media composition should be employed during ALE experiments to not only verify if a desirable mutant has emerged but also to check for possible contaminations

[3].

During the evolutionary process, aliquots of the evolving populations are usually stocked in glycerol (within 10% to 40%,

v/v) and maintained at −80 °C for further phenotypic analysis

[10][11][12]. The primary advantages are that this strategy is very easy to set up and use, requires low-cost equipment, can usually be executed by a single operator, and can be adapted to massive parallel cultures

[1][2][3][4][5][13][14][15][16][17][18][19][20][21][22][23][24][25][26][27][28][29][30][31][32][33][34][35], as summarized in

Table 1. However, batch cultures are more susceptible to random drift due to certain shortfalls, which include variations in the population density, growth rates, and different nutrient supplementations, together with fluctuations in environmental conditions

[3].

In solid media, ALE is performed using colony transfer and plating (

Figure 1B), where yeasts grow on agar plates and one or more (successfully grown) colonies are randomly chosen and periodically transferred to a new plate with fresh medium, for several generations. However, the use of such a small population hampers the selection process by increasing the chance of genetic drift in determining allele frequencies (reviewed in Swamy and Zhou

[8]), with this method being used less, in comparison with evolution in liquid medium.

Batch cultivation during long periods of time imposes some problems that usually increase the chances of failure: (i) Difficulties in continuously and frequently monitoring cells; (ii) higher susceptibility to errors, due to the periodic transfers of cells and media; (iii) complications in the maintenance of the exponential growth; (iv) difficulties in keeping the appropriate selective pressure level. However, these complications can be managed through the recent introduction of full or partial automation, as reviewed by Sandberg et al.

[6] .

2.2. Continuous Culture

The use of continuous systems, or chemostats, is the second most popular culturing technique for ALE experiments

[36]. This approach is recommended when a constant physiological state is intended, i.e., to maintain a stable population density and growth rate via a constant influx of media at a set dilution rate

[2][3][6][7]. Continuous systems are composed of bioreactors, which enable tight control over environmental parameters such as pH and oxygenation. A major drawback is the expensive cost of operation as it requires a substantial investment in the initial equipment. On the other hand, this system benefits from the increased tolerance to larger population sizes, smaller bottleneck effects, and the possibility to control the specific growth rate. The growth kinetics of the culture depends on the concentration of the limiting substrate and of any growth inhibitors

[3].

The chemostat strategy is widely applied for mutation accumulation studies (Swamy and Zhou

[8]), and additional variations are available such as retentostat—a chemostat with a filter in order to retain the biomass on the efflux—and auxostat—a chemostat with an additional feedback mechanism that controls cell density. Furthermore, the latter can be subdivided into at least four variants: Turbidostat, pH-stat, oxistat, and morbidostat. The turbidostat concept leans on the control of the cell density through variations in the dilution rate, while the pH-stat is distinguished by being based on deviations in the pH of the culture. The last two methods—oxistat and morbidostat—endorse the management of the culture’s conditions via dissolved oxygen and pH, density, or optical density, respectively

[9]. Additionally, Ekkers et al.

[9] suggested a bioreactor system entitled omnistat, which is highly flexible and involves lower costs, and can be used in many bioreactor configurations. This system can be pre-programmed to both temporal and spatial variations to accurately induce a selective regime suitable for the specific research question. The omnistat can be configured to implement various alternative bioreactor modes, such as the ones mentioned above.

3. Automated Methods for Adaptive Laboratory Evolution: High-Throughput Adaptive Evolution

Recently, there has been a growing demand to automate adaptive evolution processes, both using batch and continuous cultivation, in order to surpass difficulties allied with these methodologies. The manipulation by a machine allows the transfer of batch cultures to be carried out with a frequency of 3 to 7 times higher than the manual procedure, allowing the transfer of the cells in a constant growth phase, reducing possible fluctuations in the size of the transferred volume and preventing the loss of beneficial mutations

[1]. One such technique is entitled eVOLVER, a scalable and automated culture system that allows the precise and multiparameter regulation of growth conditions. eVOLVER was the first automated system available to perform ALE and has the huge advantage of being cost-effective and quickly re-configured to virtually implement any type of high-throughput growth experiment

[37]. This system enables ongoing control and monitoring of hundreds of individual cultures by collecting, measuring, and recording experimental data in real-time, for any time scale, allowing one to aim for desired parameters such as temperature, culture density, and media composition. The performance of this method can be surpassed through its conjunction with a genetic system designed for targeted mutagenesis of user-selected genes in vivo (OrthoRep—orthogonal DNA replication), giving rise to the automated continuous evolution (ACE;

[38]). This platform specifically targets the evolution of biomolecules. In this technique, the OrthoRep works as an orthogonal DNA polymerase-plasmid that mutates the genes of interest approximately 100,000-fold faster than the average mutation rates typically associated with the host genome in vivo, while eVOLVER’s robust framework ensures experimental durability over long timeframes. The combination of these two approaches assures the speed, depth, and scale of the continuous evolution of the ACE strategy

[38]. Due to the complexity of ALE studies, and to optimize and design the experiments, a computational framework was developed: ALEsim

[39]. With this strategy, resources can be deployed in an optimized way at different steps of the experiment in order to reduce the project timeline and accomplish the desired outputs. Perceiving the distance to optimality can help researchers to determine when to cease an ALE experiment. The most frequent mechanism of determining when to terminate an ALE trial is to assess that no more improvements in fitness are being detected.

Uncovering the genotypic basis of a particular feature is one of the main goals of exploiting adaptive evolution, and the loss of advantageous mutants imposes a restriction on discernible adaptive mechanisms. Winkler et al.

[3] developed the pioneer system VERT, in which one can attempt to visualize evolution in real time, with applicability to isolate the evolved mutants. This method enables the visualization of competition between genotypes during evolution, relying on the use of distinct fluorescent strains to visualize expansions of fluorescently market subpopulations. Changes in the proportions of distinct subpopulations, so-called adaptive events, illustrate the emergence and expansion of evolved mutants with higher fitness advantages, in comparison with the background. The strain that will be used (parental strain) for the adaptive experiment has to be marked with different fluorescent proteins, which can be generated by using classic clonal methods. VERT provides a set of measurements that reflect the relative abundance of cells expressing different fluorophores (e.g., green fluorescent protein—GFP, yellow fluorescent protein—YFP, and red fluorescent protein—RFP) within the evolving population. The authors also developed an algorithm to computationally identify frequency modifications corresponding to adaptive events.

Table 1 summarizes the discussed experimental ALE approaches, comparing the advantages and disadvantages associated with each of the aforementioned methods.