Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Rui Li | -- | 975 | 2023-01-16 13:37:13 | | | |

| 2 | Conner Chen | -2 word(s) | 973 | 2023-01-17 07:26:30 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Li, R.; Yin, Z.; Lin, H. Characteristics and Hazards of Lead–Zinc Tailings. Encyclopedia. Available online: https://encyclopedia.pub/entry/40229 (accessed on 04 March 2026).

Li R, Yin Z, Lin H. Characteristics and Hazards of Lead–Zinc Tailings. Encyclopedia. Available at: https://encyclopedia.pub/entry/40229. Accessed March 04, 2026.

Li, Rui, Ziyi Yin, Hang Lin. "Characteristics and Hazards of Lead–Zinc Tailings" Encyclopedia, https://encyclopedia.pub/entry/40229 (accessed March 04, 2026).

Li, R., Yin, Z., & Lin, H. (2023, January 16). Characteristics and Hazards of Lead–Zinc Tailings. In Encyclopedia. https://encyclopedia.pub/entry/40229

Li, Rui, et al. "Characteristics and Hazards of Lead–Zinc Tailings." Encyclopedia. Web. 16 January, 2023.

Copy Citation

Lead–zinc tailings are the typical solid wastes in mines with high yield and low utilization rates in some countries. They are mainly stockpiled in tailings reservoirs, occupying massive land resources and threatening the health of the environment.

cement

concrete

geopolymer

1. Introduction

Lead–zinc tailings are the residual solid waste of lead–zinc ore after crushing and flotation [1]. China has a wide distribution of Pb–Zn minerals, and the production of Pb and Zn ranks first in the world [2]. However, with many lean ores, few rich ores, and complex mineral composition, most lead–zinc ores are highly difficult to beneficiate [3][4]. Therefore, with the continuous development of mineral resources, the number of tailings has increased dramatically [5][6]. According to the latest data in the Annual Report on Comprehensive Utilization of Resources in China, by the end of 2021, the total annual production of tailings in China was 16.49 billion tons, while the total utilization of tailings was only 312 million tons, with a comprehensive utilization rate of only 18.9% [7]. Western developed countries have started the comprehensive development and utilization of mineral resources since the first and middle of the 20th century and now have achieved waste-free and slag-free production in some mines [8]. China, on the other hand, started late, and the comprehensive utilization rate of tailings still has a big gap compared with European and American countries. Such a large number of tailings has serious safety hazards [9][10], which will not only pollute the environment and occupy land resources but also affect the healthy development of human society [11][12][13].

In response to this problem, the National Development and Reform Commission of China pointed out that it should make the best efforts to carry out the comprehensive utilization of resources and promote the green, efficient, high quality, high value, and large-scale utilization of solid waste. At present, the utilization of lead–zinc tailings in building materials provides the advantages of less pollution, high economic benefits, and sustainable development, and it is a highly promising and valuable method for the resource utilization of tailings [14]. Promoting the research and exploration of using lead–zinc tailings in building materials is of great significance to carry out comprehensive utilization of solid waste resources.

2. Characteristics and Hazards of Lead–Zinc Tailings

2.1. Characteristics of Lead–Zinc Tailings

Lead–zinc tailings are a kind of composite minerals with a complex chemical composition [15][16][17]. There are obvious differences in the composition of lead–zinc tailings from different mines due to the differences in the beneficiation process, as shown in Table 1. However, there are also some similarities among these lead–zinc tailings in terms of composition; that is, the metal content is generally low, and the main compositions are oxides of Si, Al, Fe, Ca, and Mg [18][19]. The low content of valuable metals makes lead–zinc tailings lose some recovery value, but the high content of silica–alumina oxides gives them reuse value. By comparing the chemical composition of lead–zinc tailings with clay, it can be found that the composition of both is very similar, and the content of SiO2, Fe2O3, and Al2O3 in some lead–zinc tailings is close to that in clay. In addition, the main minerals of lead–zinc tailings include quartz, feldspar, and clay, which are very close to natural sand minerals [3]. Therefore, lead–zinc tailings can be used as raw materials to produce cement or other construction materials in place of clay or sand. In summary, although the composition of lead–zinc tailings is complex and the valuable metals are difficult to recover, lead–zinc tailings still have high potential value in the production of building materials [20].

Table 1. Chemical composition of different lead–zinc tailings (wt.%).

| References | Types | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | Na2O | SO3 | K2O | LOI |

|---|---|---|---|---|---|---|---|---|---|---|

| Wang et al. (2017) [21] | Lead–zinc tailings | 66.23 | 7.67 | 2.45 | 8.51 | 1.78 | 0.54 | - | 0.65 | 3.83 |

| Zhang et al. (2015) [22] | 69.92 | 10.41 | 1.89 | 2.19 | 1.39 | 0.51 | 0.55 | 2.17 | 3.68 | |

| Argane et al. (2015) [23] | 68.44 | 9.380 | 2.200 | 1.99 | 0.48 | 0.7 | 0.449 | 5.46 | - | |

| Jankovic et al. (2017) [24] | 43.26 | 11.11 | 15.57 | 20.01 | 4.31 | 0.92 | 0.32 | 1.00 | 5.61 | |

| Shen et al. (2013) [25] | 49.43 | 17.23 | 8.23 | 5.88 | 9.02 | 0.41 | 1.43 | 4.59 | - | |

| Shen et al. (2013) [25] | 26.97 | 5.17 | 4.36 | 33.84 | 15.48 | 0.16 | 0.55 | 1.57 | 9.53 | |

| Wei et al. (2021) [26] | Clay | 61.37 | 14.32 | 4.74 | 12.40 | 2.36 | 1.03 | 0.03 | 2.59 | - |

2.2. Hazards of Lead–Zinc Tailings

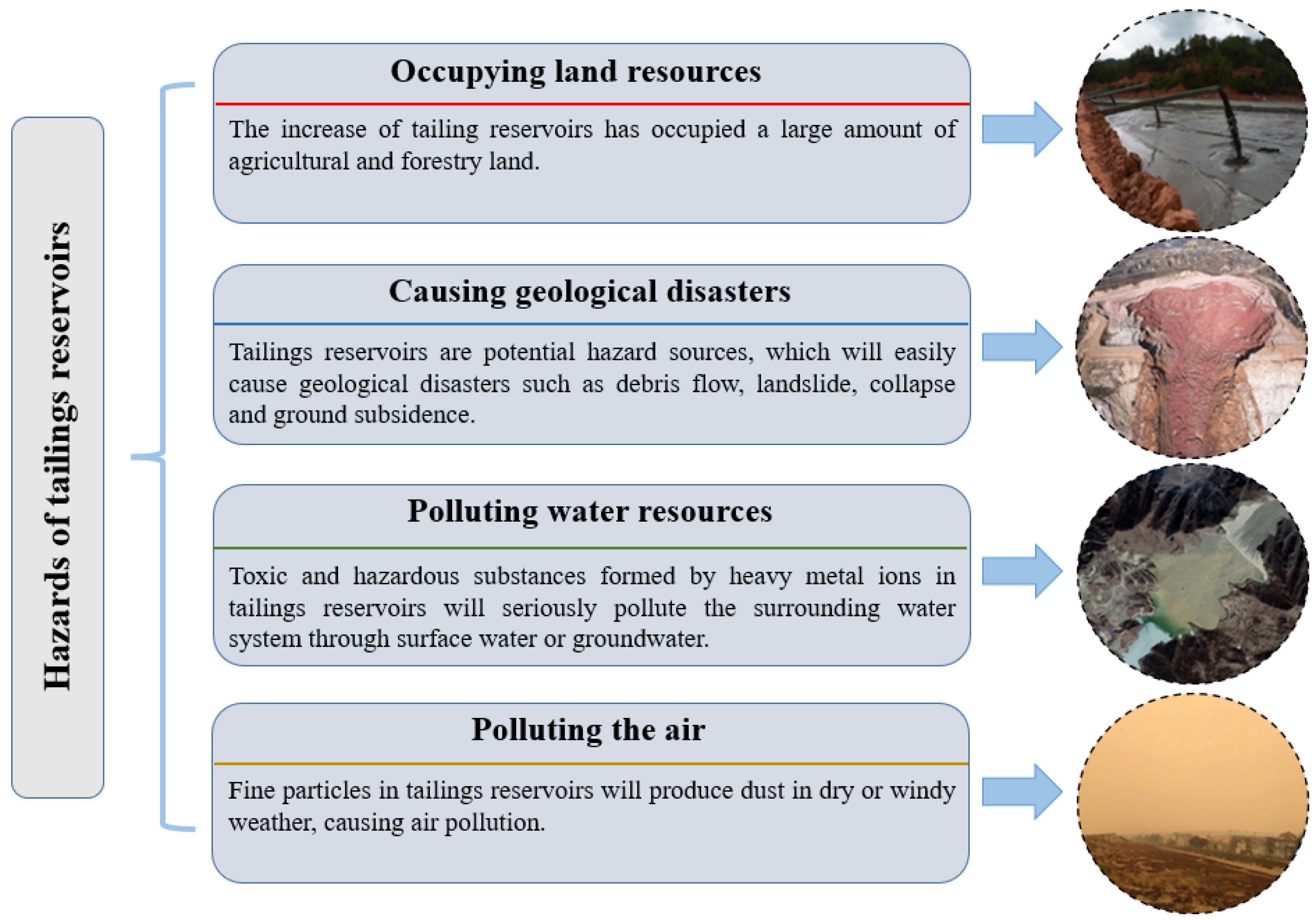

Stockpiling in tailings reservoirs is currently the most direct disposal method for lead–zinc tailings. According to the Work Plan for Preventing and Resolving Safety Risks of Tailings Reservoirs in 2020, there are nearly 8000 tailings reservoirs in China, ranking first in the world [27]. A total of 64 types of minerals are involved, of which the minerals with the largest stockpile of tailings contain Zn and Pb [28]. These tailings reservoirs not only occupy a large amount of national land area but also have certain security risks [29][30], and they are also harmful to the environment [31][32][33], as shown in Figure 1. At present, most tailings reservoirs are a dangerous source with high potential energy formed by the accumulation of tailings, which are easily disturbed to form disasters such as debris flow, resulting in major casualties and property losses [34][35][36].

Figure 1. Adverse effects of tailings reservoirs on environment and human society.

In addition, the problem of environmental pollution caused by the stockpiling of lead–zinc tailings should not be underestimated [37][38][39]. Kan et al. [40] assessed the pollution of As, Cd, Cr, Cu, Hg, Ni, Pb, and Zn by analyzing their concentration data in lead–zinc tailings reservoirs in China and found that the average concentrations of all these heavy metals in soil have exceeded the corresponding background values [41]. Under the combined effect of internal and external factors, the lead–zinc tailings in the tailings reservoirs will leach out a large amount of heavy metal liquid [42], which will seriously pollute the water resources in the nearby area after infiltrating with rainwater. Mine soil is also the major carrier of heavy metal pollution [16][17]. The contaminated soil not only affects the growth of local plants and animals but also causes food safety and leads to the entry of heavy metal elements such as Pb, Zn, and Cd into people’s bodies along the food chain [43]. Moreover, the large number of fine particles in tailings reservoirs can also cause serious dust pollution [44][45].

References

- Maruthupandian, S.; Chaliasou, A.; Kanellopoulos, A. Recycling mine tailings as precursors for cementitious binders—Methods, challenges and future outlook. Constr. Build. Mater. 2021, 312, 125333.

- Liu, X.; Zhang, Y.; Wang, N.; Mao, J. Pb-Zn metal resources situation and suggestion for Pb-Zn metals industry development in China. China Min. Mag. 2015, 24, 6–9.

- Nayak, A.; Jena, M.S.; Mandre, N.R. Beneficiation of Lead-Zinc Ores—A Review. Miner. Process. Extr. Metall. Rev. 2022, 43, 564–583.

- Li, X.; Meng, D.; Li, J.; Yin, H.; Liu, H.; Liu, X.; Cheng, C.; Xiao, Y.; Liu, Z.; Yan, M. Response of soil microbial communities and microbial interactions to long-term heavy metal contamination. Environ. Pollut. 2017, 231, 908–917.

- Ren, B.; Zhao, Y.L.; Bai, H.Y.; Kang, S.C.; Zhang, T.T.; Song, S.X. Eco-friendly geopolymer prepared from solid wastes: A critical review. Chemosphere 2021, 267, 128900.

- Zhou, Y.; Ren, B.; Hursthouse, A.S.; Zhou, S. Antimony Ore Tailings: Heavy Metals, Chemical Speciation, and Leaching Characteristics. Pol. J. Environ. Stud. 2019, 28, 485–495.

- Gu, X.W.; Ai, Y.Y.; Zhao, Y.Q.; Sun, W. Status Quo of Resource Utilization of Iron Ore Tailings. Chin. J. Nonferrous Met. 2022, 1–29. Available online: https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=CAPJ&dbname=CAPJLAST&filename=ZYXZ20220111000&uniplatform=NZKPT&v=fDyIUD2q6Qz2-SoL__QG8YGMyh5g8moc2xBVf-LlX0ETTE7HOD_XbWtxNqc_m3ag (accessed on 6 November 2022).

- Poteete, A.R. Defining political community and rights to natural resources in Botswana. Dev. Chang. 2009, 40, 281–305.

- Liu, J.; Zhao, Y.; Tan, T.; Zhang, L.; Zhu, S.; Xu, F. Evolution and modeling of mine water inflow and hazard characteristics in southern coalfields of China: A case of Meitanba mine. Int. J. Min. Sci. Technol. 2022, 32, 513–524.

- Zhu, W.; Gu, S.-Q. Casing mechanism of engineering hazards in a oil field in central China. Environ. Earth Sci. 2013, 70, 869–875.

- Xu, D.M.; Zhan, C.L.; Liu, H.X.; Lin, H.Z. A critical review on environmental implications, recycling strategies, and ecological remediation for mine tailings. Environ. Sci. Pollut. Res. 2019, 26, 35657–35669.

- Luo, X.; Ren, B.Z.; Hursthouse, A.S.; Jiang, F.; Deng, R.J. Potentially toxic elements (PTEs) in crops, soil, and water near Xiangtan manganese mine, China: Potential risk to health in the foodchain. Environ. Geochem. Health 2020, 42, 1965–1976.

- Zhang, Y.; Zhao, C.; Chen, G.; Zhou, J.; Chen, Z.; Li, Z.; Zhu, J.; Feng, T.; Chen, Y. Response of soil microbial communities to additions of straw biochar, iron oxide, and iron oxide–modified straw biochar in an arsenic-contaminated soil. Environ. Sci. Pollut. Res. 2020, 27, 23761–23768.

- Jiang, F.; Ren, B.; Hursthouse, A.S.; Zhou, Y. Trace Metal Pollution in Topsoil Surrounding the Xiangtan Manganese Mine Area (South-Central China): Source Identification, Spatial Distribution and Assessment of Potential Ecological Risks. Int. J. Environ. Res. Public Health 2018, 15, 2412.

- Tang, Z.-E.; Deng, R.-J.; Zhang, J.; Ren, B.-Z.; Hursthouse, A. Regional distribution characteristics and ecological risk assessment of heavy metal pollution of different land use in an antimony mining area—Xikuangshan, China. Hum. Ecol. Risk Assess. Int. J. 2020, 26, 1779–1794.

- Ren, B.; Zhou, Y.; Ma, H.; Deng, R.; Zhang, P.; Hou, B. Sb release characteristics of the solid waste produced in antimony mining smelting process. J. Mater. Cycles Waste Manag. 2018, 20, 193–200.

- He, S.; Lu, Y.; Li, M. Probabilistic risk analysis for coal mine gas overrun based on FAHP and BN: A case study. Environ. Sci. Pollut. Res. 2022, 29, 28458–28468.

- Yi, L.S.; He, L.; Wang, Z.X. Resource utilization of lead-zinc tailings. Multipurp. Util. Miner. Resour. 2017, 1, 12–15.

- Huang, Z.; Zhang, L.; Yang, Z.; Zhang, J.; Gao, Y.; Zhang, Y. Preparation and properties of a rock dust suppressant for a copper mine. Atmos. Pollut. Res. 2019, 10, 2010–2017.

- Akinyemi, B.A.; Alaba, P.A.; Rashedi, A. Selected performance of alkali-activated mine tailings as cementitious composites: A review. J. Build. Eng. 2022, 50, 104154.

- Lin, G.; Wang, C.L.; Qiao, C.Y.; Cui, H.L.; Chen, L.; Yu, S. Preparation and properties of autoclaved aerated concrete containing lead-zinc tailings. Rev. Romana De Mater. Rom. J. Mater. 2016, 46, 334–342.

- Zhang, D.; Shi, S.L.; Wang, C.B.; Yang, X.C.; Guo, L.J.; Xue, S.S. Preparation of Cementitious Material Using Smelting Slag and Tailings and the Solidification and Leaching of Pb2+. Adv. Mater. Sci. Eng. 2015, 2015, 352567.

- Argane, R.; Benzaazoua, M.; Hakkou, R.; Bouamrane, A. Reuse of base-metal tailings as aggregates for rendering mortars: Assessment of immobilization performances and environmental behavior. Constr. Build. Mater. 2015, 96, 296–306.

- Jankovic, K.; Susic, N.; Stojanovic, M.; Bojovic, D.; Loncar, L. The influence of tailings and cement type on durability properties of self-compacting concrete. Teh. Vjesn. Tech. Gaz. 2017, 24, 957–962.

- Shen, X.F.; Xue, Q.H.; Xu, L.; Shi, Z.W.; Zhang, H. Research of the feasibility to prepare the natural hydraulic limes from the lead and zinc mine tailing. Bull. Chin. Ceram. Soc. 2013, 32, 1973–1978.

- Wei, Z.A.; Zhao, J.K.; Wang, W.S.; Yang, Y.H.; Zhuang, S.N.; Lu, T.; Hou, Z.K. Utilizing gold mine tailings to produce sintered bricks. Constr. Build. Mater. 2021, 282, 122655.

- Fan, H.; Lu, Y.; Hu, Y.; Fang, J.; Lv, C.; Xu, C.; Feng, X.; Liu, Y. A Landslide Susceptibility Evaluation of Highway Disasters Based on the Frequency Ratio Coupling Model. Sustainability 2022, 14, 7740.

- Liao, Y.; Yu, G.; Liao, Y.; Jiang, L.; Liu, X. Environmental Conflict Risk Assessment Based on AHP-FCE: A Case of Jiuhua Waste Incineration Power Plant Project. Sustainability 2018, 10, 4095.

- Luo, X.; Ren, B.; Hursthouse, A.; Jiang, F.; Deng, R.; Wang, Z. Source identification and risk analysis of potentially toxic elements (PTEs) in rainwater runoff in manganese mine (South Central Hunan, China). Water Supply 2020, 21, 824–835.

- Han, Y.-S.; Dong, S.-K.; Chen, Z.-C.; Hu, K.-H.; Su, F.-H.; Huang, P. Assessment of secondary mountain hazards along a section of the Dujiangyan-Wenchuan highway. J. Mt. Sci. 2014, 11, 51–65.

- Xie, Q.; Ren, B.; Hursthouse, A.S.; Shi, X. Effects of mining activities on the distribution, controlling factors, and sources of metals in soils from the Xikuangshan South Mine, Hunan Province. Integr. Environ. Assess. Manag. 2021, 18, 748–756.

- Qin, B.; Li, L.; Ma, D.; Lu, Y.; Zhong, X.; Jia, Y. Control technology for the avoidance of the simultaneous occurrence of a methane explosion and spontaneous coal combustion in a coal mine: A case study. Process Saf. Environ. Prot. 2016, 103, 203–211.

- Deng, R.-J.; Jin, C.-S.; Ren, B.-Z.; Hou, B.-L.; Hursthouse, A.S. The Potential for the Treatment of Antimony-Containing Wastewater by Iron-Based Adsorbents. Water 2017, 9, 794.

- Li, C.H.; Bu, L.; Chen, L.G. Research situation of the disaster-causing mechanism of tailing dams and its developing trend. Chin. J. Eng. 2016, 38, 1039–1049.

- Zheng, Z.Y.; Luo, L.; Liu, N.; He, J.N.; Xing, A.G. Dynamic analysis of tailings dam-break in Tonglushan, Daye, Hubei. Met. Mine 2017, 12, 136–141.

- Wang, K.; Yang, P.; Hudson-Edwards, K.; Lyu, W.S.; Bu, L. Status and development for the prevention and management of tailings dam failure accidents. Chin. J. Eng. 2018, 40, 526–539.

- Chu, Y.X. Pollution characteristics and treatment measures of nonferrous metal tailings to environment. Shanxi Chem. Ind. 2020, 40, 182–183+197.

- Wang, Z.; Liao, L.; Hursthouse, A.; Song, N.; Ren, B. Sepiolite-Based Adsorbents for the Removal of Potentially Toxic Elements from Water: A Strategic Review for the Case of Environmental Contamination in Hunan, China. Int. J. Environ. Res. Public Health 2018, 15, 1653.

- Li, Y.; Xu, Z.; Ma, H.; Hursthouse, A.S. Removal of Manganese(II) from Acid Mine Wastewater: A Review of the Challenges and Opportunities with Special Emphasis on Mn-Oxidizing Bacteria and Microalgae. Water 2019, 11, 2493.

- Kan, X.Q.; Dong, Y.Q.; Feng, L.; Zhou, M.; Hou, H.B. Contamination and health risk assessment of heavy metals in China’s lead-zinc mine tailings: A meta-analysis. Chemosphere 2021, 267, 128909.

- Zhang, Y.; Ren, B.; Hursthouse, A.S.; Deng, R.; Hou, B. An Improved SWAT for Predicting Manganese Pollution Load at the Soil-Water Interface in a Manganese Mine Area. Pol. J. Environ. Stud. 2018, 27, 2357–2365.

- Wang, X.; Ren, B.Z.; Zhou, Y.Y.; Shi, X.Y. Study on the mechanism and kinetics of manganese release from waste manganese ore waste rock under rainfall leaching. Environ. Sci. Pollut. Res. 2022, 29, 5541–5551.

- Jiang, F.; Ren, B.Z.; Hursthouse, A.; Deng, R.J.; Wang, Z.H. Distribution, source identification, and ecological-health risks of potentially toxic elements (PTEs) in soil of thallium mine area (southwestern Guizhou, China). Environ. Sci. Pollut. Res. 2019, 26, 16556–16567.

- Song, G.C.; Zhang, Z. Remote sensing monitoring method for dust and wind accumulation in multimetal mining area of Xin Barag Right Banner, Inner Mongolia. Remote Sens. Nat. Resour. 2020, 32, 46–53.

- Li, M.; Lv, H.; Lu, Y.; Wang, D.; Shi, S.; Li, R. Instantaneous discharge characteristics and its methane ignition mechanism of coal mine rock damage. Environ. Sci. Pollut. Res. 2022, 29, 62495–62506.

More

Information

Subjects:

Construction & Building Technology

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

2.6K

Revisions:

2 times

(View History)

Update Date:

17 Jan 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No