Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Humaira Yasmin | -- | 1068 | 2023-01-30 16:44:41 | | | |

| 2 | Lindsay Dong | Meta information modification | 1068 | 2023-01-31 10:32:19 | | | | |

| 3 | Lindsay Dong | Meta information modification | 1068 | 2023-01-31 10:33:06 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Yasmin, H.; Giwa, S.O.; Noor, S.; Aybar, H.�. Nanofluid Preparation and Stability. Encyclopedia. Available online: https://encyclopedia.pub/entry/40603 (accessed on 28 February 2026).

Yasmin H, Giwa SO, Noor S, Aybar H�. Nanofluid Preparation and Stability. Encyclopedia. Available at: https://encyclopedia.pub/entry/40603. Accessed February 28, 2026.

Yasmin, Humaira, Solomon O. Giwa, Saima Noor, Hikmet Ş. Aybar. "Nanofluid Preparation and Stability" Encyclopedia, https://encyclopedia.pub/entry/40603 (accessed February 28, 2026).

Yasmin, H., Giwa, S.O., Noor, S., & Aybar, H.�. (2023, January 30). Nanofluid Preparation and Stability. In Encyclopedia. https://encyclopedia.pub/entry/40603

Yasmin, Humaira, et al. "Nanofluid Preparation and Stability." Encyclopedia. Web. 30 January, 2023.

Copy Citation

The advent of nanotechnology has brought about significant technological advancements in many fields of study. The birth of nanofluids as an advanced thermal transport media in the area of thermal management is a laudable and notable feat. Nanofluids (mono and hybrid nanofluids) have been extensively researched and established to be better than conventional thermal transport media due to their enhanced thermophysical and convective properties.

nanofluids

preparation

stability

Mono and Hybrid Nanofluids

1. Preparation Techniques

Mono and hybrid nanofluids were prepared by suspending mono nanoparticles (MNPs) and hybrid nanoparticles (HNPs) in orthodox thermal fluids (Figure 1). The stability of these thermal fluids is of utmost importance as it significantly influences their thermal–optical–rheological properties and thermal performance in different applications. Generally, mono and hybrid nanofluids are formulated using one-step and two-step strategies. The two-step method involves two processes; first, the synthesis of MNPs or HNPs, and second, suspending of the MNPs or HNPs into the base fluids. The two-step strategy is the most used method published in the literature for the formulation of mono and hybrid nanofluids. This method can be engaged in large-scale production of mono and hybrid nanofluids suitable for industrial application with cost benefits. The flaw associated with this method involves the possibility of sedimentation and agglomeration of MNPs and HNPs owing to the Van der Waals forces of attraction among the particles [1].

Figure 1. Representation of typical nanofluid preparation.

The one-step strategy involves simultaneous synthesis and suspension of MNPs and HNPs in the respective base fluids. This method is known to provide improved stability and homogeneity of mono and hybrid nanofluids, thereby eliminating arduous processes in comparison to the one-step strategy by reducing MNPs and HNPs clusters [1][2]. The industrial use of this method appears impracticable except for low vapor pressure fluids, and it is found to be expensive [3].

2. Stability

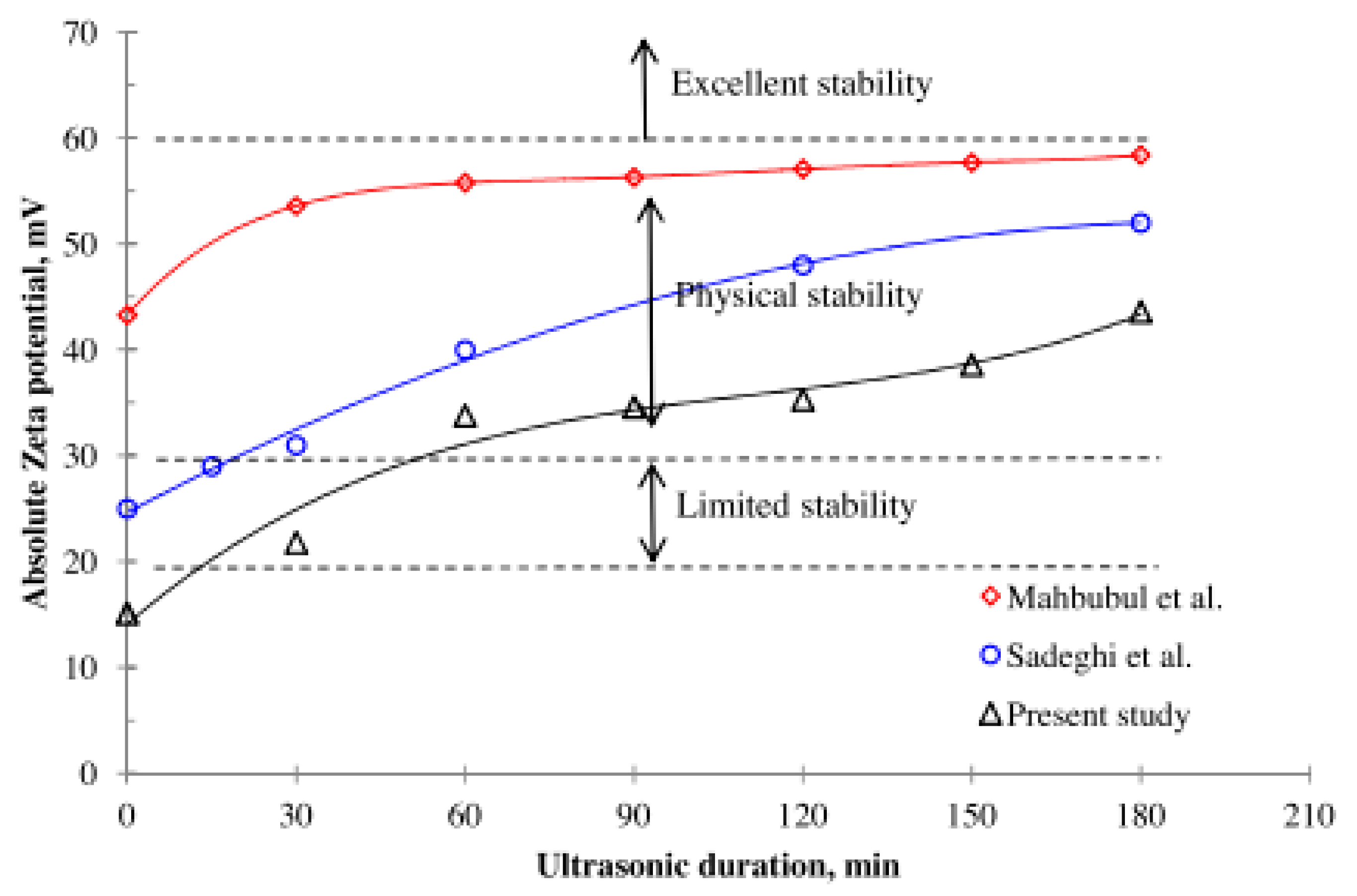

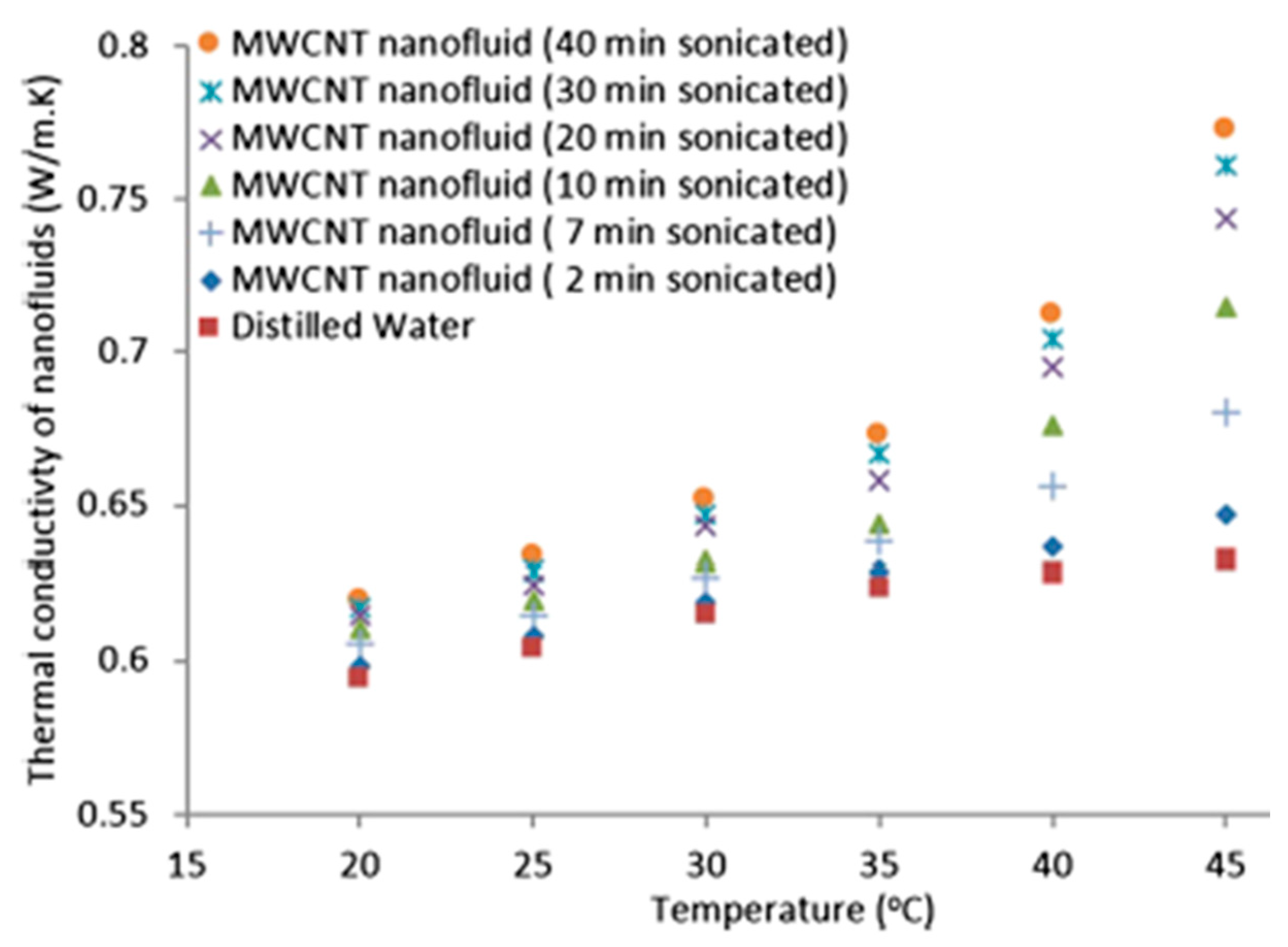

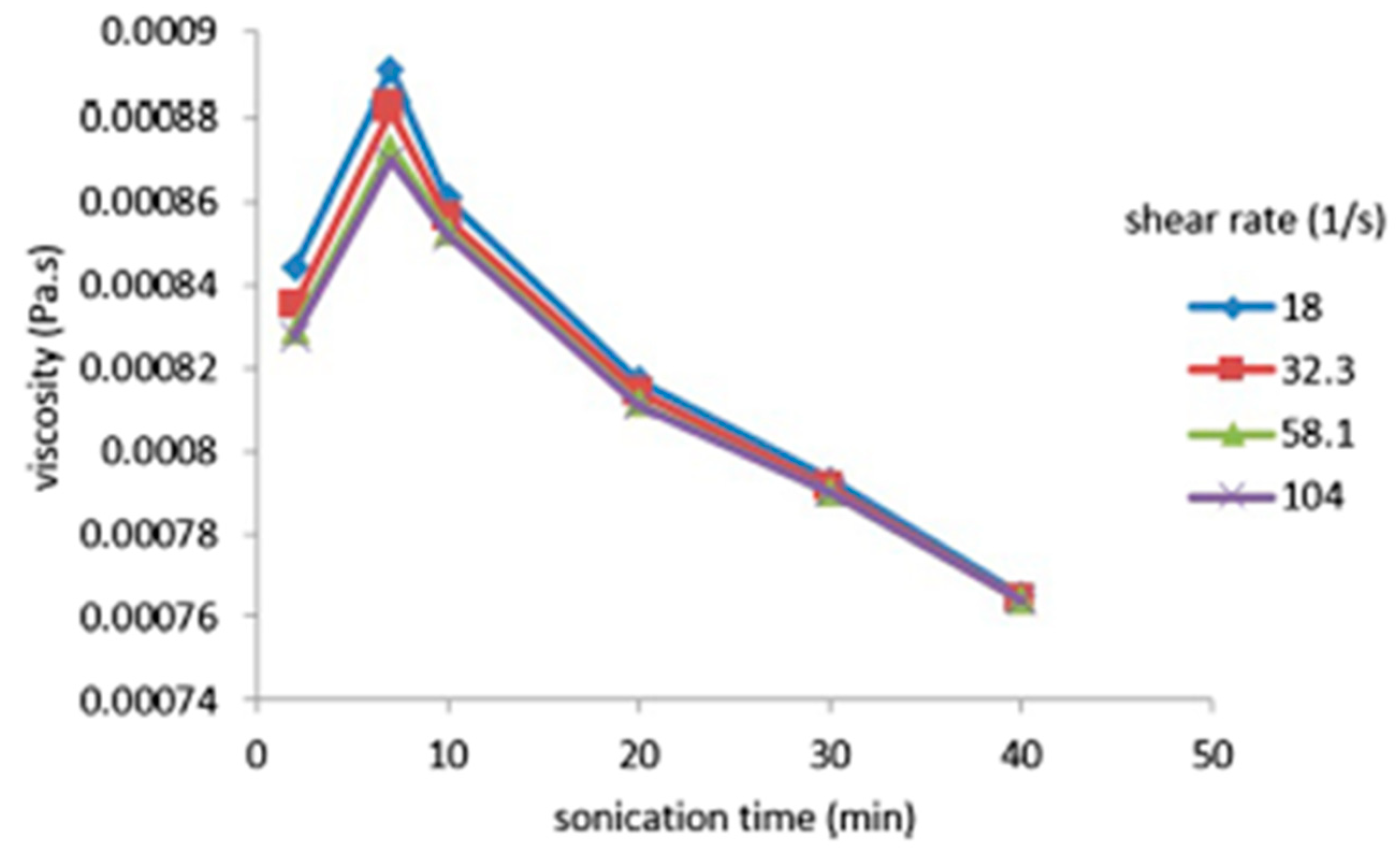

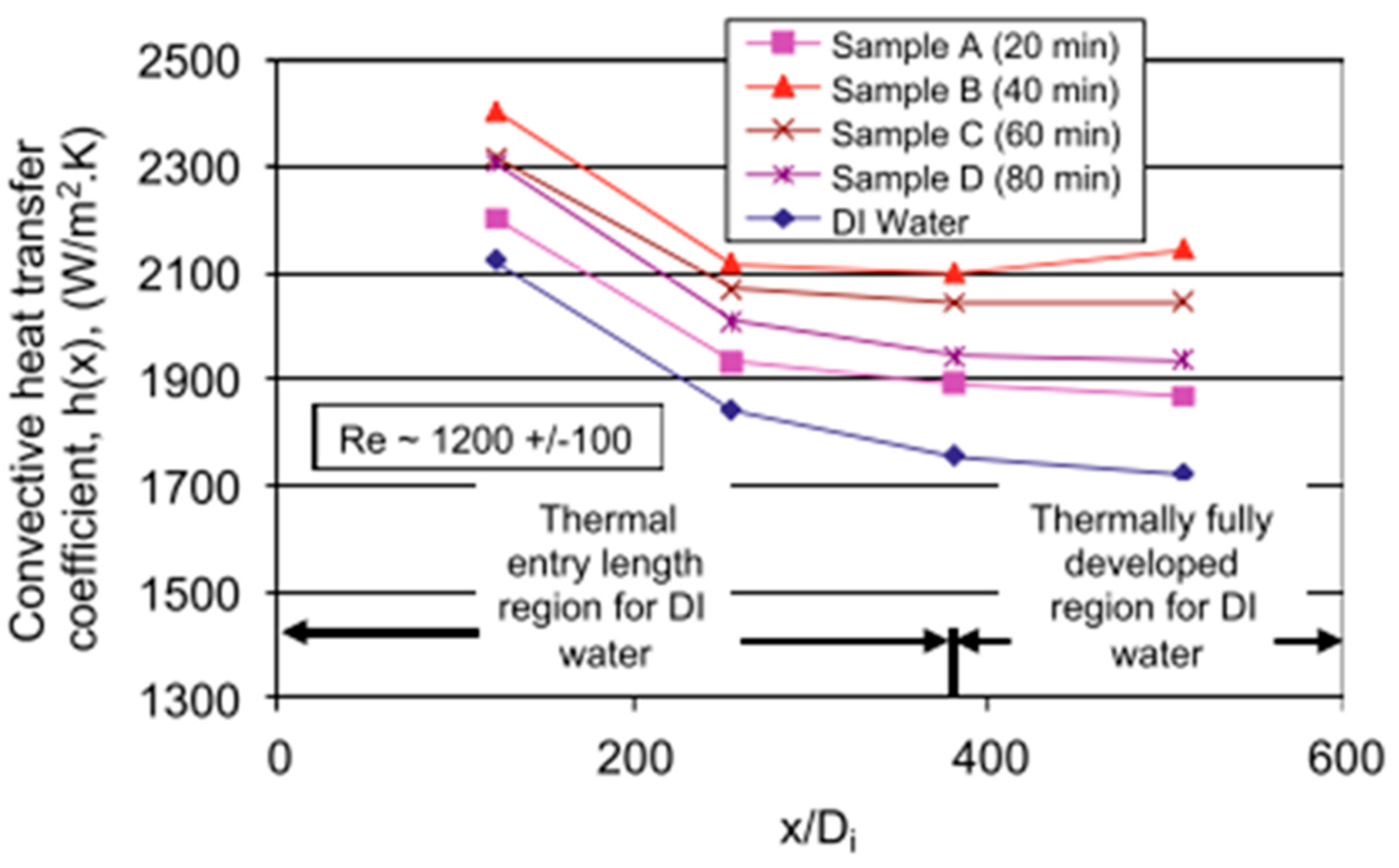

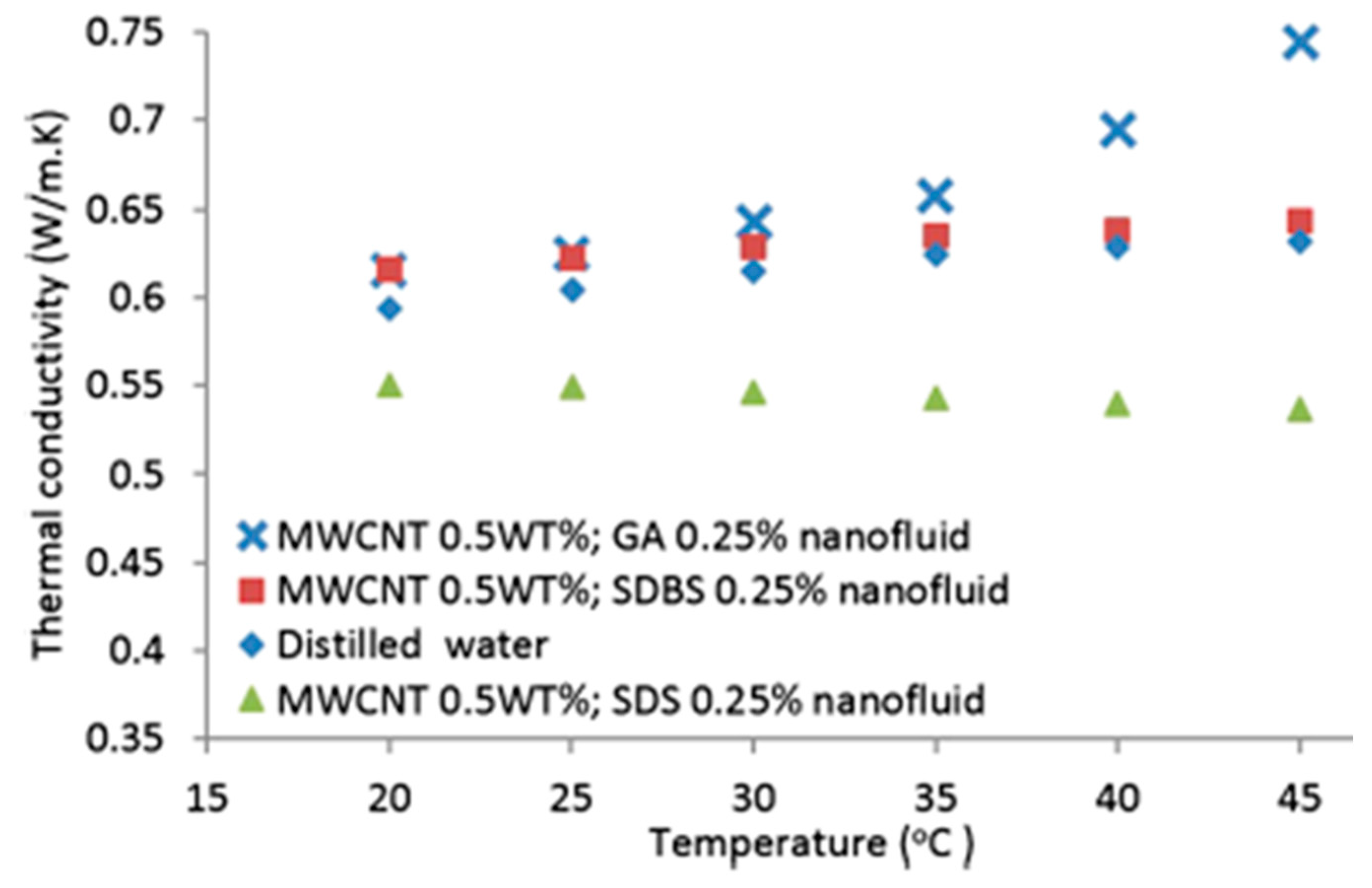

Suspending MNPs and HNPs in different base fluids induces charges leading to the formation of an electrical double layer (EDL) around the particle surface [4]. Thus, mono and hybrid nanofluids are said to be electrically conducting fluids. The imposition of a potential across these fluids causes oppositely charged electrodes to attract MNPs or HNPs and EDL. The formulation of EDL depends on the volume/weight fraction/concentration, size, and surface charge of the particles and the ion concentration in the base fluids. The application of mono and hybrid nanofluids strongly depends on the stability of these thermal fluids because their thermal–optical–rheological properties and thermal performance are linked to the concentration of MNPs or HNPs in the suspension [5][6]. Under the two-step strategy, the agglomeration and sedimentation of mono and hybrid nanofluids can be avoided, thereby improving the stability of the same by employing mechanical (sonication), surfactant addition, surface modification, and pH control techniques. Figure 2, Figure 3, Figure 4 and Figure 5 reveal the influence of viscosity, stability, thermal conductivity, and convective heat transfer performance, respectively, on sonication duration. In Figure 2, increasing sonication time is shown to enhance the stability (as measured using the zeta potential technique) of TiO2/water nanofluid. From Figure 3, the thermal conductivity of MWCNT/water nanofluid is noticed to enhance as temperature and sonication time increase. It is illustrated in Figure 4 that sonication time reduces nanofluid viscosity as the shear rate increases. In Figure 5, the peak convective heat transfer coefficient is achieved at the optimum sonication time under increasing flow development.

Figure 2. Effect of ultrasonic duration on stability of TiO2/water nanofluid. Adapted from [7].

Figure 3. Effects of ultrasonication time and temperature on thermal conductivity of nanofluids [8].

Figure 4. Variation in dynamic viscosity as function of sonication time at various shear rates at 45 °C [8].

Figure 5. Influence of sonication duration on convective heat transfer coefficient (Re = 1200) of aqueous nanofluid. Adapted from [9].

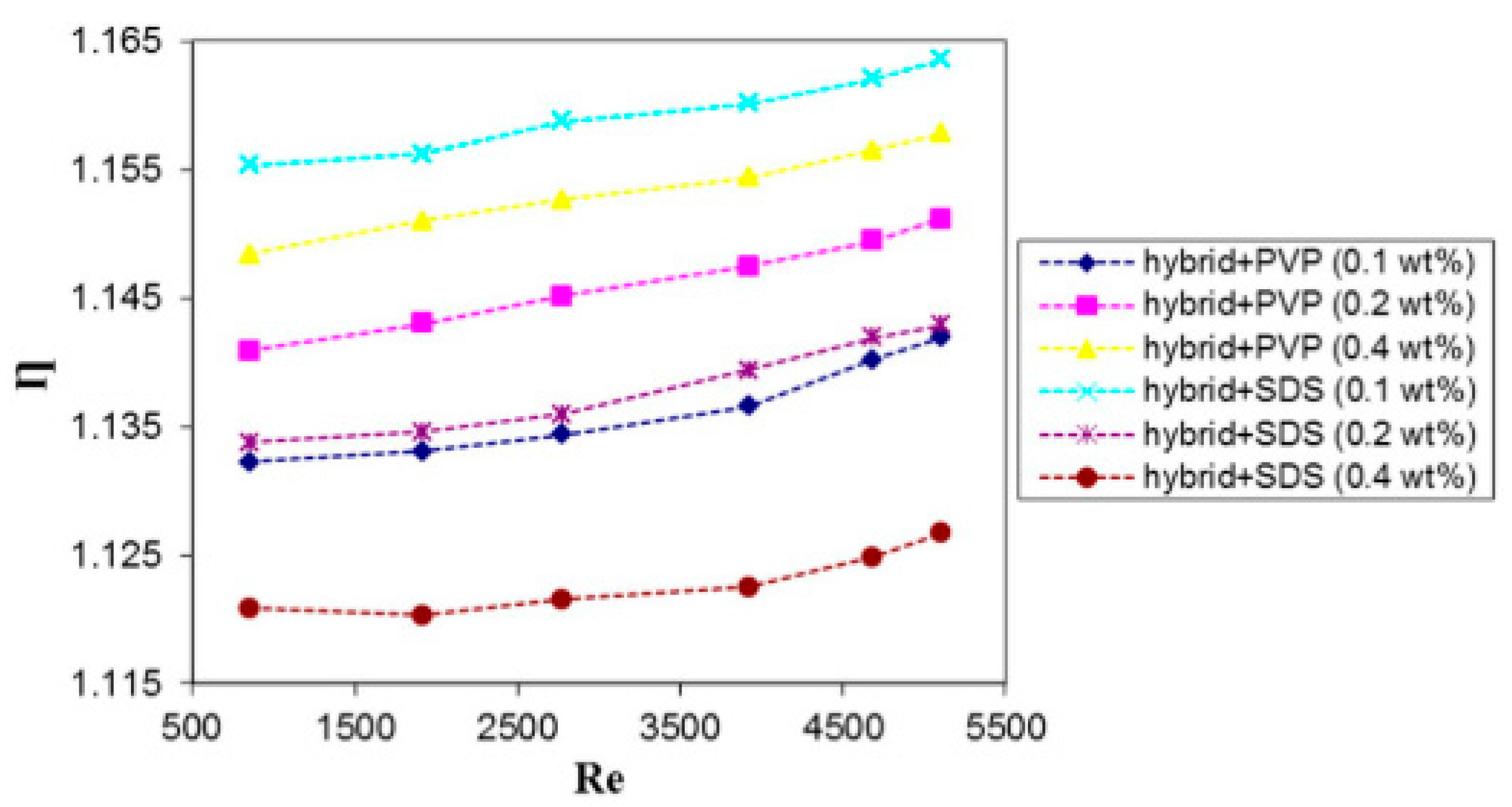

With the aid of ultrasonicators, numerous studies have reported the effect of sonication time, amplitude, modes, and probe tip width on the thermal conductivity, absorbance wavelength, viscosity, cluster size, surfactants, diameter of CNTs, and particle size [10][11][12][13][14][15][16][17][18][19]. It is reported that optimum sonication parameters lead to optimum stability conditions and other relevant measured parameters. These findings indicate the need to optimize sonication parameters in relation to other parameters to achieve improved stability. Nevertheless, this is not the case for most studies reported in the literature for mono and hybrid nanofluids, irrespective of the purpose of the experiments. Surfactants are chemical compounds used to improve the stability of mono and hybrid nanofluids by reducing the electrostatic repulsion and Van der Waals interaction between particles to evade the agglomeration of particles in the base fluid [20]. An increase in thermal conductivity, zeta potential, surface tension, and viscosity of mono and hybrid nanofluids under the utilization of different surfactants has been published in the literature [5][18][21][22][23][24]. In addition, the pH can be modulated to improve the stability of mono and hybrid nanofluids. The surface electric charges introduced due to the suspension of MNPs or HNPs into base fluids are altered to enhance the stability of mono and hybrid nanofluids. The farther the pH value from the isoelectric point (IEP), the greater the stability of the mono and hybrid nanofluids. Furthermore, the surface modification technique can be used to improve the stability of mono and hybrid nanofluids. It is worth noting that this technique is always surfactant-free with more improved stability [6][17][25]. The effect of surfactants on the thermal conductivity and thermal efficiency of mono and hybrid nanofluids is shown in Figure 6 and Figure 7, respectively. From Figure 6, variation in the thermal conductivity is observed for the 0.5 wt % MWCNT/DW nanofluid formulated using different surfactants and subjected to increasing temperature. Figure 7 shows that the thermal efficiency of a hybrid nanofluid varies with the type and concentration of surfactant used in the formulation. For all the hybrid nanofluids, the thermal efficiency increased as the Reynolds number rises.

Figure 6. Influence of different surfactants (GA, SDBS, and SDS) thermal conductivity of aqueous MWCNT nanofluids [8].

Figure 7. Influence of surfactants (PVP and SDS) on thermal efficiency of hybrid nanofluids in a helical coil heat exchanger [26].

For the characterization of mono and hybrid nanofluids, numerous techniques have been reported in the open literature. These include Raman spectroscopy, Fourier transform infrared spectroscopy, high-resolution transmission electron microscopy, X-ray diffractometer, scanning electron microscopy, vibrating sample magnetometer, transmission electron microscopy, light scattering, and energy-dispersive X-ray spectroscopy [11][27][28][29][30][31][32][33]. Scanning electron microscopy is the most reported technique for characterizing mono and hybrid nanofluids. To monitor the stability of mono and hybrid nanofluids, visual inspection, zeta potential, ultraviolet-visible (UV) spectrophotometer, and thermal property tracking (viscosity, thermal conductivity, turbidity, and density) methods are engaged [22][29][34][35][36][37][38][39][40].

References

- Sajid, M.U.; Ali, H.M. Thermal conductivity of hybrid nanofluids: A critical review. Int. J. Heat Mass Transf. 2018, 126, 211–234.

- Gupta, M.; Singh, V.; Kumar, S.; Kumar, S.; Dilbaghi, N.; Said, Z. Up to date review on the synthesis and thermophysical properties of hybrid nanofluids. J. Clean. Prod. 2018, 190, 169–192.

- Nabil, M.; Azmi, W.; Hamid, K.A.; Mamat, R.; Hagos, F.Y. An experimental study on the thermal conductivity and dynamic viscosity of TiO2-SiO2 nanofluids in water: Ethylene glycol mixture. Int. Commun. Heat Mass Transf. 2017, 86, 181–189.

- Shoghl, S.N.; Jamali, J.; Moraveji, M.K. Electrical conductivity, viscosity, and density of different nanofluids: An experimental study. Exp. Therm. Fluid Sci. 2016, 74, 339–346.

- Said, Z. Thermophysical and optical properties of SWCNTs nanofluids. Int. Commun. Heat Mass Transf. 2016, 78, 207–213.

- Alirezaie, A.; Saedodin, S.; Esfe, M.H.; Rostamian, S.H. Investigation of rheological behavior of MWCNT (COOH-functionalized)/MgO—Engine oil hybrid nanofluids and modelling the results with artificial neural networks. J. Mol. Liq. 2017, 241, 173–181.

- Mahbubul, I.; Elcioglu, E.B.; Saidur, R.; Amalina, M. Optimization of ultrasonication period for better dispersion and stability of TiO2–water nanofluid. Ultrason. Sonochem. 2017, 37, 360–367.

- Sadri, R.; Ahmadi, G.; Togun, H.; Dahari, M.; Kazi, S.N.; Sadeghinezhad, E.; Zubir, N. An experimental study on thermal conductivity and viscosity of nanofluids containing carbon nanotubes. Nanoscale Res. Lett. 2014, 9, 151.

- Garg, P.; Alvarado, J.L.; Marsh, C.; Carlson, T.A.; Kessler, D.A.; Annamalai, K. An experimental study on the effect of ultrasonication on viscosity and heat transfer performance of multi-wall carbon nanotube-based aqueous nanofluids. Int. J. Heat Mass Transf. 2009, 52, 5090–5101.

- Adio, S.A.; Sharifpur, M.; Meyer, J.P. Influence of ultrasonication energy on the dispersion consistency of Al2O3–glycerol nanofluid based on viscosity data, and model development for the required ultrasonication energy density. J. Exp. Nanosci. 2016, 11, 630–649.

- Mousavi, S.M.; Esmaeilzadeh, F.; Wang, X.P. Effects of temperature and particles volume concentration on the thermophysical properties and the rheological behavior of CuO/MgO/TiO2 aqueous ternary hybrid nanofluid: Experimental investigation. J. Therm. Anal. Calorim. 2019, 137, 879–901.

- Aparna, Z.; Michael, M.; Pabi, S.; Ghosh, S. Thermal conductivity of aqueous Al2O3/Ag hybrid nanofluid at different temperatures and volume concentrations: An experimental investigation and development of new correlation function. Powder Technol. 2019, 343, 714–722.

- Menbari, A.; Alemrajabi, A.A.; Ghayeb, Y. Investigation on the stability, viscosity and extinction coefficient of CuO–Al2O3 /Water binary mixture nanofluid. Exp. Therm. Fluid Sci. 2016, 74, 122–129.

- Ruan, B.; Jacobi, A.M. Ultrasonication effects on thermal and rheological properties of carbon nanotube suspensions. Nanoscale Res. Lett. 2012, 7, 127.

- Nguyen, V.S.; Rouxel, D.; Hadji, R.; Vincent, B.; Fort, Y. Effect of ultrasonication and dispersion stability on the cluster size of alumina nanoscale particles in aqueous solutions. Ultrason. Sonochem. 2011, 18, 382–388.

- Yu, H.; Hermann, S.; Schulz, S.E.; Gessner, T.; Dong, Z.; Li, W.J. Optimizing sonication parameters for dispersion of single-walled carbon nanotubes. Chem. Phys. 2012, 408, 11–16.

- Kole, M.; Dey, T. Effect of aggregation on the viscosity of copper oxide–gear oil nanofluids. Int. J. Therm. Sci. 2011, 50, 1741–1747.

- Wang, X.-J.; Zhu, D.-S.; Yang, S. Investigation of pH and SDBS on enhancement of thermal conductivity in nanofluids. Chem. Phys. Lett. 2009, 470, 107–111.

- Yang, J.-C.; Li, F.-C.; Zhou, W.-W.; He, Y.-R.; Jiang, B.-C. Experimental investigation on the thermal conductivity and shear viscosity of viscoelastic-fluid-based nanofluids. Int. J. Heat Mass Transf. 2012, 55, 3160–3166.

- Ebrahimi, S.; Saghravani, S.F. Influence of magnetic field on the thermal conductivity of the water based mixed Fe3O4/CuO nanofluid. J. Magn. Magn. Mater. 2017, 441, 366–373.

- Ranga Babu, J.A.; Kumar, K.K.; Srinivasa Rao, S. State-of-art review on hybrid nanofluids. Renew. Sustain. Energy Rev. 2017, 77, 551–565.

- Ramadhan, A.I.; Azmi, W.H.; Mamat, R.; Hamid, K.A.; Norsakinah, S. Investigation on stability of tri-hybrid nanofluids in water-ethylene glycol mixture. IOP Conf. Ser. Mater. Sci. Eng. 2019, 469, 012068.

- Suhaimi, N.S.; Din, M.F.M.; Ishak, M.T.; Rahman, A.R.A.; Wang, J.; Hassan, M.Z. Performance and limitation of mineral oil-based carbon nanotubes nanofluid in transformer application. Alex. Eng. J. 2022, 61, 9623–9635.

- Tiwari, A.K.; Pandya, N.S.; Said, Z.; Chhatbar, S.H.; Al-Turki, Y.A.; Patel, A.R. 3S (Sonication, surfactant, stability) impact on the viscosity of hybrid nanofluid with different base fluids: An experimental study. J. Mol. Liq. 2021, 329, 115455.

- Baby, T.T.; Ramaprabhu, S. Experimental investigation of the thermal transport properties of a carbon nanohybrid dispersed nanofluid. Nanoscale 2011, 3, 2208–2214.

- Hormozi, F.; ZareNezhad, B.; Allahyar, H. An experimental investigation on the effects of surfactants on the thermal performance of hybrid nanofluids in helical coil heat exchangers. Int. Commun. Heat Mass Transf. 2016, 78, 271–276.

- Sharifpur, M.; Adio, S.A.; Meyer, J.P. Experimental investigation and model development for effective viscosity of Al2O3–glycerol nanofluids by using dimensional analysis and GMDH-NN methods. Int. Commun. Heat Mass Transf. 2015, 68, 208–219.

- Sundar, L.S.; Ramana, E.V.; Graça, M.; Singh, M.K.; Sousa, A.C. Nanodiamond-Fe3O4 nanofluids: Preparation and measurement of viscosity, electrical and thermal conductivities. Int. Commun. Heat Mass Transf. 2016, 73, 62–74.

- Adio, S.A.; Mehrabi, M.; Sharifpur, M.; Meyer, J.P. Experimental investigation and model development for effective viscosity of MgO–ethylene glycol nanofluids by using dimensional analysis, FCM-ANFIS and GA-PNN techniques. Int. Commun. Heat Mass Transf. 2016, 72, 71–83.

- Kakavandi, A.; Akbari, M. Experimental investigation of thermal conductivity of nanofluids containing of hybrid nanoparticles suspended in binary base fluids and propose a new correlation. Int. J. Heat Mass Transf. 2018, 124, 742–751.

- Sundar, L.S.; Shusmitha, K.; Singh, M.K.; Sousa, A.C. Electrical conductivity enhancement of nanodiamond–nickel (ND–Ni) nanocomposite based magnetic nanofluids. Int. Commun. Heat Mass Transf. 2014, 57, 1–7.

- Askari, S.; Koolivand, H.; Pourkhalil, M.; Lotfi, R.; Rashidi, A. Investigation of Fe3O4/Graphene nanohybrid heat transfer properties: Experimental approach. Int. Commun. Heat Mass Transf. 2017, 87, 30–39.

- Nwaokocha, C.; Momin, M.; Giwa, S.; Sharifpur, M.; Murshed, S.; Meyer, J. Experimental investigation of thermo-convection behaviour of aqueous binary nanofluids of MgO-ZnO in a square cavity. Therm. Sci. Eng. Prog. 2022, 28, 101057.

- Garbadeen, I.; Sharifpur, M.; Slabber, J.; Meyer, J. Experimental study on natural convection of MWCNT-water nanofluids in a square enclosure. Int. Commun. Heat Mass Transf. 2017, 88, 1–8.

- Giwa, S.O.; Sharifpur, M.; Meyer, J.P.; Wongwises, S.; Mahian, O. Experimental measurement of viscosity and electrical conductivity of water-based γ-Al2O3/MWCNT hybrid nanofluids with various particle mass ratios. J. Therm. Anal. Calorim. 2020, 143, 1037–1050.

- Giwa, S.O.; Momin, M.; Nwaokocha, C.N.; Sharifpur, M.; Meyer, J.P. Influence of nanoparticles size, per cent mass ratio, and temperature on the thermal properties of water-based MgO–ZnO nanofluid: An experimental approach. J. Therm. Anal. Calorim. 2020, 143, 1063–1079.

- Babu, S.R.; Rao, G.S. Experimental investigation of natural convective heat transfer using water-alumina nanofluid with taguchi design of experiments. Int. J. Mech. Eng. Technol. 2017, 8, 795–804.

- Arani, A.A.A.; Pourmoghadam, F. Experimental investigation of thermal conductivity behavior of MWCNTS-Al2O3/ethylene glycol hybrid Nanofluid: Providing new thermal conductivity correlation. Heat Mass Transf. 2019, 55, 2329–2339.

- Ijam, A.; Golsheikh, A.M.; Saidur, R.; Ganesan, P. A glycerol–water-based nanofluid containing graphene oxide nanosheets. J. Mater. Sci. 2014, 49, 5934–5944.

- Akilu, S.; Baheta, A.T.; Said, M.A.M.; Minea, A.A.; Sharma, K. Properties of glycerol and ethylene glycol mixture based SiO2-CuO/C hybrid nanofluid for enhanced solar energy transport. Sol. Energy Mater. Sol. Cells 2018, 179, 118–128.

More

Information

Subjects:

Nanoscience & Nanotechnology; Engineering, Mechanical; Mathematics, Interdisciplinary Applications

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.6K

Revisions:

3 times

(View History)

Update Date:

31 Jan 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No